JP5654875B2 - 発泡した感圧性の接着剤の製造方法 - Google Patents

発泡した感圧性の接着剤の製造方法 Download PDFInfo

- Publication number

- JP5654875B2 JP5654875B2 JP2010541768A JP2010541768A JP5654875B2 JP 5654875 B2 JP5654875 B2 JP 5654875B2 JP 2010541768 A JP2010541768 A JP 2010541768A JP 2010541768 A JP2010541768 A JP 2010541768A JP 5654875 B2 JP5654875 B2 JP 5654875B2

- Authority

- JP

- Japan

- Prior art keywords

- adhesive

- microballoon

- mixing device

- pressure

- roll

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/32—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof from compositions containing microballoons, e.g. syntactic foams

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/40—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft

- B29B7/42—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix

- B29B7/426—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix with consecutive casings or screws, e.g. for charging, discharging, mixing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/46—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft

- B29B7/48—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws

- B29B7/485—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws with three or more shafts provided with screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/46—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft

- B29B7/48—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws

- B29B7/487—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws with consecutive casings or screws, e.g. for feeding, discharging, mixing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/74—Mixing; Kneading using other mixers or combinations of mixers, e.g. of dissimilar mixers ; Plant

- B29B7/7461—Combinations of dissimilar mixers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/74—Mixing; Kneading using other mixers or combinations of mixers, e.g. of dissimilar mixers ; Plant

- B29B7/7476—Systems, i.e. flow charts or diagrams; Plants

- B29B7/748—Plants

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/74—Mixing; Kneading using other mixers or combinations of mixers, e.g. of dissimilar mixers ; Plant

- B29B7/7476—Systems, i.e. flow charts or diagrams; Plants

- B29B7/7495—Systems, i.e. flow charts or diagrams; Plants for mixing rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/22—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length

- B29C43/24—Calendering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/22—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length

- B29C43/28—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/001—Combinations of extrusion moulding with other shaping operations

- B29C48/0011—Combinations of extrusion moulding with other shaping operations combined with compression moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/15—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor incorporating preformed parts or layers, e.g. extrusion moulding around inserts

- B29C48/154—Coating solid articles, i.e. non-hollow articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/375—Plasticisers, homogenisers or feeders comprising two or more stages

- B29C48/385—Plasticisers, homogenisers or feeders comprising two or more stages using two or more serially arranged screws in separate barrels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

- B29C48/435—Sub-screws

- B29C48/44—Planetary screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/92—Measuring, controlling or regulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/58—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising fillers only, e.g. particles, powder, beads, flakes, spheres

- B29C70/60—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising fillers only, e.g. particles, powder, beads, flakes, spheres comprising a combination of distinct filler types incorporated in matrix material, forming one or more layers, and with or without non-filled layers

- B29C70/606—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising fillers only, e.g. particles, powder, beads, flakes, spheres comprising a combination of distinct filler types incorporated in matrix material, forming one or more layers, and with or without non-filled layers and with one or more layers of non-plastics material or non-specified material, e.g. supports

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/58—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising fillers only, e.g. particles, powder, beads, flakes, spheres

- B29C70/66—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising fillers only, e.g. particles, powder, beads, flakes, spheres the filler comprising hollow constituents, e.g. syntactic foam

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K7/00—Use of ingredients characterised by shape

- C08K7/22—Expanded, porous or hollow particles

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L53/00—Compositions of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Compositions of derivatives of such polymers

- C08L53/02—Compositions of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Compositions of derivatives of such polymers of vinyl-aromatic monomers and conjugated dienes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L55/00—Compositions of homopolymers or copolymers, obtained by polymerisation reactions only involving carbon-to-carbon unsaturated bonds, not provided for in groups C08L23/00 - C08L53/00

- C08L55/02—ABS [Acrylonitrile-Butadiene-Styrene] polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J107/00—Adhesives based on natural rubber

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/08—Macromolecular additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J121/00—Adhesives based on unspecified rubbers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

- C09J123/04—Homopolymers or copolymers of ethene

- C09J123/08—Copolymers of ethene

- C09J123/0846—Copolymers of ethene with unsaturated hydrocarbons containing other atoms than carbon or hydrogen atoms

- C09J123/0853—Vinylacetate

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C09J133/10—Homopolymers or copolymers of methacrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J153/00—Adhesives based on block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Adhesives based on derivatives of such polymers

- C09J153/02—Vinyl aromatic monomers and conjugated dienes

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J155/00—Adhesives based on homopolymers or copolymers, obtained by polymerisation reactions only involving carbon-to-carbon unsaturated bonds, not provided for in groups C09J123/00 - C09J153/00

- C09J155/02—ABS [Acrylonitrile-Butadiene-Styrene] polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J201/00—Adhesives based on unspecified macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J9/00—Adhesives characterised by their physical nature or the effects produced, e.g. glue sticks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/80—Component parts, details or accessories; Auxiliary operations

- B29B7/82—Heating or cooling

- B29B7/826—Apparatus therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/80—Component parts, details or accessories; Auxiliary operations

- B29B7/88—Adding charges, i.e. additives

- B29B7/90—Fillers or reinforcements, e.g. fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92504—Controlled parameter

- B29C2948/92704—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/0097—Glues or adhesives, e.g. hot melts or thermofusible adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/06—Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts

- B29K2105/16—Fillers

- B29K2105/165—Hollow fillers, e.g. microballoons or expanded particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2007/00—Flat articles, e.g. films or sheets

- B29L2007/005—Tarpaulins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G2170/00—Compositions for adhesives

- C08G2170/40—Compositions for pressure-sensitive adhesives

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2201/00—Foams characterised by the foaming process

- C08J2201/02—Foams characterised by the foaming process characterised by mechanical pre- or post-treatments

- C08J2201/024—Preparation or use of a blowing agent concentrate, i.e. masterbatch in a foamable composition

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2203/00—Foams characterized by the expanding agent

- C08J2203/22—Expandable microspheres, e.g. Expancel®

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2207/00—Foams characterised by their intended use

- C08J2207/02—Adhesive

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2307/00—Characterised by the use of natural rubber

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2333/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers

- C08J2333/04—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters

- C08J2333/06—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Derivatives of such polymers esters of esters containing only carbon, hydrogen, and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C08J2333/10—Homopolymers or copolymers of methacrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2353/00—Characterised by the use of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers

- C08J2353/02—Characterised by the use of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers of vinyl aromatic monomers and conjugated dienes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/14—Polymer mixtures characterised by other features containing polymeric additives characterised by shape

- C08L2205/18—Spheres

- C08L2205/20—Hollow spheres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2666/00—Composition of polymers characterized by a further compound in the blend, being organic macromolecular compounds, natural resins, waxes or and bituminous materials, non-macromolecular organic substances, inorganic substances or characterized by their function in the composition

- C08L2666/02—Organic macromolecular compounds, natural resins, waxes or and bituminous materials

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2666/00—Composition of polymers characterized by a further compound in the blend, being organic macromolecular compounds, natural resins, waxes or and bituminous materials, non-macromolecular organic substances, inorganic substances or characterized by their function in the composition

- C08L2666/02—Organic macromolecular compounds, natural resins, waxes or and bituminous materials

- C08L2666/04—Macromolecular compounds according to groups C08L7/00 - C08L49/00, or C08L55/00 - C08L57/00; Derivatives thereof

- C08L2666/06—Homopolymers or copolymers of unsaturated hydrocarbons; Derivatives thereof

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/40—Additional features of adhesives in the form of films or foils characterized by the presence of essential components

- C09J2301/408—Additional features of adhesives in the form of films or foils characterized by the presence of essential components additives as essential feature of the adhesive layer

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/40—Additional features of adhesives in the form of films or foils characterized by the presence of essential components

- C09J2301/412—Additional features of adhesives in the form of films or foils characterized by the presence of essential components presence of microspheres

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/28—Web or sheet containing structurally defined element or component and having an adhesive outermost layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/28—Web or sheet containing structurally defined element or component and having an adhesive outermost layer

- Y10T428/2839—Web or sheet containing structurally defined element or component and having an adhesive outermost layer with release or antistick coating

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Polymers & Plastics (AREA)

- Medicinal Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Composite Materials (AREA)

- Materials Engineering (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Adhesive Tapes (AREA)

- Manufacture Of Porous Articles, And Recovery And Treatment Of Waste Products (AREA)

- Laminated Bodies (AREA)

Description

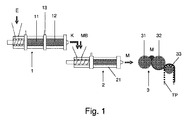

・接着剤を構成する、ポリマー、樹脂、または充填材といった成分、および未膨張のマイクロバルーンを第1の混合装置中で混合し、陽圧下で膨張温度まで加熱し、

・該マイクロバルーンを、混合装置から吐出されるときに膨張させ、

・接着剤混合物を膨張させたマイクロバルーンとともに、ロール・コータ中で層状に成形し、

・場合により、接着剤混合物を膨張させたマイクロバルーンとともに、テープ状の支持体材料または剥離材料上に塗工する、方法を含む。

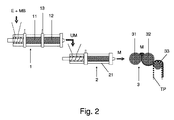

・接着剤を構成する、ポリマー、樹脂、または充填材といった成分を未膨張のマイクロバルーンと第1の混合装置中で陽圧下で混合し、温度をマイクロバルーンの膨張温度より下に調節し、

・混合された、とりわけ均一な接着剤を第1の混合装置から第2の混合装置に移送し、陽圧下で膨張温度まで加熱し、

・該マイクロバルーンを、第2の混合装置中で、または第2の混合装置から吐出されるときに膨張させ、

・接着剤混合物を膨張させたマイクロバルーンとともに、ロール・コータ中で層状に成形し、

・場合により、接着剤混合物を膨張させたマイクロバルーンとともに、帯状支持体材料または剥離材料上に塗工する、方法を含む。

・接着剤を構成する、ポリマー、樹脂、または充填材といった成分を第1の混合装置中で混合し、

・混合された、とりわけ均一な接着剤を第1の混合装置から第2の混合装置に移送し、同時に未膨張のマイクロバルーンを第2の混合装置に送入し、

・該マイクロバルーンを、第2の混合装置中で、または第2の混合装置から吐出されるときに膨張させ、

・接着剤混合物を膨張させたマイクロバルーンとともに、ロール・コータ中で層状に成形し、

・場合により、接着剤混合物を膨張させたマイクロバルーンとともに、テープ状の支持体材料または剥離材料上に塗工する、方法を含む。

・第1の混合装置が、連続式装置、とりわけ遊星ローラ押出し機、2軸押出し機、またはピン型押出し機であるか、

・第1の混合装置が、非連続式装置、とりわけZ−ニーダまたは内部ミキサであり、

・第2の混合装置が、遊星ローラ押出し機、単軸または2軸押出し機、またはピン型押出し機であり、および/または

・接着剤を膨張させたマイクロバルーンとともに支持体層に成形する成形手段が、カレンダ、ロール・コータ、またはロールと固定ドクタの形成する間隙であるのが、有利である。

表面粗さの測定

PRIMOSシステムは照明ユニットと撮影ユニットからなる。照明ユニットは、デジタル微小鏡投映機を用いて、表面上に直線を投映する。投映される平行な直線は、表面構造により偏移され、すなわち、変調される。

測定野の寸法: 14.5x23.4mm2

断面長さ: 20.0mm

表面粗さ: 縁から1.0mm離れる(Xm=21.4mm;Ym=12.5mm)

フィルタ: 3次多項式フィルタ

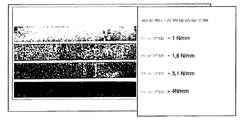

剥離強度(接着力)の試験はPSTC−1に準拠して行う。

接着テープを所定の固い接着基板(ここでは鋼板)に貼り、一定の剪断負荷をかける。耐久時間を分単位で測定する。

接着テープの1cm幅の試験片を、研磨した鋼板(試験基板)に、5cm長さにわたり、2kgのロールを10回転動して貼付する。両面接着テープは、背面を50μm厚のアルミニウム箔で被覆する。試験片を190μm厚さのPETフィルムで強化し、続いて固定装置を用いて縁を真っ直ぐに切断する。その際、強化された試験片の縁は、鋼板の縁から1mm突出させる。板は15分間試験条件下(23℃、相対湿度50%)、ただし無負荷で、測定装置中で平衡処理される。続いて、所望の試験用錘(ここでは50g)を吊るし、剪断負荷が接着面に平行に生じるようにする。解像度がμm領域の移動量測定器が、剪断移動量を時間の関数としてグラフに記録する。

低温耐衝撃性試験により、両面接着性(d/s)感圧接着テープの突発的な動的衝撃負荷への感受性を調べる。試験しようとする接着テープを用いて、試験体を、PC板とABS枠から製作する。試験しようとする両面接着テープは、これら継目構成部品の間に貼られ、続いて6kgの錘を5秒間載せる。

塗工された自己接着剤の嵩密度あるいは密度は、目付け量とそのときの層厚の比から決定される。

以下の例において、下表の原料を使用した。

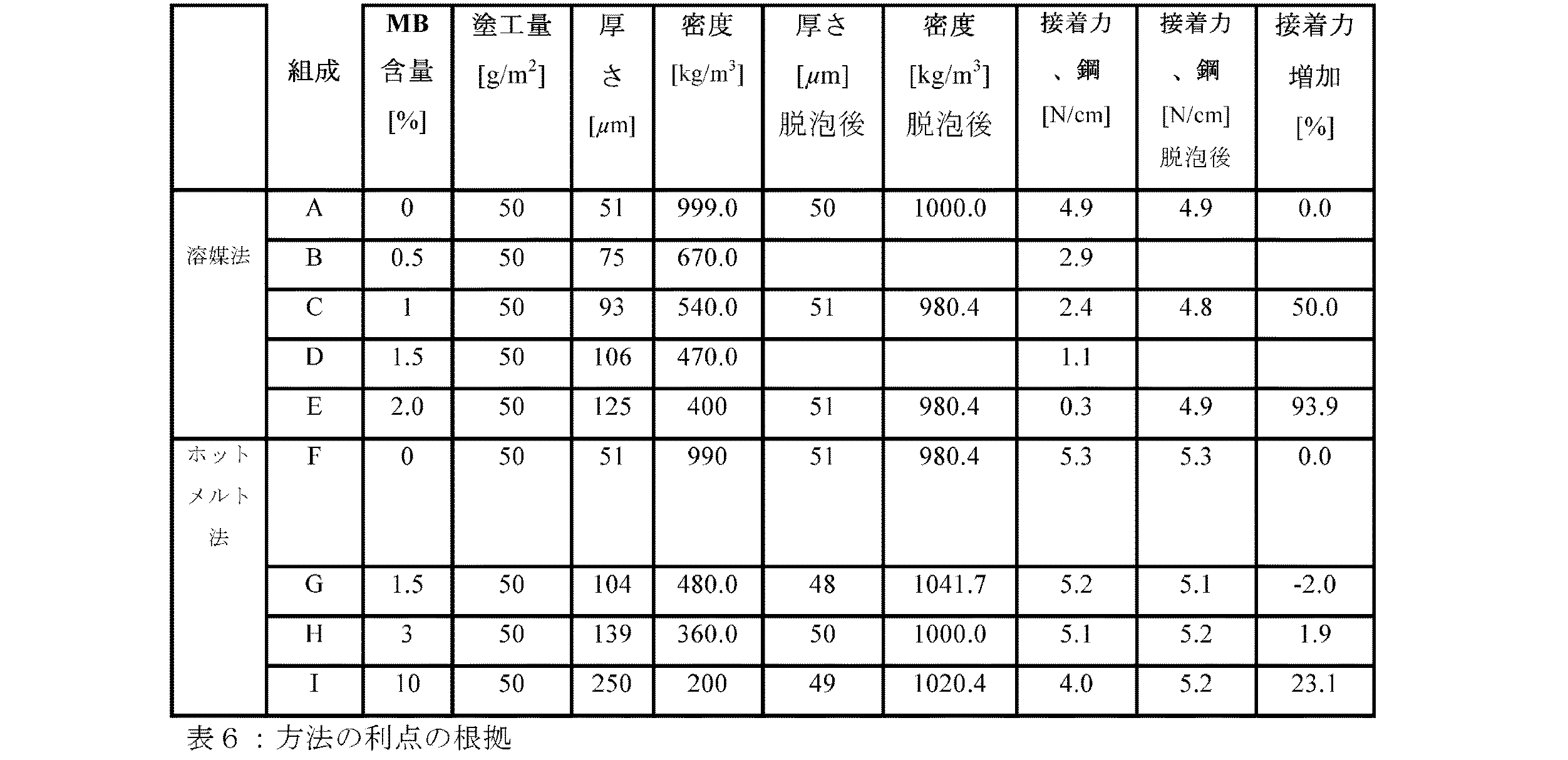

天然ゴムを用いた溶媒法接着剤の例において、わずか1重量%のマイクロバルーン含量でさえ接着剤の接着力が著しく低下する。

天然ゴムを用いたホットメルト法接着剤組成。

温度(ダイ)=130℃

回転数(スクリュー)=100rpm

ESEのパラメータ: 温度(4加熱ゾーン)=140℃

温度(ダイ)=140℃

回転数(スクリュー)=68rpm

ロール・コータのパラメータ: 温度(ドクタ・ロール)=140℃

温度(塗工ロール)=120℃

比較例1.2のNR−自己接着剤の使用。

自己接着剤中の発泡させたマイクロバルーンを破壊するために、試験する試料を真空中でプレスした。

温度: 150℃

プレス力: 10kN

真空度: −0.9bar

プレス時間: 90秒

SIS使用の溶媒法接着剤。

上記の全ての原料の、ベンジン、アセトン、トルエンからなる混合溶媒への添加、およびそれに続く室温での回転ロール台上での約10時間の混合。

SIS使用のホットメルト法接着剤。

SBS使用の接着剤組成、それぞれ重量%単位。

比較例2.1(溶媒法)と、比較例2.2(ホットメルト法)のSIS使用自己接着剤の使用。

温度: 150℃

プレス力: 10kN

真空度: −0.9bar

プレス時間: 90秒

天然ゴム使用の接着剤組成

Kautschuk SVR 3L 47.5重量%

Piccotac 1100−E 47.5重量%

Expancel 051 DU 40 5.0重量%

温度(中心スピンドル)=10℃

温度(ダイ)=160℃

回転数(スクリュー)=25rpm

ESEのパラメータ: 温度(加熱ゾーン1)=20℃

温度(加熱ゾーン2)=60℃

温度(加熱ゾーン3)=100℃

温度(加熱ゾーン4)=140℃

温度(ダイ)=140℃

回転数(スクリュー)=62rpm

ロール・コータのパラメータ: 温度(ドクタ・ロール)=130℃

温度(塗工ロール)=130℃

天然ゴム使用の接着剤組成

温度(中心スピンドル)=10℃

温度(ダイ)=160℃

回転数(スクリュー)=50rpm

ESEのパラメータ: 温度(加熱ゾーン1)=20℃

温度(加熱ゾーン2)=60℃

温度(加熱ゾーン3)=100℃

温度(加熱ゾーン4)=140℃

温度(ダイ)=140℃

回転数(スクリュー)=68rpm

ロール・コータのパラメータ: 温度(ドクタ・ロール)=130℃

温度(塗工ロール)=130℃

SIS使用の接着剤組成

Vector 4113 47.5重量%

Pentalyn H−E 47.5重量%

Expancel 051 DU 40 5.0重量%

温度(ダイ)=130℃

回転数(スクリュー)=50rpm

ロール・コータのパラメータ: 温度(ドクタ・ロール)=140℃

温度(塗工ロール)=130℃

SIS使用の接着剤組成

Vector 4113 47.5重量%

Pentalyn H−E 47.5重量%

Expancel 051 DU 40 5.0重量%

温度(ダイ)=130℃

回転数(スクリュー)=100rpm

ESEのパラメータ: 温度(4加熱ゾーン)=140℃

温度(ダイ)=140℃

回転数(スクリュー)=68rpm

ロール・コータのパラメータ: 温度(ドクタ・ロール)=140℃

温度(塗工ロール)=140℃

SBS/SIS使用の接着剤組成

Kraton D−1165 23.0重量%

Taipol SBS 3202 23.0重量%

Dercolyte A115 46.0重量%

Expancel 051 DU 40 8.0重量%

温度(ダイ)=160℃

回転数(スクリュー)=100rpm

ESEのパラメータ: 温度(4加熱ゾーン)=50℃

温度(ダイ)=50℃

回転数(スクリュー)=68rpm

ロール・コータのパラメータ: 温度(ドクタ・ロール)=140℃

温度(塗工ロール)=140℃

アクリレート共重合体使用の接着剤組成

Ac使用接着剤A

n−ブチルアクリレート 44.2重量%

2−エチルヘキシルアクリレート 44.7重量%

メチルアクリレート 8.6重量%

アクリル酸 純品 1.5重量%

Bisomer HEMA 1.0重量%

Ac使用接着剤B

n−ブチルアクリレート 44.9重量%

2−エチルヘキシルアクリレート 44.9重量%

N−tert.−ブチルアクリルアミド 6.2重量%

アクリル酸 純品 3.0重量%

無水マレイン酸 1.0重量%

Claims (9)

- 膨張させたマイクロバルーンを含有する感圧性の接着剤の製造方法であって、

接着剤を構成する成分を第1の混合装置中で混合し、

混合された接着剤を第1の混合装置から第2の混合装置に移送し、同時に未膨張のマイクロバルーンを第2の混合装置に送入し、

該マイクロバルーンを、第2の混合装置中で、または第2の混合装置から吐出されるときに膨張させ、

接着剤混合物を、膨張させたマイクロバルーンとともに、成形手段中で層状に成形し、 場合により、接着剤混合物を、膨張させたマイクロバルーンとともに、帯状支持体材料上に塗工する、方法。 - 膨張させたマイクロバルーンを含有する感圧性の接着剤の製造方法であって、

接着剤を構成する成分を未膨張のマイクロバルーンと第1の混合装置中で陽圧下で混合し、マイクロバルーンの膨張温度より低い温度に調節し、

混合された接着剤を第1の混合装置から第2の混合装置に移送し、陽圧下で膨張温度まで加熱し、

該マイクロバルーンを、第2の混合装置中で、または第2の混合装置から吐出されるときに膨張させ、

接着剤混合物を、膨張させたマイクロバルーンとともに、ロール・コータ中で層状に成形し、

場合により、接着剤混合物を、膨張させたマイクロバルーンとともに、帯状支持体材料または剥離材料上に塗工する、方法。 - 膨張させたマイクロバルーンを含有する感圧性の接着剤の製造方法であって、

接着剤を構成する成分、および未膨張のマイクロバルーンを第1の混合装置中で混合し、陽圧下で膨張温度まで加熱し、

該マイクロバルーンを、混合装置から吐出されるときに膨張させ、

接着剤混合物を、膨張させたマイクロバルーンとともに、ロール・コータ中で層状に成形し、

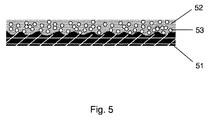

場合により、接着剤混合物を、膨張させたマイクロバルーンとともに、帯状支持体材料または剥離材料上に塗工する、方法。 - 接着剤を、ロール・コータ中で成形し、支持体材料上に塗工することを特徴とする、請求項1〜3のいずれか一つに記載の感圧性の接着剤の製造方法。

- 成形手段で成形し、発泡させた接着剤の層厚が、膨張させたマイクロバルーンの直径以下であることを特徴とする、請求項1〜4のいずれか一つに記載の感圧性の接着剤の製造方法。

- 接着テープにおいて帯状の支持体材料上の接着剤の厚さが、20μm〜3000μmであり、あるいは、剥離材料上に塗工された接着剤の厚さが20μm〜2000μmであることを特徴とする、請求項1〜5のいずれか一つに記載の感圧性の接着剤の製造方法。

- 接着テープにおいて帯状の支持体材料上の接着剤の厚さが、40μm〜150μmであることを特徴とする、請求項6に記載の感圧性の接着剤の製造方法。

- 第1の混合装置が、連続式装置であるか、

第1の混合装置が、非連続式装置であり、

第2の混合装置が、単軸押出し機であり、および/または

接着剤を、膨張させたマイクロバルーンとともに支持体層に成形する成形手段が、カレンダ、ロール・コータ、またはロールと固定ドクタの形成する間隙であることを特徴とする、請求項1に記載の方法。 - 第1の混合装置が、遊星ローラ押出し機、単軸または2軸押出し機、またはピン型押出し機であるか、

第1の混合装置が、Z−ニーダまたは内部ミキサである、

ことを特徴とする、請求項8に記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102008004388.5 | 2008-01-14 | ||

| DE102008004388A DE102008004388A1 (de) | 2008-01-14 | 2008-01-14 | Geschäumte, insbesondere druckempfindliche Klebemasse, Verfahren zur Herstellung sowie die Verwendung derselben |

| PCT/EP2009/050072 WO2009090119A1 (de) | 2008-01-14 | 2009-01-06 | Geschäumte, insbesondere druckempfindliche klebemasse, verfahren zur herstellung sowie die verwendung derselben |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011510113A JP2011510113A (ja) | 2011-03-31 |

| JP2011510113A5 JP2011510113A5 (ja) | 2012-02-16 |

| JP5654875B2 true JP5654875B2 (ja) | 2015-01-14 |

Family

ID=40560247

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010541768A Active JP5654875B2 (ja) | 2008-01-14 | 2009-01-06 | 発泡した感圧性の接着剤の製造方法 |

Country Status (12)

| Country | Link |

|---|---|

| US (3) | US20090181250A1 (ja) |

| EP (2) | EP2235098B1 (ja) |

| JP (1) | JP5654875B2 (ja) |

| KR (1) | KR101539046B1 (ja) |

| CN (1) | CN101970556B (ja) |

| CA (1) | CA2709713C (ja) |

| DE (1) | DE102008004388A1 (ja) |

| ES (1) | ES2419055T3 (ja) |

| MX (1) | MX2010007255A (ja) |

| PL (1) | PL2235098T3 (ja) |

| TW (1) | TWI527861B (ja) |

| WO (1) | WO2009090119A1 (ja) |

Families Citing this family (66)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008056980A1 (de) * | 2008-11-12 | 2010-05-20 | Tesa Se | Strahlenchemisch vernetzbare, geschäumte Selbstklebemasse basierend auf Vinylaromatenblockcopolymeren |

| DE102008059054A1 (de) * | 2008-11-26 | 2010-05-27 | Otto Bock Pur Life Science Gmbh | Polyurethanpflaster für die transdermale Applikation von Wirkstoffen und Verfahren zu dessen Herstellung |

| DE102008062368A1 (de) | 2008-12-17 | 2010-06-24 | Tesa Se | Haftklebemassen auf Basis von Naturkautschuk und Polyacrylaten |

| DE102009058101A1 (de) * | 2009-12-12 | 2011-06-16 | Bayer Materialscience Ag | Verwendung von Schichtaufbauten in Windkraftanlagen |

| DE102010031636B4 (de) * | 2010-07-21 | 2012-02-23 | Hilti Aktiengesellschaft | Ankerschiene mit Zugband |

| US20120028524A1 (en) * | 2010-08-02 | 2012-02-02 | 3M Innovative Properties Company | Duct tape with foam film backing layer |

| DE102010062669A1 (de) * | 2010-12-08 | 2012-06-14 | Tesa Se | Verfahren zur Herstellung geschäumter Polymermassen, geschäumte Polymermassen und Klebeband damit |

| US8618348B2 (en) | 2011-09-28 | 2013-12-31 | Johnson & Johnson Consumer Companies, Inc. | Dressings with a foamed adhesive layer |

| DE102011085223A1 (de) * | 2011-10-26 | 2013-05-02 | Tesa Se | Biobasierte Naturkautschukmasse und deren Verwendung |

| US9222254B2 (en) | 2012-03-13 | 2015-12-29 | Schabel Polymer Technology, Llc | Structural assembly insulation |

| DE102012210386A1 (de) * | 2012-06-20 | 2013-12-24 | Tesa Se | Kantenschutzband |

| DE102013208445A1 (de) | 2013-05-08 | 2014-11-13 | Tesa Se | Verfahren zum Herstellen einer syntaktisch geschäumten Polymermasse, vorzugsweise einer druckempfindlichen Klebemasse, Vorrichtung zur Durchführung des Verfahrens, Extrudat und Selbstklebeband |

| DE102013221847A1 (de) * | 2013-08-01 | 2015-02-05 | Tesa Se | Verfahren zum Formen eines Körpers in einer Form |

| KR101471361B1 (ko) * | 2014-03-18 | 2014-12-11 | (주)앤디포스 | 터치스크린 패널용 양면테이프 및 그 제조방법 |

| DE112014006568T5 (de) * | 2014-04-09 | 2017-02-16 | Gm Global Technology Operations, Llc | Systeme und verfahren zum verstärkten kleben |

| US10087573B1 (en) * | 2014-05-08 | 2018-10-02 | Regina B. Casperson | Elastomeric tubular casings for drawstrings and a method of laundering accessories therewith |

| JP2015218318A (ja) * | 2014-05-21 | 2015-12-07 | テーザ・ソシエタス・ヨーロピア | シンタクチックフォーム型のポリマー組成物、好ましくは感圧接着性組成物を製造する方法、その方法を実施するための装置、押出し物、および自己接着テープ |

| JP6599784B2 (ja) * | 2015-02-03 | 2019-10-30 | 積水化学工業株式会社 | 粘着テープ |

| DE102015206076A1 (de) * | 2015-04-02 | 2016-10-06 | Tesa Se | Wiederablösbarer Haftklebestreifen |

| EP3075772B1 (de) * | 2015-04-02 | 2020-08-26 | tesa SE | Wiederablösbarer haftklebestreifen |

| DE102015208792A1 (de) * | 2015-05-12 | 2016-11-17 | Tesa Se | Haftklebemasse |

| DE102016202479A1 (de) * | 2016-02-18 | 2017-08-24 | Tesa Se | Haftklebestreifen |

| KR102092951B1 (ko) * | 2016-03-21 | 2020-03-25 | 주식회사 엘지화학 | 양면 점착 테이프용 기재 필름 및 이의 제조방법 |

| DE102016207822A1 (de) * | 2016-05-06 | 2017-11-09 | Tesa Se | Selbstklebemasse auf Kautschukbasis |

| DE102016209707A1 (de) * | 2016-06-02 | 2017-12-07 | Tesa Se | Haftklebestreifen |

| JP6882857B2 (ja) * | 2016-06-27 | 2021-06-02 | 日東電工株式会社 | 粘着剤層付偏光フィルム、および液晶表示装置 |

| WO2018008741A1 (ja) | 2016-07-08 | 2018-01-11 | セメダイン株式会社 | 糸切れ性の良いステッチ塗布可能な構造用接着剤組成物 |

| JP7189768B2 (ja) * | 2016-07-15 | 2022-12-14 | 松本油脂製薬株式会社 | 樹脂組成物およびその利用 |

| CN106497446B (zh) * | 2016-11-09 | 2022-06-10 | 宁波启合新材料科技有限公司 | 一种胶带的制备方法 |

| EP3333235B1 (de) | 2016-12-09 | 2023-06-07 | tesa SE | Haftklebestreifen |

| EP3333236B1 (de) * | 2016-12-09 | 2021-03-31 | tesa SE | Haftklebestreifen |

| US20190300755A1 (en) | 2016-12-12 | 2019-10-03 | 3M Innovative Properties Company | Thin foam tapes |

| DE102017004563A1 (de) | 2017-03-05 | 2018-09-06 | Entex Rust & Mitschke Gmbh | Entgasen beim Extrudieren von Polymeren |

| FR3067929B1 (fr) * | 2017-06-23 | 2019-11-22 | Produits Dentaires Pierre Rolland | Adhesif dentaire |

| US11225942B2 (en) * | 2017-07-05 | 2022-01-18 | General Electric Company | Enhanced through-thickness resin infusion for a wind turbine composite laminate |

| US20190031923A1 (en) | 2017-07-26 | 2019-01-31 | 3M Innovative Properties Company | Backing for adhesive tape with thermal resistance |

| KR20190013128A (ko) * | 2017-07-31 | 2019-02-11 | 다우 실리콘즈 코포레이션 | 임시 결합 접착제용 실리콘 조성물, 이의 경화체를 포함하는 전자 제품 및 그 제조방법 |

| US9909035B1 (en) * | 2017-09-29 | 2018-03-06 | Mayapple Baby Llc | Mountable articles, dual-adhesive-adhesive tape and mounting methods using them |

| DE102018200957A1 (de) | 2017-10-17 | 2019-04-18 | Tesa Se | Haftklebestreifen mit teilgeschäumter Selbstklebemasse |

| DE102017218519A1 (de) | 2017-10-17 | 2019-04-18 | Tesa Se | Härtbarer Haftklebestreifen auf Basis von Vinylaromatenblockcopolymer |

| DE102017221039B4 (de) * | 2017-11-24 | 2020-09-03 | Tesa Se | Verfahren zur Herstellung einer Haftklebemasse auf Basis von Acrylnitril-Butadien-Kautschuk |

| DE102018001412A1 (de) | 2017-12-11 | 2019-06-13 | Entex Rust & Mitschke Gmbh | Entgasen beim Extrudieren von Stoffen, vorzugsweise von Kunststoffen |

| CN109466124B (zh) * | 2017-12-27 | 2021-08-06 | 宁波长阳科技股份有限公司 | 一种离型膜 |

| WO2019150492A1 (ja) * | 2018-01-31 | 2019-08-08 | 株式会社アシックス | 靴底用部材及び靴 |

| DE102018204594A1 (de) * | 2018-03-27 | 2019-10-02 | Tesa Se | Verfahren zum homogenen Einarbeiten von Füllstoff in eine, insbesondere thermisch vernetzbare, Selbstklebemasse auf Basis von nicht-thermoplastischem Elastomer |

| US20210155827A1 (en) | 2018-05-08 | 2021-05-27 | Tesa Se | Process for producing a self-adhesive composition layer foamed with microballoons |

| EP3567086B1 (de) | 2018-05-08 | 2021-08-18 | tesa SE | Verfahren zur herstellung einer mit mikroballons geschäumten selbstklebemasseschicht |

| EP3587528B1 (en) | 2018-06-22 | 2021-05-26 | 3M Innovative Properties Company | Process of manufacturing a pressure sensitive adhesive having low voc characteristics |

| DE102018211617A1 (de) | 2018-07-12 | 2020-02-27 | Tesa Se | Herstellung einer Haftklebemasse auf Basis von festem EPDM-Kautschuk |

| DE102018221589A1 (de) * | 2018-08-23 | 2020-02-27 | Tesa Se | Verfahren zur Herstellung eines insbesondere thermisch vulkanisierbaren Klebstoffs sowie eines Klebebandes mit dem thermisch vulkanisierbaren Klebstoff |

| CN109401695A (zh) * | 2018-11-08 | 2019-03-01 | 铁科腾跃科技有限公司 | 一种轻质sis型热熔压敏胶及其制备方法 |

| DE102018222679A1 (de) | 2018-12-19 | 2020-06-25 | Tesa Se | Verfahren zur Herstellung einer Haftklebemasse auf Basis von Acrylnitril-Butadien-Kautschuk sowie Klebeband, enthaltend diese Haftklebemasse |

| WO2020153357A1 (ja) * | 2019-01-22 | 2020-07-30 | 積水化学工業株式会社 | 粘着テープ、及びその製造方法 |

| DE102019202569A1 (de) | 2019-02-26 | 2020-08-27 | Tesa Se | Klebeband, umfassend mindestens zwei voneinander verschiedene Klebemassen, welche durch eine Barriereschicht voneinander getrennt sind |

| CN110564331B (zh) * | 2019-09-24 | 2020-05-19 | 苏州世华新材料科技股份有限公司 | 一种弹性压敏胶带的制备方法及弹性压敏胶带 |

| DE102019216938A1 (de) | 2019-11-04 | 2021-05-06 | Tesa Se | Geschäumte Haftklebemasseschicht und Klebeband enthaltend die geschäumte Haftklebemasseschicht |

| DE102019216942A1 (de) | 2019-11-04 | 2021-05-06 | Tesa Se | Haftklebemassen,diese enthaltende Selbstklebeprodukte und Verbunde |

| EP3825081B8 (en) * | 2019-11-22 | 2023-01-11 | BIC Violex Single Member S.A. | Razor blades |

| DE102020207783A1 (de) | 2020-06-23 | 2021-12-23 | Tesa Se | Leitfähiger doppelseitiger Haftklebestreifen |

| CN111748313B (zh) * | 2020-07-29 | 2022-04-01 | 上海仁速新材料有限公司 | 一种紫外光固化胶黏剂及其制备方法和应用 |

| DE102021203370A1 (de) | 2021-04-01 | 2022-10-06 | Tesa Se | Verwendung eines Haftklebstreifens als Abdeckung einer Hochfrequenzstrahlungsquelle |

| CN113388306B (zh) * | 2021-04-02 | 2022-08-16 | 烟台高氏化工科技有限公司 | 一种涂料组合物及其制备方法和应用 |

| DE102021204631A1 (de) | 2021-05-06 | 2022-11-10 | Tesa Se | Verfahren zum Ausformen einer syntaktisch geschäumten Polymerschicht |

| DE102022118334A1 (de) | 2022-07-21 | 2024-02-01 | Tesa Se | Schockbeständige Haftklebmasse |

| US20240328046A1 (en) * | 2023-03-27 | 2024-10-03 | Fitesa Germany Gmbh | Bonded nonwoven fabric |

| DE102023132977A1 (de) | 2023-11-27 | 2025-05-28 | Tesa Se | Schäumbare Haftklebeformulierung enthaltend hydrierte Vinylaromatenblockcopolymere |

Family Cites Families (48)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1504434B2 (de) * | 1961-07-11 | 1970-11-05 | Joh. Kleinewefers Söhne, 4150 Krefeld | Verfahren und Vorrichtung zum Herstellen von homogenen, reckbaren Folienbahnen aus nichtkristallinen makromolekularen Kunststoffen |

| US3565247A (en) | 1968-10-21 | 1971-02-23 | Minnesota Mining & Mfg | Pressure-sensitive adhesive tape product |

| US4407932A (en) * | 1981-03-12 | 1983-10-04 | Minnesota Mining & Manufacturing Co. | Fade-resistant and abrasion resistant photographic reproduction, method of preparing, and photographic product therefor |

| JPS61101578A (ja) * | 1984-10-24 | 1986-05-20 | Sekisui Chem Co Ltd | 粘着剤組成物 |

| JPS61136568A (ja) * | 1984-12-04 | 1986-06-24 | Nitto Electric Ind Co Ltd | 表面保護用フイルム |

| JPH0414434Y2 (ja) | 1985-04-08 | 1992-03-31 | ||

| US4855170A (en) * | 1986-08-21 | 1989-08-08 | Minnesota Mining And Manufacturing Company | Pressure-sensitive tape construction incorporating resilient polymeric microspheres |

| ZA876122B (en) * | 1986-08-21 | 1989-04-26 | Minnesota Mining & Mfg | Pressure-sensitive tape construction incorporating resilient polymeric microspheres |

| US4722943A (en) * | 1987-03-19 | 1988-02-02 | Pierce & Stevens Corporation | Composition and process for drying and expanding microspheres |

| JP2657965B2 (ja) * | 1987-10-31 | 1997-09-30 | 日本カーバイド工業 株式会社 | 感圧接着剤層 |

| US4891387A (en) * | 1988-06-28 | 1990-01-02 | The B. F. Goodrich Company | Bulk polymerized cycloolefin monomers containing microencapsulated blowing agents |

| JP2709353B2 (ja) * | 1989-03-14 | 1998-02-04 | 日東電工株式会社 | 自着性粘着剤及び接着テープ |

| US5024880A (en) * | 1990-01-03 | 1991-06-18 | Minnesota Mining And Manufacturing Company | Cellular pressure-sensitive adhesive membrane |

| US5264467A (en) * | 1991-09-24 | 1993-11-23 | Air Products And Chemicals, Inc. | High performance solvent-free contact adhesive |

| US5296277A (en) * | 1992-06-26 | 1994-03-22 | Minnesota Mining And Manufacturing Company | Positionable and repositionable adhesive articles |

| JPH06248242A (ja) * | 1993-02-26 | 1994-09-06 | Nippon Kakoh Seishi Kk | 再剥離性発泡粘着シート |

| JP3417596B2 (ja) | 1993-04-07 | 2003-06-16 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 弾性微小球を含有する粘着フィルム |

| US5514122A (en) | 1994-05-16 | 1996-05-07 | Minnesota Mining And Manufacturing Company | Feminine hygiene pad |

| US5476712A (en) | 1994-05-31 | 1995-12-19 | Avery Dennison Corporation | Flexographic plate mounting tape |

| JP3373946B2 (ja) * | 1994-08-31 | 2003-02-04 | ニチバン株式会社 | 気泡含有粘着テープの製造方法 |

| US6169138B1 (en) * | 1994-12-15 | 2001-01-02 | Saint-Gobain Performance Plastics Corporation | Foamed pressure sensitive tapes |

| US6479073B1 (en) * | 1996-10-07 | 2002-11-12 | 3M Innovative Properties Company | Pressure sensitive adhesive articles and methods for preparing same |

| JP3612394B2 (ja) | 1996-10-25 | 2005-01-19 | ミネソタ マイニング アンド マニュファクチャリング カンパニー | 粘着シートおよびその製造方法 |

| DE19730854A1 (de) * | 1997-07-18 | 1999-01-21 | Beiersdorf Ag | Selbstklebeband enthaltend Mikroballons in der Trägerschicht |

| US6306497B1 (en) * | 1998-03-03 | 2001-10-23 | Arkwright Incorporated | Pressure-sensitive adhesive articles for use on transparent imaging films |

| US6103152A (en) * | 1998-07-31 | 2000-08-15 | 3M Innovative Properties Co. | Articles that include a polymer foam and method for preparing same |

| JP3961697B2 (ja) * | 1998-10-07 | 2007-08-22 | 日東電工株式会社 | 自動車塗膜保護用シート |

| JP4093658B2 (ja) * | 1998-12-08 | 2008-06-04 | 日東電工株式会社 | 微細発泡粘着テープ又はシートと、その製造方法 |

| JP2000293108A (ja) * | 1999-04-02 | 2000-10-20 | Kuramoto Sangyo:Kk | 偽造防止用ラベル |

| DE19939078A1 (de) * | 1999-08-18 | 2001-02-22 | Beiersdorf Ag | Verwendung von Isocyanaten bei der Herstellung von hochviskosen selbstklebenden Massen |

| JP3594853B2 (ja) * | 1999-11-08 | 2004-12-02 | 日東電工株式会社 | 加熱剥離型粘着シート |

| US6630531B1 (en) * | 2000-02-02 | 2003-10-07 | 3M Innovative Properties Company | Adhesive for bonding to low surface energy surfaces |

| US6565697B1 (en) * | 2000-03-01 | 2003-05-20 | Brady Worldwide, Inc. | Manufacturing method for a positionable and repositionable pressure sensitive adhesive product and an article formed therefrom |

| JP2001300964A (ja) * | 2000-04-21 | 2001-10-30 | Nitto Denko Corp | カレンダーロール及び積層シートの製造方法 |

| US6803099B1 (en) * | 2000-10-10 | 2004-10-12 | Armstrong World Industries, Inc. | Self-adhering surface covering and method of making |

| JP4703833B2 (ja) * | 2000-10-18 | 2011-06-15 | 日東電工株式会社 | エネルギー線硬化型熱剥離性粘着シート、及びこれを用いた切断片の製造方法 |

| US6656319B1 (en) * | 2000-10-25 | 2003-12-02 | 3M Innovative Properties Company | Fluid-activatable adhesive articles and methods |

| US20030082362A1 (en) * | 2001-07-31 | 2003-05-01 | Khandpur Ashish K. | High cohesive strength pressure sensitive adhesive foam |

| US6777080B2 (en) * | 2002-04-04 | 2004-08-17 | 3M Innovative Properties Company | Pressure sensitive adhesive composition |

| US20040131846A1 (en) * | 2002-12-19 | 2004-07-08 | Epple Thomas C. | Microsphere containing electron beam cured pressure-sensitive adhesive tapes and methods of making and using same |

| US7285576B2 (en) * | 2003-03-12 | 2007-10-23 | 3M Innovative Properties Co. | Absorbent polymer compositions, medical articles, and methods |

| EP1724320B1 (en) * | 2004-03-11 | 2010-07-21 | Nitto Denko Corporation | Heat-peelable pressure-sensitive adhesive sheet and method of processing adherend with the heat-peelable pressure-sensitive adhesive sheet |

| BRPI0418750A (pt) * | 2004-04-14 | 2007-09-11 | Avery Dennison Company | fita adesiva sensìvel à pressão, de dupla face, método para fabricar a mesma e método para montar um objeto em um substrato |

| DE102004037910B4 (de) * | 2004-08-05 | 2015-05-07 | Tesa Se | Reversibles Verschlusssystem zum Verschließen von Gegenständen wie Beutel, Tüten, Verpackungen oder ähnlichen mit zwei Haftstreifen |

| DE102004047913A1 (de) * | 2004-09-29 | 2006-03-30 | Tesa Ag | Verfahren zur Herstellung von Selbstklebebändern mit expandierten Mikroballons in der Trägerschicht |

| US8353995B2 (en) * | 2005-07-15 | 2013-01-15 | 3M Innovative Properties Company | Automobile panel repair laminate |

| JP4849993B2 (ja) * | 2006-08-14 | 2012-01-11 | 日東電工株式会社 | 粘着シート、その製造方法および積層セラミックシートの切断方法 |

| US7691225B2 (en) * | 2007-01-15 | 2010-04-06 | Nitto Denko Corporation | Thermal-release double-coated pressure-sensitive adhesive tape or sheet and method of processing adherend |

-

2008

- 2008-01-14 DE DE102008004388A patent/DE102008004388A1/de not_active Withdrawn

- 2008-02-14 US US12/031,300 patent/US20090181250A1/en not_active Abandoned

-

2009

- 2009-01-06 PL PL09702394T patent/PL2235098T3/pl unknown

- 2009-01-06 MX MX2010007255A patent/MX2010007255A/es active IP Right Grant

- 2009-01-06 EP EP09702394A patent/EP2235098B1/de active Active

- 2009-01-06 JP JP2010541768A patent/JP5654875B2/ja active Active

- 2009-01-06 EP EP13159970.6A patent/EP2610289A3/de not_active Withdrawn

- 2009-01-06 CN CN200980108940XA patent/CN101970556B/zh active Active

- 2009-01-06 KR KR1020107018156A patent/KR101539046B1/ko active Active

- 2009-01-06 ES ES09702394T patent/ES2419055T3/es active Active

- 2009-01-06 CA CA2709713A patent/CA2709713C/en active Active

- 2009-01-06 WO PCT/EP2009/050072 patent/WO2009090119A1/de not_active Ceased

- 2009-01-12 TW TW098100924A patent/TWI527861B/zh active

-

2015

- 2015-11-30 US US14/954,289 patent/US20160083549A1/en not_active Abandoned

-

2019

- 2019-07-31 US US16/527,936 patent/US20190375909A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| US20190375909A1 (en) | 2019-12-12 |

| US20090181250A1 (en) | 2009-07-16 |

| DE102008004388A1 (de) | 2009-07-16 |

| CN101970556A (zh) | 2011-02-09 |

| TW200942590A (en) | 2009-10-16 |

| US20160083549A1 (en) | 2016-03-24 |

| WO2009090119A1 (de) | 2009-07-23 |

| ES2419055T3 (es) | 2013-08-19 |

| EP2235098A1 (de) | 2010-10-06 |

| CA2709713C (en) | 2015-12-22 |

| EP2610289A3 (de) | 2013-10-30 |

| TWI527861B (zh) | 2016-04-01 |

| CN101970556B (zh) | 2013-11-27 |

| MX2010007255A (es) | 2010-08-11 |

| EP2235098B1 (de) | 2013-03-20 |

| JP2011510113A (ja) | 2011-03-31 |

| KR101539046B1 (ko) | 2015-07-23 |

| CA2709713A1 (en) | 2009-07-23 |

| KR20100116614A (ko) | 2010-11-01 |

| EP2610289A2 (de) | 2013-07-03 |

| PL2235098T3 (pl) | 2013-08-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5654875B2 (ja) | 発泡した感圧性の接着剤の製造方法 | |

| JP5753156B2 (ja) | 発泡させたコンパウンド系の製造方法 | |

| KR100746758B1 (ko) | 낮은 표면 에너지의 표면으로의 접합용 접착제 | |

| AU759020B2 (en) | Articles that include a polymer foam and method for preparing same | |

| CN1315966C (zh) | 可拉伸剥离的泡沫材料粘合制件 | |

| KR101987865B1 (ko) | 제 1 충격 접착제 외면 및 제 2 열-활성화 외면을 지니는 양면 접착 테이프 | |

| JP4399111B2 (ja) | 自己接着性テープの製造方法 | |

| JP2012122070A (ja) | 発泡可能なポリマー組成物の製造方法、それに基づく発泡ポリマー組成物の製造方法、発泡ポリマー組成物およびそれを備えた接着テープ | |

| JP2001107002A (ja) | 高粘稠性自己接着性組成物の製造における反応性フェノール樹脂の使用 | |

| JP2015017179A (ja) | 感温性粘着剤およびその架橋方法 | |

| JP6599784B2 (ja) | 粘着テープ | |

| DE DK et al. | POLYMERSCHAUM ENTHALTENDE ARTIKEL UND VERFAHREN ZU DEREN HERSTELLUNG ARTICLE CONTENANT UNE MOUSSE POLYMERE ET PROCEDE DE PREPARATION ASSOCIE |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20111220 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20111220 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130411 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130514 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130813 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130820 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130913 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140604 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140925 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20140926 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20141021 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20141112 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20141121 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5654875 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |