JP5323706B2 - 製品包装装置 - Google Patents

製品包装装置 Download PDFInfo

- Publication number

- JP5323706B2 JP5323706B2 JP2009530959A JP2009530959A JP5323706B2 JP 5323706 B2 JP5323706 B2 JP 5323706B2 JP 2009530959 A JP2009530959 A JP 2009530959A JP 2009530959 A JP2009530959 A JP 2009530959A JP 5323706 B2 JP5323706 B2 JP 5323706B2

- Authority

- JP

- Japan

- Prior art keywords

- packaging material

- partition

- packaging

- attached

- label

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004806 packaging method and process Methods 0.000 title claims description 22

- 239000005022 packaging material Substances 0.000 claims description 116

- 238000005192 partition Methods 0.000 claims description 34

- 238000007789 sealing Methods 0.000 claims description 11

- 235000013305 food Nutrition 0.000 claims description 9

- 235000011837 pasties Nutrition 0.000 claims description 7

- 239000000463 material Substances 0.000 claims description 6

- 238000007493 shaping process Methods 0.000 claims description 6

- 235000014059 processed cheese Nutrition 0.000 claims description 5

- 238000005452 bending Methods 0.000 claims description 4

- 235000014121 butter Nutrition 0.000 claims description 4

- 235000013310 margarine Nutrition 0.000 claims description 4

- 239000003264 margarine Substances 0.000 claims description 4

- 239000007787 solid Substances 0.000 claims description 4

- 235000014347 soups Nutrition 0.000 claims description 4

- 239000000047 product Substances 0.000 description 18

- 238000000638 solvent extraction Methods 0.000 description 7

- 230000033001 locomotion Effects 0.000 description 5

- 238000011144 upstream manufacturing Methods 0.000 description 5

- 230000005540 biological transmission Effects 0.000 description 3

- 239000002985 plastic film Substances 0.000 description 3

- 229920006255 plastic film Polymers 0.000 description 3

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- 235000013351 cheese Nutrition 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 230000003670 easy-to-clean Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000011012 sanitization Methods 0.000 description 1

- 235000021057 semi-liquid food Nutrition 0.000 description 1

- 235000021055 solid food Nutrition 0.000 description 1

- 239000012265 solid product Substances 0.000 description 1

- 230000032258 transport Effects 0.000 description 1

- 235000013618 yogurt Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B59/00—Arrangements to enable machines to handle articles of different sizes, to produce packages of different sizes, to vary the contents of packages, to handle different types of packaging material, or to give access for cleaning or maintenance purposes

- B65B59/04—Machines constructed with readily-detachable units or assemblies, e.g. to facilitate maintenance

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B25/00—Packaging other articles presenting special problems

- B65B25/06—Packaging slices or specially-shaped pieces of meat, cheese, or other plastic or tacky products

- B65B25/08—Packaging slices or specially-shaped pieces of meat, cheese, or other plastic or tacky products between layers or strips of sheet or web material, e.g. in webs folded to zig-zag form

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B25/00—Packaging other articles presenting special problems

- B65B25/06—Packaging slices or specially-shaped pieces of meat, cheese, or other plastic or tacky products

- B65B25/10—Forming sector-shaped packages of cheese or like plastic products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B65/00—Details peculiar to packaging machines and not otherwise provided for; Arrangements of such details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65C—LABELLING OR TAGGING MACHINES, APPARATUS, OR PROCESSES

- B65C9/00—Details of labelling machines or apparatus

- B65C9/08—Label feeding

- B65C9/10—Label magazines

- B65C9/105—Storage arrangements including a plurality of magazines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65C—LABELLING OR TAGGING MACHINES, APPARATUS, OR PROCESSES

- B65C9/00—Details of labelling machines or apparatus

- B65C9/08—Label feeding

- B65C9/12—Removing separate labels from stacks

- B65C9/14—Removing separate labels from stacks by vacuum

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Labeling Devices (AREA)

- Basic Packing Technique (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

- Packages (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

- Dairy Products (AREA)

Description

Claims (7)

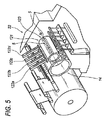

- 取付フレーム(12)、パッケージを準備する操作手段、該操作手段を駆動する手段、を備え、特に、適切な包装材料で包装されることが好ましい食品、特に、プロセスチーズ、固形スープの素、バター、マーガリンなどのペースト状食品用の包装装置(10)において、前記取付フレーム(12)は、装置に沿って長手方向に延びるとともに前記操作手段と前記駆動手段とを分割する仕切手段(120)を備え、該仕切手段から対応する操作手段が延び、前記仕切手段(120)は、前記対応する操作手段と各駆動手段とを分割する長手方向壁(120)である、包装装置(10)であって、

包装材料部品を収容する周方向に整列した複数のサイト(141)を画定する回転ボディを備える、前記仕切手段(120)から横方向に延びる包装材料部品供給手段(14)と、

包装材料形成手段(40)と、該包装材料形成手段(40)に対して包装材料を押す手段(42)と、を備えてなる包装材料形状づけ手段であって、この包装材料形状づけ手段は、前記包装材料を形状づけるように設計された軸方向開口部を備えた開口端ホッパー手段(40)として実施され、前記包装材料形成手段(40)は、前記仕切手段(120)から横方向に延びる各々の取付手段に取り付けられ、前記押し手段(42)は、前記ホッパー手段(40)の上方で、前記仕切手段(120)から横方向に延びる各々の取付手段に取り付けられる、包装材料形状づけ手段と、

前記仕切手段(120)から横方向に延びる取付手段を備えた包装材料充填手段(50)と、

前記仕切手段(120)から横方向に延びる各々の取付手段に取り付けられる、長手方向にカップ形状包装材料を供給する手段(44)と、

前記仕切手段(120)から横方向に延びる各々の取付手段に取り付けられるキャップ付加手段(52)と、

前記仕切手段(120)から横方向に延びる各々の取付手段に取り付けられるキャップ保持用タブ折り曲げ手段(54)と、

前記仕切手段(120)から横方向に延びる各々の取付手段に取り付けられる、キャップへの保持用タブシール手段(56)と、

を備えた包装装置(10)。 - 前記包装材料部品供給手段(14)の各サイトにラベル(5)を配置する手段(22)を備えることを特徴とする請求項1に記載の包装装置(10)。

- 前記ラベル配置手段(22)は、前記仕切壁(120)から横方向に延びる各々の取付手段に取り付けられることを特徴とする請求項2に記載の包装装置(10)。

- 前記ラベル配置手段(22)は、回転手段の形態をとり、前記収容手段(122)からラベルを取り上げて前記包装材料部品供給手段(14)に輸送する手段(121)を備えることを特徴とする請求項2または3に記載の包装装置(10)。

- 前記キャップ付加手段(52)は、下部位置と上部位置との間で動くことを特徴とする請求項1に記載の包装装置(10)。

- 前記キャップ保持用タブ折り曲げ手段(54)は、下部位置と上部位置との間で動くことを特徴とする請求項1に記載の包装装置(10)。

- 前記キャップへの保持用タブシール手段(56)は、下部位置と上部位置との間で動くことを特徴とする請求項1に記載の包装装置(10)。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT000682A ITBO20060682A1 (it) | 2006-10-03 | 2006-10-03 | Apparecchiatura per il confezionamento di un prodotto. |

| ITBO2006A000682 | 2006-10-03 | ||

| PCT/IB2007/002843 WO2008041082A2 (en) | 2006-10-03 | 2007-09-27 | Apparatus for packaging a product |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010505708A JP2010505708A (ja) | 2010-02-25 |

| JP2010505708A5 JP2010505708A5 (ja) | 2010-07-22 |

| JP5323706B2 true JP5323706B2 (ja) | 2013-10-23 |

Family

ID=39043175

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009530959A Active JP5323706B2 (ja) | 2006-10-03 | 2007-09-27 | 製品包装装置 |

Country Status (6)

| Country | Link |

|---|---|

| EP (2) | EP2086843B1 (ja) |

| JP (1) | JP5323706B2 (ja) |

| IT (1) | ITBO20060682A1 (ja) |

| PL (1) | PL2086843T3 (ja) |

| RU (1) | RU2452671C2 (ja) |

| WO (1) | WO2008041082A2 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8650843B2 (en) | 2011-02-04 | 2014-02-18 | Alpma Alpenland Maschinenbau Gmbh | Method of packaging products |

| DE102012019909A1 (de) * | 2012-10-11 | 2014-04-17 | Theegarten-Pactec Gmbh & Co. Kg | Hochleistungs-Verpackungsverfahren zur Verpackung von, insbesondere kleinstückigen, Produkten und Hochleistungs-Verpackungseinrichtung, insbesondere zur Durchführung des Verfahrens |

| JP6295071B2 (ja) * | 2013-12-09 | 2018-03-14 | 株式会社川島製作所 | 扇形柱状物の折込み包装 |

| EP2894103B1 (fr) | 2014-01-10 | 2016-09-07 | Robert Bosch Gmbh | Procédé et dispositif d'emballage de produits alimentaires en portions individuelles |

| CN104925330B (zh) * | 2015-06-19 | 2017-01-18 | 东莞市开胜电子有限公司 | 全自动智能打包贴标生产线 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2033849A (en) * | 1932-01-13 | 1936-03-10 | Garrett W Mudd | Labeling machine |

| SU98723A1 (ru) * | 1952-11-29 | 1953-11-30 | И.А. Черненко | Автомат дл выделки пачек и наполнени , их папиросами |

| DE2115656C2 (de) * | 1971-03-31 | 1983-03-03 | Gerhard Schubert GmbH, 7180 Crailsheim | Verpackungsmaschine |

| CH533561A (it) * | 1971-12-28 | 1973-02-15 | Giavazzi Marco | Apparecchiatura per il prelievo in successione dell'ultimo foglio di una mazzetta |

| US3835619A (en) * | 1972-10-30 | 1974-09-17 | Reisman J & Sons Inc | Apparatus for assembling tubular cartons |

| DE3639994A1 (de) * | 1986-11-22 | 1988-05-26 | Focke & Co | Verpackungsmaschine, insbesondere fuer zigarettenpackungen |

| DE3709267A1 (de) * | 1987-03-20 | 1988-09-29 | Bosch Gmbh Robert | Verpackungsmaschine mit einrichtungen zum fuellen und verschliessen von beutelpackungen |

| GB8808087D0 (en) * | 1988-04-07 | 1988-05-11 | Thames Sack & Bag Co Ltd | Bag feeding apparatus |

| US5122216A (en) * | 1989-02-15 | 1992-06-16 | Goodwin Graphics, Inc. | Multi-ply mailer form and method of manufacture therefor |

| IT1279846B1 (it) * | 1995-08-11 | 1997-12-18 | Rossi & Catelli Spa | Impianto di imbottigliamento asettico in continuo |

| DE19859060B4 (de) * | 1998-12-22 | 2006-10-05 | Robert Bosch Gmbh | Verpackungsmaschine |

| IT1309326B1 (it) * | 1999-07-07 | 2002-01-22 | Ohg Natalino Corazza S P A | Confezione per un prodotto alimentare pastoso, procedimento eapparecchiatura per la realizzazione di tale confezione. |

| IT1311107B1 (it) * | 1999-10-22 | 2002-02-28 | Ohg Natalino Corazza S P A | Apparecchio per il confezionamento di un prodotto alimentare, inparticolare un prodotto alimentare pastoso. |

| ITBO20020234A1 (it) * | 2002-04-24 | 2003-10-24 | Corazza Spa | Apparato per la fornitura di involucri di confezionamento di un prodotto alimentare |

| DE10301186A1 (de) * | 2003-01-15 | 2004-07-29 | Iwk Verpackungstechnik Gmbh | Verpackungsmaschine |

| ITMI20032425A1 (it) * | 2003-12-11 | 2005-06-12 | Gruppo Smaic Macchinari Ind S R L | Procedimento e macchina per il confezionamento di prodotti pastosi-estrudibili ad esempio formaggini |

-

2006

- 2006-10-03 IT IT000682A patent/ITBO20060682A1/it unknown

-

2007

- 2007-09-27 WO PCT/IB2007/002843 patent/WO2008041082A2/en active Application Filing

- 2007-09-27 JP JP2009530959A patent/JP5323706B2/ja active Active

- 2007-09-27 EP EP07825214A patent/EP2086843B1/en active Active

- 2007-09-27 PL PL07825214T patent/PL2086843T3/pl unknown

- 2007-09-27 RU RU2009112011/13A patent/RU2452671C2/ru active

- 2007-09-27 EP EP10182105A patent/EP2277782B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| RU2452671C2 (ru) | 2012-06-10 |

| ITBO20060682A1 (it) | 2008-04-04 |

| EP2277782A3 (en) | 2011-05-25 |

| WO2008041082A2 (en) | 2008-04-10 |

| RU2009112011A (ru) | 2010-11-10 |

| EP2277782A2 (en) | 2011-01-26 |

| EP2277782B1 (en) | 2012-09-05 |

| WO2008041082A3 (en) | 2008-08-21 |

| JP2010505708A (ja) | 2010-02-25 |

| PL2086843T3 (pl) | 2013-08-30 |

| EP2086843A2 (en) | 2009-08-12 |

| EP2086843B1 (en) | 2013-02-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5323706B2 (ja) | 製品包装装置 | |

| JPH03148409A (ja) | 寸法の異なる物品の包装装置 | |

| KR100786562B1 (ko) | 약제분포장치 | |

| US4897980A (en) | Apparatus for forming a bulk package | |

| RU2391266C1 (ru) | Упаковочная машина, в которой используется термосвариваемая пленка | |

| AU2006325513B2 (en) | Vertical carton loading process and system for clips of a stacked sheet material | |

| AU2013370677A1 (en) | Packaged food product | |

| CA2471448A1 (en) | Machine for packaging containers | |

| CN112918818A (zh) | 一种多只包装机 | |

| CN209064521U (zh) | 包装机和包装堆叠体 | |

| JP6980251B2 (ja) | カップ状容器への小袋供給方法 | |

| KR101400727B1 (ko) | 비닐포장지 제조장치 | |

| KR102112335B1 (ko) | 공간 확보형 식품 포장기 | |

| JP5513894B2 (ja) | ペースト状食品の包装装置 | |

| KR101539273B1 (ko) | 용기를 한 개씩 포장하는 멀티 포장기 | |

| JP5184231B2 (ja) | 複数包装品の位置決め包装方法及び装置 | |

| EP3221219B1 (en) | A plant for packaging products inside respective containers | |

| CN110979815A (zh) | 湿巾包装装盒生产线 | |

| US20170001748A1 (en) | Method and apparatus for fitting carrying handles on packs or multipacks | |

| KR200336061Y1 (ko) | 왕복 운동형 보호 커버 시트 부착 장치 | |

| US20050081487A1 (en) | Method and apparatus for fitting stretchable sleeves | |

| JP4342882B2 (ja) | 野菜類の袋詰め投入装置 | |

| CS490190A3 (en) | Process and apparatus for removing, straightening and arranging of filled packages and other articles | |

| EP1044880A1 (en) | Device for placing sacks filled with a product in a box | |

| WO2024115081A1 (en) | Apparatus for filling food packages |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100601 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100601 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20110330 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20110330 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20110330 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120420 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120508 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120807 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120814 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120907 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120914 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20121005 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20121015 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121106 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130625 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130717 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5323706 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |