JP4172935B2 - 表示装置をもつ継手 - Google Patents

表示装置をもつ継手 Download PDFInfo

- Publication number

- JP4172935B2 JP4172935B2 JP2001523562A JP2001523562A JP4172935B2 JP 4172935 B2 JP4172935 B2 JP 4172935B2 JP 2001523562 A JP2001523562 A JP 2001523562A JP 2001523562 A JP2001523562 A JP 2001523562A JP 4172935 B2 JP4172935 B2 JP 4172935B2

- Authority

- JP

- Japan

- Prior art keywords

- nut

- joint

- coupling

- marking

- ferrule

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000008878 coupling Effects 0.000 claims abstract description 42

- 238000010168 coupling process Methods 0.000 claims abstract description 42

- 238000005859 coupling reaction Methods 0.000 claims abstract description 42

- 230000000007 visual effect Effects 0.000 claims description 14

- 239000003550 marker Substances 0.000 claims description 3

- 238000006073 displacement reaction Methods 0.000 abstract description 18

- 230000004323 axial length Effects 0.000 abstract description 5

- 238000004040 coloring Methods 0.000 abstract description 3

- 238000007788 roughening Methods 0.000 abstract description 3

- 230000000712 assembly Effects 0.000 abstract 1

- 238000000429 assembly Methods 0.000 abstract 1

- 238000000034 method Methods 0.000 description 18

- 230000006835 compression Effects 0.000 description 5

- 238000007906 compression Methods 0.000 description 5

- 238000013461 design Methods 0.000 description 4

- 230000008901 benefit Effects 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 230000009471 action Effects 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 238000010329 laser etching Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 239000002390 adhesive tape Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000010422 painting Methods 0.000 description 1

- 244000144985 peep Species 0.000 description 1

- 239000011295 pitch Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000009987 spinning Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

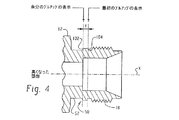

- F16L19/00—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts

- F16L19/06—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts in which radial clamping is obtained by wedging action on non-deformed pipe ends

- F16L19/065—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts in which radial clamping is obtained by wedging action on non-deformed pipe ends the wedging action being effected by means of a ring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L19/00—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts

- F16L19/08—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts with metal rings which bite into the wall of the pipe

- F16L19/10—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts with metal rings which bite into the wall of the pipe the profile of the ring being altered

- F16L19/103—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts with metal rings which bite into the wall of the pipe the profile of the ring being altered with more than one ring per pipe end being used

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L19/00—Joints in which sealing surfaces are pressed together by means of a member, e.g. a swivel nut, screwed on, or into, one of the joint parts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

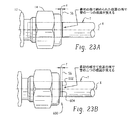

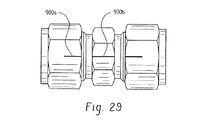

- F16L2201/00—Special arrangements for pipe couplings

- F16L2201/10—Indicators for correct coupling

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Joints With Pressure Members (AREA)

- Mutual Connection Of Rods And Tubes (AREA)

- External Artificial Organs (AREA)

- Joints That Cut Off Fluids, And Hose Joints (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

- Fittings On The Vehicle Exterior For Carrying Loads, And Devices For Holding Or Mounting Articles (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/395,386 US6279242B1 (en) | 1999-09-13 | 1999-09-13 | Intrinsic gauging for tube fittings |

| US09/395,386 | 1999-09-13 | ||

| US15996599P | 1999-10-18 | 1999-10-18 | |

| US60/159,965 | 1999-10-18 | ||

| PCT/US2000/024900 WO2001020214A1 (en) | 1999-09-13 | 2000-09-12 | Tube fitting with indicating means |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2003509645A JP2003509645A (ja) | 2003-03-11 |

| JP2003509645A5 JP2003509645A5 (enExample) | 2005-12-22 |

| JP4172935B2 true JP4172935B2 (ja) | 2008-10-29 |

Family

ID=26856488

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001523562A Expired - Fee Related JP4172935B2 (ja) | 1999-09-13 | 2000-09-12 | 表示装置をもつ継手 |

Country Status (12)

| Country | Link |

|---|---|

| EP (1) | EP1216377B1 (enExample) |

| JP (1) | JP4172935B2 (enExample) |

| KR (1) | KR20020039671A (enExample) |

| CN (1) | CN1192178C (enExample) |

| AT (1) | ATE360171T1 (enExample) |

| AU (2) | AU778387B2 (enExample) |

| CA (2) | CA2384835C (enExample) |

| DE (1) | DE60034466T2 (enExample) |

| IL (1) | IL148632A0 (enExample) |

| MX (1) | MXPA02002878A (enExample) |

| TW (1) | TW552369B (enExample) |

| WO (1) | WO2001020214A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101935616B1 (ko) * | 2010-07-09 | 2019-01-04 | 스와겔로크 컴패니 | 가요성 토크 칼라를 구비한 도관 이음쇠 |

| US10774961B2 (en) | 2014-06-04 | 2020-09-15 | Parker-Hannifin Corporation | Compression fitting with torque nut |

Families Citing this family (51)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6279242B1 (en) | 1999-09-13 | 2001-08-28 | Swagelok Company | Intrinsic gauging for tube fittings |

| US7194817B2 (en) | 1999-09-13 | 2007-03-27 | Swagelok Company | Intrinsic gauging for tube fittings |

| US6640457B2 (en) * | 1999-09-13 | 2003-11-04 | Swagelok Company | Intrinsic gauging for tube fittings |

| JP2004526911A (ja) | 2001-02-06 | 2004-09-02 | スウエイジロク・カンパニー | 分離可能な管グリップ装置を備えた管継手 |

| US7066496B2 (en) | 2001-02-06 | 2006-06-27 | Swagelok Company | Fitting with separable gripping device for pipe and tube |

| TW530142B (en) | 2001-02-06 | 2003-05-01 | Swagelok Co | Tube fitting for stainless steel tubing |

| US7407196B2 (en) | 2003-08-06 | 2008-08-05 | Swagelok Company | Tube fitting with separable tube gripping device |

| US7416225B2 (en) | 2001-02-06 | 2008-08-26 | Swagelok Company | Fitting for metal pipe and tubing |

| AUPR447001A0 (en) | 2001-04-19 | 2001-05-17 | Philmac Pty Ltd | Pipe coupling |

| ATE387980T1 (de) | 2002-07-17 | 2008-03-15 | Shell Int Research | Verfahren zur verbindung von expandierbaren rohren |

| EP1532474B1 (en) | 2002-07-18 | 2012-08-15 | Shell Internationale Research Maatschappij B.V. | Marking of pipe joints |

| US7774917B2 (en) | 2003-07-17 | 2010-08-17 | Tubefuse Applications B.V. | Forge welding tubulars |

| JP2005036947A (ja) * | 2003-07-18 | 2005-02-10 | Ihara Science Corp | 管継手 |

| US7497483B2 (en) | 2004-04-22 | 2009-03-03 | Swagelok Company | Fitting for tube and pipe with cartridge |

| TW200602577A (en) * | 2004-04-22 | 2006-01-16 | Swagelok Co | Fitting for tube and pipe |

| FR2872561B1 (fr) * | 2004-06-30 | 2008-02-08 | Chuchu Decayeux Soc Par Action | Dispositif de raccord d'un tuyau, procede de montage associe et dispositif de tirette |

| US20080309076A1 (en) * | 2005-02-25 | 2008-12-18 | Waters Investments Limited | Device and Method for a Fluid-Tight Connection |

| JP5342880B2 (ja) | 2006-01-13 | 2013-11-13 | スウエイジロク・カンパニー | 適合された係合面を有する継手 |

| WO2008051500A1 (en) * | 2006-10-23 | 2008-05-02 | Swagelok Company | Installation arrangement for a conduct gripping device |

| JP2008286338A (ja) * | 2007-05-18 | 2008-11-27 | Daikin Ind Ltd | 食い込み式管継手、冷凍装置及び温水装置 |

| JP5457348B2 (ja) * | 2007-07-27 | 2014-04-02 | スウエイジロク・カンパニー | 中心合わせを伴う管またはパイプ継手のための先細ナット |

| DE102007048948B4 (de) * | 2007-10-12 | 2014-11-27 | Dr. Ing. H.C. F. Porsche Aktiengesellschaft | Verbindungsanordnung |

| DE112009001330T5 (de) | 2008-06-02 | 2011-04-14 | Swagelok Co., Solon | Vorrichtung und Verfahren zum Beurteilen eines Passstückzusammenbaus |

| US10215315B2 (en) | 2008-09-05 | 2019-02-26 | Parker-Hannifin Corporation | Tube compression fitting and flared fitting used with connection body and method of making same |

| US7837238B2 (en) * | 2009-01-12 | 2010-11-23 | Krausz Industries Development Ltd | Pipe grip ring |

| EP3054204B1 (en) * | 2009-02-20 | 2017-11-22 | Swagelok Company | Fitting assembly evaluating apparatus |

| CN105065810B (zh) | 2009-02-20 | 2018-06-12 | 斯瓦戈洛克公司 | 具有扭矩箍的导管配件以及用于拉近导管配件的方法 |

| US8876170B2 (en) | 2009-04-27 | 2014-11-04 | Swagelok Company | Tapered drive nut for conduit fitting |

| CA2779014C (en) * | 2009-11-20 | 2014-07-22 | Alcoa Inc. | Lockwireless anti-rotation fitting |

| KR100987334B1 (ko) * | 2010-02-11 | 2010-10-12 | 주식회사 비엠티 | 조임량 확인이 가능한 튜브 피팅 구조 |

| US8569070B2 (en) * | 2010-07-16 | 2013-10-29 | Idex Health & Science Llc | Connection assembly for ultra high pressure liquid chromatography |

| US8523503B2 (en) * | 2010-07-30 | 2013-09-03 | Nuovo Pignone, S.P.A. | Threaded joint and method of sealing a threaded joint |

| KR20140060880A (ko) * | 2012-11-13 | 2014-05-21 | 디케이락 주식회사 | 결합돌기와 첵 마아킹이 형성된 튜브체결구 |

| KR101338185B1 (ko) * | 2012-12-10 | 2013-12-09 | 주식회사 새롬테크 | 수밀구조를 갖는 파이프 이음구 |

| KR101372931B1 (ko) * | 2013-06-12 | 2014-03-12 | 주식회사 유니락 | 파이프 피팅 장치 |

| EP3140580B1 (en) | 2014-05-09 | 2020-03-25 | Swagelok Company | Conduit fitting with components adapted for facilitating assembly |

| JP6410465B2 (ja) * | 2014-05-14 | 2018-10-24 | 株式会社Kvk | 管継手 |

| WO2016144723A1 (en) * | 2015-03-06 | 2016-09-15 | Swagelok Company | Systems and methods for strain detection in a coupling |

| US10584814B2 (en) | 2016-03-23 | 2020-03-10 | Swagelok Company | Conduit fitting with stroke resisting features |

| US10508762B2 (en) * | 2017-03-20 | 2019-12-17 | Brian B. Kim | Assembly of a flexible tube and a fitting body and a method thereof |

| JP6561340B2 (ja) * | 2017-06-13 | 2019-08-21 | 株式会社トヨックス | 管継手 |

| CN108317153B (zh) * | 2017-10-24 | 2019-12-10 | 喜利得股份公司 | 具有接合指示件的紧固件联接件 |

| PL3951229T3 (pl) * | 2019-03-27 | 2024-07-01 | Nippon Steel Corporation | Połączenie gwintowe dla rury stalowej |

| CN114222881B (zh) * | 2019-06-13 | 2024-03-08 | 帕克-汉尼芬公司 | 用于将流体输送管道互连的螺纹联接组件 |

| CN111140400B (zh) * | 2019-12-23 | 2021-10-22 | 北京航空航天大学 | 一种电推进发动机的阳极进气组件 |

| CN111102408A (zh) * | 2019-12-23 | 2020-05-05 | 北京航空航天大学 | 一种电推进发动机的阴极管路绝缘密封接头 |

| US11435328B2 (en) * | 2020-02-28 | 2022-09-06 | Agilent Technologies, Inc. | Unions and couplers |

| CN111322470B (zh) * | 2020-03-13 | 2021-09-14 | 浙江双森金属科技股份有限公司 | 一种锁扩式管道连接件 |

| WO2023064726A1 (en) * | 2021-10-15 | 2023-04-20 | Reliance Worldwide Corporation | Water heater expansion tank fitting tees |

| KR102880336B1 (ko) | 2022-04-20 | 2025-11-03 | 디케이락 주식회사 | 회전수 제어가 가능한 자동회전 체결공구 및 이를 이용한 체결방법 |

| KR102819382B1 (ko) * | 2022-11-25 | 2025-06-13 | 주식회사 디오하베스트 | 무용접 방식에 의한 파이프나 튜브의 체결장치에 사용되는 지그 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2029798A (en) * | 1934-04-30 | 1936-02-04 | John C Schellin | Hose coupling thread terminus indicator |

| US3103373A (en) | 1961-06-29 | 1963-09-10 | Crawford Fitting Co | Controlled phase sequential gripping device |

| US3287813A (en) | 1961-12-04 | 1966-11-29 | Crawford Fitting Co | Gauge for coupling components |

| GB1361372A (en) * | 1972-03-13 | 1974-07-24 | Weatherhead Co | Tube couplings |

| US4162802A (en) * | 1978-03-27 | 1979-07-31 | Aeroquip Corporation | Permanent flareless tube connector |

| GB2049853B (en) * | 1979-05-23 | 1983-04-27 | Neil Holdings Ltd James | Pipe couplings |

| US5388866A (en) * | 1990-03-09 | 1995-02-14 | Lourdes Industries | High pressure coupling with provision for preventing separation of parts and with anti-galling provision |

| DE19709464C2 (de) * | 1997-03-07 | 2000-03-09 | Voss Armaturen | Rohrverschraubung mit Schneidring für metallische Rohrleitungen |

| JP3044612B2 (ja) * | 1997-09-19 | 2000-05-22 | 日本ピラー工業株式会社 | 継手用締付部材の合成樹脂製締付規制具 |

-

2000

- 2000-09-12 KR KR1020027003353A patent/KR20020039671A/ko not_active Withdrawn

- 2000-09-12 CA CA002384835A patent/CA2384835C/en not_active Expired - Fee Related

- 2000-09-12 WO PCT/US2000/024900 patent/WO2001020214A1/en not_active Ceased

- 2000-09-12 EP EP00968351A patent/EP1216377B1/en not_active Expired - Lifetime

- 2000-09-12 CA CA002629361A patent/CA2629361A1/en not_active Abandoned

- 2000-09-12 JP JP2001523562A patent/JP4172935B2/ja not_active Expired - Fee Related

- 2000-09-12 MX MXPA02002878A patent/MXPA02002878A/es unknown

- 2000-09-12 AT AT00968351T patent/ATE360171T1/de not_active IP Right Cessation

- 2000-09-12 CN CNB008156123A patent/CN1192178C/zh not_active Expired - Fee Related

- 2000-09-12 DE DE60034466T patent/DE60034466T2/de not_active Expired - Fee Related

- 2000-09-12 IL IL14863200A patent/IL148632A0/xx unknown

- 2000-09-12 AU AU78284/00A patent/AU778387B2/en not_active Ceased

- 2000-09-13 TW TW089118727A patent/TW552369B/zh not_active IP Right Cessation

-

2005

- 2005-01-12 AU AU2005200125A patent/AU2005200125A1/en not_active Abandoned

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101935616B1 (ko) * | 2010-07-09 | 2019-01-04 | 스와겔로크 컴패니 | 가요성 토크 칼라를 구비한 도관 이음쇠 |

| US10774961B2 (en) | 2014-06-04 | 2020-09-15 | Parker-Hannifin Corporation | Compression fitting with torque nut |

Also Published As

| Publication number | Publication date |

|---|---|

| AU7828400A (en) | 2001-04-17 |

| IL148632A0 (en) | 2002-09-12 |

| EP1216377A1 (en) | 2002-06-26 |

| CN1192178C (zh) | 2005-03-09 |

| AU778387B2 (en) | 2004-12-02 |

| EP1216377B1 (en) | 2007-04-18 |

| ATE360171T1 (de) | 2007-05-15 |

| TW552369B (en) | 2003-09-11 |

| KR20020039671A (ko) | 2002-05-27 |

| CN1390285A (zh) | 2003-01-08 |

| CA2384835C (en) | 2008-08-12 |

| AU2005200125A1 (en) | 2005-02-10 |

| DE60034466T2 (de) | 2008-01-03 |

| MXPA02002878A (es) | 2003-07-21 |

| JP2003509645A (ja) | 2003-03-11 |

| WO2001020214A1 (en) | 2001-03-22 |

| CA2384835A1 (en) | 2001-03-22 |

| CA2629361A1 (en) | 2001-03-22 |

| DE60034466D1 (de) | 2007-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4172935B2 (ja) | 表示装置をもつ継手 | |

| US7194817B2 (en) | Intrinsic gauging for tube fittings | |

| US6640457B2 (en) | Intrinsic gauging for tube fittings | |

| US6502323B2 (en) | Intrinsic gauging for tube fittings | |

| CN103477139B (zh) | 带有装配识别的用于管路或软管的连接装置 | |

| US12173817B2 (en) | Threaded coupling assemblies for interconnecting fluid-carrying conduits | |

| US6363598B1 (en) | Method of assembling pipe joints | |

| US7954860B2 (en) | Coupling mechanism | |

| AU2001227538A1 (en) | Method of assembling pipe joints | |

| JP2007248464A (ja) | 燃焼力学モニタリングシステムのための深さを設定工具及び目標深さにプローブを配置する方法 | |

| EP1536175A2 (en) | Tube fitting with indicating means | |

| KR101452360B1 (ko) | 청각적 또는 촉각적으로 인지가능한 인지부재를 갖는 관이음 조립체 | |

| JP2002264044A (ja) | マーキング用治具 | |

| US7448143B2 (en) | Method and system for inserting a probe | |

| JP6276243B2 (ja) | 管継手 | |

| JP5298843B2 (ja) | 配管用マーキング治具 | |

| JP2002147662A (ja) | 継 手 | |

| JPH0996393A (ja) | 管接続部の検査治具及び検査方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050223 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050223 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070904 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20071203 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20071210 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20080204 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080303 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080408 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080507 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080805 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080812 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110822 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |