JP4698990B2 - 溶接機用電源装置 - Google Patents

溶接機用電源装置 Download PDFInfo

- Publication number

- JP4698990B2 JP4698990B2 JP2004266616A JP2004266616A JP4698990B2 JP 4698990 B2 JP4698990 B2 JP 4698990B2 JP 2004266616 A JP2004266616 A JP 2004266616A JP 2004266616 A JP2004266616 A JP 2004266616A JP 4698990 B2 JP4698990 B2 JP 4698990B2

- Authority

- JP

- Japan

- Prior art keywords

- welding

- current

- setting

- welding conditions

- power supply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/32—Accessories

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Arc Welding Control (AREA)

- Generation Of Surge Voltage And Current (AREA)

- Lining Or Joining Of Plastics Or The Like (AREA)

Description

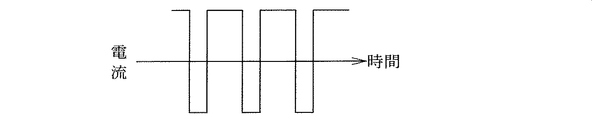

設定されたピーク電流:IP

ベース電流:IB=(1/4)×IP

初期電流:IS=(1/3)×IP

クレータ電流:IC=(1/3)×IP

アフターフロー時間:IP=5〜200Aで、5.0〜30.0秒の範囲で自動設定

ホット電流:20A(固定値)

パルス幅:ヂューティサイクル50%

プリフロー時間:0.1秒

アップスロープ時間:TU=(1/100)XIP

ダウンスロープ時間:TD=(2/100)XIP

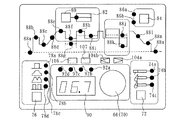

96 操作パネル

105 メモリ

106 記憶用押釦スイッチ

107 呼出し用押釦スイッチ

Claims (2)

- 商用交流電源が供給される電源入力端子と、

前記電源入力端子に接続された主電源スイッチと、

溶接プロセス及び各種のパラメータを含む溶接条件が供給され、供給された前記溶接条件に従った溶接出力を出力する溶接機用電源部と、

前記溶接条件を設定する操作パネル部と、

記憶手段と、

前記主電源スイッチがターンオフされたとき、前回設定されていた前記溶接条件である前溶接条件を前記記憶手段に記憶させ、前記主電源スイッチがターンオンされたとき、前記記憶手段から前記前溶接条件を読み出して前記電源部に供給する手段と、

前記操作パネル部によって設定された複数種類の前記溶接条件を登録溶接条件として前記記憶手段に記憶させ、前記登録溶接条件のうち1つを読み出して、前記溶接機用電源部に供給する手段とを、

具備し、

ピーク電流に対する溶接条件が設定されるとき、前記ピーク電流に対応するベース電流、初期電流、クレータ電流及びアフターフロー時間が自動的に設定され、ホットスタート電流、パルス幅、プリフロー時間、アップスロープ時間及びダウンスロープ時間が予め決定された固定値に設定される

溶接機用電源装置。 - 商用交流電源が供給される電源入力端子と、

前記電源入力端子に接続された主電源スイッチと、

溶接プロセス及び各種のパラメータを含む溶接条件が供給され、供給された前記溶接条件に従った溶接出力を出力する溶接機用電源部と、

前記溶接条件を設定する操作パネル部と、

記憶手段と、

前記主電源スイッチがターンオフされたとき、前回設定されていた前記溶接条件である前溶接条件を前記記憶手段に記憶させ、前記主電源スイッチがターンオンされたとき、前記記憶手段から前記前溶接条件を読み出して前記電源部に供給する手段と、

前記操作パネル部によって設定された複数種類の前記溶接条件を登録溶接条件として前記記憶手段に記憶させ、前記登録溶接条件のうち1つを読み出して、前記溶接機用電源部に供給する手段とを、具備し、ピーク電流に対する溶接条件が設定されるとき、前記ピーク電流に対応するベース電流、初期電流、クレータ電流、アフターフロー時間、アップスロープ時間及びダウンスロープ時間が自動的に設定され、ホットスタート電流、パルス幅及びプリフロー時間が、予め決定された固定値に設定される

溶接機用電源装置。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004266616A JP4698990B2 (ja) | 2004-09-14 | 2004-09-14 | 溶接機用電源装置 |

| TW094131411A TWI348410B (en) | 2004-09-14 | 2005-09-13 | Power supply apparatus for welder |

| CNB2005101096479A CN100528446C (zh) | 2004-09-14 | 2005-09-14 | 焊接机用电源装置 |

| US11/228,463 US7388171B2 (en) | 2004-09-14 | 2005-09-16 | Power supply apparatus for welder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004266616A JP4698990B2 (ja) | 2004-09-14 | 2004-09-14 | 溶接機用電源装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006082091A JP2006082091A (ja) | 2006-03-30 |

| JP2006082091A5 JP2006082091A5 (ja) | 2008-05-22 |

| JP4698990B2 true JP4698990B2 (ja) | 2011-06-08 |

Family

ID=36032789

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004266616A Expired - Lifetime JP4698990B2 (ja) | 2004-09-14 | 2004-09-14 | 溶接機用電源装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7388171B2 (ja) |

| JP (1) | JP4698990B2 (ja) |

| CN (1) | CN100528446C (ja) |

| TW (1) | TWI348410B (ja) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8604389B2 (en) * | 2006-02-06 | 2013-12-10 | Illinois Tool Works Inc. | Welding wire feed speed control system method |

| US8350182B2 (en) * | 2006-09-11 | 2013-01-08 | Hypertherm, Inc. | Portable autonomous material processing system |

| JP5145888B2 (ja) * | 2007-11-15 | 2013-02-20 | パナソニック株式会社 | 溶接装置 |

| US8592722B2 (en) * | 2008-11-03 | 2013-11-26 | Illinois Tool Works Inc. | Weld parameter interface |

| US8546726B2 (en) * | 2009-06-03 | 2013-10-01 | Illinois Tool Works Inc. | Systems and devices for determining weld cable inductance |

| US8455794B2 (en) * | 2009-06-03 | 2013-06-04 | Illinois Tool Works Inc. | Welding power supply with digital control of duty cycle |

| US8604384B2 (en) | 2009-06-18 | 2013-12-10 | Illinois Tool Works Inc. | System and methods for efficient provision of arc welding power source |

| US8618441B2 (en) * | 2010-10-05 | 2013-12-31 | Lincoln Global, Inc. | Output control for auto-reconnect welding/cutting equipment |

| US8835807B2 (en) * | 2010-10-27 | 2014-09-16 | Illinois Tool Works Inc. | Web configuration system for customizing welding systems |

| JP5756298B2 (ja) * | 2011-01-27 | 2015-07-29 | 株式会社ダイヘン | 溶接用電源装置及び溶接機 |

| JP5756297B2 (ja) * | 2011-01-27 | 2015-07-29 | 株式会社ダイヘン | 溶接用電源装置及び溶接機 |

| WO2012135066A1 (en) * | 2011-03-25 | 2012-10-04 | Illinois Tool Works Inc. | Welding systems with means for adjust and displaying ranges of parameters setting the latter; method of setting such welding parameters |

| US10817043B2 (en) * | 2011-07-26 | 2020-10-27 | Nvidia Corporation | System and method for entering and exiting sleep mode in a graphics subsystem |

| CN103286418B (zh) * | 2012-03-02 | 2016-03-02 | 深圳麦格米特电气股份有限公司 | 一种三相焊机电路 |

| US9539661B2 (en) | 2013-06-24 | 2017-01-10 | Illinois Tool Works Inc. | Welding power supply extended range system and method |

| US9584024B2 (en) | 2013-06-24 | 2017-02-28 | Illinois Tool Works Inc. | Metal working power supply converter system and method |

| JP6168701B2 (ja) * | 2014-03-04 | 2017-07-26 | 株式会社神戸製鋼所 | Tig溶接システム、プログラム及びtig溶接方法 |

| JP6584744B2 (ja) | 2014-03-13 | 2019-10-02 | 株式会社三社電機製作所 | 溶接機用電源装置 |

| US10486270B2 (en) | 2014-04-07 | 2019-11-26 | Illinois Tool Works Inc. | System for determining inductance of a power cable |

| JP5859065B2 (ja) * | 2014-06-04 | 2016-02-10 | 株式会社神戸製鋼所 | 溶接条件導出装置 |

| US10449614B2 (en) | 2014-12-18 | 2019-10-22 | Illinois Tool Works Inc. | Systems and methods for solid state sensor measurements of welding cables |

| US10682722B2 (en) | 2014-12-18 | 2020-06-16 | Illinois Tool Works Inc. | Systems and methods for measuring characteristics of a welding cable with a low power transceiver |

| US10734918B2 (en) | 2015-12-28 | 2020-08-04 | Illinois Tool Works Inc. | Systems and methods for efficient provision of arc welding power source |

| WO2019203279A1 (ja) * | 2018-04-20 | 2019-10-24 | パナソニックIpマネジメント株式会社 | 溶接機 |

| TWI733067B (zh) * | 2018-12-06 | 2021-07-11 | 優鋼機械股份有限公司 | 電子式扭力工具之設定方法 |

| EP3711891A1 (de) | 2019-03-18 | 2020-09-23 | Fronius International GmbH | Bedienpanel für ein schweissgerät ; schweissgerät mit einem solchen panel ; verfahren zum konfigurieren von schweissparameter eines solchen schweissgerätes |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3477005A (en) | 1967-01-26 | 1969-11-04 | Calvin T Weems | Remote amperage control drive for electric welders |

| US4163886A (en) * | 1976-09-16 | 1979-08-07 | Hitachi, Ltd. | Control apparatus for an automatic pipe welder |

| GB1549399A (en) | 1977-06-13 | 1979-08-08 | Safety Prod Ltd | Fastener |

| JPS5825871A (ja) * | 1981-08-10 | 1983-02-16 | Hitachi Seiko Ltd | ア−ク溶接機 |

| DE8134835U1 (de) | 1981-11-28 | 1982-05-06 | Basf Ag, 6700 Ludwigshafen | Behaelter fuer eine bandkassette |

| DE3513263A1 (de) | 1985-04-13 | 1986-10-23 | Agfa-Gevaert Ag, 5090 Leverkusen | Etui zur aufnahme einer magnetbandcassette |

| JPS63165946A (ja) * | 1986-12-27 | 1988-07-09 | Sharp Corp | デ−タ処理装置 |

| US4973821A (en) | 1989-04-03 | 1990-11-27 | Donald L. Martin | Control unit for welding apparatus having offset and tracking control features |

| KR930012128B1 (ko) * | 1989-08-28 | 1993-12-24 | 가부시기가이샤 도시바 | 재개기능을 가진 컴퓨터 유니트 |

| JP2877378B2 (ja) * | 1989-09-29 | 1999-03-31 | 株式会社東芝 | パーソナルコンピュータ |

| JPH04258375A (ja) * | 1991-02-05 | 1992-09-14 | Hitachi Seiko Ltd | アーク溶接電源 |

| US5278390A (en) * | 1993-03-18 | 1994-01-11 | The Lincoln Electric Company | System and method for controlling a welding process for an arc welder |

| GB2278501B (en) | 1993-05-18 | 1996-10-09 | John Frederick Harvey | 19" Rack mounted power distribution unit |

| JPH08137625A (ja) * | 1994-11-15 | 1996-05-31 | Fujitsu Ltd | ディスク制御装置 |

| JP3004889B2 (ja) * | 1995-03-06 | 2000-01-31 | 株式会社三社電機製作所 | 非消耗電極式アーク溶接機 |

| US5722887A (en) | 1995-08-17 | 1998-03-03 | Tamarack Technologies, Inc. | Automatic program ventilation control system |

| KR100434206B1 (ko) * | 1995-09-19 | 2004-09-13 | 가부시키가이샤 야스카와덴키 | 자동용접조건설정장치 |

| US6122162A (en) | 1996-06-28 | 2000-09-19 | Matsushita Electric Industrial Co., Ltd. | Portable device and concentrator therefor |

| JP3235777B2 (ja) | 1996-09-24 | 2001-12-04 | 株式会社三社電機製作所 | 電源装置 |

| US5745567A (en) | 1996-11-07 | 1998-04-28 | Ericsson, Inc. | Detent assembly for housing cover |

| US6121889A (en) | 1997-04-24 | 2000-09-19 | Intermatic Incorporated | In-wall electronic timer |

| JP3231694B2 (ja) | 1998-01-27 | 2001-11-26 | 株式会社三社電機製作所 | 溶接用電源装置 |

| JP2001259838A (ja) * | 2000-03-23 | 2001-09-25 | Daihen Corp | 交流パルスmig/mag溶接方法及び電源装置 |

| EP1145794B1 (en) | 2000-04-11 | 2005-11-16 | Matsushita Electric Industrial Co., Ltd. | Welding condition inputting equipment |

| JP2002331361A (ja) * | 2001-05-01 | 2002-11-19 | Obara Corp | 溶接制御装置のメモリ保護方法 |

| US6596972B1 (en) | 2001-07-17 | 2003-07-22 | Lincoln Global, Inc. | Welding accessory arrangement |

| JP2003136241A (ja) * | 2001-11-07 | 2003-05-14 | Sansha Electric Mfg Co Ltd | 溶接機用電源装置 |

| TW565485B (en) * | 2001-11-07 | 2003-12-11 | Sansha Electric Mfg Co Ltd | Power supply apparatus for welder |

-

2004

- 2004-09-14 JP JP2004266616A patent/JP4698990B2/ja not_active Expired - Lifetime

-

2005

- 2005-09-13 TW TW094131411A patent/TWI348410B/zh not_active IP Right Cessation

- 2005-09-14 CN CNB2005101096479A patent/CN100528446C/zh not_active Expired - Fee Related

- 2005-09-16 US US11/228,463 patent/US7388171B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN1748923A (zh) | 2006-03-22 |

| US20060054610A1 (en) | 2006-03-16 |

| US7388171B2 (en) | 2008-06-17 |

| TW200615077A (en) | 2006-05-16 |

| TWI348410B (en) | 2011-09-11 |

| CN100528446C (zh) | 2009-08-19 |

| JP2006082091A (ja) | 2006-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4698990B2 (ja) | 溶接機用電源装置 | |

| KR100281315B1 (ko) | 용접용 전원장치 및 그 제조방법 | |

| TW565485B (en) | Power supply apparatus for welder | |

| CA2475314C (en) | Method and apparatus of electronic selection of an output mode of a welding power source | |

| JP4641137B2 (ja) | 溶接機 | |

| JP4980297B2 (ja) | 溶接機用電源装置 | |

| CN106607640A (zh) | 用于交流焊接的飞溅得到减少的焊接系统 | |

| TW200824248A (en) | Power supply apparatus for welder | |

| KR100477570B1 (ko) | 용접기용 전원장치 | |

| JP4558227B2 (ja) | 溶接電源装置 | |

| JPH08300156A (ja) | 交流プラズマアーク溶接機 | |

| JP3607648B2 (ja) | 溶接用電源装置の製造方法 | |

| KR200287067Y1 (ko) | 가우징 겸용 인버터 용접기 | |

| KR101437827B1 (ko) | 다용도 용접기 및 이를 이용한 다용도 용접방법 | |

| US8664566B2 (en) | Arc welding apparatus and method | |

| JP2592650B2 (ja) | 抵抗溶接における通電制御方法及び装置 | |

| KR100891385B1 (ko) | 귀금속용 전기 용접기 | |

| KR20160092578A (ko) | 하이브리드 용접장치 | |

| CN109746548A (zh) | 非自耗电极式电弧焊接方法 | |

| JPH01197068A (ja) | 溶接アーク起動装置 | |

| JP2003001417A (ja) | 加工条件表示装置を備えたアーク加工機及びアーク溶接機の溶接条件表示装置 | |

| JP2002096166A (ja) | アーク溶接装置 | |

| JP2003019556A (ja) | アーク溶接機の溶接条件表示機能を備えたリモコン装置 | |

| Forgács et al. | Power stages and microcontroller based timing of a multi-function power converter for welding | |

| JPH01178369A (ja) | 溶接アーク起動装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070712 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080407 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20091127 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100831 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101124 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110120 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20110301 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110302 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4698990 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |