JP5732354B2 - 研磨パッド - Google Patents

研磨パッド Download PDFInfo

- Publication number

- JP5732354B2 JP5732354B2 JP2011190859A JP2011190859A JP5732354B2 JP 5732354 B2 JP5732354 B2 JP 5732354B2 JP 2011190859 A JP2011190859 A JP 2011190859A JP 2011190859 A JP2011190859 A JP 2011190859A JP 5732354 B2 JP5732354 B2 JP 5732354B2

- Authority

- JP

- Japan

- Prior art keywords

- polishing

- region

- light transmission

- polishing pad

- transmission region

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000005498 polishing Methods 0.000 title claims description 151

- 238000000034 method Methods 0.000 claims description 72

- 230000005540 biological transmission Effects 0.000 claims description 53

- 239000004065 semiconductor Substances 0.000 claims description 21

- 230000002093 peripheral effect Effects 0.000 claims description 18

- 238000004519 manufacturing process Methods 0.000 claims description 16

- 230000008569 process Effects 0.000 claims description 11

- 230000000149 penetrating effect Effects 0.000 claims description 3

- 238000005452 bending Methods 0.000 claims description 2

- 235000012431 wafers Nutrition 0.000 description 40

- 239000010410 layer Substances 0.000 description 39

- 229920005862 polyol Polymers 0.000 description 25

- 150000003077 polyols Chemical class 0.000 description 25

- 238000003756 stirring Methods 0.000 description 25

- 239000000463 material Substances 0.000 description 24

- 239000002002 slurry Substances 0.000 description 22

- 229920005989 resin Polymers 0.000 description 20

- 239000011347 resin Substances 0.000 description 20

- -1 polytetrafluoroethylene Polymers 0.000 description 18

- 229920005749 polyurethane resin Polymers 0.000 description 17

- 238000001514 detection method Methods 0.000 description 16

- 229920005830 Polyurethane Foam Polymers 0.000 description 15

- 239000011496 polyurethane foam Substances 0.000 description 15

- 230000003287 optical effect Effects 0.000 description 14

- 239000004970 Chain extender Substances 0.000 description 11

- 238000006243 chemical reaction Methods 0.000 description 11

- 238000002834 transmittance Methods 0.000 description 11

- 230000007423 decrease Effects 0.000 description 10

- 239000006260 foam Substances 0.000 description 10

- 238000005187 foaming Methods 0.000 description 10

- 239000000203 mixture Substances 0.000 description 10

- 239000000853 adhesive Substances 0.000 description 9

- 239000007789 gas Substances 0.000 description 9

- 239000012948 isocyanate Substances 0.000 description 9

- 150000002513 isocyanates Chemical class 0.000 description 9

- 229920002635 polyurethane Polymers 0.000 description 9

- 239000004814 polyurethane Substances 0.000 description 9

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 8

- 230000001070 adhesive effect Effects 0.000 description 8

- 239000012790 adhesive layer Substances 0.000 description 8

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 7

- 238000002156 mixing Methods 0.000 description 7

- 239000004745 nonwoven fabric Substances 0.000 description 7

- 230000000704 physical effect Effects 0.000 description 7

- 229910052710 silicon Inorganic materials 0.000 description 7

- 239000010703 silicon Substances 0.000 description 7

- 238000001723 curing Methods 0.000 description 6

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 6

- 230000005484 gravity Effects 0.000 description 6

- 238000005259 measurement Methods 0.000 description 6

- 229920000728 polyester Polymers 0.000 description 6

- YPFDHNVEDLHUCE-UHFFFAOYSA-N propane-1,3-diol Chemical compound OCCCO YPFDHNVEDLHUCE-UHFFFAOYSA-N 0.000 description 6

- 239000004094 surface-active agent Substances 0.000 description 6

- IBOFVQJTBBUKMU-UHFFFAOYSA-N 4,4'-methylene-bis-(2-chloroaniline) Chemical compound C1=C(Cl)C(N)=CC=C1CC1=CC=C(N)C(Cl)=C1 IBOFVQJTBBUKMU-UHFFFAOYSA-N 0.000 description 5

- 239000004698 Polyethylene Substances 0.000 description 5

- 150000001875 compounds Chemical class 0.000 description 5

- 239000006185 dispersion Substances 0.000 description 5

- 229920001971 elastomer Polymers 0.000 description 5

- 229920000573 polyethylene Polymers 0.000 description 5

- 238000003825 pressing Methods 0.000 description 5

- 239000005060 rubber Substances 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 4

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 4

- 238000000227 grinding Methods 0.000 description 4

- 230000007246 mechanism Effects 0.000 description 4

- 239000004417 polycarbonate Substances 0.000 description 4

- 229920000515 polycarbonate Polymers 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- QJENIOQDYXRGLF-UHFFFAOYSA-N 4-[(4-amino-3-ethyl-5-methylphenyl)methyl]-2-ethyl-6-methylaniline Chemical compound CC1=C(N)C(CC)=CC(CC=2C=C(CC)C(N)=C(C)C=2)=C1 QJENIOQDYXRGLF-UHFFFAOYSA-N 0.000 description 3

- 229920000178 Acrylic resin Polymers 0.000 description 3

- 239000004925 Acrylic resin Substances 0.000 description 3

- 239000004721 Polyphenylene oxide Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 3

- 239000004793 Polystyrene Substances 0.000 description 3

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 3

- 239000012295 chemical reaction liquid Substances 0.000 description 3

- 238000004049 embossing Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000001746 injection moulding Methods 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 229920000768 polyamine Polymers 0.000 description 3

- 229920001225 polyester resin Polymers 0.000 description 3

- 239000004645 polyester resin Substances 0.000 description 3

- 229920000570 polyether Polymers 0.000 description 3

- 229920001155 polypropylene Polymers 0.000 description 3

- 239000004800 polyvinyl chloride Substances 0.000 description 3

- 229920000915 polyvinyl chloride Polymers 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000012360 testing method Methods 0.000 description 3

- VOZKAJLKRJDJLL-UHFFFAOYSA-N 2,4-diaminotoluene Chemical compound CC1=CC=C(N)C=C1N VOZKAJLKRJDJLL-UHFFFAOYSA-N 0.000 description 2

- PISLZQACAJMAIO-UHFFFAOYSA-N 2,4-diethyl-6-methylbenzene-1,3-diamine Chemical compound CCC1=CC(C)=C(N)C(CC)=C1N PISLZQACAJMAIO-UHFFFAOYSA-N 0.000 description 2

- BSYVFGQQLJNJJG-UHFFFAOYSA-N 2-[2-(2-aminophenyl)sulfanylethylsulfanyl]aniline Chemical compound NC1=CC=CC=C1SCCSC1=CC=CC=C1N BSYVFGQQLJNJJG-UHFFFAOYSA-N 0.000 description 2

- WTPYFJNYAMXZJG-UHFFFAOYSA-N 2-[4-(2-hydroxyethoxy)phenoxy]ethanol Chemical compound OCCOC1=CC=C(OCCO)C=C1 WTPYFJNYAMXZJG-UHFFFAOYSA-N 0.000 description 2

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 241000234587 Canna Species 0.000 description 2

- 235000005273 Canna coccinea Nutrition 0.000 description 2

- 239000004677 Nylon Substances 0.000 description 2

- 239000002033 PVDF binder Substances 0.000 description 2

- 239000005062 Polybutadiene Substances 0.000 description 2

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 2

- YIMQCDZDWXUDCA-UHFFFAOYSA-N [4-(hydroxymethyl)cyclohexyl]methanol Chemical compound OCC1CCC(CO)CC1 YIMQCDZDWXUDCA-UHFFFAOYSA-N 0.000 description 2

- 239000006061 abrasive grain Substances 0.000 description 2

- 230000002378 acidificating effect Effects 0.000 description 2

- 150000001412 amines Chemical class 0.000 description 2

- 125000003277 amino group Chemical group 0.000 description 2

- 238000000149 argon plasma sintering Methods 0.000 description 2

- 239000011324 bead Substances 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 239000003054 catalyst Substances 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 229920006351 engineering plastic Polymers 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- 238000005530 etching Methods 0.000 description 2

- 125000000524 functional group Chemical group 0.000 description 2

- 229910052736 halogen Inorganic materials 0.000 description 2

- 150000002367 halogens Chemical class 0.000 description 2

- 238000007542 hardness measurement Methods 0.000 description 2

- XXMIOPMDWAUFGU-UHFFFAOYSA-N hexane-1,6-diol Chemical compound OCCCCCCO XXMIOPMDWAUFGU-UHFFFAOYSA-N 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 description 2

- 229920003049 isoprene rubber Polymers 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 229910021645 metal ion Inorganic materials 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- FSWDLYNGJBGFJH-UHFFFAOYSA-N n,n'-di-2-butyl-1,4-phenylenediamine Chemical compound CCC(C)NC1=CC=C(NC(C)CC)C=C1 FSWDLYNGJBGFJH-UHFFFAOYSA-N 0.000 description 2

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 description 2

- 229920001778 nylon Polymers 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 229920006122 polyamide resin Polymers 0.000 description 2

- 229920002857 polybutadiene Polymers 0.000 description 2

- 229920001610 polycaprolactone Polymers 0.000 description 2

- 239000004632 polycaprolactone Substances 0.000 description 2

- 229920005668 polycarbonate resin Polymers 0.000 description 2

- 239000004431 polycarbonate resin Substances 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 229920005672 polyolefin resin Polymers 0.000 description 2

- 229920002223 polystyrene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 2

- 239000011342 resin composition Substances 0.000 description 2

- 238000007788 roughening Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 2

- RTTZISZSHSCFRH-UHFFFAOYSA-N 1,3-bis(isocyanatomethyl)benzene Chemical compound O=C=NCC1=CC=CC(CN=C=O)=C1 RTTZISZSHSCFRH-UHFFFAOYSA-N 0.000 description 1

- VGHSXKTVMPXHNG-UHFFFAOYSA-N 1,3-diisocyanatobenzene Chemical compound O=C=NC1=CC=CC(N=C=O)=C1 VGHSXKTVMPXHNG-UHFFFAOYSA-N 0.000 description 1

- WZCQRUWWHSTZEM-UHFFFAOYSA-N 1,3-phenylenediamine Chemical compound NC1=CC=CC(N)=C1 WZCQRUWWHSTZEM-UHFFFAOYSA-N 0.000 description 1

- OHLKMGYGBHFODF-UHFFFAOYSA-N 1,4-bis(isocyanatomethyl)benzene Chemical compound O=C=NCC1=CC=C(CN=C=O)C=C1 OHLKMGYGBHFODF-UHFFFAOYSA-N 0.000 description 1

- ALQLPWJFHRMHIU-UHFFFAOYSA-N 1,4-diisocyanatobenzene Chemical compound O=C=NC1=CC=C(N=C=O)C=C1 ALQLPWJFHRMHIU-UHFFFAOYSA-N 0.000 description 1

- CDMDQYCEEKCBGR-UHFFFAOYSA-N 1,4-diisocyanatocyclohexane Chemical compound O=C=NC1CCC(N=C=O)CC1 CDMDQYCEEKCBGR-UHFFFAOYSA-N 0.000 description 1

- UNVGBIALRHLALK-UHFFFAOYSA-N 1,5-Hexanediol Chemical compound CC(O)CCCCO UNVGBIALRHLALK-UHFFFAOYSA-N 0.000 description 1

- SBJCUZQNHOLYMD-UHFFFAOYSA-N 1,5-Naphthalene diisocyanate Chemical compound C1=CC=C2C(N=C=O)=CC=CC2=C1N=C=O SBJCUZQNHOLYMD-UHFFFAOYSA-N 0.000 description 1

- LFSYUSUFCBOHGU-UHFFFAOYSA-N 1-isocyanato-2-[(4-isocyanatophenyl)methyl]benzene Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=CC=C1N=C=O LFSYUSUFCBOHGU-UHFFFAOYSA-N 0.000 description 1

- HQCHAOKWWKLXQH-UHFFFAOYSA-N 2,6-Dichloro-para-phenylenediamine Chemical compound NC1=CC(Cl)=C(N)C(Cl)=C1 HQCHAOKWWKLXQH-UHFFFAOYSA-N 0.000 description 1

- RLYCRLGLCUXUPO-UHFFFAOYSA-N 2,6-diaminotoluene Chemical compound CC1=C(N)C=CC=C1N RLYCRLGLCUXUPO-UHFFFAOYSA-N 0.000 description 1

- BSESQBBHCKBEIW-UHFFFAOYSA-N 2-amino-4-[(3-amino-4-carboxyphenyl)methyl]benzoic acid Chemical compound C1=C(C(O)=O)C(N)=CC(CC=2C=C(N)C(C(O)=O)=CC=2)=C1 BSESQBBHCKBEIW-UHFFFAOYSA-N 0.000 description 1

- TXDBDYPHJXUHEO-UHFFFAOYSA-N 2-methyl-4,6-bis(methylsulfanyl)benzene-1,3-diamine Chemical compound CSC1=CC(SC)=C(N)C(C)=C1N TXDBDYPHJXUHEO-UHFFFAOYSA-N 0.000 description 1

- SXFJDZNJHVPHPH-UHFFFAOYSA-N 3-methylpentane-1,5-diol Chemical compound OCCC(C)CCO SXFJDZNJHVPHPH-UHFFFAOYSA-N 0.000 description 1

- UPMLOUAZCHDJJD-UHFFFAOYSA-N 4,4'-Diphenylmethane Diisocyanate Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=C(N=C=O)C=C1 UPMLOUAZCHDJJD-UHFFFAOYSA-N 0.000 description 1

- YBRVSVVVWCFQMG-UHFFFAOYSA-N 4,4'-diaminodiphenylmethane Chemical compound C1=CC(N)=CC=C1CC1=CC=C(N)C=C1 YBRVSVVVWCFQMG-UHFFFAOYSA-N 0.000 description 1

- RQEOBXYYEPMCPJ-UHFFFAOYSA-N 4,6-diethyl-2-methylbenzene-1,3-diamine Chemical compound CCC1=CC(CC)=C(N)C(C)=C1N RQEOBXYYEPMCPJ-UHFFFAOYSA-N 0.000 description 1

- PPUHQXZSLCCTAN-UHFFFAOYSA-N 4-[(4-amino-2,3-dichlorophenyl)methyl]-2,3-dichloroaniline Chemical compound ClC1=C(Cl)C(N)=CC=C1CC1=CC=C(N)C(Cl)=C1Cl PPUHQXZSLCCTAN-UHFFFAOYSA-N 0.000 description 1

- VIOMIGLBMQVNLY-UHFFFAOYSA-N 4-[(4-amino-2-chloro-3,5-diethylphenyl)methyl]-3-chloro-2,6-diethylaniline Chemical compound CCC1=C(N)C(CC)=CC(CC=2C(=C(CC)C(N)=C(CC)C=2)Cl)=C1Cl VIOMIGLBMQVNLY-UHFFFAOYSA-N 0.000 description 1

- NWIVYGKSHSJHEF-UHFFFAOYSA-N 4-[(4-amino-3,5-diethylphenyl)methyl]-2,6-diethylaniline Chemical compound CCC1=C(N)C(CC)=CC(CC=2C=C(CC)C(N)=C(CC)C=2)=C1 NWIVYGKSHSJHEF-UHFFFAOYSA-N 0.000 description 1

- AOFIWCXMXPVSAZ-UHFFFAOYSA-N 4-methyl-2,6-bis(methylsulfanyl)benzene-1,3-diamine Chemical compound CSC1=CC(C)=C(N)C(SC)=C1N AOFIWCXMXPVSAZ-UHFFFAOYSA-N 0.000 description 1

- MQJKPEGWNLWLTK-UHFFFAOYSA-N Dapsone Chemical compound C1=CC(N)=CC=C1S(=O)(=O)C1=CC=C(N)C=C1 MQJKPEGWNLWLTK-UHFFFAOYSA-N 0.000 description 1

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 239000005057 Hexamethylene diisocyanate Substances 0.000 description 1

- 239000005058 Isophorone diisocyanate Substances 0.000 description 1

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 1

- 229920000877 Melamine resin Polymers 0.000 description 1

- 241001112258 Moca Species 0.000 description 1

- 239000004696 Poly ether ether ketone Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004697 Polyetherimide Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 239000004433 Thermoplastic polyurethane Substances 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 229920001807 Urea-formaldehyde Polymers 0.000 description 1

- ISKQADXMHQSTHK-UHFFFAOYSA-N [4-(aminomethyl)phenyl]methanamine Chemical compound NCC1=CC=C(CN)C=C1 ISKQADXMHQSTHK-UHFFFAOYSA-N 0.000 description 1

- 239000003522 acrylic cement Substances 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 125000002029 aromatic hydrocarbon group Chemical group 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- QHIWVLPBUQWDMQ-UHFFFAOYSA-N butyl prop-2-enoate;methyl 2-methylprop-2-enoate;prop-2-enoic acid Chemical compound OC(=O)C=C.COC(=O)C(C)=C.CCCCOC(=O)C=C QHIWVLPBUQWDMQ-UHFFFAOYSA-N 0.000 description 1

- UBAZGMLMVVQSCD-UHFFFAOYSA-N carbon dioxide;molecular oxygen Chemical compound O=O.O=C=O UBAZGMLMVVQSCD-UHFFFAOYSA-N 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical compound OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000012461 cellulose resin Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 125000006575 electron-withdrawing group Chemical group 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 125000005843 halogen group Chemical group 0.000 description 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- RRAMGCGOFNQTLD-UHFFFAOYSA-N hexamethylene diisocyanate Chemical compound O=C=NCCCCCCN=C=O RRAMGCGOFNQTLD-UHFFFAOYSA-N 0.000 description 1

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- NIMLQBUJDJZYEJ-UHFFFAOYSA-N isophorone diisocyanate Chemical compound CC1(C)CC(N=C=O)CC(C)(CN=C=O)C1 NIMLQBUJDJZYEJ-UHFFFAOYSA-N 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 229940018564 m-phenylenediamine Drugs 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 229940102398 methyl anthranilate Drugs 0.000 description 1

- 125000002816 methylsulfanyl group Chemical group [H]C([H])([H])S[*] 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 238000000016 photochemical curing Methods 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 229920005906 polyester polyol Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 229920001601 polyetherimide Polymers 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 239000002952 polymeric resin Substances 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920005990 polystyrene resin Polymers 0.000 description 1

- 229920000909 polytetrahydrofuran Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000011417 postcuring Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000011541 reaction mixture Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000007261 regionalization Effects 0.000 description 1

- 238000005488 sandblasting Methods 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 150000005846 sugar alcohols Polymers 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 150000003512 tertiary amines Chemical class 0.000 description 1

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- 125000004149 thio group Chemical group *S* 0.000 description 1

- DVKJHBMWWAPEIU-UHFFFAOYSA-N toluene 2,4-diisocyanate Chemical compound CC1=CC=C(N=C=O)C=C1N=C=O DVKJHBMWWAPEIU-UHFFFAOYSA-N 0.000 description 1

- RUELTTOHQODFPA-UHFFFAOYSA-N toluene 2,6-diisocyanate Chemical compound CC1=C(N=C=O)C=CC=C1N=C=O RUELTTOHQODFPA-UHFFFAOYSA-N 0.000 description 1

- 238000005809 transesterification reaction Methods 0.000 description 1

- 238000013519 translation Methods 0.000 description 1

- 125000003258 trimethylene group Chemical group [H]C([H])([*:2])C([H])([H])C([H])([H])[*:1] 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

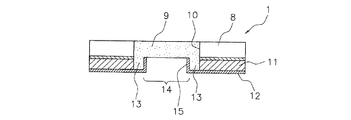

- B24B37/205—Lapping pads for working plane surfaces provided with a window for inspecting the surface of the work being lapped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/22—Lapping pads for working plane surfaces characterised by a multi-layered structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011190859A JP5732354B2 (ja) | 2011-09-01 | 2011-09-01 | 研磨パッド |

| CN201280041433.0A CN103747918A (zh) | 2011-09-01 | 2012-08-24 | 抛光垫 |

| US14/241,008 US9156126B2 (en) | 2011-09-01 | 2012-08-24 | Polishing pad |

| PCT/JP2012/071472 WO2013031692A1 (ja) | 2011-09-01 | 2012-08-24 | 研磨パッド |

| KR1020147007404A KR101633745B1 (ko) | 2011-09-01 | 2012-08-24 | 연마 패드 |

| TW101131547A TWI480942B (zh) | 2011-09-01 | 2012-08-30 | Polishing pad |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011190859A JP5732354B2 (ja) | 2011-09-01 | 2011-09-01 | 研磨パッド |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013052459A JP2013052459A (ja) | 2013-03-21 |

| JP2013052459A5 JP2013052459A5 (enExample) | 2014-05-08 |

| JP5732354B2 true JP5732354B2 (ja) | 2015-06-10 |

Family

ID=47756182

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011190859A Expired - Fee Related JP5732354B2 (ja) | 2011-09-01 | 2011-09-01 | 研磨パッド |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9156126B2 (enExample) |

| JP (1) | JP5732354B2 (enExample) |

| KR (1) | KR101633745B1 (enExample) |

| CN (1) | CN103747918A (enExample) |

| TW (1) | TWI480942B (enExample) |

| WO (1) | WO2013031692A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI808744B (zh) * | 2021-05-04 | 2023-07-11 | 南韓商Skc索密思有限公司 | 拋光墊、拋光墊的製備方法以及利用該拋光墊的半導體裝置的製造方法 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8961266B2 (en) | 2013-03-15 | 2015-02-24 | Applied Materials, Inc. | Polishing pad with secondary window seal |

| TWI593511B (zh) * | 2016-06-08 | 2017-08-01 | 智勝科技股份有限公司 | 研磨墊及研磨方法 |

| KR101945874B1 (ko) * | 2017-08-07 | 2019-02-11 | 에스케이씨 주식회사 | 표면 처리된 연마패드용 윈도우 및 이를 포함하는 연마패드 |

| CN109202693B (zh) * | 2017-10-16 | 2021-10-12 | Skc索密思株式会社 | 防泄漏抛光垫及其制造方法 |

| JP7525271B2 (ja) * | 2020-03-03 | 2024-07-30 | 富士紡ホールディングス株式会社 | 研磨パッド及び研磨パッドの製造方法 |

| US11633830B2 (en) * | 2020-06-24 | 2023-04-25 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | CMP polishing pad with uniform window |

| US20230059394A1 (en) * | 2021-07-02 | 2023-02-23 | Skc Solmics Co., Ltd. | Polishing pad and method for manufacturing semiconductor device using the same |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6832950B2 (en) * | 2002-10-28 | 2004-12-21 | Applied Materials, Inc. | Polishing pad with window |

| US6454630B1 (en) | 1999-09-14 | 2002-09-24 | Applied Materials, Inc. | Rotatable platen having a transparent window for a chemical mechanical polishing apparatus and method of making the same |

| US6524164B1 (en) | 1999-09-14 | 2003-02-25 | Applied Materials, Inc. | Polishing pad with transparent window having reduced window leakage for a chemical mechanical polishing apparatus |

| DE60011798T2 (de) | 1999-09-29 | 2005-11-10 | Rohm and Haas Electronic Materials CMP Holdings, Inc., Wilmington | Schleifkissen |

| US20020137431A1 (en) * | 2001-03-23 | 2002-09-26 | Labunsky Michael A. | Methods and apparatus for polishing and planarization |

| DE60228784D1 (de) * | 2001-04-25 | 2008-10-23 | Jsr Corp | Lichtduchlässiges Polierkissen für eine Halbleiterschleife |

| JP4131632B2 (ja) | 2001-06-15 | 2008-08-13 | 株式会社荏原製作所 | ポリッシング装置及び研磨パッド |

| JP2004327974A (ja) * | 2003-04-09 | 2004-11-18 | Jsr Corp | 研磨パッド、その製造法と製造用金型および半導体ウエハの研磨方法 |

| JP2004343090A (ja) * | 2003-04-22 | 2004-12-02 | Jsr Corp | 研磨パッドおよび半導体ウェハの研磨方法 |

| KR20040093402A (ko) | 2003-04-22 | 2004-11-05 | 제이에스알 가부시끼가이샤 | 연마 패드 및 반도체 웨이퍼의 연마 방법 |

| JP2004327779A (ja) * | 2003-04-25 | 2004-11-18 | Toray Ind Inc | 研磨パッド、研磨装置及び半導体デバイスの製造方法 |

| KR100532440B1 (ko) * | 2003-06-05 | 2005-11-30 | 삼성전자주식회사 | 윈도로의 유체의 침투를 막는 실링 장벽부를 가지는 화학기계적 연마 장비에 사용되는 연마 패드 |

| US6984163B2 (en) * | 2003-11-25 | 2006-01-10 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Polishing pad with high optical transmission window |

| US7018581B2 (en) * | 2004-06-10 | 2006-03-28 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Method of forming a polishing pad with reduced stress window |

| US7520968B2 (en) * | 2004-10-05 | 2009-04-21 | Applied Materials, Inc. | Conductive pad design modification for better wafer-pad contact |

| US7764377B2 (en) * | 2005-08-22 | 2010-07-27 | Applied Materials, Inc. | Spectrum based endpointing for chemical mechanical polishing |

| US7621798B1 (en) * | 2006-03-07 | 2009-11-24 | Applied Materials, Inc. | Reducing polishing pad deformation |

| JP5146927B2 (ja) | 2006-10-18 | 2013-02-20 | 東洋ゴム工業株式会社 | 長尺研磨パッドの製造方法 |

| JP2008226911A (ja) * | 2007-03-08 | 2008-09-25 | Jsr Corp | 化学機械研磨用パッド、化学機械研磨用積層体パッド、および化学機械研磨方法 |

| JP5274798B2 (ja) * | 2007-08-20 | 2013-08-28 | 東洋ゴム工業株式会社 | 研磨パッド及びその製造方法 |

| US8083570B2 (en) | 2008-10-17 | 2011-12-27 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Chemical mechanical polishing pad having sealed window |

-

2011

- 2011-09-01 JP JP2011190859A patent/JP5732354B2/ja not_active Expired - Fee Related

-

2012

- 2012-08-24 CN CN201280041433.0A patent/CN103747918A/zh active Pending

- 2012-08-24 KR KR1020147007404A patent/KR101633745B1/ko not_active Expired - Fee Related

- 2012-08-24 US US14/241,008 patent/US9156126B2/en active Active

- 2012-08-24 WO PCT/JP2012/071472 patent/WO2013031692A1/ja not_active Ceased

- 2012-08-30 TW TW101131547A patent/TWI480942B/zh not_active IP Right Cessation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI808744B (zh) * | 2021-05-04 | 2023-07-11 | 南韓商Skc索密思有限公司 | 拋光墊、拋光墊的製備方法以及利用該拋光墊的半導體裝置的製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US9156126B2 (en) | 2015-10-13 |

| TWI480942B (zh) | 2015-04-11 |

| TW201330078A (zh) | 2013-07-16 |

| WO2013031692A1 (ja) | 2013-03-07 |

| US20140213151A1 (en) | 2014-07-31 |

| JP2013052459A (ja) | 2013-03-21 |

| CN103747918A (zh) | 2014-04-23 |

| KR101633745B1 (ko) | 2016-06-27 |

| KR20140051441A (ko) | 2014-04-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5110677B2 (ja) | 研磨パッド | |

| JP4943233B2 (ja) | 研磨パッドの製造方法 | |

| CN101448607B (zh) | 抛光垫 | |

| JP4971028B2 (ja) | 研磨パッドの製造方法 | |

| JP5732354B2 (ja) | 研磨パッド | |

| JP2014104521A (ja) | 研磨パッド | |

| CN100349267C (zh) | 研磨垫及半导体器件的制造方法 | |

| JP2009224384A (ja) | 研磨パッド及び半導体デバイスの製造方法 | |

| JP2006110686A (ja) | 研磨パッド | |

| JP4744087B2 (ja) | 研磨パッド及び半導体デバイスの製造方法 | |

| JP2007260827A (ja) | 研磨パッドの製造方法 | |

| JP5255286B2 (ja) | 研磨パッド | |

| JP4888905B2 (ja) | 研磨パッドの製造方法 | |

| JP5146927B2 (ja) | 長尺研磨パッドの製造方法 | |

| JP2006187837A (ja) | 研磨パッド | |

| JP4941735B2 (ja) | 研磨パッドの製造方法 | |

| WO2016052155A1 (ja) | 研磨パッド | |

| JP4831476B2 (ja) | 研磨パッドの製造方法 | |

| JP2016066781A (ja) | 研磨パッド | |

| JP4730605B2 (ja) | 長尺研磨パッドの製造方法 | |

| WO2016047451A1 (ja) | 研磨パッド | |

| JP2017119316A (ja) | 研磨パッド | |

| JP2017117976A (ja) | 研磨パッド及び半導体デバイスの製造方法 | |

| JP2017119314A (ja) | 研磨パッドの使用方法 | |

| JP2017119315A (ja) | 積層研磨パッド製造用光透過領域積層部材、及び研磨領域積層部材、並びに積層研磨パッド製造用キット、並びに積層研磨パッド |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140326 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140709 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150114 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150316 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150401 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150413 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5732354 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| LAPS | Cancellation because of no payment of annual fees |