JP4474190B2 - 回転部材を装着する方法及び装置 - Google Patents

回転部材を装着する方法及び装置 Download PDFInfo

- Publication number

- JP4474190B2 JP4474190B2 JP2004120950A JP2004120950A JP4474190B2 JP 4474190 B2 JP4474190 B2 JP 4474190B2 JP 2004120950 A JP2004120950 A JP 2004120950A JP 2004120950 A JP2004120950 A JP 2004120950A JP 4474190 B2 JP4474190 B2 JP 4474190B2

- Authority

- JP

- Japan

- Prior art keywords

- shaft

- ring

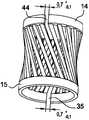

- hyperboloid

- curvature

- hourglass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title description 17

- 238000003780 insertion Methods 0.000 claims description 12

- 230000037431 insertion Effects 0.000 claims description 12

- 230000020169 heat generation Effects 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 description 14

- 238000000465 moulding Methods 0.000 description 5

- 210000000481 breast Anatomy 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 238000007373 indentation Methods 0.000 description 2

- 238000009607 mammography Methods 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 238000004846 x-ray emission Methods 0.000 description 2

- 125000002066 L-histidyl group Chemical group [H]N1C([H])=NC(C([H])([H])[C@](C(=O)[*])([H])N([H])[H])=C1[H] 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000001739 density measurement Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000003698 laser cutting Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J35/00—X-ray tubes

- H01J35/02—Details

- H01J35/04—Electrodes ; Mutual position thereof; Constructional adaptations therefor

- H01J35/08—Anodes; Anti cathodes

- H01J35/10—Rotary anodes; Arrangements for rotating anodes; Cooling rotary anodes

- H01J35/101—Arrangements for rotating anodes, e.g. supporting means, means for greasing, means for sealing the axle or means for shielding or protecting the driving

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C17/00—Sliding-contact bearings for exclusively rotary movement

- F16C17/02—Sliding-contact bearings for exclusively rotary movement for radial load only

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C27/00—Elastic or yielding bearings or bearing supports, for exclusively rotary movement

- F16C27/02—Sliding-contact bearings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J9/00—Apparatus or processes specially adapted for the manufacture, installation, removal, maintenance of electric discharge tubes, discharge lamps, or parts thereof; Recovery of material from discharge tubes or lamps

- H01J9/02—Manufacture of electrodes or electrode systems

- H01J9/18—Assembling together the component parts of electrode systems

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2235/00—X-ray tubes

- H01J2235/10—Drive means for anode (target) substrate

- H01J2235/1046—Bearings and bearing contact surfaces

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2235/00—X-ray tubes

- H01J2235/10—Drive means for anode (target) substrate

- H01J2235/1046—Bearings and bearing contact surfaces

- H01J2235/1053—Retainers or races

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/70—Interfitted members

- Y10T403/7047—Radially interposed shim or bushing

- Y10T403/7061—Resilient

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Rolls And Other Rotary Bodies (AREA)

- Sliding-Contact Bearings (AREA)

- Vibration Prevention Devices (AREA)

- Apparatus For Radiation Diagnosis (AREA)

- Manufacture Of Motors, Generators (AREA)

- X-Ray Techniques (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0350113A FR2853990B1 (fr) | 2003-04-17 | 2003-04-17 | Dispositif de montage d'une anode tournante d'un tube a rayons x et procede de fabrication de ce dispositif |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004316919A JP2004316919A (ja) | 2004-11-11 |

| JP2004316919A5 JP2004316919A5 (enExample) | 2009-07-02 |

| JP4474190B2 true JP4474190B2 (ja) | 2010-06-02 |

Family

ID=33042059

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004120950A Expired - Fee Related JP4474190B2 (ja) | 2003-04-17 | 2004-04-16 | 回転部材を装着する方法及び装置 |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US7149281B2 (enExample) |

| JP (1) | JP4474190B2 (enExample) |

| FR (1) | FR2853990B1 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB0308957D0 (en) | 2003-04-17 | 2003-05-28 | Lillishall Plastics And Engine | Tolerance ring assembly |

| DE102005018369A1 (de) * | 2005-03-30 | 2006-10-05 | Hofmann Mess- Und Auswuchttechnik Gmbh & Co. Kg | Drehanoden-Röntgenröhre |

| DE102006017305A1 (de) * | 2006-04-12 | 2007-10-18 | Gerd Eisenblätter Gmbh | Befestigungssystem, Befestigungsadapter und Befestigungsverfahren |

| US7850389B2 (en) * | 2006-08-15 | 2010-12-14 | Intriplex Technologies, Inc. | Tolerance ring having various end tab designs to prevent interlocking |

| US8233242B2 (en) * | 2007-04-24 | 2012-07-31 | Saint-Gobain Performance Plastics Rencol Limited | Tolerance ring with overlapping layers |

| DE202007012052U1 (de) * | 2007-08-29 | 2009-01-08 | Oerlikon Leybold Vacuum Gmbh | Turbomolekularpumpe |

| US8414348B2 (en) * | 2009-02-13 | 2013-04-09 | Flambeau, Inc. | Reconfigurable rotatable performance device |

| US8968049B2 (en) | 2011-03-31 | 2015-03-03 | Flambeau, Inc. | Spacer for an adjustable width rotatable performance device |

| US9873065B2 (en) | 2014-07-15 | 2018-01-23 | 106 Labs, L.L.C. | Hyperboloid device with sliding elements |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USRE24783E (en) * | 1960-02-16 | Apparatus and method for making spirally corrugated metal tubes | ||

| US246846A (en) * | 1881-09-06 | wilde | ||

| US1013769A (en) * | 1909-12-01 | 1912-01-02 | Broderick Haskell | Machine for making spiral latticed poles or the like. |

| US1554781A (en) * | 1923-10-10 | 1925-09-22 | Blecker Lipman | Diabolo |

| US1833145A (en) * | 1925-07-07 | 1931-11-24 | Wilhelm Harold Frederick | Connecter |

| US2569850A (en) * | 1947-03-08 | 1951-10-02 | Atf Inc | Crimping device |

| US2640168A (en) * | 1950-11-09 | 1953-05-26 | Machlett Lab Inc | Electron tube |

| US2785453A (en) * | 1952-06-11 | 1957-03-19 | Alan W Wentz | Separable fastener structure |

| US3270697A (en) * | 1962-10-02 | 1966-09-06 | B & W Inc | Method for forming a pipe centering device |

| US3271053A (en) * | 1964-07-02 | 1966-09-06 | Kurachi Hisaharu | Means for coupling a hose to a pipe |

| US3394972A (en) * | 1965-05-21 | 1968-07-30 | Kaman Corp | Journal bearing |

| FR1470088A (fr) * | 1967-04-21 | 1967-02-17 | Torrington Mfg Co | Procédé de fabrication de cages pour roulements |

| US3902772A (en) * | 1973-06-14 | 1975-09-02 | Schaeffler Ohg Industriewerk | Bearing cage |

| US4130926A (en) * | 1977-02-17 | 1978-12-26 | Ceraver S.A. | Method of producing a rod anchoring structure |

| US4203312A (en) * | 1977-09-29 | 1980-05-20 | Spiral Tubing Corporation | Corrugated tubing with variable depth corrugations and method of making the same |

| NL7713634A (nl) * | 1977-12-09 | 1979-06-12 | Philips Nv | Roentgenbuis met draaianode. |

| US4286894A (en) * | 1979-03-21 | 1981-09-01 | Roller Bearing Company Of America | Tolerance rings |

| FR2506873B1 (fr) * | 1981-06-01 | 1986-08-22 | Glaenzer Spicer Sa | Joint a tripode a retenue axiale |

| DE3151229A1 (de) * | 1981-12-23 | 1983-06-30 | Siemens AG, 1000 Berlin und 8000 München | Verfahren und vorrichtung zur optimierung der emission einer roentgenroehre |

| US4474493A (en) * | 1982-09-09 | 1984-10-02 | Modular Systems, Inc. | Dowel fastener and joints including same |

| CS232586B1 (en) * | 1983-03-31 | 1985-02-14 | Frantisek Starek | Seating of rotating parts of a x-ray tube's anode |

| DE9017291U1 (de) * | 1990-01-11 | 1991-03-14 | Siemens AG, 8000 München | Röntgenröhre |

| FR2668359B1 (fr) * | 1990-10-24 | 1998-02-20 | Gen Electric Cgr | Mammographe muni d'un porte-aiguille perfectionne. |

| FR2717619B1 (fr) * | 1994-03-18 | 1996-04-26 | Ge Medical Syst Sa | Tube à rayons X à spectre de raies d'intensité relative variable. |

| JP3399513B2 (ja) * | 1999-08-10 | 2003-04-21 | 日本電気株式会社 | ヘリカルアンテナおよびその製造方法 |

| FR2846784B1 (fr) * | 2002-10-30 | 2005-02-11 | Ge Med Sys Global Tech Co Llc | Ensemble de palier pour le montage a rotation d'une anode rotative d'un dispositif d'emission de rayons x et dispositif d'emission de rayon x equipe d'un tel ensemble. |

-

2003

- 2003-04-17 FR FR0350113A patent/FR2853990B1/fr not_active Expired - Fee Related

-

2004

- 2004-04-15 US US10/825,512 patent/US7149281B2/en not_active Expired - Fee Related

- 2004-04-16 JP JP2004120950A patent/JP4474190B2/ja not_active Expired - Fee Related

-

2006

- 2006-10-30 US US11/589,467 patent/US20070101794A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| US20070101794A1 (en) | 2007-05-10 |

| US7149281B2 (en) | 2006-12-12 |

| JP2004316919A (ja) | 2004-11-11 |

| FR2853990A1 (fr) | 2004-10-22 |

| FR2853990B1 (fr) | 2006-12-29 |

| US20040240615A1 (en) | 2004-12-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4474190B2 (ja) | 回転部材を装着する方法及び装置 | |

| BR112014018852B1 (pt) | Motor e método de redução de vibração para um motor | |

| JP6895200B2 (ja) | 圧電モータ、圧電モータ用の摺動材、及び注入機器 | |

| CN101903764B (zh) | 转子和x射线ct扫描器 | |

| US20070188027A1 (en) | Motor | |

| JP2001357807A (ja) | X線管において異種金属を接合するための結合部材を有するコンプライアント継手 | |

| CN107567318B (zh) | 具有筒的牙科和/或外科器械及相应的筒 | |

| JP2004316919A5 (enExample) | ||

| JP2006258286A (ja) | 振動低減ブラケット | |

| WO2013175329A1 (en) | Balancing in an x-ray tube | |

| CN118352210B (zh) | 用于ct球管的管芯组件 | |

| JPH11319711A (ja) | 振動発生装置および前記振動発生装置への分銅の取付方法 | |

| JP6318245B2 (ja) | 熱膨張に適合する回転陽極の装着 | |

| JP4807730B2 (ja) | 曲げ疲労試験機及び曲げ疲労試験方法 | |

| JPH1080080A (ja) | ブラシレスモータ | |

| JPS6019619B2 (ja) | X線管用回転陽極 | |

| JP3267419B2 (ja) | 回転電機 | |

| JP2559145Y2 (ja) | 超音波振動装置 | |

| AU2020203260B2 (en) | Damping means of an electric motor of an airflow generating apparatus and said apparatus comprising the damping means | |

| JP2000057982A (ja) | 回転陽極型x線管およびその製造方法 | |

| JP2019036498A (ja) | 回転陽極型のx線管 | |

| JPH07336941A (ja) | 振動モータ、振動モータが組み込まれるケーシング、並びに振動モータが組み込まれる振動発生装置 | |

| CN106469959B (zh) | 马达及其轴管组件 | |

| JP2002203502A (ja) | 回転陽極型x線管およびその製造方法 | |

| JPH10243605A (ja) | 軸固定型モータ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070323 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070323 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090518 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091027 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100120 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100120 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100120 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100216 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100308 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130312 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4474190 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130312 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140312 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |