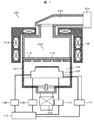

JP5618638B2 - プラズマ処理装置または試料載置台 - Google Patents

プラズマ処理装置または試料載置台 Download PDFInfo

- Publication number

- JP5618638B2 JP5618638B2 JP2010129522A JP2010129522A JP5618638B2 JP 5618638 B2 JP5618638 B2 JP 5618638B2 JP 2010129522 A JP2010129522 A JP 2010129522A JP 2010129522 A JP2010129522 A JP 2010129522A JP 5618638 B2 JP5618638 B2 JP 5618638B2

- Authority

- JP

- Japan

- Prior art keywords

- wafer

- heater

- temperature

- film

- dielectric film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/02—Pretreatment of the material to be coated, e.g. for coating on selected surface areas

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Drying Of Semiconductors (AREA)

- Plasma Technology (AREA)

- Control Of Resistance Heating (AREA)

- Resistance Heating (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010129522A JP5618638B2 (ja) | 2010-06-07 | 2010-06-07 | プラズマ処理装置または試料載置台 |

| US12/854,242 US9150967B2 (en) | 2010-06-07 | 2010-08-11 | Plasma processing apparatus and sample stage |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010129522A JP5618638B2 (ja) | 2010-06-07 | 2010-06-07 | プラズマ処理装置または試料載置台 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2011258614A JP2011258614A (ja) | 2011-12-22 |

| JP2011258614A5 JP2011258614A5 (enExample) | 2013-07-18 |

| JP5618638B2 true JP5618638B2 (ja) | 2014-11-05 |

Family

ID=45063451

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010129522A Active JP5618638B2 (ja) | 2010-06-07 | 2010-06-07 | プラズマ処理装置または試料載置台 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US9150967B2 (enExample) |

| JP (1) | JP5618638B2 (enExample) |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5618638B2 (ja) * | 2010-06-07 | 2014-11-05 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置または試料載置台 |

| US8944080B2 (en) * | 2011-08-02 | 2015-02-03 | Visera Technologies Company Limited | Cleaning system, cleaning device, and method of using cleaning device |

| US9281226B2 (en) * | 2012-04-26 | 2016-03-08 | Applied Materials, Inc. | Electrostatic chuck having reduced power loss |

| JP5975755B2 (ja) * | 2012-06-28 | 2016-08-23 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置およびプラズマ処理方法 |

| JP6276919B2 (ja) | 2013-02-01 | 2018-02-07 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置および試料台 |

| EP2960933B1 (en) * | 2013-02-25 | 2017-12-06 | Kyocera Corporation | Sample holding tool |

| JP6202720B2 (ja) * | 2013-03-29 | 2017-09-27 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置およびプラズマ処理方法 |

| JP6313983B2 (ja) * | 2014-01-29 | 2018-04-18 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置およびプラズマ処理方法 |

| JP6277015B2 (ja) * | 2014-02-28 | 2018-02-07 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置 |

| KR102372801B1 (ko) * | 2014-07-08 | 2022-03-10 | 와틀로 일렉트릭 매뉴팩츄어링 컴파니 | 접합 층의 통합 온도 감지를 갖춘 접합 조립체 |

| JP6469985B2 (ja) * | 2014-07-28 | 2019-02-13 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置 |

| JP6424049B2 (ja) * | 2014-09-12 | 2018-11-14 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置 |

| JP6361495B2 (ja) * | 2014-12-22 | 2018-07-25 | 東京エレクトロン株式会社 | 熱処理装置 |

| JP6697997B2 (ja) * | 2016-09-30 | 2020-05-27 | 新光電気工業株式会社 | 静電チャック、基板固定装置 |

| US11276590B2 (en) | 2017-05-17 | 2022-03-15 | Applied Materials, Inc. | Multi-zone semiconductor substrate supports |

| JP6924618B2 (ja) * | 2017-05-30 | 2021-08-25 | 東京エレクトロン株式会社 | 静電チャック及びプラズマ処理装置 |

| JP6483296B2 (ja) * | 2018-01-11 | 2019-03-13 | 株式会社日立ハイテクノロジーズ | プラズマ処理方法 |

| KR102411272B1 (ko) | 2018-03-26 | 2022-06-22 | 엔지케이 인슐레이터 엘티디 | 정전척 히터 |

| JP7278035B2 (ja) * | 2018-06-20 | 2023-05-19 | 新光電気工業株式会社 | 静電チャック、基板固定装置 |

| US11373890B2 (en) * | 2018-12-17 | 2022-06-28 | Applied Materials, Inc. | Wireless in-situ real-time measurement of electrostatic chucking force in semiconductor wafer processing |

| JP7555197B2 (ja) * | 2020-04-07 | 2024-09-24 | 株式会社日立ハイテク | プラズマ処理装置 |

| JP7060771B1 (ja) | 2021-02-04 | 2022-04-26 | 日本碍子株式会社 | 半導体製造装置用部材 |

| WO2024180642A1 (ja) | 2023-02-28 | 2024-09-06 | 株式会社日立ハイテク | プラズマ処理装置およびプラズマ処理装置の試料台の製造方法 |

| JP2025081109A (ja) | 2023-11-15 | 2025-05-27 | キヤノントッキ株式会社 | 静電チャック、成膜装置、吸着方法、成膜方法、電子デバイスの製造方法、及び静電チャックの製造方法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6166897A (en) * | 1997-01-22 | 2000-12-26 | Tomoegawa Paper Co., Ltd. | Static chuck apparatus and its manufacture |

| US20020036881A1 (en) * | 1999-05-07 | 2002-03-28 | Shamouil Shamouilian | Electrostatic chuck having composite base and method |

| JP3881908B2 (ja) * | 2002-02-26 | 2007-02-14 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置 |

| US7544251B2 (en) * | 2004-10-07 | 2009-06-09 | Applied Materials, Inc. | Method and apparatus for controlling temperature of a substrate |

| US8038796B2 (en) * | 2004-12-30 | 2011-10-18 | Lam Research Corporation | Apparatus for spatial and temporal control of temperature on a substrate |

| JP5018244B2 (ja) * | 2007-05-30 | 2012-09-05 | 住友大阪セメント株式会社 | 静電チャック |

| JP2009170509A (ja) * | 2008-01-11 | 2009-07-30 | Hitachi High-Technologies Corp | ヒータ内蔵静電チャックを備えたプラズマ処理装置 |

| JP5618638B2 (ja) * | 2010-06-07 | 2014-11-05 | 株式会社日立ハイテクノロジーズ | プラズマ処理装置または試料載置台 |

-

2010

- 2010-06-07 JP JP2010129522A patent/JP5618638B2/ja active Active

- 2010-08-11 US US12/854,242 patent/US9150967B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20110297082A1 (en) | 2011-12-08 |

| US9150967B2 (en) | 2015-10-06 |

| JP2011258614A (ja) | 2011-12-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5618638B2 (ja) | プラズマ処理装置または試料載置台 | |

| KR102760927B1 (ko) | 정전척 어셈블리 | |

| JP5203612B2 (ja) | プラズマ処理装置 | |

| JP5876992B2 (ja) | プラズマ処理装置 | |

| JP7446495B2 (ja) | プラズマ処理装置、算出方法および算出プログラム | |

| KR102092623B1 (ko) | 플라스마 처리 장치 | |

| JP5414172B2 (ja) | プラズマ処理装置及びプラズマ処理方法 | |

| KR102188409B1 (ko) | 기판 처리 장치 및 탑재대 | |

| US10964513B2 (en) | Plasma processing apparatus | |

| JP7202972B2 (ja) | プラズマ処理装置、プラズマ状態検出方法およびプラズマ状態検出プログラム | |

| TWI863942B (zh) | 電漿處理裝置、計算方法及計算程式 | |

| JP2010010231A (ja) | プラズマ処理装置 | |

| TWI878290B (zh) | 電漿處理裝置、計算方法及計算程式 | |

| JP4611217B2 (ja) | ウエハ載置用電極 | |

| TW202522659A (zh) | 載置台及基板處理裝置 | |

| JP7555197B2 (ja) | プラズマ処理装置 | |

| JP2013232680A (ja) | プラズマ処理装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130520 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130520 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130520 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140122 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140204 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140331 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140819 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140916 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5618638 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |