JP5274250B2 - 高速低圧エミッタ - Google Patents

高速低圧エミッタ Download PDFInfo

- Publication number

- JP5274250B2 JP5274250B2 JP2008517024A JP2008517024A JP5274250B2 JP 5274250 B2 JP5274250 B2 JP 5274250B2 JP 2008517024 A JP2008517024 A JP 2008517024A JP 2008517024 A JP2008517024 A JP 2008517024A JP 5274250 B2 JP5274250 B2 JP 5274250B2

- Authority

- JP

- Japan

- Prior art keywords

- liquid

- emitter

- gas

- nozzle

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000007789 gas Substances 0.000 claims description 96

- 239000007788 liquid Substances 0.000 claims description 39

- 238000000034 method Methods 0.000 claims description 28

- 238000007599 discharging Methods 0.000 claims description 17

- 230000035939 shock Effects 0.000 claims description 10

- 238000004891 communication Methods 0.000 claims description 9

- 239000000779 smoke Substances 0.000 claims description 7

- 230000007704 transition Effects 0.000 claims description 5

- 239000011261 inert gas Substances 0.000 claims description 4

- 239000000203 mixture Substances 0.000 claims description 4

- 239000003595 mist Substances 0.000 claims description 3

- 238000005282 brightening Methods 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 24

- 239000002245 particle Substances 0.000 description 12

- 238000000889 atomisation Methods 0.000 description 9

- 230000001629 suppression Effects 0.000 description 8

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 6

- 239000001301 oxygen Substances 0.000 description 6

- 229910052760 oxygen Inorganic materials 0.000 description 6

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 3

- 238000002485 combustion reaction Methods 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 239000000567 combustion gas Substances 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 230000003993 interaction Effects 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000009692 water atomization Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C37/00—Control of fire-fighting equipment

- A62C37/08—Control of fire-fighting equipment comprising an outlet device containing a sensor, or itself being the sensor, i.e. self-contained sprinklers

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C31/00—Delivery of fire-extinguishing material

- A62C31/005—Delivery of fire-extinguishing material using nozzles

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C31/00—Delivery of fire-extinguishing material

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C31/00—Delivery of fire-extinguishing material

- A62C31/02—Nozzles specially adapted for fire-extinguishing

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C35/00—Permanently-installed equipment

- A62C35/58—Pipe-line systems

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C35/00—Permanently-installed equipment

- A62C35/58—Pipe-line systems

- A62C35/60—Pipe-line systems wet, i.e. containing extinguishing material even when not in use

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C35/00—Permanently-installed equipment

- A62C35/58—Pipe-line systems

- A62C35/64—Pipe-line systems pressurised

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C35/00—Permanently-installed equipment

- A62C35/58—Pipe-line systems

- A62C35/68—Details, e.g. of pipes or valve systems

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C37/00—Control of fire-fighting equipment

- A62C37/08—Control of fire-fighting equipment comprising an outlet device containing a sensor, or itself being the sensor, i.e. self-contained sprinklers

- A62C37/10—Releasing means, e.g. electrically released

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C99/00—Subject matter not provided for in other groups of this subclass

- A62C99/0009—Methods of extinguishing or preventing the spread of fire by cooling down or suffocating the flames

- A62C99/0072—Methods of extinguishing or preventing the spread of fire by cooling down or suffocating the flames using sprayed or atomised water

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B1/00—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means

- B05B1/26—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means with means for mechanically breaking-up or deflecting the jet after discharge, e.g. with fixed deflectors; Breaking-up the discharged liquid or other fluent material by impinging jets

- B05B1/262—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means with means for mechanically breaking-up or deflecting the jet after discharge, e.g. with fixed deflectors; Breaking-up the discharged liquid or other fluent material by impinging jets with fixed deflectors

- B05B1/265—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means with means for mechanically breaking-up or deflecting the jet after discharge, e.g. with fixed deflectors; Breaking-up the discharged liquid or other fluent material by impinging jets with fixed deflectors the liquid or other fluent material being symmetrically deflected about the axis of the nozzle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/02—Spray pistols; Apparatus for discharge

- B05B7/08—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/02—Spray pistols; Apparatus for discharge

- B05B7/08—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point

- B05B7/0807—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point to form intersecting jets

- B05B7/0853—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point to form intersecting jets with one single gas jet and several jets constituted by a liquid or a mixture containing a liquid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/02—Spray pistols; Apparatus for discharge

- B05B7/08—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point

- B05B7/0892—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point the outlet orifices for jets constituted by a liquid or a mixture containing a liquid being disposed on a circle

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Fire-Extinguishing By Fire Departments, And Fire-Extinguishing Equipment And Control Thereof (AREA)

- Nozzles (AREA)

- Fire Alarms (AREA)

- Discharge Lamp (AREA)

- Special Wing (AREA)

- Cosmetics (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

- Saccharide Compounds (AREA)

Description

液体をオリフィスから吐出する工程と、

気体を出口から吐出する工程と、

出口とデフレクタ面との間に第1衝撃領域を形成する工程と、

デフレクタ面に近接して第2衝撃領域を形成する工程と、

液体‐気体流をエミッタから放出する工程とを含む。

気体45は、約マッハ1.5でノズル出口16を出ると共に、デフレクタ面22に衝突する。同時に、水47は出口オリフィス52から吐出される。

Claims (36)

- 気体流に混入された液体を霧化すると共に吐出するエミッタであって、該エミッタは、前記液体の加圧源および前記気体の加圧源に対して連通状態で接続可能であり、

入口と断面円状の出口とを備え、かつ、これらの間を貫通する気体流を吐出可能なノズルと、該ノズルの入口は前記加圧気体源に対して連通状態で接続されることと、

前記エミッタ内においてノズルを包囲し、かつ、前記加圧液体源と連通する環状室と、

前記環状室から延在し、かつ、前記ノズルの出口に近接して配置された出口オリフィスを有するダクトと、

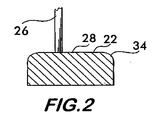

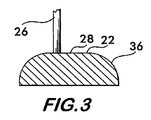

前記ノズルの出口に対向するように配置され、ノズルから吐出される気体流およびダクトから吐出される液体流と対向して直交するように配向され、さらに、ノズルの出口の直径と等しい最小直径を有する平坦面を含む第1の面、および該平坦面の端縁部において面取りされた傾斜面を含む第2の面を有するデフレクタ面とを備え、液体は、気体流に混入されると霧化されて前記デフレクタ面の第1の面に衝突すると共に該デフレクタ面から離れ外方かつ下方に流れる液体‐気体流を形成することとを特徴とするスプリンクラヘッド用エミッタ。 - 前記ノズルは先細ノズルである請求項1に記載のエミッタ。

- 前記出口は、3.18ミリメートル(1/8インチ)から25.4ミリメートル(1インチ)の直径を有する請求項1に記載のエミッタ。

- 前記オリフィスは、0.79ミリメートル(1/32インチ)から3.18ミリメートル(1/8インチ)の直径を有する請求項1に記載のエミッタ。

- 前記デフレクタ面は、2.54ミリメートル(1/10インチ)から19.05ミリメートル(3/4インチ)の距離だけ、前記ノズルの出口から離間されている請求項1に記載のエミッタ。

- 前記傾斜面は、前記平坦面から測定された時に、15度から45度の後退角を有する請求項1に記載のエミッタ。

- 前記出口オリフィスは、0.40ミリメートル(1/64インチ)から3.18ミリメートル(1/8インチ)の距離だけ、前記ノズルの出口から離間されている請求項1に記載のエミッタ。

- 前記ノズルは、199.948kPa(29psia)から413.686kPa(60psia)の気体圧範囲で作動するように構成される請求項1に記載のエミッタ。

- 前記ダクトは、6.89476kPa(1psig)から344.738kPa(50psig)の液圧範囲で作動するように構成される請求項1に記載のエミッタ。

- さらに前記出口オリフィスを複数含む請求項1に記載のエミッタ。

- 前記デフレクタ面内に位置決めされ、前記平坦面によって包囲される閉鎖端空隙をさらに含む請求項1に記載のエミッタ。

- 気体流に混入された液体を霧化すると共に吐出するエミッタであって、該エミッタは、前記液体の加圧源および前記気体の加圧源に対して連通状態で接続可能であり、

入口と断面円状の出口とを備え、かつ、これらの間を貫通する気体流を吐出可能なノズルと、該ノズルの入口は前記加圧気体源に対して連通状態で接続されることと、

前記エミッタ内においてノズルを包囲し、かつ、前記加圧液体源と連通する環状室と、

前記環状室から延在し、かつ、前記ノズルの出口に近接して配置された出口オリフィスを有するダクトと、

前記ノズルの出口に対向するように配置され、ノズルから吐出される気体流およびダクトから吐出される液体流と対向して直交するように配向され、さらに、ノズルの出口の直径と等しい最小直径を有する平坦面を含む第1の面、および該平坦面の端縁部において湾曲面を含む第2の面を有するデフレクタ面とを備え、液体は、気体流に混入されると霧化されて前記デフレクタ面の第1の面に衝突すると共に該デフレクタ面から離れ外方かつ下方に流れる液体‐気体流を形成することとを特徴とするスプリンクラヘッド用エミッタ。 - 前記デフレクタ面内に位置決めされ、前記平坦面によって包囲される閉鎖端空隙をさらに含む請求項12に記載のエミッタ。

- 請求項1または12に記載のエミッタの作動方法であって、

前記液体流を前記オリフィスから吐出する工程と、

前記気体流を前記出口から超音速にて吐出する工程と、

前記出口と前記デフレクタ面との間における超音速から亜音速までの流動移行領域に第1衝撃領域を形成する工程と、

前記デフレクタ面に近接して気体流の第2衝撃領域を形成する工程と、

前記第1および第2衝撃領域の少なくとも一方において前記液体流を前記気体流に混入させて液体−気体流を形成する工程と、

前記液体‐気体流を前記エミッタから外方かつ下方に放出する工程とを含むこととを特徴とする方法。 - 前記液体‐気体流に複数の衝撃波光輝を形成する工程を含む請求項14に記載の方法。

- 前記ノズルから気体流を排出させた後で膨張気体流噴流を形成する工程を含む請求項14に記載の方法。

- 199.948kPa(29psia)から413.686kPa(60psia)の圧力で、気体を前記入口に供給する工程を含む請求項14に記載の方法。

- 6.89476kPa(1psig)から344.738kPa(50psig)の圧力で、液体を前記ダクトに供給する工程を含む請求項14に記載の方法。

- 前記第2衝撃領域に近接して、前記液体流を前記気体流に混入させる工程を含む請求項14に記載の方法。

- 前記第1衝撃領域に近接して、前記液体流を前記気体流に混入させる工程を含む請求項14に記載の方法。

- 前記液体‐気体流は前記デフレクタ面から離間しない請求項14に記載の方法。

- 前記エミッタから気体噴流ノイズ以外の大きな音響エネルギを生じさせない工程を含む請求項14に記載の方法。

- 前記気体流に運動量を生じさせる工程をさらに含む請求項14に記載の方法。

- 前記液体‐気体流は、前記エミッタから457.2ミリメートル(18インチ)の距離で、毎分360メートル(1,200フィート)の速度を有する請求項23に記載の方法。

- 前記液体‐気体流は、前記エミッタから2.4メートル(8フィート)の距離で、毎分210メートル(700フィート)の速度を有する請求項24に記載の方法。

- 前記デフレクタ面の傾斜部を設けることにより、前記エミッタから所定の先端角を有する流れパターンを形成する工程をさらに含む請求項14に記載の方法。

- 前記気体流と大気との間の圧力差を用いて、該気体流に液体を吸い込む工程を含む請求項14に記載の方法。

- 前記液体を前記気体流に混入させると共に、該液体を直径が20μm未満の滴となるように霧化させる工程を含む請求項14に記載の方法。

- 酸素消耗煙層を前記ノズルの出口から吐出された気体流に吸い込むと共に、該煙層を前記エミッタの液体‐気体流に混入させる工程を含む請求項14に記載の方法。

- 前記出口から不活性気体を吐出する工程を含む請求項14に記載の方法。

- 前記出口から不活性気体および化学的活性気体の混合物を吐出する工程を含む請求項14に記載の方法。

- 前記気体混合物は空気を含む請求項31に記載の方法。

- 請求項1または12に記載のエミッタの作動方法であって、

前記液体流を出口オリフィスから吐出する工程と、

前記気体流を前記ノズル出口から超音速にて吐出して、前記ノズルから過膨張気体流噴流を形成する工程と、

前記過膨張気体流噴流を前記デフレクタ面の平坦面に衝突させる工程と、

前記液体流を前記過膨張気体流噴流に混入させて液体−気体流を形成する工程と、

前記液体‐気体流を前記エミッタから放出する工程とを含むこととを特徴とする方法。 - 前記出口と前記デフレクタ面との間における超音速から亜音速までの流動移行領域に第1衝撃領域を形成する工程と、

前記デフレクタ面に近接して気体流の第2衝撃領域を形成する工程と、

前記第1および第2衝撃領域の少なくとも一方において前記液体流を前記気体流に混入させて液体−気体流を形成する工程とをさらに含む請求項33に記載の方法。 - 前記エミッタからの前記液体‐気体流に、複数の衝撃波光輝を形成する工程をさらに含む請求項33に記載の方法。

- 酸素消耗煙層を前記ノズルの出口から吐出された気体流に吸い込むと共に、該煙層を前記エミッタの液体‐気体流に混入させる工程を含む請求項33に記載の方法。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US68986405P | 2005-06-13 | 2005-06-13 | |

| US60/689,864 | 2005-06-13 | ||

| US77640706P | 2006-02-24 | 2006-02-24 | |

| US60/776,407 | 2006-02-24 | ||

| PCT/US2006/023013 WO2006135890A2 (en) | 2005-06-13 | 2006-06-13 | High velocity low pressure emitter |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008546524A JP2008546524A (ja) | 2008-12-25 |

| JP2008546524A5 JP2008546524A5 (ja) | 2010-10-14 |

| JP5274250B2 true JP5274250B2 (ja) | 2013-08-28 |

Family

ID=37532897

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008517025A Active JP4897805B2 (ja) | 2005-06-13 | 2006-06-13 | 高速低圧エミッタを用いる火災鎮圧システム |

| JP2008517024A Active JP5274250B2 (ja) | 2005-06-13 | 2006-06-13 | 高速低圧エミッタ |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008517025A Active JP4897805B2 (ja) | 2005-06-13 | 2006-06-13 | 高速低圧エミッタを用いる火災鎮圧システム |

Country Status (19)

| Country | Link |

|---|---|

| US (4) | US7726408B2 (ja) |

| EP (2) | EP1893305B1 (ja) |

| JP (2) | JP4897805B2 (ja) |

| KR (3) | KR101275515B1 (ja) |

| CN (2) | CN101247859B (ja) |

| AR (3) | AR057370A1 (ja) |

| AU (2) | AU2006257832B2 (ja) |

| BR (2) | BRPI0612038B1 (ja) |

| CA (2) | CA2611987C (ja) |

| ES (2) | ES2418147T3 (ja) |

| HK (2) | HK1110250A1 (ja) |

| IL (2) | IL187925A (ja) |

| MX (2) | MX2007015843A (ja) |

| MY (2) | MY146845A (ja) |

| NO (2) | NO344063B1 (ja) |

| PL (1) | PL1893305T3 (ja) |

| SG (2) | SG128596A1 (ja) |

| TW (2) | TWI341750B (ja) |

| WO (2) | WO2006135890A2 (ja) |

Families Citing this family (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SG128596A1 (en) | 2005-06-13 | 2007-01-30 | Victaulic Co Of America | High velocity low pressure emitter |

| FI118515B (fi) * | 2006-09-26 | 2007-12-14 | Marioff Corp Oy | Suihkutuspää, suihkutuslaitteisto ja menetelmä palon sammuttamiseksi |

| AR062764A1 (es) * | 2006-11-06 | 2008-12-03 | Victaulic Co Of America | Metodo y aparato para secar redes de canerias equipadas con rociadores |

| US7857069B2 (en) * | 2006-12-05 | 2010-12-28 | Fm Global Technologies Llc | System valve activation methods for deluge-like wet pipe sprinkler system |

| EP2195095A4 (en) * | 2007-09-24 | 2013-12-04 | Utc Fire & Security Corp | HYBRID INERT GAS FIRE SUPPRESSION SYSTEM |

| CA2700407A1 (en) * | 2007-09-24 | 2009-04-02 | Utc Fire & Security Corporation | Inert gas flooding fire suppression with water augmentation |

| GB0803959D0 (en) * | 2008-03-03 | 2008-04-09 | Pursuit Dynamics Plc | An improved mist generating apparatus |

| JP5189417B2 (ja) * | 2008-06-25 | 2013-04-24 | 三ツ星ベルト株式会社 | 静電植毛パイル拡散ノズル |

| US9033061B2 (en) * | 2009-03-23 | 2015-05-19 | Kidde Technologies, Inc. | Fire suppression system and method |

| CN102470386A (zh) * | 2009-08-11 | 2012-05-23 | 积水医疗株式会社 | 涂敷装置及液态物的涂敷方法 |

| US9140398B2 (en) | 2010-04-02 | 2015-09-22 | Pentair Flow Technologies, Llc | Air aspiration device |

| US20110308823A1 (en) * | 2010-06-17 | 2011-12-22 | Dharmendr Len Seebaluck | Programmable controller for a fire prevention system |

| US10532237B2 (en) | 2010-08-05 | 2020-01-14 | Victaulic Company | Dual mode agent discharge system with multiple agent discharge capability |

| US20120217028A1 (en) * | 2011-02-24 | 2012-08-30 | Kidde Technologies, Inc. | Active odorant warning |

| JP2012179330A (ja) * | 2011-03-03 | 2012-09-20 | Hochiki Corp | スプリンクラー消火設備 |

| US8887820B2 (en) | 2011-05-12 | 2014-11-18 | Fike Corporation | Inert gas suppression system nozzle |

| EP2766099B1 (en) * | 2011-10-14 | 2019-05-15 | UTC Fire & Security Corporation | Low pressure sprinkler system for use in buildings |

| US9805588B2 (en) | 2012-05-30 | 2017-10-31 | Factory Mutual Insurance Company | Wireless fire protection valve inspection and monitoring systems, and methods for automated inspection and monitoring of fire protection systems |

| WO2014008020A2 (en) * | 2012-07-03 | 2014-01-09 | Marioff Corporation Oy | Fire suppression system |

| EP2964341A2 (en) | 2013-03-07 | 2016-01-13 | Tyco Fire Products LP | Corrosion resistant nozzle |

| RU2536959C1 (ru) * | 2013-07-26 | 2014-12-27 | Андрей Николаевич Дубровский | Пневмоакустический распылитель жидкостей |

| US9540962B2 (en) | 2014-07-14 | 2017-01-10 | Siemens Energy, Inc. | Power plant air cooled heat exchanger or condenser with pressurized gas entrained cooling liquid mister |

| US9403046B2 (en) * | 2014-11-05 | 2016-08-02 | WWTemplar LLC | Remote control of fire suppression systems |

| CN104524724A (zh) * | 2014-12-25 | 2015-04-22 | 李春龙 | 基于电-高频振动转化的超声波强化雾化喷淋灭火降烟装置 |

| AU2017248279B2 (en) * | 2016-04-08 | 2021-12-09 | Tyco Fire Products Lp | Modular and expandable fire suppression system |

| WO2019032188A1 (en) * | 2017-08-07 | 2019-02-14 | Fireaway Inc. | WET-DRY FIRE EXTINGUISHING AGENT |

| US11117007B2 (en) * | 2017-11-10 | 2021-09-14 | Carrier Corporation | Noise reducing fire suppression nozzles |

| AU2018385712A1 (en) | 2017-12-14 | 2020-07-02 | Adaptive Global Solutions, LLC | Fire resistant aerial vehicle for suppressing widespread fires |

| CN108245816A (zh) * | 2017-12-23 | 2018-07-06 | 丁玉琴 | 一种车载自动干粉灭火装置 |

| WO2019143888A1 (en) * | 2018-01-18 | 2019-07-25 | Engineered Corrosion Solutions, Llc | Systems and methods for determining a volume of a pipe network |

| KR102390242B1 (ko) * | 2018-05-21 | 2022-04-22 | 바르질라 모스 에이에스 | 버너 노즐 |

| US10553085B1 (en) | 2019-01-25 | 2020-02-04 | Lghorizon, Llc | Home emergency guidance and advisement system |

| US11465259B2 (en) * | 2019-02-13 | 2022-10-11 | The Boeing Company | System and method for fluid cavitation processing a part |

| CN110195672B (zh) * | 2019-06-14 | 2020-06-30 | 清华大学 | 利用超音速气流增强雾化的喷油器 |

| US11043095B1 (en) | 2020-06-16 | 2021-06-22 | Lghorizon, Llc | Predictive building emergency guidance and advisement system |

| US11583770B2 (en) | 2021-03-01 | 2023-02-21 | Lghorizon, Llc | Systems and methods for machine learning-based emergency egress and advisement |

| US11626002B2 (en) | 2021-07-15 | 2023-04-11 | Lghorizon, Llc | Building security and emergency detection and advisement system |

Family Cites Families (69)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2519619A (en) * | 1944-08-04 | 1950-08-22 | Inst Gas Technology | Acoustic generator |

| US3084874A (en) * | 1959-08-12 | 1963-04-09 | Aeroprojects Inc | Method and apparatus for generating aerosols |

| US3117551A (en) * | 1960-08-12 | 1964-01-14 | Gen Precision Inc | Liquid fuel propellant |

| US3070313A (en) * | 1962-03-05 | 1962-12-25 | Astrosonics Inc | Apparatus for the acoustic treatment of liquids |

| US3108749A (en) * | 1962-03-28 | 1963-10-29 | Gen Motors Corp | Vibratory apparatus for atomizing liquids |

| US3157359A (en) * | 1962-12-24 | 1964-11-17 | Astrosonics Inc | Large volume liquid atomizer employing an acoustic generator |

| US3371869A (en) * | 1963-12-23 | 1968-03-05 | Sonic Dev Corp | Compressible fluid sonic pressure wave atomizing apparatus |

| US3297255A (en) * | 1965-04-19 | 1967-01-10 | Astrosonics Inc | Reverse flow acoustic generator spray nozzle |

| US3326467A (en) * | 1965-12-20 | 1967-06-20 | William K Fortman | Atomizer with multi-frequency exciter |

| GB1207609A (en) * | 1968-08-06 | 1970-10-07 | Nat Res Dev | Improvements in or relating to fluid atomisers |

| US5845846A (en) * | 1969-12-17 | 1998-12-08 | Fujisaki Electric Co., Ltd. | Spraying nozzle and method for ejecting liquid as fine particles |

| US3741484A (en) * | 1970-09-30 | 1973-06-26 | Decafix Ltd | Atomisers |

| US3779460A (en) * | 1972-03-13 | 1973-12-18 | Combustion Equip Ass | Acoustic nozzle |

| US3829015A (en) * | 1972-06-22 | 1974-08-13 | Combustion Equipment Ass Inc | Acoustic nozzle |

| GB1446225A (en) * | 1973-10-26 | 1976-08-18 | Decafix Ltd | Atomisers |

| FR2264598B2 (ja) * | 1974-03-20 | 1979-04-13 | Fives Cail Babcock | |

| JPS5941780B2 (ja) * | 1976-05-27 | 1984-10-09 | 三菱プレシジョン株式会社 | 流体の複合噴流方法と複合ノズルユニツト |

| CA1051063A (en) * | 1976-05-27 | 1979-03-20 | Mitsubishi Precision Co. | Method of and apparatus for generating mixed and atomized fluids |

| US4109862A (en) * | 1977-04-08 | 1978-08-29 | Nathaniel Hughes | Sonic energy transducer |

| US4281717A (en) * | 1979-10-25 | 1981-08-04 | Williams Robert M | Expolosion suppression system for fire or expolosion susceptible enclosures |

| US4361285A (en) * | 1980-06-03 | 1982-11-30 | Fluid Kinetics, Inc. | Mixing nozzle |

| US4408719A (en) * | 1981-06-17 | 1983-10-11 | Last Anthony J | Sonic liquid atomizer |

| US4531588A (en) * | 1984-02-06 | 1985-07-30 | Lockheed Corporation | Fire suppression system |

| JPH062681Y2 (ja) * | 1987-02-17 | 1994-01-26 | オムロン株式会社 | 霧化器 |

| US4871489A (en) * | 1986-10-07 | 1989-10-03 | Corning Incorporated | Spherical particles having narrow size distribution made by ultrasonic vibration |

| EP0521167A4 (en) * | 1991-01-18 | 1993-12-29 | Vitaly Grigorievich Pavljuk | Sprayer |

| US5248087A (en) * | 1992-05-08 | 1993-09-28 | Dressler John L | Liquid droplet generator |

| US5297501A (en) * | 1992-12-28 | 1994-03-29 | National Technical Systems | Intense noise generator |

| US5405085A (en) * | 1993-01-21 | 1995-04-11 | White; Randall R. | Tuneable high velocity thermal spray gun |

| CA2119430A1 (en) * | 1993-04-20 | 1994-10-21 | Joseph P. Mercurio | Dense oxide coatings by thermal spraying |

| US5495893A (en) * | 1994-05-10 | 1996-03-05 | Ada Technologies, Inc. | Apparatus and method to control deflagration of gases |

| US6314754B1 (en) | 2000-04-17 | 2001-11-13 | Igor K. Kotliar | Hypoxic fire prevention and fire suppression systems for computer rooms and other human occupied facilities |

| US5687905A (en) * | 1995-09-05 | 1997-11-18 | Tsai; Shirley Cheng | Ultrasound-modulated two-fluid atomization |

| EP0798019A1 (de) * | 1996-03-30 | 1997-10-01 | Minimax GmbH | Verfahren und Vorrichtung zur Verdüsung von flüssigem Löschmittel in stationären Löschanlagen |

| US5647438A (en) * | 1996-04-25 | 1997-07-15 | Fike Corporation | Explosion suppressant dispersion nozzle |

| US5829684A (en) * | 1996-10-28 | 1998-11-03 | Grinnell Corporation | Pendent-type diffuser impingement water mist nozzle |

| JPH114905A (ja) * | 1997-04-23 | 1999-01-12 | Bunka Shutter Co Ltd | ウォーターミストを利用した消火、消煙装置及び方法 |

| RU2121390C1 (ru) * | 1997-05-14 | 1998-11-10 | Научно-исследовательский институт низких температур при МАИ (Московском государственном авиационном институте - техническом университете) | Установка для пожаротушения |

| US6009869A (en) * | 1997-12-29 | 2000-01-04 | Allegiance Corporation | Supersonic nozzle nebulizer |

| RU2131379C1 (ru) * | 1998-02-06 | 1999-06-10 | Научно-исследовательский институт низких температур при Московском государственном авиационном институте - техническом университете | Способ пожаротушения с использованием летательного аппарата и устройство для его осуществления |

| US5983944A (en) * | 1998-03-20 | 1999-11-16 | Niv; Shaul E. | Apparatus for active fluid control |

| US6059044A (en) * | 1998-05-15 | 2000-05-09 | Grinnell Corporation | Fire protection sprinkler and deflector |

| WO2000037143A1 (en) * | 1998-12-23 | 2000-06-29 | Lockwood Hanford N | Low pressure dual fluid atomizer |

| WO2000041769A1 (en) * | 1999-01-11 | 2000-07-20 | New World Technologies Corp. | Fire suppression apparatus and method |

| US6322003B1 (en) * | 1999-06-11 | 2001-11-27 | Spraying Systems Co. | Air assisted spray nozzle |

| US6261338B1 (en) * | 1999-10-12 | 2001-07-17 | Praxair Technology, Inc. | Gas and powder delivery system and method of use |

| NL1013893C2 (nl) | 1999-12-20 | 2001-06-21 | Stork Friesland Bv | Inrichting voor het verstuiven van een vloeibaar product, een daarvan voorziene sproeidroog- en conditionerings-inrichting alsmede een werkwijze voor het conditioneren van een vloeibaar product. |

| JP2001276677A (ja) * | 2000-03-31 | 2001-10-09 | Yamamoto Yogyo Kako Kk | 塗材用ガン |

| DE60122125T2 (de) | 2000-04-17 | 2007-03-01 | Kotliar, Igor K. | Hypoxische brandbekämpfungsysteme und atmungsfähige feuerlöschmittel |

| US6560991B1 (en) * | 2000-12-28 | 2003-05-13 | Kotliar Igor K | Hyperbaric hypoxic fire escape and suppression systems for multilevel buildings, transportation tunnels and other human-occupied environments |

| US6557374B2 (en) * | 2000-12-28 | 2003-05-06 | Igor K. Kotliar | Tunnel fire suppression system and methods for selective delivery of breathable fire suppressant directly to fire site |

| US6502421B2 (en) | 2000-12-28 | 2003-01-07 | Igor K. Kotliar | Mobile firefighting systems with breathable hypoxic fire extinguishing compositions for human occupied environments |

| CA2310303C (en) * | 2000-05-30 | 2003-10-07 | Systemes Fireflex Inc. | Virtual accelerator for detecting an alarm condition within a pressurized gas sprinkler system and method thereof |

| AUPQ802400A0 (en) * | 2000-06-07 | 2000-06-29 | Burns, Alan Robert | Propulsion system |

| WO2002024261A2 (en) * | 2000-09-25 | 2002-03-28 | Evit Laboratories, Inc. | Shock wave aerosolization apparatus and method |

| DE10100867A1 (de) * | 2001-01-11 | 2002-07-25 | Buender Glas Gmbh | Verfahren und Vorrichtung zum Erzeugen eines Aerosols |

| JP2003010330A (ja) * | 2001-07-02 | 2003-01-14 | Nipro Corp | 生体接着剤投与用スプレーヘッド |

| EP1441860B1 (en) * | 2001-10-11 | 2012-08-01 | Life Mist, LLC | Apparatus comprising a pneumoacoustic atomizer |

| CN2507495Y (zh) * | 2001-12-13 | 2002-08-28 | 南京消防器材厂 | 混合气体自动灭火装置 |

| ATE364794T1 (de) * | 2002-10-11 | 2007-07-15 | Pursuit Dynamics Plc | Strahlpumpe |

| CN2582661Y (zh) * | 2002-12-17 | 2003-10-29 | 中国科学技术大学 | 消防用液体雾化喷头 |

| KR20050088243A (ko) | 2002-12-30 | 2005-09-02 | 넥타르 테라퓨틱스 | 프리필름화 분무기 |

| JP4387674B2 (ja) * | 2003-02-05 | 2009-12-16 | アネスト岩田株式会社 | 微量粉末物質の液体混合装置 |

| US7223351B2 (en) * | 2003-04-17 | 2007-05-29 | Great Lakes Chemical Corporation | Fire extinguishing mixtures, methods and systems |

| JP4659616B2 (ja) * | 2003-06-23 | 2011-03-30 | 正明 池田 | 渦流式液体微粒化ノズル |

| KR200341245Y1 (ko) | 2003-11-27 | 2004-02-11 | 이원일 | 내부혼합형 2유체 분무노즐 |

| JP2005296874A (ja) * | 2004-04-14 | 2005-10-27 | Ikeuchi:Kk | 超微霧噴射ノズル |

| SG128596A1 (en) | 2005-06-13 | 2007-01-30 | Victaulic Co Of America | High velocity low pressure emitter |

| AR062764A1 (es) | 2006-11-06 | 2008-12-03 | Victaulic Co Of America | Metodo y aparato para secar redes de canerias equipadas con rociadores |

-

2006

- 2006-06-12 SG SG200603979A patent/SG128596A1/en unknown

- 2006-06-13 AU AU2006257832A patent/AU2006257832B2/en active Active

- 2006-06-13 US US11/451,794 patent/US7726408B2/en active Active

- 2006-06-13 CN CN200680028765XA patent/CN101247859B/zh active Active

- 2006-06-13 MY MYPI20062788A patent/MY146845A/en unknown

- 2006-06-13 BR BRPI0612038-5A patent/BRPI0612038B1/pt active IP Right Grant

- 2006-06-13 BR BRPI0612039-3A patent/BRPI0612039B1/pt active IP Right Grant

- 2006-06-13 CA CA2611987A patent/CA2611987C/en active Active

- 2006-06-13 US US11/451,795 patent/US7721811B2/en active Active

- 2006-06-13 PL PL06773057T patent/PL1893305T3/pl unknown

- 2006-06-13 MX MX2007015843A patent/MX2007015843A/es active IP Right Grant

- 2006-06-13 EP EP06773057A patent/EP1893305B1/en active Active

- 2006-06-13 TW TW095121013A patent/TWI341750B/zh active

- 2006-06-13 CN CN2006800287753A patent/CN101511433B/zh active Active

- 2006-06-13 ES ES06773058T patent/ES2418147T3/es active Active

- 2006-06-13 ES ES06773057T patent/ES2389505T3/es active Active

- 2006-06-13 AU AU2006257833A patent/AU2006257833B2/en active Active

- 2006-06-13 WO PCT/US2006/023013 patent/WO2006135890A2/en active Application Filing

- 2006-06-13 JP JP2008517025A patent/JP4897805B2/ja active Active

- 2006-06-13 MX MX2007015846A patent/MX2007015846A/es active IP Right Grant

- 2006-06-13 KR KR1020127025399A patent/KR101275515B1/ko active IP Right Grant

- 2006-06-13 EP EP06773058.0A patent/EP1893307B1/en active Active

- 2006-06-13 WO PCT/US2006/023014 patent/WO2006135891A2/en active Application Filing

- 2006-06-13 SG SG200604008A patent/SG128599A1/en unknown

- 2006-06-13 KR KR1020087000986A patent/KR101244237B1/ko active IP Right Grant

- 2006-06-13 CA CA2611961A patent/CA2611961C/en active Active

- 2006-06-13 JP JP2008517024A patent/JP5274250B2/ja active Active

- 2006-06-13 TW TW095121011A patent/TWI340657B/zh active

- 2006-06-13 MY MYPI20062789A patent/MY146730A/en unknown

- 2006-06-14 AR ARP060102505A patent/AR057370A1/es not_active Application Discontinuation

-

2007

- 2007-12-06 IL IL187925A patent/IL187925A/en active IP Right Grant

- 2007-12-10 IL IL188017A patent/IL188017A/en active IP Right Grant

-

2008

- 2008-01-14 NO NO20080212A patent/NO344063B1/no unknown

- 2008-01-14 KR KR1020087000985A patent/KR101263768B1/ko active IP Right Grant

- 2008-01-14 NO NO20080211A patent/NO339394B1/no unknown

- 2008-04-29 HK HK08104752.2A patent/HK1110250A1/xx unknown

- 2008-04-29 HK HK08104751.3A patent/HK1110249A1/xx unknown

-

2010

- 2010-04-08 US US12/756,457 patent/US8141798B2/en active Active

- 2010-04-08 US US12/756,546 patent/US8376059B2/en active Active

- 2010-07-19 AR ARP100102626A patent/AR077323A2/es active IP Right Grant

- 2010-07-19 AR ARP100102625A patent/AR077582A2/es not_active Application Discontinuation

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5274250B2 (ja) | 高速低圧エミッタ | |

| KR100555747B1 (ko) | 액체 분사기 | |

| CA2556649C (en) | Improvements in or relating to a method and apparatus for generating a mist | |

| US9010663B2 (en) | Method and apparatus for generating a mist | |

| US20020030122A1 (en) | Method and apparatus for generating water sprays, and methods of cleaning using water sprays | |

| JPH0439502A (ja) | 液体燃料燃焼装置 | |

| JPS58182010A (ja) | 液体燃料燃焼装置 | |

| JPH04353304A (ja) | 液体燃料燃焼装置 | |

| JPH04169704A (ja) | 液体燃料燃焼装置 | |

| TH83969A (th) | อุปกาณ์พ่นฝอยแรงตันต่ำที่มีอัตราเร็วสูง |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090319 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100825 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120113 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120124 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20120203 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120424 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20121030 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20130130 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20130131 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130227 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20130306 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130423 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130514 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5274250 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |