JP3877870B2 - 基板成形金型、及び基板成形金型における成形基板の板厚調整方法 - Google Patents

基板成形金型、及び基板成形金型における成形基板の板厚調整方法 Download PDFInfo

- Publication number

- JP3877870B2 JP3877870B2 JP14022698A JP14022698A JP3877870B2 JP 3877870 B2 JP3877870 B2 JP 3877870B2 JP 14022698 A JP14022698 A JP 14022698A JP 14022698 A JP14022698 A JP 14022698A JP 3877870 B2 JP3877870 B2 JP 3877870B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- shim

- base

- molding die

- substrate molding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

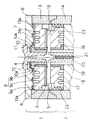

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/263—Moulds with mould wall parts provided with fine grooves or impressions, e.g. for record discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/263—Moulds with mould wall parts provided with fine grooves or impressions, e.g. for record discs

- B29C2045/2646—Means for adjusting the axial dimension of the mould cavity

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Manufacturing Optical Record Carriers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP14022698A JP3877870B2 (ja) | 1997-05-30 | 1998-05-21 | 基板成形金型、及び基板成形金型における成形基板の板厚調整方法 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP14265397 | 1997-05-30 | ||

| JP9-142653 | 1997-05-30 | ||

| JP14022698A JP3877870B2 (ja) | 1997-05-30 | 1998-05-21 | 基板成形金型、及び基板成形金型における成形基板の板厚調整方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH1142648A JPH1142648A (ja) | 1999-02-16 |

| JPH1142648A5 JPH1142648A5 (enExample) | 2005-09-08 |

| JP3877870B2 true JP3877870B2 (ja) | 2007-02-07 |

Family

ID=26472823

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP14022698A Expired - Fee Related JP3877870B2 (ja) | 1997-05-30 | 1998-05-21 | 基板成形金型、及び基板成形金型における成形基板の板厚調整方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3877870B2 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| HK1027253A2 (en) * | 2000-07-31 | 2000-12-08 | 谢宁乐 | Mould for injection moulding |

-

1998

- 1998-05-21 JP JP14022698A patent/JP3877870B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1142648A (ja) | 1999-02-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR19990078021A (ko) | 반도체장치제조용금형및압축성형법을이용한반도체장치제조방법 | |

| US4196522A (en) | Alignment fixture | |

| US6095786A (en) | Substrate forming mold, and plate thickness adjusting method of formed substrate in substrate forming mold | |

| JP3877870B2 (ja) | 基板成形金型、及び基板成形金型における成形基板の板厚調整方法 | |

| KR20190124654A (ko) | 스택드 앤 코어드 로케이터 브레이크 캘리퍼 | |

| JPH0828615A (ja) | 摩擦パッド | |

| JP3429828B2 (ja) | 打抜機への抜型、雌型の取り付け方法及び抜型、雌型の位置決め取り付け用部材 | |

| JP3747197B2 (ja) | ローラ軸受リング製造方法及びローラ軸受リング | |

| JP2002056578A (ja) | ディスク状情報記録媒体、スタンパ、スタンパ打ち抜き装置、ディスク原盤およびハブ取り付け装置 | |

| JPS6240142B2 (enExample) | ||

| JPS61204842A (ja) | デイスク状記録媒体 | |

| JP3409215B2 (ja) | ディスク基板成形金型 | |

| CN114367713B (zh) | 一种分片式3d打印涡轮导向叶片毛坯的机加工方法 | |

| KR100602000B1 (ko) | 디스크 기판의 성형용 금형 | |

| JP3113577B2 (ja) | モールドベース | |

| US20220088667A1 (en) | Method for manufacturing brake disc and brake disc | |

| JP2023511060A (ja) | 電気めっき鋼線セグメントによる接合組立型砥石車 | |

| JPH029855Y2 (enExample) | ||

| CN119439434B (zh) | 一种棱镜粘接结构及粘接方法 | |

| CN215614527U (zh) | 一种钣金压鼓包工装 | |

| US6500512B2 (en) | Apparatus and method for use in the manufacture of multiple layer optical discs | |

| JPH0543327U (ja) | 光デイスク基板製造用金型 | |

| JPH02182323A (ja) | 精密金属円板の製造方法 | |

| JPH0636486Y2 (ja) | ハードディスク検査装置のヘッド取付機構 | |

| JPH1142648A5 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050316 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050316 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060424 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060509 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060707 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060801 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060928 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061024 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20061101 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |