JP6171108B2 - 成膜装置及び成膜方法 - Google Patents

成膜装置及び成膜方法 Download PDFInfo

- Publication number

- JP6171108B2 JP6171108B2 JP2016556907A JP2016556907A JP6171108B2 JP 6171108 B2 JP6171108 B2 JP 6171108B2 JP 2016556907 A JP2016556907 A JP 2016556907A JP 2016556907 A JP2016556907 A JP 2016556907A JP 6171108 B2 JP6171108 B2 JP 6171108B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- deposition

- film forming

- plate

- etching

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H10P14/6329—

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/04—Coating on selected surface areas, e.g. using masks

- C23C14/046—Coating cavities or hollow spaces, e.g. interior of tubes; Infiltration of porous substrates

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/14—Metallic material, boron or silicon

- C23C14/16—Metallic material, boron or silicon on metallic substrates or on substrates of boron or silicon

- C23C14/165—Metallic material, boron or silicon on metallic substrates or on substrates of boron or silicon by cathodic sputtering

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/14—Metallic material, boron or silicon

- C23C14/18—Metallic material, boron or silicon on other inorganic substrates

- C23C14/185—Metallic material, boron or silicon on other inorganic substrates by cathodic sputtering

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/3407—Cathode assembly for sputtering apparatus, e.g. Target

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/58—After-treatment

- C23C14/5826—Treatment with charged particles

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32018—Glow discharge

- H01J37/32036—AC powered

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32366—Localised processing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32403—Treating multiple sides of workpieces, e.g. 3D workpieces

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32458—Vessel

- H01J37/32477—Vessel characterised by the means for protecting vessels or internal parts, e.g. coatings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32458—Vessel

- H01J37/32513—Sealing means, e.g. sealing between different parts of the vessel

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32623—Mechanical discharge control means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/34—Gas-filled discharge tubes operating with cathodic sputtering

- H01J37/3402—Gas-filled discharge tubes operating with cathodic sputtering using supplementary magnetic fields

- H01J37/3405—Magnetron sputtering

- H01J37/3408—Planar magnetron sputtering

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/34—Gas-filled discharge tubes operating with cathodic sputtering

- H01J37/3411—Constructional aspects of the reactor

- H01J37/3414—Targets

- H01J37/3426—Material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/34—Gas-filled discharge tubes operating with cathodic sputtering

- H01J37/3476—Testing and control

-

- H10P14/42—

-

- H10P14/44—

-

- H10P50/242—

-

- H10W20/033—

-

- H10W20/054—

-

- H10W20/055—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2237/00—Discharge tubes exposing object to beam, e.g. for analysis treatment, etching, imaging

- H01J2237/32—Processing objects by plasma generation

- H01J2237/33—Processing objects by plasma generation characterised by the type of processing

- H01J2237/334—Etching

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Analytical Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Metallurgy (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Power Engineering (AREA)

- Inorganic Chemistry (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Manufacturing & Machinery (AREA)

- General Physics & Mathematics (AREA)

- Physical Vapour Deposition (AREA)

- Electrodes Of Semiconductors (AREA)

- Optics & Photonics (AREA)

- Drying Of Semiconductors (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Plasma Technology (AREA)

- Physical Deposition Of Substances That Are Components Of Semiconductor Devices (AREA)

Description

Claims (9)

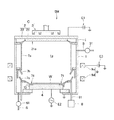

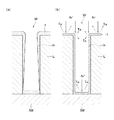

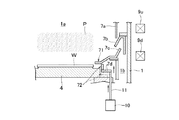

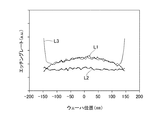

- ターゲットが配置される真空チャンバと、真空チャンバ内で基板を保持するステージと、ターゲットに所定の電力を投入する第1電源と、ステージに交流電力を投入する第2電源とを備え、第1電源によりターゲットに電力投入してターゲットをスパッタリングする成膜処理と、第2電源によりステージに交流電力を投入して基板に成膜された薄膜をエッチングするエッチング処理とを行う成膜装置であって、ステージの周囲を囲う防着板が配置されるものにおいて、

ステージで保持される基板の成膜面側を上とし、基板に近接する防着板の部分が基板上面と同等の平面上に位置する、前記成膜処理を行う成膜位置と、この防着板の部分が基板上面から上方に位置する、前記エッチング処理を行うエッチング位置と、前記防着板の部分が前記エッチング位置よりも更に上方に位置する、基板搬送持の搬送位置との間で防着板を上下動する駆動手段を備えることを特徴とする成膜装置。 - 前記防着板の基板に近接する部分に、下方にのびる突条を設けたことを特徴とする請求項1記載の成膜装置。

- 前記突条の高さは、前記成膜位置と前記エッチング位置との間の距離と同等以上に設定されることを特徴とする請求項2記載の成膜装置。

- 前記突条の高さは10〜30mmの範囲に設定されることを特徴とする請求項2または請求項3記載の成膜装置。

- 前記防着板の下方に配置される第2防着板と、第2防着板の上端部が基板よりも下方に位置する成膜位置と、この上端部がエッチング位置に移動した前記防着板の基板に近接するエッチング位置との間で第2防着板を上下動する第2駆動手段とを更に備えることを特徴とする請求項1記載の成膜装置。

- 真空チャンバに上下一対のコイルが設けられ、第2電源によりステージに交流電力を投入したときに発生するプラズマを上下方向で挟むように真空チャンバに対して上下一対のコイルが位置決めされていることを特徴とする請求項1〜5のいずれか1項記載の成膜装置。

- 真空チャンバ内のステージにより基板を保持し、ステージの周囲を囲うように防着板を配置し、真空チャンバ内のターゲットに所定の電力を投入してスパッタリングする成膜工程と、ターゲットへの電力投入を停止し、ステージに交流電力を投入して基板に成膜された薄膜をエッチングするエッチング工程とを含む成膜方法において、

ステージで保持される基板の成膜面側を上とし、前記成膜工程にて基板に近接する防着板の部分が基板上面と同等の平面上に位置する成膜位置に防着板を移動させ、前記エッチング工程にてこの防着板の部分が基板上面から上方に位置する、成膜位置とは異なるエッチング位置に防着板を移動させ、基板をステージに受け渡す搬送時に前記防着板の部分が前記エッチング位置よりも更に上方に位置するように防着板を移動させることを特徴とする成膜方法。 - 前記エッチング位置は前記成膜位置よりも10〜30mm上方に位置することを特徴とする請求項7記載の成膜方法。

- 前記成膜工程にて基板上面よりも下方に第2防着板が配置され、前記エッチング工程にて前記第2防着板を上方に移動させ、前記エッチング工程で薄膜から飛散する粒子が、前記防着板の基板に近接する部分と基板との間を通過して真空チャンバ内面に付着することを防止するようにしたことを特徴とする請求項7または8記載の成膜方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015034740 | 2015-02-25 | ||

| JP2015034740 | 2015-02-25 | ||

| PCT/JP2016/000989 WO2016136255A1 (ja) | 2015-02-25 | 2016-02-24 | 成膜装置及び成膜方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2016136255A1 JPWO2016136255A1 (ja) | 2017-04-27 |

| JP6171108B2 true JP6171108B2 (ja) | 2017-07-26 |

Family

ID=56788426

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016556907A Active JP6171108B2 (ja) | 2015-02-25 | 2016-02-24 | 成膜装置及び成膜方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20170004995A1 (ja) |

| JP (1) | JP6171108B2 (ja) |

| KR (1) | KR101926677B1 (ja) |

| CN (1) | CN107408504B (ja) |

| TW (1) | TWI599669B (ja) |

| WO (1) | WO2016136255A1 (ja) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3623496B1 (en) * | 2017-05-09 | 2022-08-31 | FUJIFILM Corporation | Film forming device and method for forming piezoelectric film |

| JP7594852B2 (ja) | 2018-10-11 | 2024-12-05 | 日本発條株式会社 | ステージ、成膜装置、および膜加工装置 |

| JP7057442B2 (ja) * | 2018-11-16 | 2022-04-19 | 株式会社アルバック | 真空処理装置 |

| JP7060633B2 (ja) * | 2020-01-29 | 2022-04-26 | キヤノントッキ株式会社 | 成膜装置及び電子デバイス製造装置 |

| JP7438853B2 (ja) * | 2020-06-05 | 2024-02-27 | 株式会社アルバック | マグネトロンスパッタリング装置 |

| JP7239549B2 (ja) * | 2020-12-10 | 2023-03-14 | キヤノントッキ株式会社 | 成膜装置、成膜方法及び電子デバイスの製造方法 |

| CN112981334B (zh) * | 2021-02-05 | 2022-09-16 | 北京北方华创微电子装备有限公司 | 半导体加工设备及对半导体加工设备进行清理的工艺 |

| CN115354276B (zh) * | 2022-07-18 | 2024-04-26 | 中国电子科技集团公司第四十八研究所 | 一种用于刻蚀及溅射的工件台 |

| KR102744848B1 (ko) * | 2022-07-21 | 2024-12-19 | 솔믹스 주식회사 | 포커스 링 및 이를 포함하는 플라즈마 식각장치 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62298444A (ja) * | 1986-06-16 | 1987-12-25 | Hitachi Ltd | プラズマ処理装置 |

| US6110395A (en) * | 1997-08-26 | 2000-08-29 | Trikon Technologies, Inc. | Method and structure for controlling plasma uniformity |

| US20080190760A1 (en) * | 2007-02-08 | 2008-08-14 | Applied Materials, Inc. | Resputtered copper seed layer |

| WO2010070845A1 (ja) * | 2008-12-15 | 2010-06-24 | 株式会社アルバック | スパッタリング装置及びスパッタリング方法 |

| JP5654939B2 (ja) * | 2011-04-20 | 2015-01-14 | 株式会社アルバック | 成膜装置 |

| US10099245B2 (en) * | 2013-03-14 | 2018-10-16 | Applied Materials, Inc. | Process kit for deposition and etching |

-

2016

- 2016-02-24 JP JP2016556907A patent/JP6171108B2/ja active Active

- 2016-02-24 US US15/125,726 patent/US20170004995A1/en not_active Abandoned

- 2016-02-24 CN CN201680001052.8A patent/CN107408504B/zh active Active

- 2016-02-24 WO PCT/JP2016/000989 patent/WO2016136255A1/ja not_active Ceased

- 2016-02-24 KR KR1020177006966A patent/KR101926677B1/ko active Active

- 2016-02-25 TW TW105105676A patent/TWI599669B/zh active

Also Published As

| Publication number | Publication date |

|---|---|

| TW201702412A (zh) | 2017-01-16 |

| CN107408504A (zh) | 2017-11-28 |

| JPWO2016136255A1 (ja) | 2017-04-27 |

| WO2016136255A1 (ja) | 2016-09-01 |

| US20170004995A1 (en) | 2017-01-05 |

| KR20170041903A (ko) | 2017-04-17 |

| KR101926677B1 (ko) | 2018-12-07 |

| TWI599669B (zh) | 2017-09-21 |

| CN107408504B (zh) | 2021-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6171108B2 (ja) | 成膜装置及び成膜方法 | |

| US9543126B2 (en) | Collimator for use in substrate processing chambers | |

| TWI780173B (zh) | 濺鍍裝置 | |

| JP6559233B2 (ja) | マグネトロンスパッタリング装置 | |

| JP5461690B2 (ja) | スパッタリング装置及びスパッタリング方法 | |

| CN109154076B (zh) | 成膜方法和溅射装置 | |

| JP6030813B1 (ja) | 高周波スパッタリング装置及びスパッタリング方法 | |

| JP2016011445A (ja) | スパッタリング方法 | |

| JP6088780B2 (ja) | プラズマ処理方法及びプラズマ処理装置 | |

| JP5914786B1 (ja) | 絶縁物ターゲット | |

| JP6509553B2 (ja) | スパッタリング装置 | |

| JP5693175B2 (ja) | スパッタリング方法 | |

| JP7262235B2 (ja) | スパッタリング装置及びスパッタリング方法 | |

| JP5265309B2 (ja) | スパッタリング方法 | |

| JP5558020B2 (ja) | 成膜方法 | |

| JP2016225579A (ja) | プラズマ処理装置およびプラズマ処理方法 | |

| JP7326106B2 (ja) | スパッタリング装置 | |

| JP2003073801A (ja) | スパッタ装置およびその方法 | |

| JP2018135575A (ja) | スパッタリング装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160909 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160909 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170418 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170616 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170627 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170703 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6171108 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |