JP4933180B2 - 製袋包装機 - Google Patents

製袋包装機 Download PDFInfo

- Publication number

- JP4933180B2 JP4933180B2 JP2006194966A JP2006194966A JP4933180B2 JP 4933180 B2 JP4933180 B2 JP 4933180B2 JP 2006194966 A JP2006194966 A JP 2006194966A JP 2006194966 A JP2006194966 A JP 2006194966A JP 4933180 B2 JP4933180 B2 JP 4933180B2

- Authority

- JP

- Japan

- Prior art keywords

- vertical

- heat sealer

- packaging machine

- bag making

- seal portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/18—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using heated tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/02—Preparation of the material, in the area to be joined, prior to joining or welding

- B29C66/024—Thermal pre-treatments

- B29C66/0242—Heating, or preheating, e.g. drying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

- B29C66/1122—Single lap to lap joints, i.e. overlap joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/13—Single flanged joints; Fin-type joints; Single hem joints; Edge joints; Interpenetrating fingered joints; Other specific particular designs of joint cross-sections not provided for in groups B29C66/11 - B29C66/12

- B29C66/133—Fin-type joints, the parts to be joined being flexible

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/43—Joining a relatively small portion of the surface of said articles

- B29C66/431—Joining the articles to themselves

- B29C66/4312—Joining the articles to themselves for making flat seams in tubular or hollow articles, e.g. transversal seams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/43—Joining a relatively small portion of the surface of said articles

- B29C66/432—Joining a relatively small portion of the surface of said articles for making tubular articles or closed loops, e.g. by joining several sheets ; for making hollow articles or hollow preforms

- B29C66/4322—Joining a relatively small portion of the surface of said articles for making tubular articles or closed loops, e.g. by joining several sheets ; for making hollow articles or hollow preforms by joining a single sheet to itself

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/832—Reciprocating joining or pressing tools

- B29C66/8322—Joining or pressing tools reciprocating along one axis

- B29C66/83221—Joining or pressing tools reciprocating along one axis cooperating reciprocating tools, each tool reciprocating along one axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/84—Specific machine types or machines suitable for specific applications

- B29C66/849—Packaging machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/91—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux

- B29C66/914—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux

- B29C66/9141—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature

- B29C66/91421—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature of the joining tools

- B29C66/91423—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature of the joining tools using joining tools having different temperature zones or using several joining tools with different temperatures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C53/00—Shaping by bending, folding, twisting, straightening or flattening; Apparatus therefor

- B29C53/36—Bending and joining, e.g. for making hollow articles

- B29C53/38—Bending and joining, e.g. for making hollow articles by bending sheets or strips at right angles to the longitudinal axis of the article being formed and joining the edges

- B29C53/48—Bending and joining, e.g. for making hollow articles by bending sheets or strips at right angles to the longitudinal axis of the article being formed and joining the edges for articles of indefinite length, i.e. bending a strip progressively

- B29C53/50—Bending and joining, e.g. for making hollow articles by bending sheets or strips at right angles to the longitudinal axis of the article being formed and joining the edges for articles of indefinite length, i.e. bending a strip progressively using internal forming surfaces, e.g. mandrels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/91—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux

- B29C66/919—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux characterised by specific temperature, heat or thermal flux values or ranges

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Package Closures (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

Description

規制部材は、縦ヒートシーラの縦シール部が送り出される側の端部に直近して連結されているので、縦ヒートシーラ内において一部が残されている縦シール部及びそれに続く未シール部としての側縁部の状態に最も効果的に影響を及ぼし、曲成された包装材からの起立状態を維持することができる。また、縦ヒートシーラは固定側縦ヒートシーラ部と当該固定側縦ヒートシーラ部に対して接離可能な可動側縦ヒートシーラ部とを備えており、規制部材は固定側縦ヒートシーラ部に連結されているので、固定側縦ヒートシーラ部は製袋包装機の作動中に位置を変えず、製袋包装機の運転中において規制部材は縦シール部及びそれに続く未シール部としての側縁部に対して一定の相対位置に置くことができる。また、規制部材に備わる規制片を縦シール部の各側方にそれぞれに対向配置させているので、縦シール部の倒れようとする方向がいずれであってもその倒れを規制することができ、また、規制部材は規制片を開閉可能に作動させるアクチュエータ部を備えることにより、規制片を縦シール部から遠く後退させた開き位置と、縦シール部に接近させるが完全には閉じずに縦シール部の通過を許容する接近位置との間で開閉させることができ、更に、規制部材の製袋包装機へのセットの際、及び製袋包装機からセット解除の際に、アクチュエータ部によって規制片を開状態としているので、規制部材のセット時に既シール部としての縦シール部や未シール部としての重なった側縁部と干渉することがなく、また、包装機の運転中止中で、縦ヒートシーラ及び規制部材を製袋包装機へのセット状態から解除する場合には、規制部材を開くとともに製袋包装機から手前側に後退させ、その後、縦ヒートシーラを左右に開くなどすることにより、規制部材を縦シール部や側縁部と干渉しない位置に後退させた上で、縦ヒートシーラを製袋包装機へのセット状態から解除することができる。

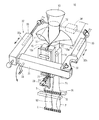

12 投入筒 13 ホッパ

14 ベルト送り機構 15 縦ヒートシーラ

15a 固定側ヒートシールバー 15b 可動側ヒートシールバー

15c 下側端部 16 横ヒートシーラ

20 規制部材 21 規制片

22 アクチュエータ部 23 フィンガ

30 縦軸 31 第1フレーム

32(32a,32b) 第2フレーム

33 ハンドル 34 モータ

35 ねじ伝動機構

50,52 縦シール部 51,51 側端縁

Fw ウェブ状包装材 Ft 筒状包装材

G 隙間

Claims (4)

- 間欠送りされる包装材を筒状包装材に成形するため前記包装材の走行両側の側縁部を合掌状の縦シール部にシールする縦ヒートシーラを備えた製袋包装機において、

前記縦ヒートシーラは、固定側縦ヒートシーラ部と当該固定側縦ヒートシーラ部に対して接離可能な可動側縦ヒートシーラ部とを備えており、

前記縦ヒートシーラから送り出された前記縦シール部の倒れを規制する規制部材が、前記縦ヒートシーラの前記縦シール部が送り出される側の端部に直近し且つ前記固定側縦ヒートシーラ部に連結されて配設されており、

前記規制部材は、前記縦シール部の各側方にそれぞれに対向配置された規制片と、前記規制片を開閉可能に作動させるアクチュエータ部とを備えており、

前記両規制片は、前記規制部材の前記製袋包装機へのセットの際、及び前記製袋包装機からセット解除の際に、前記アクチュエータ部によって開状態とされる

ことから成る製袋包装機。 - 前記規制部材を支持し且つ前記製袋包装機の正面に対して左端又は右端に設けられた縦軸の回りに回動して開閉する扉状の第1フレームと、前記第1フレームを前記製袋包装機の正面に対して進退自在に支持する第2フレームとを更に備えていることから成る請求項1に記載の製袋包装機。

- 前記両規制片は、少なくとも前記包装材の送り開始時からその後の前記縦ヒートシーラの作動開始時までに渡って、前記アクチュエータ部によって前記縦シール部に接近した接近位置に作動されることから成る請求項1に記載の製袋包装機。

- 前記両規制片は、ワイヤ状、ロッド状又はプレート状の形態を備えていることから成る請求項1に記載の製袋包装機。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006194966A JP4933180B2 (ja) | 2006-07-14 | 2006-07-14 | 製袋包装機 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006194966A JP4933180B2 (ja) | 2006-07-14 | 2006-07-14 | 製袋包装機 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008018997A JP2008018997A (ja) | 2008-01-31 |

| JP4933180B2 true JP4933180B2 (ja) | 2012-05-16 |

Family

ID=39075271

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006194966A Expired - Fee Related JP4933180B2 (ja) | 2006-07-14 | 2006-07-14 | 製袋包装機 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4933180B2 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6279369B2 (ja) * | 2014-03-19 | 2018-02-14 | 株式会社イシダ | 製袋包装機 |

| JP6742625B2 (ja) * | 2016-04-28 | 2020-08-19 | 株式会社イシダ | 包装装置 |

| JP6697513B2 (ja) * | 2018-07-12 | 2020-05-20 | 日本ハムファクトリー株式会社 | 包装材の製造装置および包装材の製造方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2548399B2 (ja) * | 1989-10-13 | 1996-10-30 | 松下電器産業株式会社 | バーナ |

| JP3468558B2 (ja) * | 1993-10-15 | 2003-11-17 | 株式会社川島製作所 | 縦形四方シール製袋充填包装機 |

| JP2003116479A (ja) * | 2001-10-16 | 2003-04-22 | Omori Mach Co Ltd | コンニャク用横型ピロー包装装置 |

| JP2004099174A (ja) * | 2002-08-23 | 2004-04-02 | Sanko Kikai Kk | 自動包装機械 |

| JP4373701B2 (ja) * | 2003-05-02 | 2009-11-25 | 株式会社川島製作所 | ガゼット包装機 |

| JP2005231722A (ja) * | 2004-02-23 | 2005-09-02 | Fuji Mach Co Ltd | 縦型製袋充填機における袋成形装置 |

| JP4644048B2 (ja) * | 2005-06-17 | 2011-03-02 | 株式会社東京自働機械製作所 | 縦形製袋充填機 |

-

2006

- 2006-07-14 JP JP2006194966A patent/JP4933180B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008018997A (ja) | 2008-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6363692B2 (en) | Method and apparatus for placing a product in a flexible recloseable container | |

| US4676051A (en) | Method and apparatus for forming, filling and sealing bags made from a continuous plastic sheet | |

| US6810641B2 (en) | Method and apparatus for forming double zipper bags | |

| JP6109594B2 (ja) | 袋包装体の耳折り装置を備えた横型包装機 | |

| WO2009154175A1 (ja) | 製袋包装機 | |

| JP5955542B2 (ja) | 横型製袋充填包装機 | |

| JP4773747B2 (ja) | ピロー包装機 | |

| JP6521605B2 (ja) | コーナーシール装置及び包装機 | |

| JP5941652B2 (ja) | 横型製袋充填包装機におけるピロー包装体の耳折り装置 | |

| JP4933180B2 (ja) | 製袋包装機 | |

| JP2002019737A (ja) | ヒートシール装置 | |

| JP6255178B2 (ja) | 包装機 | |

| JP4463060B2 (ja) | 角底袋のための縦形製袋充填包装機 | |

| JP4875877B2 (ja) | ヘム付き袋製袋装置 | |

| JP6914621B2 (ja) | 充填包装機および充填包装方法 | |

| JP6407823B2 (ja) | 角底袋用の縦型製袋充填包装機 | |

| US20080163589A1 (en) | Combined packaging machine | |

| JP7719497B2 (ja) | 製袋包装装置 | |

| JP5995303B2 (ja) | 製袋充填包装機 | |

| JP7070878B2 (ja) | ベルト隙間設定機能を備えた製袋充填包装機 | |

| JP4132940B2 (ja) | ガセット包装機 | |

| JP3969783B2 (ja) | 製袋充填包装機 | |

| JP7012300B2 (ja) | 包装機用ヒーターバー装置 | |

| US20240351301A1 (en) | Method and tubular bag machine for the continuous production of block-bottom bags | |

| JP5941651B2 (ja) | 横型製袋充填包装機及びそのエンドシール制御装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090710 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20111028 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111115 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120114 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120207 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120216 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4933180 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150224 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |