JP4635672B2 - 溶融金属の精錬方法 - Google Patents

溶融金属の精錬方法 Download PDFInfo

- Publication number

- JP4635672B2 JP4635672B2 JP2005085220A JP2005085220A JP4635672B2 JP 4635672 B2 JP4635672 B2 JP 4635672B2 JP 2005085220 A JP2005085220 A JP 2005085220A JP 2005085220 A JP2005085220 A JP 2005085220A JP 4635672 B2 JP4635672 B2 JP 4635672B2

- Authority

- JP

- Japan

- Prior art keywords

- desulfurization

- hot metal

- refining

- molten metal

- agent

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Treatment Of Steel In Its Molten State (AREA)

- Refinement Of Pig-Iron, Manufacture Of Cast Iron, And Steel Manufacture Other Than In Revolving Furnaces (AREA)

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

Description

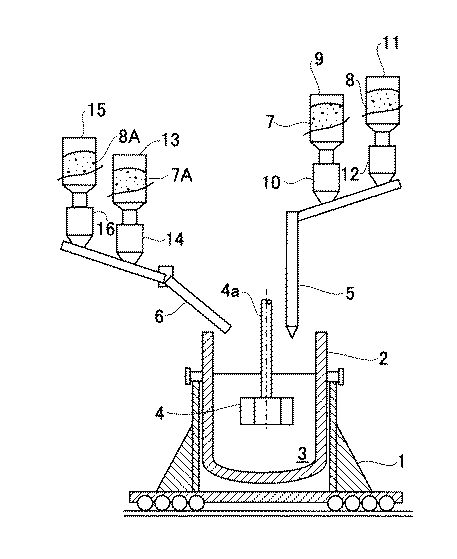

2 溶銑鍋

3 溶銑

4 攪拌羽根

5 上吹きランス

6 投入口

7 脱硫剤

8 脱酸源

Claims (5)

- 攪拌子を有する機械式攪拌装置を用いて溶融金属を精錬するに際し、前記攪拌子の回転数R(1/秒)に対する角速度の変化振動数F(1/秒)の比である変速振動数比F/Rを1以上として、前記攪拌子の回転角速度を精錬処理中に周期的に変更して溶融金属を攪拌することを特徴とする、溶融金属の精錬方法。

- 前記攪拌子の回転制御を、インバーターにより行うことを特徴とする、請求項1に記載の溶融金属の精錬方法。

- 前記攪拌子の回転制御を、カムを用いて機械的に行うことを特徴とする、請求項1に記載の溶融金属の精錬方法。

- 溶融金属よりも低密度の精錬剤を添加することを特徴とする、請求項1ないし請求項3の何れか1つに記載の溶融金属の精錬方法。

- 前記溶融金属が溶銑であり、前記精錬が脱硫処理であることを特徴とする、請求項1ないし請求項4の何れか1つに記載の溶融金属の精錬方法。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005085220A JP4635672B2 (ja) | 2005-03-24 | 2005-03-24 | 溶融金属の精錬方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005085220A JP4635672B2 (ja) | 2005-03-24 | 2005-03-24 | 溶融金属の精錬方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006265625A JP2006265625A (ja) | 2006-10-05 |

| JP4635672B2 true JP4635672B2 (ja) | 2011-02-23 |

Family

ID=37201894

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005085220A Expired - Fee Related JP4635672B2 (ja) | 2005-03-24 | 2005-03-24 | 溶融金属の精錬方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4635672B2 (ja) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5151112B2 (ja) * | 2006-10-20 | 2013-02-27 | Jfeスチール株式会社 | 溶銑の脱硫処理方法 |

| JP4844679B2 (ja) * | 2009-03-11 | 2011-12-28 | Jfeスチール株式会社 | 溶銑の脱硫処理方法 |

| JP5195737B2 (ja) * | 2009-12-24 | 2013-05-15 | Jfeスチール株式会社 | 溶銑の脱硫方法 |

| JP5987633B2 (ja) * | 2011-10-28 | 2016-09-07 | Jfeスチール株式会社 | インペラ回転軸の断面形状決定方法および溶銑撹拌装置用インペラ回転軸の製造方法 |

| BR112015001168B1 (pt) * | 2012-07-20 | 2019-09-24 | Jfe Steel Corporation | Método de tratamento preliminar de ferro gusa líquido e agitador para tratamento preliminar de ferro gusa líquido |

| CN117685781A (zh) * | 2023-12-13 | 2024-03-12 | 宜春赣锋锂业有限公司 | 一种锂硼合金合成装置及方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5834126A (ja) * | 1981-08-25 | 1983-02-28 | Nippon Steel Corp | 溶鋼の脱ガス・脱介在物方法 |

| JPS61166908A (ja) * | 1985-01-17 | 1986-07-28 | Nippon Steel Corp | 溶銑の脱硫方法 |

| JPS62109909A (ja) * | 1985-11-08 | 1987-05-21 | Kawasaki Steel Corp | 溶融金属の強撹拌精錬法 |

| JP4170646B2 (ja) * | 2002-03-25 | 2008-10-22 | 株式会社神戸製鋼所 | 溶銑の攪拌式成分調整装置 |

-

2005

- 2005-03-24 JP JP2005085220A patent/JP4635672B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006265625A (ja) | 2006-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102471814B (zh) | 铁水的脱硫方法 | |

| JP4845078B2 (ja) | 溶銑の脱硫方法 | |

| JP5862738B2 (ja) | 溶銑の脱硫処理用精錬容器 | |

| JP6061053B2 (ja) | 溶銑の脱硫方法および脱硫剤 | |

| JP5177170B2 (ja) | 溶銑の脱硫方法 | |

| JP5195737B2 (ja) | 溶銑の脱硫方法 | |

| JP4635672B2 (ja) | 溶融金属の精錬方法 | |

| JP5130663B2 (ja) | 溶融鉄の精錬方法 | |

| JP4998676B2 (ja) | インペラーを用いた溶融金属の攪拌方法 | |

| JP5045031B2 (ja) | 溶銑の脱硫剤及び脱硫処理方法 | |

| JP4715369B2 (ja) | 溶銑の脱硫処理方法 | |

| JP5066923B2 (ja) | 溶銑の脱硫処理方法 | |

| JP2014177674A (ja) | 精錬用攪拌体及び溶融鉄の精錬方法 | |

| JP2015218390A (ja) | 機械式攪拌とガス攪拌とを併用した溶銑の脱硫方法 | |

| JP5446300B2 (ja) | 溶銑の脱硫処理方法 | |

| JP2010116612A (ja) | 溶銑の脱硫方法 | |

| JP4984928B2 (ja) | 溶銑の脱硫方法 | |

| JP2007247045A (ja) | 溶銑の脱硫方法 | |

| JP4998691B2 (ja) | 金属帯被覆脱硫用ワイヤー及び溶鉄の脱硫処理方法 | |

| JP7548256B2 (ja) | 撹拌羽根及び溶銑の脱硫方法 | |

| JP5418248B2 (ja) | 溶銑の脱硫方法 | |

| JP5790230B2 (ja) | 溶銑の脱硫方法 | |

| JP6238019B2 (ja) | 復硫の少ない溶銑脱硫方法 | |

| TWI564396B (zh) | Method of preventing backwashing of molten iron after desulfurization | |

| JP2017133058A (ja) | 溶銑の脱硫方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20060921 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071228 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100723 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100803 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100928 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101026 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101108 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131203 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |