JP6129403B2 - シール・泡止め器具 - Google Patents

シール・泡止め器具 Download PDFInfo

- Publication number

- JP6129403B2 JP6129403B2 JP2016506663A JP2016506663A JP6129403B2 JP 6129403 B2 JP6129403 B2 JP 6129403B2 JP 2016506663 A JP2016506663 A JP 2016506663A JP 2016506663 A JP2016506663 A JP 2016506663A JP 6129403 B2 JP6129403 B2 JP 6129403B2

- Authority

- JP

- Japan

- Prior art keywords

- seal

- carbon dioxide

- pressure vessel

- cap

- port

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000006260 foam Substances 0.000 title description 11

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 claims description 146

- 229910002092 carbon dioxide Inorganic materials 0.000 claims description 73

- 239000001569 carbon dioxide Substances 0.000 claims description 73

- 239000007788 liquid Substances 0.000 claims description 40

- 238000007789 sealing Methods 0.000 claims description 30

- 238000000034 method Methods 0.000 claims description 18

- 230000008569 process Effects 0.000 claims description 11

- 230000007246 mechanism Effects 0.000 claims description 9

- 238000009738 saturating Methods 0.000 claims description 4

- 239000003566 sealing material Substances 0.000 claims description 3

- 230000008878 coupling Effects 0.000 claims 4

- 238000010168 coupling process Methods 0.000 claims 4

- 238000005859 coupling reaction Methods 0.000 claims 4

- 235000013361 beverage Nutrition 0.000 description 13

- 238000005187 foaming Methods 0.000 description 10

- 235000014171 carbonated beverage Nutrition 0.000 description 8

- 230000003254 anti-foaming effect Effects 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 5

- 239000011555 saturated liquid Substances 0.000 description 4

- 239000007921 spray Substances 0.000 description 4

- 239000003795 chemical substances by application Substances 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 239000013530 defoamer Substances 0.000 description 3

- 230000002452 interceptive effect Effects 0.000 description 3

- 238000003756 stirring Methods 0.000 description 3

- 239000006188 syrup Substances 0.000 description 3

- 235000020357 syrup Nutrition 0.000 description 3

- 238000013019 agitation Methods 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 2

- 238000007872 degassing Methods 0.000 description 2

- 229920006395 saturated elastomer Polymers 0.000 description 2

- 238000013022 venting Methods 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 239000002518 antifoaming agent Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 235000008504 concentrate Nutrition 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 238000012864 cross contamination Methods 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 239000003205 fragrance Substances 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 235000019640 taste Nutrition 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L2/00—Non-alcoholic beverages; Dry compositions or concentrates therefor; Their preparation

- A23L2/52—Adding ingredients

- A23L2/54—Mixing with gases

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/236—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids specially adapted for aerating or carbonating beverages

- B01F23/2361—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids specially adapted for aerating or carbonating beverages within small containers, e.g. within bottles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/236—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids specially adapted for aerating or carbonating beverages

- B01F23/2362—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids specially adapted for aerating or carbonating beverages for aerating or carbonating within receptacles or tanks, e.g. distribution machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/2366—Parts; Accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/50—Movable or transportable mixing devices or plants

- B01F33/501—Movable mixing devices, i.e. readily shifted or displaced from one place to another, e.g. portable during use

- B01F33/5014—Movable mixing devices, i.e. readily shifted or displaced from one place to another, e.g. portable during use movable by human force, e.g. kitchen or table devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F35/00—Accessories for mixers; Auxiliary operations or auxiliary devices; Parts or details of general application

- B01F35/45—Closures or doors specially adapted for mixing receptacles; Operating mechanisms therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/0042—Details of specific parts of the dispensers

- B67D1/0057—Carbonators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J13/00—Covers or similar closure members for pressure vessels in general

- F16J13/24—Covers or similar closure members for pressure vessels in general with safety devices, e.g. to prevent opening prior to pressure release

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L23/00—Flanged joints

- F16L23/16—Flanged joints characterised by the sealing means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/237—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids characterised by the physical or chemical properties of gases or vapours introduced in the liquid media

- B01F23/2376—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids characterised by the physical or chemical properties of gases or vapours introduced in the liquid media characterised by the gas being introduced

- B01F23/23762—Carbon dioxide

- B01F23/237621—Carbon dioxide in beverages

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Food Science & Technology (AREA)

- Nutrition Science (AREA)

- Polymers & Plastics (AREA)

- Devices For Dispensing Beverages (AREA)

- Pressure Vessels And Lids Thereof (AREA)

- Closures For Containers (AREA)

- Gasket Seals (AREA)

- Medicinal Chemistry (AREA)

- Hydrology & Water Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Organic Chemistry (AREA)

Description

本願は、2013年4月4日に出願された米国特許仮出願第61/808,317号の優先権主張出願である。この先の出願を参照により引用し、その記載内容全体を本明細書の一部とする。

Claims (24)

- ガス入口ポート及びガス出口ポートを備えたキャップ付きの圧力容器用のシールであって、

密封材料で作られた本体を有し、前記本体は、前記キャップ付き圧力容器に接触して前記キャップを前記圧力容器に対して密封するよう構成された密封部分を有し、

炭酸ガス飽和プロセス中、前記圧力容器内の液体と前記ガス入口ポート及び前記ガス出口ポートとの接触を阻止するよう構成されたラビリンスを有する、シール。 - 前記シールの頂面上に形成されたリブを更に有する、請求項1記載のシール。

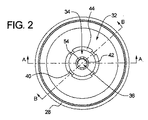

- 前記密封部分から半径方向内方に延びる外側チャネルを更に有する、請求項1記載のシール。

- 弁を備えた中央部分を更に有する、請求項3記載のシール。

- 前記中央部分は、内側チャネル及び前記内側チャネルから半径方向内方に位置決めされた空所を備えている、請求項4記載のシール。

- 前記内側チャネル及び前記空所は、前記炭酸ガス飽和プロセス中、前記弁をバイパスする液体を拡散させると共に閉じ込めるよう構成されている、請求項5記載のシール。

- 前記弁は、ガスを流通させることができると共に前記圧力容器内に入っている前記液体のエネルギーを拡散させるよう構成されたフラップ弁である、請求項4記載のシール。

- 前記外側チャネルを前記内側チャネルから隔てる第1の壁と、

前記内側チャネルを前記空所から隔てる第2の壁と、

前記第1の壁に形成されていて、前記外側チャネルを前記内側チャネルに空圧的に結合する少なくとも1つの第1のポートと、

前記第2の壁に形成されていて、前記内側チャネルを前記空所に空圧的に結合する少なくとも1つの第2のポートと、を更に有する、請求項5記載のシール。 - 前記少なくとも1つの第1のポートは、前記少なくとも1つの第2のポートと半径方向に整合していない、請求項8記載のシール。

- 前記第1の壁は、前記キャップに接触し、それにより前記圧力容器が加圧されたときに、前記シールが前記ガス出口ポートに当たって潰れるのを阻止するよう構成されている、請求項8記載のシール。

- 前記中央部分は、着脱式カバーを含む、請求項5記載のシール。

- 前記中央部分は、前記第1の壁に取り外し可能に取り付けられたカバーを含む、請求項8記載のシール。

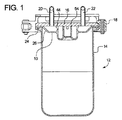

- バッチ炭酸ガス飽和装置であって、

ガス入口ポート及びガス出口ポートを備えたキャップを含む圧力容器を有し、

前記キャップと前記圧力容器との間に位置決めされていて、前記キャップとシールとの間に第1のチャンバを構成すると共に、前記圧力容器と前記シールとの間に第2のチャンバを構成するシール器具を有し、前記シールは、第1のチャンバから第2のチャンバへのガスの流れを可能にするが、前記圧力容器内の液体が前記ガス入口ポート及び前記ガス出口ポートに接触するのを阻止するよう構成されたラビリンスを有し、

前記キャップ及び前記シール器具を前記圧力容器に対して取り外し可能にロックするロック機構を有する、バッチ炭酸ガス飽和装置。 - 前記シールは、前記圧力容器と前記キャップに接触して前記キャップを前記圧力容器に対して密封する密封部分を含む、請求項13記載のバッチ炭酸ガス飽和装置。

- 前記シールは、前記シールの頂面上に形成され、炭酸ガス飽和サイクル中、圧力下にあるとき、前記キャップ及び前記圧力容器を密封するリブを含む、請求項13記載のバッチ炭酸ガス飽和装置。

- 前記シールは、前記密封部分から半径方向内方に延びる外側チャネルを含む、請求項14記載のバッチ炭酸ガス飽和装置。

- 前記シールは、弁を備えた中央部分を含む、請求項16記載のバッチ炭酸ガス飽和装置。

- 前記中央部分は、内側チャネル及び前記内側チャネルから半径方向内方に位置決めされた空所を更に含む、請求項17記載のバッチ炭酸ガス飽和装置。

- 前記内側チャネル及び前記空所は、フラップ弁をバイパスする液体を拡散させると共に閉じ込める、請求項18記載のバッチ炭酸ガス飽和装置。

- 前記弁は、ガスを流通させることができると共に前記圧力容器内に入っている液体のエネルギーを拡散させるフラップ弁である、請求項17記載のバッチ炭酸ガス飽和装置。

- 前記シールは、

前記外側チャネルを前記内側チャネルから隔てる第1の壁と、

前記内側チャネルを前記空所から隔てる第2の壁と、

前記第1の壁に形成されていて、前記外側チャネルを前記内側チャネルに空圧的に結合する少なくとも1つの第1のポートと、

前記第2の壁に形成されていて、前記内側チャネルを前記空所に空圧的に結合する少なくとも1つの第2のポートと、を更に有する、請求項18記載のバッチ炭酸ガス飽和装置。 - 前記少なくとも1つの第1のポートと前記少なくとも1つの第2のポートは、半径方向に互いに整合していない、請求項21記載のバッチ炭酸ガス飽和装置。

- 前記第1の壁は、前記キャップに接触し、それにより前記圧力容器が加圧されたときに、前記シールが前記ガス出口ポートに当たって潰れるのを阻止するよう構成されている、請求項21記載のバッチ炭酸ガス飽和装置。

- 前記中央部分は、カバーを含む、請求項18記載のバッチ炭酸ガス飽和装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201361808317P | 2013-04-04 | 2013-04-04 | |

| US61/808,317 | 2013-04-04 | ||

| PCT/US2014/033040 WO2014165802A1 (en) | 2013-04-04 | 2014-04-04 | Seal and anti foam device |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016522363A JP2016522363A (ja) | 2016-07-28 |

| JP2016522363A5 JP2016522363A5 (ja) | 2017-03-16 |

| JP6129403B2 true JP6129403B2 (ja) | 2017-05-17 |

Family

ID=51654644

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016506663A Active JP6129403B2 (ja) | 2013-04-04 | 2014-04-04 | シール・泡止め器具 |

Country Status (8)

| Country | Link |

|---|---|

| US (2) | US9339056B2 (ja) |

| JP (1) | JP6129403B2 (ja) |

| KR (1) | KR20150143551A (ja) |

| CN (1) | CN105451572B (ja) |

| CA (1) | CA2908164A1 (ja) |

| GB (1) | GB2526735A (ja) |

| MX (1) | MX2015013991A (ja) |

| WO (1) | WO2014165802A1 (ja) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20140079867A1 (en) * | 2012-04-05 | 2014-03-20 | Anheuser-Busch, Llc | Systems and methods for customized fermented beverages |

| US9255654B2 (en) * | 2012-09-14 | 2016-02-09 | United Technologies Corporation | Hard lead egress adapter for an instrumentation component |

| JP2016500564A (ja) * | 2012-10-18 | 2016-01-14 | コーネリアス インコーポレイテッド | 飲料を炭酸ガス飽和させる装置 |

| US9114368B2 (en) | 2013-03-08 | 2015-08-25 | Cornelius, Inc. | Batch carbonator and method of forming a carbonated beverage |

| US20150327718A1 (en) | 2014-02-14 | 2015-11-19 | Remington Designs, Llc | Apparatuses and methods for solute extraction |

| WO2015198233A1 (en) * | 2014-06-24 | 2015-12-30 | Sodastream Industries Ltd. | Automatic release of pressure in a home soda machine |

| US10477883B2 (en) | 2015-08-25 | 2019-11-19 | Cornelius, Inc. | Gas injection assemblies for batch beverages having spargers |

| US10785996B2 (en) | 2015-08-25 | 2020-09-29 | Cornelius, Inc. | Apparatuses, systems, and methods for inline injection of gases into liquids |

| US20170304784A1 (en) * | 2016-04-26 | 2017-10-26 | Cornelius, Inc. | Gas dissolution assemblies for batch beverages |

| US11040314B2 (en) | 2019-01-08 | 2021-06-22 | Marmon Foodservice Technologies, Inc. | Apparatuses, systems, and methods for injecting gasses into beverages |

| CN110935345A (zh) * | 2019-11-08 | 2020-03-31 | 南阳柯丽尔科技有限公司 | 一种双层正喷灯箱胶片涂布液制取用双轴混合搅拌装置 |

| CN111692335B (zh) * | 2020-06-19 | 2022-03-18 | 康佩思节能技术(上海)有限公司 | 一种用于空压机油气桶的卸压加油口盖及油气桶 |

Family Cites Families (60)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB233743A (en) | 1923-12-18 | 1925-05-18 | George Francis Sugden | A new or improved apparatus for charging liquids with carbon dioxide gas |

| US1960640A (en) | 1932-02-13 | 1934-05-29 | Roy W Lajeunesse | Beverage shaker |

| US2006313A (en) | 1933-09-26 | 1935-06-25 | Charles A Geddes | Self-carbonating dispensing system |

| US2556038A (en) | 1946-07-10 | 1951-06-05 | Kollsman Paul | Apparatus for carbonating beverages |

| PT68320A (en) | 1977-07-29 | 1978-08-01 | Sodastream Ltd | Portable apparatus for carbonating water |

| US4208903A (en) | 1979-01-19 | 1980-06-24 | The Coca-Cola Company | Automatic carbonation shaker |

| US4323090A (en) | 1980-05-19 | 1982-04-06 | Bronardi Inc. | Apparatus for aerating liquids |

| ZA835729B (en) | 1982-08-20 | 1984-09-26 | Sodastream Ltd | Liquid aerating apparatus |

| US4481986A (en) | 1982-09-13 | 1984-11-13 | Meyers Louis B | Method and apparatus for making carbonated beverages |

| DK279985A (da) | 1984-06-25 | 1985-12-26 | Isoworth Ltd | Fremgangsmaade og apparat til carbonisering |

| CA1265990A (en) | 1984-10-08 | 1990-02-20 | Neil K. Sutherland | Domestic carbonator |

| JPH0645396B2 (ja) * | 1985-09-04 | 1994-06-15 | ザ・コカ−コ−ラ・カンパニ− | 接続装置 |

| GB2186265B (en) * | 1986-02-10 | 1989-11-01 | Isoworth Ltd | Beverage dispensing apparatus |

| US4850269A (en) | 1987-06-26 | 1989-07-25 | Aquatec, Inc. | Low pressure, high efficiency carbonator and method |

| US4869396A (en) | 1987-08-24 | 1989-09-26 | Kirin Beer Kabushiki Kaisha | Draught beer dispensing system |

| GB2210441B (en) * | 1987-10-01 | 1992-03-04 | Isoworth Ltd | Pressure vessel |

| US4940212A (en) | 1989-01-12 | 1990-07-10 | Burton John W | Compact carbonated beverage making system |

| US5118009A (en) | 1989-09-28 | 1992-06-02 | Charles Novitsky | Carbonated beverage dispenser, system and method |

| JPH0720043Y2 (ja) * | 1989-12-20 | 1995-05-10 | 自動車機器株式会社 | リザーバキャップ |

| US5156871A (en) | 1991-05-01 | 1992-10-20 | Imi Cornelius Inc. | Low cost beverage carbonating apparatus and method |

| IL98266A (en) | 1991-05-26 | 1994-08-26 | Feldman Joseph | Dosage valve extract for use in systems for making carbonated sweetened beverages |

| US5192513A (en) | 1991-07-26 | 1993-03-09 | William C. Stumphauzer | High speed process and apparatus for carbonating water |

| CN1060073A (zh) * | 1991-11-02 | 1992-04-08 | 广州市天河华南电器技术咨询公司 | 全塑迷宫式弹性过盈配合密封结构 |

| CN2134366Y (zh) * | 1992-03-28 | 1993-05-26 | 简国洪 | 具迷宫式弹性过盈密封结构的塑料瓶 |

| US5260081A (en) | 1992-11-19 | 1993-11-09 | William C. Stumphauzer | Process and apparatus for rapidly carbonating a liquid beverage |

| US5531254A (en) | 1994-02-22 | 1996-07-02 | Rosenbach; Arnie | Portable hand activated carbonator |

| US5460846A (en) | 1994-03-21 | 1995-10-24 | William C. Stumphauzer | Process and apparatus for rapidly carbonating a liquid beverage using a single pressure vessel |

| US5549037A (en) | 1994-03-21 | 1996-08-27 | Effervescent Products, Llc | Gas generator attachment |

| GB2287932B (en) | 1994-03-29 | 1997-11-12 | Guinness Brewing Worldwide | A beverage dispensing system |

| US6092811A (en) * | 1996-04-30 | 2000-07-25 | Jamco Products, Llc | Hybrid gasket |

| US6041970A (en) | 1996-08-30 | 2000-03-28 | Imi Cornelius Inc. | Pre-mix beverage dispensing system and components thereof |

| DE29702772U1 (de) * | 1997-02-17 | 1997-04-03 | Protechna S.A., Freiburg/Fribourg | Belüftungsventil aus Kunststoff für Behälter |

| US6167718B1 (en) | 1997-04-20 | 2001-01-02 | Edward M. Halimi | Self-carbonating self-cooling beverage container |

| SE512304C2 (sv) * | 1998-04-22 | 2000-02-28 | Drinkit International Ab | Tryckbehållare för satsvis gassättning av vätska |

| US6073811A (en) | 1998-11-05 | 2000-06-13 | Costea; Thomas | Carbonated beverage dispenser |

| DE19852165A1 (de) * | 1998-11-12 | 2000-05-18 | Mettler Toledo Gmbh | Box |

| US6155452A (en) * | 1998-12-28 | 2000-12-05 | Laurent; Hervej. | Arrangement for resealing carbonated beverage containers |

| AU2000244283A1 (en) | 2000-05-15 | 2001-11-26 | Ben Dagan | A device and a method for carbonating and dispensing liquids |

| US6530400B2 (en) | 2001-02-20 | 2003-03-11 | Dispensing Systems International, Inc. | Intermediate pressure dispensing method for a carbonated beverage |

| YU78403A (sh) | 2001-04-06 | 2004-11-25 | Nicol, Scott | Sistem i postupak za gaziranje |

| US6478179B1 (en) * | 2001-08-10 | 2002-11-12 | Ken L. Alexander | Resealable cap for carbonated beverage can |

| DE20112974U1 (de) * | 2001-08-13 | 2002-09-19 | RPC Bramlage GmbH, 49393 Lohne | Behälterverschluss |

| FR2840968B1 (fr) * | 2002-06-13 | 2004-08-06 | Commissariat Energie Atomique | Joint d'etancheite en graphite souple et a gaine matallique pour haute temperature |

| US6869081B1 (en) * | 2002-12-20 | 2005-03-22 | Jjenco, Inc. | Constant seating stress gasket system |

| US20040216903A1 (en) * | 2003-04-15 | 2004-11-04 | Wierenga Paul H. | Hermetically sealed gas propellant cartridge for fire extinguishers |

| US7267247B1 (en) | 2003-09-25 | 2007-09-11 | Crunkleton Iii James T | Portable beverage dispensing system |

| US9284177B2 (en) | 2004-06-07 | 2016-03-15 | Claude Ramon Litto | Flexible bottle wrapper for preservation and dispensation of air sensitive materials |

| US20080187632A1 (en) * | 2005-05-04 | 2008-08-07 | Matthew Eric Smith | Beverage Foaming Devices |

| US20070158371A1 (en) | 2006-01-11 | 2007-07-12 | Christopher Lupfer | Method and apparatus for gasifying and/or maintaining gasification in liquids |

| US20110020508A1 (en) | 2007-04-05 | 2011-01-27 | Rising Phoenix Co. | Select Serving and Flavored Sparkling Beverage Maker |

| US20120098148A1 (en) | 2009-03-16 | 2012-04-26 | Koslow Evan E | Apparatus, systems and methods for controlling the mass transfer of gases into liquids |

| US8641016B2 (en) | 2009-11-18 | 2014-02-04 | Patrick J. Tatera | Carbonation device |

| US8267007B2 (en) | 2009-11-18 | 2012-09-18 | Tatera Patrick J | Carbonation device |

| US20110180565A1 (en) | 2010-01-23 | 2011-07-28 | Falcon Taps, Llc | Method and Apparatus for Dispensing Product |

| EP2754376B1 (en) | 2010-02-01 | 2015-03-25 | Keurig Green Mountain, Inc. | Method and apparatus for cartridge-based carbonation of beverages |

| US8541039B2 (en) | 2010-06-02 | 2013-09-24 | Protect Plus Llc | Water purifying and flavor infusion device |

| RU2598556C2 (ru) | 2011-06-03 | 2016-09-27 | Бревилл Пти Лимитед | Газирующее устройство |

| US9218704B2 (en) | 2011-11-01 | 2015-12-22 | Pepsico, Inc. | Dispensing system and user interface |

| US9375686B2 (en) | 2012-10-10 | 2016-06-28 | Whirlpool Corporation | Apparatus, method and systems for providing selectable level carbonated water |

| US9114368B2 (en) | 2013-03-08 | 2015-08-25 | Cornelius, Inc. | Batch carbonator and method of forming a carbonated beverage |

-

2014

- 2014-04-04 JP JP2016506663A patent/JP6129403B2/ja active Active

- 2014-04-04 CA CA2908164A patent/CA2908164A1/en not_active Abandoned

- 2014-04-04 WO PCT/US2014/033040 patent/WO2014165802A1/en active Application Filing

- 2014-04-04 US US14/245,717 patent/US9339056B2/en not_active Expired - Fee Related

- 2014-04-04 KR KR1020157031339A patent/KR20150143551A/ko not_active Application Discontinuation

- 2014-04-04 CN CN201480019681.4A patent/CN105451572B/zh not_active Expired - Fee Related

- 2014-04-04 MX MX2015013991A patent/MX2015013991A/es unknown

- 2014-04-04 GB GB1516514.5A patent/GB2526735A/en not_active Withdrawn

-

2016

- 2016-04-13 US US15/097,735 patent/US20160219919A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| GB201516514D0 (en) | 2015-11-04 |

| KR20150143551A (ko) | 2015-12-23 |

| US9339056B2 (en) | 2016-05-17 |

| WO2014165802A1 (en) | 2014-10-09 |

| CN105451572A (zh) | 2016-03-30 |

| JP2016522363A (ja) | 2016-07-28 |

| CA2908164A1 (en) | 2014-10-09 |

| GB2526735A (en) | 2015-12-02 |

| US20140302212A1 (en) | 2014-10-09 |

| MX2015013991A (es) | 2016-07-05 |

| US20160219919A1 (en) | 2016-08-04 |

| WO2014165802A8 (en) | 2014-11-20 |

| CN105451572B (zh) | 2017-10-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6129403B2 (ja) | シール・泡止め器具 | |

| US5014727A (en) | Bubbler device for washing semiconductor materials | |

| RU2019119607A (ru) | Способ получения и выдачи газированного пива из пивного концентрата | |

| US3397871A (en) | Carbonator | |

| US20140113045A1 (en) | Apparatus for carbonating beverages | |

| US20170332672A1 (en) | Gas Infusing Devices and Gas Manifolds for Batch Beverage Machines | |

| RU2019119504A (ru) | Способ получения и выдачи газированного пива из пивного концентрата | |

| RU2019119502A (ru) | Способ получения и выдачи газированного пива из пивного концентрата | |

| JP2017063616A (ja) | 消泡機能付き反応槽 | |

| KR100611685B1 (ko) | 거품발생을 억제하면서 산소공급이 가능한 미생물 배양의교반장치 | |

| JP7035189B2 (ja) | 中空糸膜モジュール及びその洗浄方法 | |

| KR102213440B1 (ko) | 탄산수 제조 장치 | |

| JP2001259384A (ja) | スパイラル型膜モジュールの洗浄方法 | |

| JP2004237268A (ja) | 酸素水生成装置 | |

| JPS63252538A (ja) | 薬液供給装置 | |

| US6270063B1 (en) | Ozone diffuser for deionized water | |

| JP2007125545A (ja) | 排水処理装置 | |

| US454586A (en) | Fermenting-vat | |

| JP2017064590A (ja) | ガス溶解水生成装置 | |

| KR20150144507A (ko) | 미용을 위한 휴대용 탄산수 제조장치 | |

| JP7063846B2 (ja) | 流体排出弁 | |

| KR200236404Y1 (ko) | 오존 살균 냉·온 정수기 | |

| KR100925564B1 (ko) | 액상 고분자 물질 탈포 장치 | |

| KR101541755B1 (ko) | 탄산 음용수의 초기 냉각 유지 기능을 갖는 탄산 음용수 제조장치 | |

| KR20180002189A (ko) | 기액접촉 및 탈기를 위한 중공사 맴브레인 필터 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170206 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170206 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20170206 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20170227 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170313 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170411 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6129403 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |