JP6586420B2 - ヒドリドシランを含む組成物の重合及びそれに次ぐケイ素含有層の製造のためのその重合体の使用のための方法及び装置 - Google Patents

ヒドリドシランを含む組成物の重合及びそれに次ぐケイ素含有層の製造のためのその重合体の使用のための方法及び装置 Download PDFInfo

- Publication number

- JP6586420B2 JP6586420B2 JP2016538797A JP2016538797A JP6586420B2 JP 6586420 B2 JP6586420 B2 JP 6586420B2 JP 2016538797 A JP2016538797 A JP 2016538797A JP 2016538797 A JP2016538797 A JP 2016538797A JP 6586420 B2 JP6586420 B2 JP 6586420B2

- Authority

- JP

- Japan

- Prior art keywords

- hydridosilane

- polymerization

- aerosol

- substrate

- composition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 title claims description 162

- 238000000034 method Methods 0.000 title claims description 106

- 239000000203 mixture Substances 0.000 title claims description 95

- 238000006116 polymerization reaction Methods 0.000 title claims description 74

- 229910052710 silicon Inorganic materials 0.000 title claims description 49

- 239000010703 silicon Substances 0.000 title claims description 49

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 title claims description 47

- 238000004519 manufacturing process Methods 0.000 title claims description 24

- 229920000642 polymer Polymers 0.000 title claims description 14

- 239000000758 substrate Substances 0.000 claims description 105

- 238000006243 chemical reaction Methods 0.000 claims description 99

- 239000000443 aerosol Substances 0.000 claims description 97

- 239000007788 liquid Substances 0.000 claims description 63

- 238000000576 coating method Methods 0.000 claims description 50

- 239000002105 nanoparticle Substances 0.000 claims description 47

- 239000011248 coating agent Substances 0.000 claims description 46

- 230000015572 biosynthetic process Effects 0.000 claims description 39

- 239000002904 solvent Substances 0.000 claims description 32

- 229910000077 silane Inorganic materials 0.000 claims description 27

- 230000008569 process Effects 0.000 claims description 25

- 239000007795 chemical reaction product Substances 0.000 claims description 19

- VEDJZFSRVVQBIL-UHFFFAOYSA-N trisilane Chemical compound [SiH3][SiH2][SiH3] VEDJZFSRVVQBIL-UHFFFAOYSA-N 0.000 claims description 17

- 229910052739 hydrogen Inorganic materials 0.000 claims description 13

- 125000004122 cyclic group Chemical group 0.000 claims description 12

- 239000001257 hydrogen Substances 0.000 claims description 12

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims description 11

- 238000001816 cooling Methods 0.000 claims description 11

- 238000004528 spin coating Methods 0.000 claims description 11

- 239000002019 doping agent Substances 0.000 claims description 10

- -1 tetrasilane Chemical compound 0.000 claims description 10

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 claims description 9

- CVLHDNLPWKYNNR-UHFFFAOYSA-N pentasilolane Chemical compound [SiH2]1[SiH2][SiH2][SiH2][SiH2]1 CVLHDNLPWKYNNR-UHFFFAOYSA-N 0.000 claims description 9

- 229910052698 phosphorus Inorganic materials 0.000 claims description 9

- 239000011574 phosphorus Substances 0.000 claims description 9

- 239000002994 raw material Substances 0.000 claims description 9

- 239000007789 gas Substances 0.000 claims description 8

- 229910001867 inorganic solvent Inorganic materials 0.000 claims description 8

- 239000003049 inorganic solvent Substances 0.000 claims description 8

- 239000003960 organic solvent Substances 0.000 claims description 8

- 239000007787 solid Substances 0.000 claims description 8

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 7

- 239000012298 atmosphere Substances 0.000 claims description 7

- 229910052796 boron Inorganic materials 0.000 claims description 7

- 229910052756 noble gas Inorganic materials 0.000 claims description 7

- 239000003505 polymerization initiator Substances 0.000 claims description 7

- 239000003607 modifier Substances 0.000 claims description 6

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 claims description 6

- 239000002685 polymerization catalyst Substances 0.000 claims description 5

- 230000000379 polymerizing effect Effects 0.000 claims description 5

- LUXIMSHPDKSEDK-UHFFFAOYSA-N bis(disilanyl)silane Chemical compound [SiH3][SiH2][SiH2][SiH2][SiH3] LUXIMSHPDKSEDK-UHFFFAOYSA-N 0.000 claims description 4

- GCOJIFYUTTYXOF-UHFFFAOYSA-N hexasilinane Chemical compound [SiH2]1[SiH2][SiH2][SiH2][SiH2][SiH2]1 GCOJIFYUTTYXOF-UHFFFAOYSA-N 0.000 claims description 4

- GADSHBHCKVKXLO-UHFFFAOYSA-N bis(disilanylsilyl)silane Chemical compound [SiH3][SiH2][SiH2][SiH2][SiH2][SiH2][SiH3] GADSHBHCKVKXLO-UHFFFAOYSA-N 0.000 claims description 3

- 238000003618 dip coating Methods 0.000 claims description 3

- LICVGLCXGGVLPA-UHFFFAOYSA-N disilanyl(disilanylsilyl)silane Chemical compound [SiH3][SiH2][SiH2][SiH2][SiH2][SiH3] LICVGLCXGGVLPA-UHFFFAOYSA-N 0.000 claims description 3

- 238000007606 doctor blade method Methods 0.000 claims description 3

- 238000007641 inkjet printing Methods 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 73

- 239000000243 solution Substances 0.000 description 42

- 239000002826 coolant Substances 0.000 description 18

- 238000002604 ultrasonography Methods 0.000 description 18

- 239000002245 particle Substances 0.000 description 17

- 239000011521 glass Substances 0.000 description 16

- 238000010438 heat treatment Methods 0.000 description 15

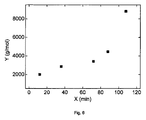

- 238000005227 gel permeation chromatography Methods 0.000 description 11

- WJTCGQSWYFHTAC-UHFFFAOYSA-N cyclooctane Chemical compound C1CCCCCCC1 WJTCGQSWYFHTAC-UHFFFAOYSA-N 0.000 description 10

- 239000004914 cyclooctane Substances 0.000 description 10

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 9

- 238000012387 aerosolization Methods 0.000 description 9

- 239000000463 material Substances 0.000 description 8

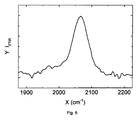

- 238000005033 Fourier transform infrared spectroscopy Methods 0.000 description 7

- 230000008901 benefit Effects 0.000 description 5

- 239000010408 film Substances 0.000 description 5

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 229910021417 amorphous silicon Inorganic materials 0.000 description 4

- 238000000151 deposition Methods 0.000 description 4

- 150000002835 noble gases Chemical class 0.000 description 4

- 229910052760 oxygen Inorganic materials 0.000 description 4

- 239000002243 precursor Substances 0.000 description 4

- 239000000047 product Substances 0.000 description 4

- 239000004065 semiconductor Substances 0.000 description 4

- 150000004756 silanes Chemical class 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- 238000001069 Raman spectroscopy Methods 0.000 description 3

- 238000001237 Raman spectrum Methods 0.000 description 3

- 239000003054 catalyst Substances 0.000 description 3

- 229910021419 crystalline silicon Inorganic materials 0.000 description 3

- 239000006185 dispersion Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000011065 in-situ storage Methods 0.000 description 3

- 239000007791 liquid phase Substances 0.000 description 3

- 239000000178 monomer Substances 0.000 description 3

- 150000003254 radicals Chemical class 0.000 description 3

- 238000005481 NMR spectroscopy Methods 0.000 description 2

- 125000004429 atom Chemical group 0.000 description 2

- 238000004630 atomic force microscopy Methods 0.000 description 2

- 238000000889 atomisation Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 150000001639 boron compounds Chemical class 0.000 description 2

- 239000012159 carrier gas Substances 0.000 description 2

- 230000002925 chemical effect Effects 0.000 description 2

- 230000008021 deposition Effects 0.000 description 2

- PZPGRFITIJYNEJ-UHFFFAOYSA-N disilane Chemical compound [SiH3][SiH3] PZPGRFITIJYNEJ-UHFFFAOYSA-N 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 238000010894 electron beam technology Methods 0.000 description 2

- 238000010828 elution Methods 0.000 description 2

- 238000005530 etching Methods 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 238000004050 hot filament vapor deposition Methods 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- 238000004949 mass spectrometry Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000012299 nitrogen atmosphere Substances 0.000 description 2

- 230000000704 physical effect Effects 0.000 description 2

- 238000000623 plasma-assisted chemical vapour deposition Methods 0.000 description 2

- 229920000548 poly(silane) polymer Polymers 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 238000001004 secondary ion mass spectrometry Methods 0.000 description 2

- 238000000527 sonication Methods 0.000 description 2

- 238000001228 spectrum Methods 0.000 description 2

- 230000003746 surface roughness Effects 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229910005329 FeSi 2 Inorganic materials 0.000 description 1

- 238000004566 IR spectroscopy Methods 0.000 description 1

- 229910008045 Si-Si Inorganic materials 0.000 description 1

- 229910006411 Si—Si Inorganic materials 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 238000012644 addition polymerization Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000011088 calibration curve Methods 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000004587 chromatography analysis Methods 0.000 description 1

- 239000000084 colloidal system Substances 0.000 description 1

- 238000007334 copolymerization reaction Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000005670 electromagnetic radiation Effects 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 238000007306 functionalization reaction Methods 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000003533 inorganic-organic solvent mixture Substances 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 238000010884 ion-beam technique Methods 0.000 description 1

- 238000002386 leaching Methods 0.000 description 1

- MOUPNEIJQCETIW-UHFFFAOYSA-N lead chromate Chemical compound [Pb+2].[O-][Cr]([O-])(=O)=O MOUPNEIJQCETIW-UHFFFAOYSA-N 0.000 description 1

- 239000008263 liquid aerosol Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000000877 morphologic effect Effects 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 238000006384 oligomerization reaction Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000000399 optical microscopy Methods 0.000 description 1

- 230000005693 optoelectronics Effects 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 229920000620 organic polymer Polymers 0.000 description 1

- 239000003791 organic solvent mixture Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 238000006303 photolysis reaction Methods 0.000 description 1

- 230000015843 photosynthesis, light reaction Effects 0.000 description 1

- 238000001874 polarisation spectroscopy Methods 0.000 description 1

- 238000012643 polycondensation polymerization Methods 0.000 description 1

- 238000012667 polymer degradation Methods 0.000 description 1

- 239000002954 polymerization reaction product Substances 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000011541 reaction mixture Substances 0.000 description 1

- 238000007151 ring opening polymerisation reaction Methods 0.000 description 1

- 238000009738 saturating Methods 0.000 description 1

- 238000004626 scanning electron microscopy Methods 0.000 description 1

- 150000003376 silicon Chemical class 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 230000002277 temperature effect Effects 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- 238000007669 thermal treatment Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

- 238000004506 ultrasonic cleaning Methods 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- 239000002918 waste heat Substances 0.000 description 1

- 238000007704 wet chemistry method Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D183/00—Coating compositions based on macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon, with or without sulfur, nitrogen, oxygen, or carbon only; Coating compositions based on derivatives of such polymers

- C09D183/16—Coating compositions based on macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon, with or without sulfur, nitrogen, oxygen, or carbon only; Coating compositions based on derivatives of such polymers in which all the silicon atoms are connected by linkages other than oxygen atoms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G77/00—Macromolecular compounds obtained by reactions forming a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon in the main chain of the macromolecule

- C08G77/04—Polysiloxanes

- C08G77/06—Preparatory processes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G77/00—Macromolecular compounds obtained by reactions forming a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon in the main chain of the macromolecule

- C08G77/60—Macromolecular compounds obtained by reactions forming a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon in the main chain of the macromolecule in which all the silicon atoms are connected by linkages other than oxygen atoms

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/02—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition

- C23C18/12—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material

- C23C18/1204—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material inorganic material, e.g. non-oxide and non-metallic such as sulfides, nitrides based compounds

- C23C18/122—Inorganic polymers, e.g. silanes, polysilazanes, polysiloxanes

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F71/00—Manufacture or treatment of devices covered by this subclass

- H10F71/121—The active layers comprising only Group IV materials

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Health & Medical Sciences (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Mechanical Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Inorganic Chemistry (AREA)

- Metallurgy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Silicon Compounds (AREA)

- Silicon Polymers (AREA)

- Liquid Deposition Of Substances Of Which Semiconductor Devices Are Composed (AREA)

- Formation Of Insulating Films (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013020518.2 | 2013-12-11 | ||

| DE102013020518.2A DE102013020518A1 (de) | 2013-12-11 | 2013-12-11 | Verfahren und Vorrichtung zur Polymerisation einer Zusammensetzung enthaltend Hydridosilane und anschließenden Verwendung der Polymerisate zur Herstellung von siliziumhaltigen Schichten |

| PCT/DE2014/000617 WO2015085980A1 (de) | 2013-12-11 | 2014-11-26 | Verfahren zur polymerisation einer zusammensetzung enthaltend hydridosilane und anschliessenden verwendung der polymerisate zur herstellung von siliciumhaltigen schichten |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017509138A JP2017509138A (ja) | 2017-03-30 |

| JP2017509138A5 JP2017509138A5 (enExample) | 2018-09-27 |

| JP6586420B2 true JP6586420B2 (ja) | 2019-10-02 |

Family

ID=52432606

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016538797A Expired - Fee Related JP6586420B2 (ja) | 2013-12-11 | 2014-11-26 | ヒドリドシランを含む組成物の重合及びそれに次ぐケイ素含有層の製造のためのその重合体の使用のための方法及び装置 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10053599B2 (enExample) |

| EP (1) | EP3080192B1 (enExample) |

| JP (1) | JP6586420B2 (enExample) |

| CN (1) | CN105793328B (enExample) |

| DE (1) | DE102013020518A1 (enExample) |

| WO (1) | WO2015085980A1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015225289A1 (de) | 2015-12-15 | 2017-06-22 | Evonik Degussa Gmbh | Dotierte Zusammensetzungen, Verfahren zu ihrer Herstellung und ihre Verwendung |

| KR102097646B1 (ko) * | 2016-03-11 | 2020-04-06 | 가부시키가이샤 리코 | 비상 정지 압력 센서, 안전 장치 및 안전 시스템 |

| WO2017223323A1 (en) * | 2016-06-25 | 2017-12-28 | Applied Materials, Inc. | Flowable amorphous silicon films for gapfill applications |

| KR102271768B1 (ko) | 2017-04-07 | 2021-06-30 | 어플라이드 머티어리얼스, 인코포레이티드 | 반응성 어닐링을 사용하는 갭충전 |

| DE102017010263A1 (de) * | 2017-11-07 | 2019-05-09 | Forschungszentrum Jülich GmbH | Verfahren zur Herstellung von hydrogenierten amorphen siliziumhaltigen Komposit-Kolloiden und zur Verkapselung von Substanzen mit hydrogenierten amorphen siliziumhaltigen Komposit-Schichten, sowie hydrogenierte amorphe siliziumhaltige Komposit-Kolloide und mit siliziumhaltigen Komposit-Schichten verkapselte Substanzen und deren Verwendung |

| WO2019217985A1 (en) * | 2018-05-14 | 2019-11-21 | The University Of Melbourne | A method of generating radicals by ultrasound |

| US11401166B2 (en) | 2018-10-11 | 2022-08-02 | L'Air Liaquide, Société Anonyme pour l'Etude et l'Exploitation des Procédés Georges Claude | Process for producing isomer enriched higher silanes |

| US11097953B2 (en) | 2018-10-11 | 2021-08-24 | L'Air Liquide, Société Anonyme pour l'Etude et l'Exploitation des Procédés Georges Claude | Process for producing liquid polysilanes and isomer enriched higher silanes |

| US11230474B2 (en) | 2018-10-11 | 2022-01-25 | L'Air Liquide, Société Anonyme pour l'Etude et l'Exploitation des Procédés Georges Claude | Process for producing isomer enriched higher silanes |

| US10752507B2 (en) | 2018-10-11 | 2020-08-25 | L'Air Liquide, Société Anonyme pour l'Etude et l'Exploitation des Procédés Georges Claude | Process for producing liquid polysilanes and isomer enriched higher silanes |

| DE102023118799A1 (de) * | 2023-07-17 | 2025-01-23 | Forschungszentrum Jülich GmbH | Silizium Dünnschichten hergestellt durch CVD mittels Flüssigsilanen mit einstellbarem Kohlenstoffgehalt |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3211255B2 (ja) * | 1990-07-10 | 2001-09-25 | 三井化学株式会社 | シラン誘導体、ポリシラン化合物、その製造方法および用途 |

| WO2000059014A1 (fr) | 1999-03-30 | 2000-10-05 | Seiko Epson Corporation | cROCEDE PRODUCTION D'UN FILM DE SILICIUM ET COMPOSITION D'ENCRE POUR IMPRIMANTE A JET D'ENCRE |

| JP2003313299A (ja) * | 2002-04-22 | 2003-11-06 | Seiko Epson Corp | 高次シラン組成物及び該組成物を用いたシリコン膜の形成方法 |

| JP2004165474A (ja) * | 2002-11-14 | 2004-06-10 | Matsushita Electric Ind Co Ltd | 光電変換素子及びその製造方法 |

| EP1599298A4 (en) * | 2003-02-20 | 2007-05-02 | Lam Res Corp | METHOD AND DEVICE FOR MEGASCULAR CLEANING OF PATTERNED SUBSTRATES |

| DE102005027757A1 (de) * | 2005-06-15 | 2006-12-28 | Gesellschaft zur Förderung von Medizin-, Bio- und Umwelttechnologien e.V. | Verfahren zur Herstellung von Polymeren |

| KR20090029494A (ko) * | 2007-09-18 | 2009-03-23 | 엘지전자 주식회사 | 비정질 실리콘 및 나노 결정질 실리콘의 복합 박막을이용한 태양전지 및 그 제조방법 |

| DE102009053806A1 (de) * | 2009-11-18 | 2011-05-19 | Evonik Degussa Gmbh | Verfahren zur Herstellung von Siliciumschichten |

| DE102010002405A1 (de) * | 2010-02-26 | 2011-09-01 | Evonik Degussa Gmbh | Verfahren zur Oligomerisierung von Hydridosilanen, die mit dem Verfahren herstellbaren Oligomerisate und ihre Verwendung |

| KR20130069611A (ko) * | 2010-04-06 | 2013-06-26 | 엔디에스유 리서치 파운데이션 | 액체 실란계 조성물 및 실리콘계 물질의 제조 방법 |

| DE102010041842A1 (de) | 2010-10-01 | 2012-04-05 | Evonik Degussa Gmbh | Verfahren zur Herstellung höherer Hydridosilanverbindungen |

| DE102010055564A1 (de) | 2010-12-23 | 2012-06-28 | Johann-Wolfgang-Goethe Universität Frankfurt am Main | Verfahren und Vorrichtung zur Abscheidung von Silizium auf einem Substrat |

| DE102013010099B4 (de) * | 2013-06-18 | 2015-07-09 | Evonik Industries Ag | Verfahren zur Herstellung strukturierter Beschichtungen, mit dem Verfahren hergestellte strukturierte Beschichtungen und ihre Verwendung |

-

2013

- 2013-12-11 DE DE102013020518.2A patent/DE102013020518A1/de not_active Ceased

-

2014

- 2014-11-26 EP EP14830938.8A patent/EP3080192B1/de active Active

- 2014-11-26 CN CN201480066856.7A patent/CN105793328B/zh not_active Expired - Fee Related

- 2014-11-26 US US15/100,831 patent/US10053599B2/en active Active

- 2014-11-26 WO PCT/DE2014/000617 patent/WO2015085980A1/de not_active Ceased

- 2014-11-26 JP JP2016538797A patent/JP6586420B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015085980A1 (de) | 2015-06-18 |

| EP3080192B1 (de) | 2023-09-20 |

| CN105793328B (zh) | 2019-07-09 |

| DE102013020518A1 (de) | 2015-06-11 |

| JP2017509138A (ja) | 2017-03-30 |

| US20160297997A1 (en) | 2016-10-13 |

| EP3080192A1 (de) | 2016-10-19 |

| US10053599B2 (en) | 2018-08-21 |

| CN105793328A (zh) | 2016-07-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6586420B2 (ja) | ヒドリドシランを含む組成物の重合及びそれに次ぐケイ素含有層の製造のためのその重合体の使用のための方法及び装置 | |

| JP4768182B2 (ja) | 微結晶質Si:H膜を製造するためのプラズマCVD方法及び装置 | |

| JP2017509138A5 (enExample) | ||

| Iyer et al. | Solution-based synthesis of crystalline silicon from liquid silane through laser and chemical annealing | |

| KR20080109778A (ko) | 얇은 실리콘 또는 게르마늄 시트 및 얇은 시트로 형성된 광전지 | |

| JP2007182370A (ja) | 酸化亜鉛ナノワイヤの製造方法及びその製造方法により製造された酸化亜鉛ナノワイヤ | |

| US10940456B2 (en) | Method for producing hydrogenated amorphous silicon-containing colloids and/or composite colloids and for encapsulating substances with hydrogenated amorphous silicon-containing composite colloids, hydrogenated amorphous silicon-containing colloids and/or composite colloids, substances encapsulated with silicon-containing composite layers, and use thereof | |

| GB2539016A (en) | Novel process | |

| US20160251227A1 (en) | Synthesis of si-based nano-materials using liquid silanes | |

| KR101735140B1 (ko) | 규소 층의 제조 방법 | |

| Pivin et al. | Ion beam induced conversion of Si-based polymers and gels layers into ceramics coatings | |

| CN112839903B (zh) | 用于生产液体聚硅烷和异构体富集的高级硅烷的方法 | |

| Nisar et al. | Growth of ultra-thin large sized 2D flakes at air–liquid interface to obtain 2D-WS2 monolayers | |

| CN120058525A (zh) | 一种微波辅助合成的钙钛矿半导体材料绿色制备工艺 | |

| Rajabali et al. | Evolution of Phosphorene Sheets through Direct Crystallization of Thin‐Film Red Phosphorus | |

| CN113861985A (zh) | 一种高产原位钝化中红外HgTe胶体量子点制备方法 | |

| Cahyono et al. | Reduced energy bandgap of a-Si: H films deposited by PECVD at elevating temperatures | |

| CN118084344A (zh) | 一种亲水涂层、制备方法及器件 | |

| US20140339474A1 (en) | Silicone composition comprising nanoparticles and cured product formed therefrom | |

| LbL et al. | Effects of RF Power on structural properties of nc-Si: H thin films deposited by layer-by-layer (LbL) deposition Technique | |

| Frey et al. | Deposition of Silicon Films from Liquid Cyclopentasilane Precursors Using High Pressure Spray System | |

| TW201409567A (zh) | 塗覆鈍化層之矽晶圓 | |

| Tong et al. | Effects of substrate temperature on the properties of hydrogenated nanocrystalline silicon thin film grown by layer-by-layer technique | |

| Savkina et al. | Structured silicon surface via cavitation processing for the photovoltaic and biomedical application | |

| Koshevoi et al. | Investigation of the Phase Composition and Morphology of Silicon Structures by Using the Raman Spectroscopy to Determine the Parameter of Crystallinity |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170710 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180309 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180314 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20180608 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180815 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20180815 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190123 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190409 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20190828 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190909 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6586420 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |