JP4067164B2 - 研磨方法及び研磨装置 - Google Patents

研磨方法及び研磨装置 Download PDFInfo

- Publication number

- JP4067164B2 JP4067164B2 JP06434498A JP6434498A JP4067164B2 JP 4067164 B2 JP4067164 B2 JP 4067164B2 JP 06434498 A JP06434498 A JP 06434498A JP 6434498 A JP6434498 A JP 6434498A JP 4067164 B2 JP4067164 B2 JP 4067164B2

- Authority

- JP

- Japan

- Prior art keywords

- polishing

- polished

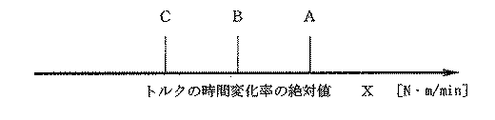

- torque

- uniformity

- wafer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP06434498A JP4067164B2 (ja) | 1998-02-27 | 1998-02-27 | 研磨方法及び研磨装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP06434498A JP4067164B2 (ja) | 1998-02-27 | 1998-02-27 | 研磨方法及び研磨装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH11251272A JPH11251272A (ja) | 1999-09-17 |

| JPH11251272A5 JPH11251272A5 (enExample) | 2005-08-25 |

| JP4067164B2 true JP4067164B2 (ja) | 2008-03-26 |

Family

ID=13255537

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP06434498A Expired - Fee Related JP4067164B2 (ja) | 1998-02-27 | 1998-02-27 | 研磨方法及び研磨装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4067164B2 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001138219A (ja) * | 1999-11-19 | 2001-05-22 | Disco Abrasive Syst Ltd | 研磨装置 |

| JP4827292B2 (ja) * | 2000-11-01 | 2011-11-30 | アプライド マテリアルズ インコーポレイテッド | 研磨装置 |

| JP3456642B2 (ja) * | 2000-11-10 | 2003-10-14 | 茂徳科技股▲ふん▼有限公司 | 化学機械研磨法において平坦化したいフィルムの厚さを決定する方法 |

| JP2003318140A (ja) | 2002-04-26 | 2003-11-07 | Applied Materials Inc | 研磨方法及び装置 |

| JP4664617B2 (ja) * | 2004-04-27 | 2011-04-06 | 富士通セミコンダクター株式会社 | 研磨装置及び方法 |

| US20100099342A1 (en) * | 2008-10-21 | 2010-04-22 | Applied Materials, Inc. | Pad conditioner auto disk change |

| JP6817778B2 (ja) * | 2016-10-18 | 2021-01-20 | 株式会社荏原製作所 | 局所研磨装置、局所研磨方法およびプログラム |

| SG10202111787PA (en) | 2016-10-18 | 2021-11-29 | Ebara Corp | Local polisher, method of a local polisher and program |

| KR102525737B1 (ko) * | 2016-11-16 | 2023-04-26 | 주식회사 케이씨텍 | 화학 기계적 연마장치 및 그 제어방법 |

| CN118268990B (zh) * | 2024-06-03 | 2024-08-16 | 合肥晶合集成电路股份有限公司 | 晶圆化学机械抛光方法、系统、设备及介质 |

-

1998

- 1998-02-27 JP JP06434498A patent/JP4067164B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH11251272A (ja) | 1999-09-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9211631B2 (en) | Grinding wheel truing tool and manufacturing method thereof, and truing apparatus, method for manufacturing grinding wheel and wafer edge grinding apparatus using the same | |

| US6517414B1 (en) | Method and apparatus for controlling a pad conditioning process of a chemical-mechanical polishing apparatus | |

| US6783436B1 (en) | Polishing pad with optimized grooves and method of forming same | |

| KR100818683B1 (ko) | 경면 면취 웨이퍼, 경면 면취용 연마 클로스 및 경면 면취연마장치 및 방법 | |

| TWI774805B (zh) | 晶圓加工方法 | |

| JP4067164B2 (ja) | 研磨方法及び研磨装置 | |

| JP2004142083A (ja) | ウエハ研磨装置およびウエハ研磨方法 | |

| CN113941954B (zh) | 一种大面积石英晶片研磨装置及其研磨方法 | |

| WO2000067950A1 (en) | Method and device for simultaneously grinding double surfaces, and method and device for simultaneously lapping double surfaces | |

| JPH09270401A (ja) | 半導体ウェーハの研磨方法 | |

| WO2018083931A1 (ja) | 半導体ウェーハの両面研磨方法 | |

| US9908213B2 (en) | Method of CMP pad conditioning | |

| JP2023088052A (ja) | 半導体結晶ウェハの製造装置および製造方法 | |

| CN208663464U (zh) | 化学机械研磨装置 | |

| JP2003151934A (ja) | Cmp装置及びcmp用研磨パッドの調整方法 | |

| JP2002066905A (ja) | 半導体装置の製造方法及びその装置 | |

| CN112454161B (zh) | 研削装置及研削方法 | |

| JP3706306B2 (ja) | モジュール制御プラテン製作システム及び方法 | |

| US20240009792A1 (en) | Grinding method for slice wafer | |

| TW200527525A (en) | Method for CMP removal rate compensation | |

| JPH10315124A (ja) | 研磨方法および研磨装置 | |

| JP2000202758A (ja) | 研磨布コンディショナを備えたウェハ研磨装置 | |

| JP3847500B2 (ja) | 半導体ウェハ平坦化加工方法および平坦化加工装置 | |

| JPH10202508A (ja) | 研磨方法 | |

| JP3019849B1 (ja) | 化学的機械的研磨装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20050202 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050215 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050215 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20050202 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20071207 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080108 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080108 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110118 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |