JP3877870B2 - Substrate molding die and method for adjusting thickness of molded substrate in substrate molding die - Google Patents

Substrate molding die and method for adjusting thickness of molded substrate in substrate molding die Download PDFInfo

- Publication number

- JP3877870B2 JP3877870B2 JP14022698A JP14022698A JP3877870B2 JP 3877870 B2 JP3877870 B2 JP 3877870B2 JP 14022698 A JP14022698 A JP 14022698A JP 14022698 A JP14022698 A JP 14022698A JP 3877870 B2 JP3877870 B2 JP 3877870B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- shim

- base

- molding die

- substrate molding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/263—Moulds with mould wall parts provided with fine grooves or impressions, e.g. for record discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/263—Moulds with mould wall parts provided with fine grooves or impressions, e.g. for record discs

- B29C2045/2646—Means for adjusting the axial dimension of the mould cavity

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Manufacturing Optical Record Carriers (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、例えば、光ディスク等に使用する樹脂基板を成形することに利用可能な、基板成形金型、及び基板成形金型における成形基板の板厚調整方法に関するものである。

【0002】

【従来の技術】

従来より、メモリ媒体としての光ディスクの基板の成形には樹脂材料が用いられている。この基板は、嵌合する一対の金型である固定金型と可動金型との間に形成した隙間に、溶融樹脂を流入させた後に、固化させて成形するものである。

【0003】

そこで従来は、成形された基板の板厚分布が、金型を形成する部材の加工精度で決まっていた。しかし、光ディスクの記録容量が大きくなるにつれて光ディスク基板に要求される板厚の精度が高くなってきた。これは、基板のチルトの影響を低減するために基板の板厚を薄くする必要があるためである。

【0004】

特開平7−266378号公報には、固定金型と可動金型との接合面を形成する接合部材とこれを取り付ける取付型板との間にシムを設ける方法が開示されている。この場合、キャビティ厚が変わるため基板の外径を形作る外周リングを弾性部材でスタンパ側に押し当てている。

【0005】

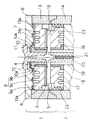

図19にその金型の断面図を示す。固定金型101と可動金型102とは締まって固定突当リング103と可動突当リング104とが当たって止まる。固定突当リング103は固定取付型板105とシム106を介して嵌合する。固定取付型板105には内周側に向かって、順に固定鏡面盤107、固定ブッシュ108、スプルブッシュ109が設けられている。固定鏡面盤107上にはスタンパ110が、内周と外周とをそれぞれ、スタンパホルダー111、外周リング112とで保持されている。外周リング112は可動金型102と連動して動く構造のため、弾性部材であるバネ113でスタンパ110側に押し当てている。可動金型102側は、可動突当リング104が可動取付型板114にボルト止めされており、内周側に順に可動鏡面盤115、可動ブッシュ116、エジェクタパンチ117、カットパンチ118、エジェクタピン119が設けられている。固定鏡面盤107および可動鏡面盤115には、それぞれ、温調溝120および121が設けられている。成形基板の板厚の調整はシム106の板厚を変えることで行う。

【0006】

【発明が解決しようとする課題】

しかしながら、このような特開平7−266378号公報で示された従来の方法では、固定金型と可動金型とが突き当てられた際に両金型間に形成されるキャビティの厚みを規定する箇所にシムを配置している。そのために、成形された基板の全体的な厚みの調整は可能であるが、成形された基板の面内ばらつき、すなわち、径方向や周方向の厚みのばらつきを抑制することは困難である。

【0007】

本発明は、このような従来の金型の課題を考慮し、成形基板の厚みばらつきを抑制することができる基板成形金型、及び基板成形金型における成形基板の板厚調整方法を提供することを目的とする。

【0008】

【課題を解決するための手段】

第1の本発明(請求項1記載の本発明に対応)は、基板を成形する一対の基板成形部材と、

前記一対の基板成形部材の内、一方の基板成形部材を保持する固定基盤と、

前記一対の基板成形部材の内、他方の基板成形部材を保持する可動基盤と、

前記一対の基板成形部材が嵌合された際、それら一対の基板成形部材の間に、前記基板を成形する所定の隙間を設けるために互いに突き当てられる、前記固定基盤及び可動基盤に設けられ且つ前記基板成形部材より外側の位置に配置された一対の突当部材と、

前記隙間を調整するために、前記一方の基板成形部材と前記固定基盤との間及び/又は前記他方の基板成形部材と前記可動基盤との間であって、且つ、前記突当部材の内側に配置される隙間調整手段とを備えた基板成形金型である。

【0009】

又、第2の本発明(請求項2記載の本発明に対応)は、前記基板成形部材が複数の金型構成部材の組み合わせにより構成されている場合、前記複数の金型構成部材の内、全部又は一部の金型構成部材と前記基盤との間に、前記隙間調整手段が設けられている上記第1の発明の基板成形金型である。

【0010】

又、第3の本発明(請求項3記載の本発明に対応)は、前記基板成形部材に形成された、温度調整用の媒体を流す溝を覆うための蓋部材を備え、

前記隙間調整手段が、前記蓋部材と前記固定基盤又は可動基盤との間に設けられている上記第1の発明の基板成形金型である。

【0011】

又、第4の本発明(請求項4記載の本発明に対応)は、前記突当部材は環状につながっており、

前記基盤と前記基板成形部材との接合面の外周端が、前記突当部材の内周壁面に当たる位置に、前記基盤の段差があり、

前記隙間調整手段が、前記基盤の段差がある前記突当部材の内周壁面に隣接して配置されている上記第1の発明の基板成形金型である。

【0012】

又、第5の本発明(請求項5記載の本発明に対応)は、前記基板成形部材は、前記隙間に通じる貫通孔を中央部に有し、かつ前記貫通孔から一端側の外周部がはみ出して嵌合するように配置された環状部材を含み、

前記基盤と前記環状部材以外の前記基板成形部材との接合面の内周端が、前記環状部材の前記外周部の壁面に当たる位置に、前記基盤の段差があり、

前記隙間調整手段が、前記基盤の段差がある前記環状部材の前記外周部の壁面に隣接して配置されている上記第1の発明の基板成形金型である。

【0013】

又、第16の本発明(請求項16記載の本発明に対応)は、基板を成形する一対の基板成形部材と、

前記一対の基板成形部材の内、一方の基板成形部材を保持する固定基盤と、

前記一対の基板成形部材の内、他方の基板成形部材を保持する可動基盤と、

前記一対の基板成形部材が嵌合された際、それら一対の基板成形部材の間に、前記基板を成形する所定の隙間を設けるために互いに突き当てられる、前記固定基盤及び可動基盤に設けられ且つ前記基板成形部材より外側の位置に配置された一対の突当部材とを備えた基板成形金型における成形基板の板厚調整方法であって、

前記隙間を調整するために、前記一方の基板成形部材と前記固定基盤との間及び/又は前記他方の基板成形部材と前記可動基盤との間であって、且つ、前記突当部材の内側に隙間調整手段を配置する基板成形金型における成形基板の板厚調整方法である。

【0014】

又、第17の本発明(請求項17記載の本発明に対応)は、前記基板成形部材が複数の金型構成部材の組み合わせにより構成されている場合、

前記隙間調整手段を、前記複数の金型構成部材の内、全部又は一部の金型構成部材と前記基盤との間に設ける上記第16の発明の基板成形金型における成形基板の板厚調整方法である。

【0015】

又、第18の本発明(請求項18記載の本発明に対応)は、前記基板成形部材に設けられた、温度調整用の媒体を流す溝を覆うための蓋部材が設けられている場合、

前記隙間調整手段を、前記蓋部材と前記固定基盤又は可動基盤との間に設ける上記第16の発明の基板成形金型における成形基板の板厚調整方法である。

【0016】

又、第19の本発明(請求項19記載の本発明に対応)は、前記突当部材は環状につながっており、前記基盤と前記基板成形部材との接合面の外周端が、前記突当部材の内周壁面に当たる位置に、前記基盤の段差がある場合、

前記隙間調整手段を、前記基盤の段差がある前記突当部材の内周壁面に隣接して配置することを特徴とする上記第16の発明の基板成形金型における成形基板の板厚調整方法である。

【0017】

又、第20の本発明(請求項20記載の本発明に対応)は、前記基板成形部材は、前記隙間に通じる貫通孔を中央部に有し、かつ前記貫通孔から一端側の外周部がはみ出して嵌合するように配置された環状部材を含み、

前記基盤と前記環状部材以外の前記基板成形部材との接合面の内周端が、前記環状部材の前記外周部の壁面に当たる位置に、前記基盤の段差がある場合、

前記隙間調整手段を、前記基盤の段差がある前記環状部材の前記外周部の壁面に隣接して配置する上記第16の発明の基板成形金型における成形基板の板厚調整方法である。

【0018】

【発明の実施の形態】

以下、本発明の実施の形態について、図1から図18を用いて説明する。

【0019】

(実施の形態1)

本発明の基板成形用金型の実施の形態1を示す断面図を図1に示す。

【0020】

図1に示すように、金型は、摺動しない固定金型1と摺動する可動金型2とからなる。

【0021】

図1では、スタンパ3を固定金型1側に装着する場合を示す。スタンパ3は、内周および外周をスタンパホルダー4と外周リング5とで固定鏡面盤6に固定される。固定鏡面盤6は温調溝7があり、温調溝7をふさぐように固定鏡面盤6はOリングを介して固定金型基盤8にボルト止めされている。

【0022】

この固定鏡面盤6と固定金型基盤8との接合面にはシム9が配されている。固定鏡面盤6の内側には順にスタンパホルダー4、固定ブッシュ10、スプルブッシュ11が設けられている。スプルブッシュ11には孔があり、ここから溶融樹脂が金型内に流入する。また、固定ブッシュ10と固定金型基盤8との接合面にはスプルブッシュ11に嵌合する環状のシム12がある。尚、本発明の一方の基板成形部材は、スタンパ3、スタンパホルダー4、固定鏡面盤6、及び固定ブッシュ10等を含むものである。

【0023】

シム9は成形基板の径方向と周方向の板厚ばらつきを調整するために設ける。一方、シム12はシム9を設けた結果、固定ブッシュ10と固定金型基盤8との間に生じる隙間を埋めるために設ける。したがって、シム9を設けても固定ブッシュ10と固定金型基盤8との間に隙間が生じない場合はシム12は必要ない。

【0024】

シム9は固定鏡面盤6と固定金型基盤8とに挟まれて押さえつけられることで、摩擦力によって固定される。ここでシム9を配置する際に、耐熱粘性流体、例えば、グリースをシム9に塗布するとシム9が一時固定されるため、固定鏡面盤6と固定金型基盤8とを接合する場合にシム9の移動が抑制され、設定通りの設置が容易になる。

【0025】

金型は高温になるため塗布液は耐熱性が必要である。また、金型は多数の部品から構成されているため分解組立をするごとにミクロンオーダーで部材間の寸法が変わる。したがって、シム9を接着剤で固定しないことが好ましい。

【0026】

シム12はスプルブッシュ11によって位置が規定されて移動が抑制される。

【0027】

一方、可動金型2では、可動突当リング14が固定突当リング13と突当り、金型内にキャビティ15が形成される。この可動突当リング14は、可動金型基盤16にボルト止めする。可動突当リング14より内周側には、順に、可動鏡面盤17、可動ブッシュ18、エジェクタパンチ19、カットパンチ20、エジェクタピン21が設けられている。カットパンチ20は成形基板の内周に孔を形成するものであり、エジェクタパンチ19とエジェクタピン21は、基板とスプルとを、それぞれ、押し出す役割を持つ。可動鏡面盤17にも温調溝22が設けられている。尚、本発明の他方の基板成形部材は、可動鏡面盤17、可動ブッシュ18、及びエジェクタパンチ19等を含むものである。

【0028】

23はバネであり、外周リング5をスタンパ3側に押しつけるものである。

【0029】

内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に用いるシム9,12として、幅が10mmで、厚みが5μm,10μm,15μm,・・・,50μmまでの5μm毎に厚みの設定されたものを用意し、次の様な実験を行った。

【0030】

図2は、シムの配置を示す平面図である。又、図3(a)は、シムを挿入しないで成形した成形基板301aの板厚分布を示す図であり、図3(b)は、図2に示した配置にシムを挿入して成形した成形基板301bの板厚分布を示す図であり、図中に示す板厚の単位はmmである。

【0031】

この場合、図2に示すシムの配置は、固定突当リング13の内側の固定金型基盤8上を可動金型2側から固定金型1側を見た場合のものであり、図2中、最外周円201は、図1で示した固定鏡面盤6の外周部に対応し、最内周円202は、図1で示した固定ブッシュ10の中央の孔の内縁部に対応している。又、図3(a)、図3(b)に示す基板301a、301bの板厚の分布図の向きは、図2に示すシムの配置図の向きに対応している。

【0032】

基板の板厚の測定位置は、同図に示す様に、半径23mm,40mm,58mm(図中では、それぞれ、符号302,303,304を付した)の3つの同心円周上であり、且つ、金型の鉛直上方を基準として45度間隔で基板の中心から延びる放射状の8本の直線上の、各交点の位置である。即ち、各基板毎に、各円周上においてそれぞれ8箇所、合計24箇所について板厚を測定した。又、シムの厚みは、図2に示す通り、シム9a、9b、12の順に、それぞれ5μm、20μm、20μmである。又、成形条件は、最大型締め圧は20トン、金型温度は125℃、サイクルは8秒とした。

【0033】

この結果、シムを入れない従来構成の場合は、図3(a)に示す通り、最大板厚が0.618mm、最小板厚が0.586mmであることから、成形基板1枚内の板厚ばらつきは、最大32μmとなり、30μm以上あった。これに対して、シムを挿入した本実施の形態の構成では、図3(b)に示す通り、最大板厚が0.607mm、最小板厚が0.599mmであることから、成形基板1枚内の板厚ばらつきは、最大8μmとなり、10μm未満にまでばらつき幅を小さくすることが出来た。

【0034】

ここで、板厚ばらつきの分布と、シムの配置の関係について図2、図3(a)を参照しながら述べる。

【0035】

即ち、図2に示す様に、中央部にシム9bとして20μmの板厚のものを入れたのは、シムを入れない場合の、半径23mmの円周(図3(a)中、符号302を付した点線の円周に対応)上での板厚が、半径58mmの円周(図3(a)中、符号304を付した点線の円周に対応)上での板厚より約20μm厚いためである。

【0036】

又、図2に示す様に、外周部にシム9aとして5μmの板厚のものを入れたのは、シムを入れない場合に周方向で生じている約10μmの板厚差(図3(a)参照)を改善するためである。即ち、シム9aを図中に示した位置に入れて、固定鏡面盤6を全体的に傾けることにより、周方向の板厚のばらつきを低減した。

【0037】

図1では、シム9は固定鏡面盤6の内外周に配しているが、シム9は溝7のない面ならどこに敷いても良い。

【0038】

(実施の形態2)

本発明の基板成形用金型の実施の形態2を示す断面図を図4に示す。

【0039】

図1と比べて異なるのは、第1に、固定鏡面盤6の温調溝7を覆う蓋板24を設け、固定鏡面盤6を蓋板24を介して固定金型基盤8に固定する構造とし、シム9をその蓋板24と固定金型基盤8との間に配した点である。

【0040】

第2に、シム9aが、固定突当リング13の内周壁面13aと隣接して配置されており、又、シム9bが、固定ブッシュ10の外周壁面10aと隣接して配置されている点である。

【0041】

固定鏡面盤6と固定金型基盤8との間に蓋板24を設けたことによって、温調溝7を流れる媒体が漏れる可能性はなくなる。また、シムを敷く位置の制限が実施の形態1よりなくなる。さらに、固定鏡面盤6と蓋板24とをボルト止め等で一体にすることで固定金型基盤8と固定鏡面盤6との着脱が容易になる。

【0042】

また、シム9を配する接合面の端面に環状部材を嵌合させることで、シム9が他部材の接合面に移動する可能性がなくなる。

【0043】

このシム9にも、実施の形態1と同様に、耐熱粘性流体、例えば、グリースをシム9に塗布するとシム9が一時固定されるため、蓋板24と固定金型基盤8とを接合する場合にシム9の移動が抑制され、設定通りの設置が容易になる。

【0044】

シム12は実施の形態1と同様に環状とした。シム12はスプルブッシュ11に規定されて移動が抑制される。

【0045】

内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に用いるシム9,12として、幅が5mmで、厚みが5μm,10μm,15μm,・・・,50μmまでの5μm毎に厚みの設定されたものを用意し、次の様な実験を行った。

【0046】

図5は、シムの配置を示す図である。又、図6(a)は、シムを挿入しないで成形した成形基板301aの板厚分布を示す図であり、図3(b)は、図5に示した配置にシムを挿入して成形した成形基板301bの板厚分布を示す図であり、図中に示す板厚の単位はmmである。

【0047】

この場合、図5に示すシムの配置は、固定突当リング13の内側の固定金型基盤8上を可動金型2側から固定金型1側を見た場合のものであり、図5中、最外周円201は、図4で示した固定鏡面盤6の外周部に対応し、最内周円202は、図4で示した固定ブッシュ10の中央の孔の内縁部に対応している。又、図5中、周円501は、図4で示した固定ブッシュ10の外周部10aに対応している。又、図6(a)、図6(b)に示す基板301a、301bの板厚の分布図の向きは、図5に示すシムの配置図の向きに対応している。

【0048】

基板の板厚の測定位置は、図3(a)で説明した内容と同じである。又、シムの厚みは、図5に示す通りである。又、成形条件は、図3(a)、図3(b)で述べたものと同じである。

【0049】

この結果、シムを入れない従来構成の場合は、図6(a)に示す通り、最大板厚が0.618mm、最小板厚が0.587mmであることから、成形基板1枚内の板厚ばらつきは、最大31μmであった。これに対して、シムを挿入した本実施の形態の構成では、図6(b)に示す通り、最大板厚が0.603mm、最小板厚が0.597mmであることから、成形基板1枚内の板厚ばらつきは、最大6μmとなり、10μm未満にまでばらつき幅を小さくすることが出来た。

【0050】

ここで、板厚ばらつきの分布と、シムの配置の関係について図5、図6(a)を参照しながら述べる。

【0051】

シムを入れない場合の板厚分布は、図6(a)に示すよう、径方向では、半径23mmの円周上での板厚が、半径58mmの円周上での板厚より約20μm強厚い。シム9bとして板厚20μmのものを入れたとして、半径23mm、40mm,58mmの円周上での板厚値から、0.610mm,0.600mm,0.590mmを引くと、周方向では、基板301a上の右上が10μm強厚いことがわかる(図6(a)参照)。

【0052】

そこで、シム9aとシム9bを図5に示す位置に入れた。又、基板301a上の右上の半径40mmの円周上で、僅かに盛り上がっている。そこで、シム9cを図5に示す位置に入れて、その盛り上がりを矯正した。

【0053】

ここで、シム12は環状のものを用いたが異なっても良い。この場合、シム12の位置は内側をスプルブッシュ11で規定される。一方、シム12の位置の外側は固定側金型基盤8に設けた段差によって規定される。

【0054】

(実施の形態3)

本発明の基板成形用金型の実施の形態3を示す断面図を図7に示す。又、図8(a)は、シムの配置を示す平面図である。この場合、図8(a)に示すシムの配置は、固定突当リング13の内側の固定金型基盤8上を可動金型2側から固定金型1側を見た場合のものであり、図8(a)中、最外周円201は、図7で示した固定鏡面盤6の外周部に対応し、最内周円202は、図7で示した固定ブッシュ10の中央の孔の内縁部に対応している。又、図8(a)中、周円501は、図7で示した固定ブッシュ10の外周部10aに対応している。

【0055】

実施の形態2との相違点はシム9を環状としたことであり、実施の形態2と同様に接合面の端面で環状部材と隣接するように配置している。具体的な環状部材は、内周側が固定ブッシュ10であり、外周側が固定突当リング13である。この結果、シム9の移動は抑制される。

【0056】

シム9は内周と外周とで厚みを調整することによって成形基板のばらつきを抑制できる。ここで、環状のシム9の別の例として、図8(b)に示すように、その板厚が環状内の場所によって異なる様な形状のものを用いても良い。図8(b)は、場所によって板厚の異なる環状シムの平面図及び断面図を示している。

【0057】

また、シム12も環状で、スプルブッシュ11によって位置が規定されて移動が抑制される。

【0058】

内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に用いるシム9,12として、幅が10mmで、厚みが5μm,10μm,15μm,・・・,50μmまでの5μm毎に厚みの設定されたものを用意して、上記実施の形態と同様の実験を行った。成形条件も上記実施の形態と同様である。

【0059】

この結果、シムを入れない従来構成の場合は、成形基板1枚内の板厚ばらつきは、最大30μm以上であったが、シムを挿入した本実施の形態の構成では、そのばらつきは、最大15μm未満にまでばらつき幅を小さくすることが出来た。又、図8(b)に示したシムを用いた場合は、最大10μm未満にまでばらつき幅を小さくすることが出来た。

【0060】

ここではシム12に環状のものを用いたが、異なるものを用いても構わない。

【0061】

又、図8(a)には、シム9として、異なる径のものを2枚挿入している例を示したが、ばらつきの分布の状況によっては、一方のみでも良い。

【0062】

(実施の形態4)

本発明の基板成形用金型の実施の形態4を示す断面図を図9に示す。又、図10は、シム12とピン25a、25bの配置を示す平面図である。この場合、図10に示すシム12とピン25の配置は、固定突当リング13の内側の固定金型基盤8上を可動金型2側から固定金型1側を見た場合のものであり、図10中、最外周円201は、図9で示した固定鏡面盤6の外周部に対応し、最内周円202は、図9で示した固定ブッシュ10の中央の孔の内縁部に対応している。

【0063】

図4と異なるのは、シム9を敷く接合面を形成する部材に複数の凹凸の嵌合部を設け、凸部に嵌入する孔をシム9に設けた点である。図9では、図11(a)に示すように、固定金型基盤8にピン25を嵌入し、蓋板24でのピン25が対応する箇所にピン25が挿入される凹部を形成している。そして、孔を有するシム9をピン25に嵌入した後にシム9は固定鏡面盤6と固定金型基盤8とで押さえつけられる。この結果、シム9の移動が抑制される。

【0064】

シム12は環状である。したがって、シム12は嵌合するスプルブッシュ11で規定され、移動が抑制される。

【0065】

ピン25の断面形状とシム9に有する孔の形状を図11(b)から図11(f)に示す。図11(b)のように1個の円形のピン25で1個のシム9を固定する場合はピン回りに回転する移動が考えられる。そこで、図11(c)に示すようにシム9に通すピン25の数が複数であれば回転移動は抑制される。

【0066】

また、1つのシム9に通すピン25の数が1個であってもピン25の断面形状およびシム9の孔形状が真円以外であればシム9の回転移動は抑制される。ピン25の断面形状およびシム9の孔形状は、例えば多角形、好ましくは図11(d)および(e)に示す四角形か三角形、あるいは図11(f)に示す長円がある。

【0067】

また、1つのシム9に通すピンの数が1個であっても、シム9を接合面の端面と嵌合する環状部材と隣接するように配置すればシム9の回転移動は抑制される。

【0068】

例えば、図9に示すように、蓋板24と固定金型基盤8との接合面401が、固定突当リング13の内周壁面と当たる位置に段差402が形成されている。この段差402の内周部分に、シム9aの端面が隣接するように、シム9aとシム9aが嵌入するピン25aを配置すれば良い。又、同様に、上記接合面401が、固定ブッシュ10の外周壁面と当たる位置に段差403が形成されている。この段差403の外周部分に、シム9bの端面が隣接するように、シム9bとシム9bが嵌入するピン25bを配置すれば良い。

【0069】

以上のどの構成においても、内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に用いるシム9,12として、幅が10mmで、厚みが5μm,10μm,15μm,・・・,50μmまでの5μm毎に厚みの設定されたものを用意し、次の様な実験を行った。成形条件は、上記実施の形態と同様で、最大型締め圧は20トン、金型温度は125℃、サイクルは8秒とした。

【0070】

その結果、成形基板1枚内の板厚ばらつきは、従来構造の場合は30μm以上あったが、本発明の実施の形態4では10μm未満になった。また、定期的に金型を外してシム9とシム12の移動を調べたところシム9とシム12の移動は見られなかった。

【0071】

実施の形態4ではピン25を固定金型基盤8側に設け、ピン25が入る凹部を蓋板24側に設けたが、反対にピン25を蓋24側に設ける構成であっても構わない。

【0072】

また、シム12にもシム9と同様に孔を設け、この孔に嵌入するピンを設けても良い。

【0073】

さらに、シムを嵌入する凸部として部材に嵌入するピンではなしに金型部材を直接加工しても構わない。

【0074】

(実施の形態5)

本発明の基板成形用金型の実施の形態5を示す断面図を図12に示す。

【0075】

図12に示す構成は、図1の構成と比べて、固定鏡面盤6に凸部を設け、それと嵌合する凹部を固定金型基盤8に設け、凹凸の嵌合部の当たり平面間にシム9を設けている点が異なる。

【0076】

また、固定ブッシュに凸部を設け、それと嵌合する凹部を固定金型基盤8に設け、凹凸の嵌合部の当たり平面間にシム12を設けている点が異なる。

【0077】

シム9とシム12は凹部の底部と同じ形状で、かつ、その底部にはまっているため移動が抑制される。

【0078】

この凹凸部の位置は、接合面に散在していれば良いが、一様に散在しているかキャビティ15と同心円上に存在することが好ましい。凹凸部を同心円上に設ける場合は少なくとも接合面の内周と外周とに設ける必要がある。これは、内周と外周とに設けたシム9の厚みを調整することで、成形基板の径方向のばらつきを抑制できるからである。また、周方向に設けた複数のシム9の厚みを調整することで、成形基板の周方向のばらつきを抑制できるからである。

【0079】

図13に、シム9又は12を挿入するための凹部601の配置を表した平面図を示す。この場合、図13に示す凹部601の配置は、固定突当リング13の内側の固定金型基盤8上を可動金型2側から固定金型1側を見た場合のものである。図13中、最外周円201は、図12で示した固定鏡面盤6の外周部に対応し、最内周円202は、図12で示した固定ブッシュ10の中央の孔の内縁部に対応している。

【0080】

ここでは、シムの外形、及び凹部の断面形状は円形とした。凹部の直径は10mm、シムの直径は9mmとした。

【0081】

又、内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に対して、シム9、12として、5μmから50μmまで5μm毎の厚みのものを用意して、上記実施の形態と同様の実験を行った。成形条件も上記実施の形態と同様である。

【0082】

この結果、シムを入れない従来構成の場合は、成形基板1枚内の板厚ばらつきは、最大30μm以上であったが、シムを挿入した本実施の形態の構成では、最大10μm未満にまでばらつき幅を小さくすることが出来た。

【0083】

また、本実施の形態では、シムの外形を円形としたが、これに限らず、シムの外形は凹部に入ればどのような形状でも勿論良い。また、凹部の断面形状は円形でなくてもかまわない。

【0084】

(実施の形態6)

本発明の基板成形用金型の実施の形態6を示す断面図を図14に示す。

【0085】

図14に示す構成では、図4に示すシム9の代わりに、蓋板24と固定金型基盤8との接合面に突き当て部材26を設けている。詳細には、図16(a)に示すように、本発明の突出部材に対応するこの突き当て部材26は周囲にネジ山が切ってあり、固定金型基盤8に設けた側面にネジ山を有する凹部にねじ込まれている。そこで、この突き当て部材26は回転させることで固定金型基盤8からの飛び出し量を調整できる。尚、本発明の突出量は、この飛び出し量に対応する。

【0086】

具体的には、突き当て部材26の直径を10mm、ネジ山のピッチを0.5mmとすると、飛び出し量を10μm調整するのに、50分の1回転させることになる。そこで、飛び出し量を調整するには、図17(a)、図17(b)に示すように、回転比の異なるギアなどを用い、例えば、調整側を10回転させると突き当て部材26を1回転させる治具を用いると良い。

【0087】

尚、図17(a)は、図17(b)のAA断面図である。図17(a)に示す702〜704は回転比の異なるギヤである。又、図17(b)に示す、先端部701が、突き当て部材26側である。

【0088】

又、突き当て部材26の頭には溝があり、この溝に、図17(b)に示す工具の先端部701をはめ込み回転が容易に出来るようにしてある。溝形状としては、真円以外で有れば良く、例えば、図16(b)から(e)に示すようなマイナス、プラス、四角形、六角形等がある。

【0089】

この突き当て部材26は蓋板24と固定金型基盤8との接合面に散在していれば良いが、一様に散在しているかキャビティ15と同心円上に存在することが好ましい。これは、周方向に設けた複数の突き当て部材26の突出量を調整することで成形基板の周方向のばらつきを抑制できるからである。また、突き当て部材26を同心円上に設ける場合は少なくとも接合面の内周と外周とに設ける必要がある。これは、内周と外周とに設けた突き当て部材26の突出量を調整することで成形基板の径方向のばらつきを抑制できるからである。

【0090】

図15に、凹凸部の配置の一例を表した平面図を示す。この場合、図15に示す凹凸部(突き当て部材26)の配置は、固定突当リング13の内側の固定金型基盤8上を、可動金型2側から固定金型1側に向かって見た場合のものである。

【0091】

シム12は環状で、内周と外周を、それぞれ、スプルブッシュ11と固定金型基盤8とで規定される。

【0092】

内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に対して、シム12として、5μmから50μmまで5μm毎の厚みのものを用意して、かつ、突き当て部材26の突出量を調整して、上記実施の形態と同様の実験を行った。成形条件も上記実施の形態と同様である。

【0093】

この結果、従来構成の場合は、成形基板1枚内の板厚ばらつきは、最大30μmであったが、突き当て部材26を利用した本実施の形態の構成では、最大10μm未満にまでばらつき幅を小さくすることが出来た。

【0094】

突き当て部材26は、固定金型基盤8に螺入しているため固定されているので横方向へは移動しない。しかし、回転する可能性がある。そこで、ネジ部には接着剤等で回転を防止する必要がある。

【0095】

機械的にネジ部の回転を抑制する構成を図16(f)(g)に示す。図16(f)は断面図であり、図16(g)は突き当て部材26の頭側から見た平面図である。固定金型基盤8の突き当て部材26が嵌入する箇所の表面に座ぐりを設け、回転止めとしてナット27を突き当て部材26と嵌合する。ナット27を固定金型基盤8に押しつけることで突き当て部材26と固定金型基盤8のネジ部にあった隙間をなくして突き当て部材26の回転が抑制される。

【0096】

もちろん、固定ブッシュ10と固定金型基盤8との接合面に、シム12の代わりに突き当て部材を用いても構わない。

【0097】

(実施の形態7)

本発明の基板成形用金型の実施の形態7を示す断面図を図18に示す。

【0098】

上記実施の形態では、隙間調整手段が固定金型1側にある場合を示してきたが、実施の形態7では隙間調整手段が可動金型2側にある。

【0099】

可動鏡面盤17の温調溝22を覆うように蓋板28が可動鏡面盤17と接合され、蓋板28は可動金型基盤16と接合する。

【0100】

蓋板28と可動金型基盤16との接合面の外周側にピン29とシム30とを設ける。シム30にはピン29が差し込まれる孔を設けている。このピン29と対応する蓋板28にはへこみが設けられ、ピン29が当たらなくしてある。そして、シム30がこのピン29に嵌合することで、シム30は固定され移動しなくなる。

【0101】

シム31は環状をしており、可動金型基盤16と蓋板28との間および可動金型基盤16と可動ブッシュ18との間にまたがって敷いてある。これは、可動鏡面盤17と可動ブッシュ18とが隣接し、かつ、可動金型基盤16と同一平面で接するような構造になっているためである。

【0102】

成形基板の径方向のばらつきはシム30とシム31との厚み調整で抑制し、周方向のばらつきはシム30の周方向の厚み調整で抑制する。

【0103】

内径15mm、外径120mm、板厚0.6mmの樹脂基板を成形する金型に対して、シム30とシム31としては、その幅がそれぞれ10mmと20mmのもであり、厚みが5μmから50μmまで5μm毎の厚みのものを用意して、上記実施の形態と同様の実験を行った。成形条件も上記実施の形態と同様である。

【0104】

この結果、シムを利用しない従来構成の場合は、成形基板1枚内の板厚ばらつきは、最大30μmであったが、シム30,31を利用した本実施の形態の構成では、最大10μm未満にまでばらつき幅を小さくすることが出来た。

以上の実施の形態では固定金型もしくは可動金型に鏡面盤の温調溝を覆う蓋板を設け、蓋板と金型基盤との接合面にピンとシムを設けたが、もちろん、両金型にピンとシムとを設けても良い。

【0105】

また、ピンは金型基盤側でなく蓋板側に固定される構造でも良い。

【0106】

また、ピンの断面形状およびシムの孔形状は真円以外であれば良い。

【0107】

以上のように本発明によれば、成形基板の1枚内の板厚ばらつきが10μm未満の高精度が得られる。

【0108】

即ち、成形基板の板厚調整をきめ細かく行うことが可能で、成形基板の径方向や周方向に発生する厚みのばらつきを低減することが出来る。

【0109】

また、成形動作を継続し続けても、上記精度が持続されるという顕著な効果が得られる。

【0110】

【発明の効果】

以上述べたところから明らかなよう本発明は、成形基板の厚みばらつきを抑制することができるという長所を有する。

【図面の簡単な説明】

【図1】本発明の実施の形態1の基板成形用金型を示す断面図

【図2】本発明の実施の形態1の基板成形用金型のシムの配置を示す平面図

【図3】(a):本発明の実施の形態1の基板成形用金型にシムを挿入する前の基板の板厚分布図

(b):本発明の実施の形態1の基板成形用金型にシムを挿入した後の基板の板厚分布図

【図4】本発明の実施の形態2の基板成形用金型を示す断面図

【図5】本発明の実施の形態2の基板成形用金型のシムの配置を示す平面図

【図6】(a):本発明の実施の形態2の基板成形用金型にシムを挿入する前の基板の板厚分布図

(b):本発明の実施の形態2の基板成形用金型にシムを挿入した後の基板の板厚分布図

【図7】本発明の実施の形態3の基板成形用金型を示す断面図

【図8】(a):本発明の実施の形態3の基板成形用金型のシムの配置を示す平面図

(b):本発明の実施の形態3の基板成形用金型のシムの形状を示す平面図と断面図

【図9】本発明の実施の形態4の基板成形用金型を示す断面図

【図10】本発明の実施の形態4の基板成形用金型のシムとピンの配置を示す平面図

【図11】(a):本発明の実施の形態4の基板成形用金型のピンとシムとの構成を示した断面図

(b):本発明の実施の形態4の基板成形用金型のシム形状を示した平面図

(c):本発明の実施の形態4の基板成形用金型のシム形状を示した平面図

(d):本発明の実施の形態4の基板成形用金型のシム形状を示した平面図

(e):本発明の実施の形態4の基板成形用金型のシム形状を示した平面図

(f):本発明の実施の形態4の基板成形用金型のシム形状を示した平面図

【図12】本発明の実施の形態5の基板成形用金型を示す断面図

【図13】本発明の実施の形態5の基板成形用金型のシムを設ける凹部の配置を示した断面図

【図14】本発明の実施の形態6の基板成形用金型を示す断面図

【図15】本発明の実施の形態6の基板成形用金型の突き当て部材の配置を示した平面図

【図16】(a):本発明の実施の形態6の基板成形用金型の突き当て部材の構成を示した断面図

(b):本発明の実施の形態6の基板成形用金型の突き当て部材の頭の溝形状を示した平面図

(c):本発明の実施の形態6の基板成形用金型の突き当て部材の頭の溝形状を示した平面図

(d):本発明の実施の形態6の基板成形用金型の突き当て部材の頭の溝形状を示した平面図

(e):本発明の実施の形態6の基板成形用金型の突き当て部材の頭の溝形状を示した平面図

(f):本発明の実施の形態6の基板成形用金型の突き当て部材の構成を示した断面図

(g):本発明の実施の形態6の基板成形用金型の突き当て部材の構成を示した平面図

【図17】(a):本発明の実施の形態6の基板成形用金型の突き当て部材の突出量を調整する治具の断面図

(b):本発明の実施の形態6の基板成形用金型の突き当て部材の突出量を調整する治具の側面図

【図18】本発明の実施の形態7の基板成形用金型を示す断面図

【図19】従来例の基板成形用金型を示す断面図

【符号の説明】

1 固定金型

2 可動金型

3 スタンパ

4 スタンパホルダー

5 外周リング

6 固定鏡面盤

7、22 温調溝

8 固定金型基盤

9、12、30、31 シム

10 固定ブッシュ

11 スプルブッシュ

13 固定突当リング

14 可動突当リング

15 キャビティ

16 可動金型基盤

17 可動鏡面盤

18 可動ブッシュ

19 エジェクタパンチ

20 カットパンチ

21 エジェクタピン

23 バネ

24、28 蓋板

25、29 ピン

26 突き当て部材

27 ナット

101 固定金型

102 可動金型

103 固定突当リング

104 可動突当リング

105 固定取付型板

106 シム

107 固定鏡面盤

108 固定ブッシュ

109 スプルブッシュ

110 スタンパ

111 スタンパホルダー

112 外周リング

113 バネ

114 可動取付型板

115 可動鏡面盤

116 可動ブッシュ

117 エジェクタパンチ

118 カットパンチ

119 エジェクタピン

120、121 温調溝

201 固定鏡面盤の外周端

202 固定ブッシュの内周端

301 基板

302 半径23mmの円周

303 半径40mmの円周

304 半径58mmの円周

401 接合面

402、403 段差

501 固定ブッシュの外周部

601 凹部

701 先端部

702〜704 ギヤ[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a substrate molding die and a method for adjusting the thickness of a molded substrate in a substrate molding die, which can be used for molding a resin substrate used for an optical disc or the like, for example.

[0002]

[Prior art]

Conventionally, a resin material has been used for forming a substrate of an optical disk as a memory medium. This substrate is formed by allowing molten resin to flow into a gap formed between a fixed mold and a movable mold, which are a pair of molds to be fitted, and then solidifying and molding.

[0003]

Therefore, conventionally, the thickness distribution of the molded substrate has been determined by the processing accuracy of the member forming the mold. However, as the recording capacity of the optical disc increases, the accuracy of the plate thickness required for the optical disc substrate has increased. This is because it is necessary to reduce the thickness of the substrate in order to reduce the influence of the substrate tilt.

[0004]

Japanese Patent Application Laid-Open No. 7-266378 discloses a method of providing a shim between a joining member that forms a joining surface between a fixed mold and a movable mold and an attachment mold plate to which the joining member is attached. In this case, since the cavity thickness changes, the outer ring that forms the outer diameter of the substrate is pressed against the stamper side by an elastic member.

[0005]

FIG. 19 shows a sectional view of the mold. The fixed mold 101 and the

[0006]

[Problems to be solved by the invention]

However, in the conventional method disclosed in Japanese Patent Laid-Open No. 7-266378, the thickness of the cavity formed between the two molds when the fixed mold and the movable mold are abutted is defined. A shim is placed at the location. Therefore, it is possible to adjust the overall thickness of the molded substrate, but it is difficult to suppress in-plane variations of the molded substrate, that is, variations in thickness in the radial direction and the circumferential direction.

[0007]

The present invention takes into consideration the problems of the conventional molds as described above, and suppresses variation in the thickness of the molded substrate.ShapeAn object of the present invention is to provide a mold and a method for adjusting the thickness of a molded substrate in a substrate molding die.

[0008]

[Means for Solving the Problems]

A first aspect of the present invention (corresponding to the present invention of claim 1) is a pair of substrate forming members for forming a substrate,

Of the pair of substrate forming members, a fixed base for holding one substrate forming member,

Of the pair of substrate forming members, a movable base for holding the other substrate forming member;

When the pair of substrate forming members are fitted, the fixed substrate and the movable substrate are abutted against each other to provide a predetermined gap for forming the substrate between the pair of substrate forming members, andAt a position outside the substrate molding memberA pair of abutting members arranged;

In order to adjust the gap, between the one substrate molding member and the fixed base and / or between the other substrate molding member and the movable base and inside the abutting member It is a board | substrate shaping | molding die provided with the clearance gap adjustment means arrange | positioned.

[0009]

Further, according to a second aspect of the present invention (corresponding to the present invention of claim 2), when the substrate molding member is constituted by a combination of a plurality of mold constituent members, among the plurality of mold constituent members, The substrate molding die according to the first aspect of the present invention, wherein the gap adjusting means is provided between all or part of the mold constituent members and the base.

[0010]

The third aspect of the present invention (corresponding to the third aspect of the present invention) includes a lid member for covering the groove for flowing the temperature adjusting medium formed in the substrate molding member,

In the substrate molding die according to the first invention, the gap adjusting means is provided between the lid member and the fixed base or the movable base.

[0011]

According to a fourth aspect of the present invention (corresponding to the fourth aspect of the present invention), the abutting member isConnected to the ring,

Between the substrate and the substrate molding member.At the position where the outer peripheral end of the joining surface hits the inner peripheral wall surface of the abutting member, there is a step of the base,

The gap adjusting means isOn the inner peripheral wall surface of the abutting member with the step of the baseThe substrate molding die according to the first aspect of the present invention, which is arranged adjacent to the first invention.

[0012]

The fifth invention (corresponding to the invention described in claim 5)The substrate molding member includes an annular member having a through hole leading to the gap in a central portion, and arranged so that an outer peripheral portion on one end side protrudes from the through hole and is fitted,

AboveWith the baseOther than the annular memberThe inner peripheral end of the joint surface with the substrate molding member isAboveAnnular memberOf the outer peripheryThere is a step of the base at the position hitting the wall surface,

The gap adjusting means is configured so that the annular member having the step of the base hasOf the outer peripheryIt is a board | substrate shaping | molding die of the said 1st invention arrange | positioned adjacent to a wall surface.

[0013]

According to a sixteenth aspect of the present invention (corresponding to the present invention of claim 16), a pair of substrate forming members for forming a substrate,

Of the pair of substrate forming members, a fixed base for holding one substrate forming member,

Of the pair of substrate forming members, a movable base for holding the other substrate forming member;

When the pair of substrate forming members are fitted, the fixed substrate and the movable substrate are abutted against each other to provide a predetermined gap for forming the substrate between the pair of substrate forming members, andAt a position outside the substrate molding memberA method for adjusting the thickness of a molded substrate in a substrate molding die provided with a pair of disposed abutting members,

In order to adjust the gap, between the one substrate molding member and the fixed base and / or between the other substrate molding member and the movable base and inside the abutting member This is a method for adjusting the thickness of a molded substrate in a substrate molding die in which a gap adjusting means is arranged.

[0014]

Further, according to a seventeenth aspect of the present invention (corresponding to the present invention of claim 17), when the substrate molding member is constituted by a combination of a plurality of mold constituent members,

Adjusting the thickness of the molded substrate in the substrate molding die according to the sixteenth aspect of the present invention, wherein the gap adjusting means is provided between all or a part of the plurality of mold constituent members and the base. Is the method.

[0015]

Further, an eighteenth aspect of the present invention (corresponding to the present invention of claim 18) is provided with a lid member for covering a groove for flowing a temperature adjusting medium provided in the substrate forming member.

The method for adjusting the thickness of a molded substrate in the substrate molding die according to the sixteenth aspect of the present invention, wherein the gap adjusting means is provided between the lid member and the fixed base or the movable base.

[0016]

According to a nineteenth aspect of the present invention (corresponding to the present invention of claim 19), the abutting member isConnected to the ring,Between the substrate and the substrate molding member.When there is a step of the base at a position where the outer peripheral end of the joining surface hits the inner peripheral wall surface of the abutting member,

The gap adjusting means;On the inner peripheral wall surface of the abutting member with the step of the baseIt is the board | substrate thickness adjustment method of the shaping | molding board | substrate in the board | substrate shaping die of the said 16th invention characterized by arrange | positioning adjacent.

[0017]

The twentieth aspect of the invention (corresponding to the invention of claim 20)The substrate molding member includes an annular member having a through hole leading to the gap in a central portion, and arranged so that an outer peripheral portion on one end side protrudes from the through hole and is fitted,

AboveWith the baseOther than the annular memberThe inner peripheral end of the joint surface with the substrate molding member isAboveAnnular memberOf the outer peripheryIf there is a step in the base at a position that hits the wall,

The gap adjusting means may be formed on the annular member having a step on the base.Of the outer peripheryA method for adjusting the thickness of a molded substrate in the substrate molding die according to the sixteenth aspect of the present invention, which is disposed adjacent to a wall surface.

[0018]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, embodiments of the present invention will be described with reference to FIGS.

[0019]

(Embodiment 1)

FIG. 1 is a cross-sectional

[0020]

As shown in FIG. 1, the mold includes a fixed

[0021]

FIG. 1 shows a case where the

[0022]

A

[0023]

The

[0024]

The

[0025]

Since the mold becomes high temperature, the coating solution needs to have heat resistance. In addition, since the mold is composed of a large number of parts, the dimension between members changes in micron order every time disassembly and assembly are performed. Therefore, it is preferable not to fix the

[0026]

The position of the

[0027]

On the other hand, in the

[0028]

A

[0029]

As

[0030]

FIG. 2 is a plan view showing the arrangement of shims. FIG. 3A is a view showing the thickness distribution of the molded

[0031]

In this case, the arrangement of the shim shown in FIG. 2 is that when the fixed

[0032]

As shown in the figure, the measurement positions of the board thickness are on three concentric circumferences having radii of 23 mm, 40 mm, and 58 mm (indicated by

[0033]

As a result, in the case of the conventional configuration without the shim, the maximum plate thickness is 0.618 mm and the minimum plate thickness is 0.586 mm as shown in FIG. The variation was a maximum of 32 μm, which was 30 μm or more. On the other hand, in the configuration of the present embodiment in which the shim is inserted, as shown in FIG. 3B, the maximum plate thickness is 0.607 mm and the minimum plate thickness is 0.599 mm. The maximum plate thickness variation was 8 μm, and the variation width could be reduced to less than 10 μm.

[0034]

Here, the relationship between the distribution of the plate thickness variation and the shim arrangement will be described with reference to FIGS. 2 and 3A.

[0035]

That is, as shown in FIG. 2, a 20 μm-

[0036]

Also, as shown in FIG. 2, the thickness of the

[0037]

In FIG. 1, the

[0038]

(Embodiment 2)

FIG. 4 is a cross-sectional view showing a second embodiment of the substrate molding die of the present invention.

[0039]

1 differs from FIG. 1 in that first, a

[0040]

Secondly, the

[0041]

By providing the

[0042]

Moreover, the possibility that the

[0043]

Similarly to the first embodiment, when a heat-resistant viscous fluid, for example, grease is applied to the

[0044]

The

[0045]

As

[0046]

FIG. 5 is a diagram showing the arrangement of shims. FIG. 6A is a diagram showing the thickness distribution of a molded

[0047]

In this case, the arrangement of the shim shown in FIG. 5 is a case where the fixed

[0048]

The measurement position of the thickness of the substrate is the same as that described in FIG. The thickness of the shim is as shown in FIG. The molding conditions are the same as those described in FIGS. 3 (a) and 3 (b).

[0049]

As a result, in the case of the conventional configuration without shims, the maximum plate thickness is 0.618 mm and the minimum plate thickness is 0.587 mm as shown in FIG. The variation was a maximum of 31 μm. On the other hand, in the configuration of the present embodiment in which the shim is inserted, as shown in FIG. 6B, the maximum plate thickness is 0.603 mm and the minimum plate thickness is 0.597 mm. The maximum plate thickness variation was 6 μm, and the variation width could be reduced to less than 10 μm.

[0050]

Here, the relationship between the distribution of the plate thickness variation and the shim arrangement will be described with reference to FIGS. 5 and 6A.

[0051]

As shown in FIG. 6A, the plate thickness distribution without the shim is about 20 μm larger in the radial direction than the plate thickness on the circumference of the radius of 23 mm than the plate thickness on the circumference of the radius of 58 mm. thick. Assuming that a

[0052]

Therefore, the

[0053]

Here, the

[0054]

(Embodiment 3)

FIG. 7 is a cross-sectional view showing a third embodiment of the substrate molding die of the present invention. FIG. 8A is a plan view showing the arrangement of shims. In this case, the arrangement of the shim shown in FIG. 8A is a case where the fixed

[0055]

The difference from the second embodiment is that the

[0056]

The

[0057]

Further, the

[0058]

As

[0059]

As a result, in the case of the conventional configuration in which no shim is inserted, the plate thickness variation within one molded substrate is 30 μm or more at maximum, but in the configuration of the present embodiment in which the shim is inserted, the variation is 15 μm at maximum. The variation width could be reduced to less than. Further, when the shim shown in FIG. 8B was used, the variation width could be reduced to a maximum of less than 10 μm.

[0060]

Although the

[0061]

FIG. 8A shows an example in which two

[0062]

(Embodiment 4)

FIG. 9 is a cross-sectional view showing a fourth embodiment of the substrate molding die of the present invention. FIG. 10 is a plan view showing the arrangement of the

[0063]

4 differs from FIG. 4 in that a plurality of concave and convex fitting portions are provided in a member forming a joint surface on which the

[0064]

The

[0065]

The cross-sectional shape of the

[0066]

Further, even if the number of

[0067]

Further, even if the number of pins passing through one

[0068]

For example, as shown in FIG. 9, a

[0069]

In any of the above configurations, the

[0070]

As a result, the thickness variation in one molded substrate was 30 μm or more in the conventional structure, but was less than 10 μm in the fourth embodiment of the present invention. Further, when the movement of the

[0071]

In the fourth embodiment, the

[0072]

Also, the

[0073]

Furthermore, you may process a metal mold member directly instead of the pin which inserts in a member as a convex part which inserts a shim.

[0074]

(Embodiment 5)

FIG. 12 is a sectional

[0075]

Compared to the configuration of FIG. 1, the configuration shown in FIG. 12 is provided with a convex portion on the fixed

[0076]

Moreover, the point which provided the convex part in the fixed bush, provided the recessed part fitted with it in the fixed mold base |

[0077]

Since the

[0078]

The positions of the uneven portions are only required to be scattered on the joint surface, but are preferably scattered uniformly or concentrically with the

[0079]

FIG. 13 is a plan view showing the arrangement of the

[0080]

Here, the outer shape of the shim and the cross-sectional shape of the recess are circular. The diameter of the recess was 10 mm, and the diameter of the shim was 9 mm.

[0081]

In addition, for the mold for molding a resin substrate having an inner diameter of 15 mm, an outer diameter of 120 mm, and a plate thickness of 0.6 mm, shims 9 and 12 having thicknesses of 5 μm to 50 μm are prepared every 5 μm. Experiments similar to the morphology were performed. The molding conditions are the same as in the above embodiment.

[0082]

As a result, in the case of the conventional configuration in which no shim is inserted, the thickness variation within one molded substrate is 30 μm or more at maximum, but in the configuration of the present embodiment in which the shim is inserted, the variation is less than 10 μm at maximum. The width could be reduced.

[0083]

In this embodiment, the outer shape of the shim is circular. However, the shape of the shim is not limited to this, and the outer shape of the shim may be any shape as long as it enters the recess. Moreover, the cross-sectional shape of the recess may not be circular.

[0084]

(Embodiment 6)

FIG. 14 is a sectional

[0085]

In the configuration shown in FIG. 14, an abutting

[0086]

Specifically, if the diameter of the abutting

[0087]

FIG. 17A is a cross-sectional view taken along the line AA in FIG. 702 to 704 shown in FIG. 17A are gears having different rotation ratios. Moreover, the front-end |

[0088]

Further, there is a groove at the head of the abutting

[0089]

The abutting

[0090]

FIG. 15 is a plan view illustrating an example of the arrangement of the uneven portions. In this case, the arrangement of the concavo-convex portion (abutting member 26) shown in FIG. 15 is such that the fixed

[0091]

The

[0092]

For a mold for molding a resin substrate having an inner diameter of 15 mm, an outer diameter of 120 mm, and a plate thickness of 0.6 mm, a

[0093]

As a result, in the case of the conventional configuration, the thickness variation within one molded substrate was 30 μm at the maximum, but in the configuration of the present embodiment using the abutting

[0094]

The abutting

[0095]

A configuration for mechanically suppressing the rotation of the screw portion is shown in FIGS. FIG. 16F is a cross-sectional view, and FIG. 16G is a plan view seen from the head side of the abutting

[0096]

Of course, an abutting member may be used instead of the

[0097]

(Embodiment 7)

FIG. 18 is a sectional view showing a seventh embodiment of the substrate molding die of the present invention.

[0098]

In the above embodiment, the case where the gap adjusting means is on the fixed

[0099]

A

[0100]

A

[0101]

The

[0102]

Variation in the radial direction of the molded substrate is suppressed by adjusting the thickness of the

[0103]

For a mold for molding a resin substrate having an inner diameter of 15 mm, an outer diameter of 120 mm, and a plate thickness of 0.6 mm, the

[0104]

As a result, in the case of the conventional configuration that does not use shims, the plate thickness variation within one molded substrate is 30 μm at the maximum, but in the configuration of this

In the above embodiment, a cover plate that covers the temperature control groove of the mirror surface board is provided on the fixed mold or the movable mold, and pins and shims are provided on the joint surface between the cover plate and the mold base. You may provide a pin and a shim in.

[0105]

Further, the pin may be structured to be fixed to the lid plate side instead of the mold base side.

[0106]

The cross-sectional shape of the pin and the hole shape of the shim may be other than a perfect circle.

[0107]

As described above, according to the present invention, it is possible to obtain a high accuracy in which the thickness variation within one sheet of the molded substrate is less than 10 μm.

[0108]

That is, it is possible to finely adjust the thickness of the molded substrate, and it is possible to reduce variations in thickness that occur in the radial direction and circumferential direction of the molded substrate.

[0109]

Further, even if the molding operation is continued, the remarkable effect that the accuracy is maintained can be obtained.

[0110]

【The invention's effect】

As is apparent from the above description, the present invention has an advantage that variation in thickness of the molded substrate can be suppressed.

[Brief description of the drawings]

FIG. 1 is a cross-sectional view showing a substrate molding die according to a first embodiment of the present invention.

FIG. 2 is a plan view showing the arrangement of shims in a substrate molding die according to the first embodiment of the present invention.

FIG. 3A is a board thickness distribution diagram before a shim is inserted into a board molding die according to the first embodiment of the present invention.

(B): Thickness distribution diagram of the substrate after the shim is inserted into the substrate molding die according to the first embodiment of the present invention

FIG. 4 is a cross-sectional view showing a substrate molding die according to a second embodiment of the present invention.

FIG. 5 is a plan view showing shim arrangement of a substrate molding die according to a second embodiment of the present invention.

FIG. 6A is a board thickness distribution diagram before a shim is inserted into a board molding die according to a second embodiment of the present invention.

(B): Thickness distribution diagram of the substrate after the shim is inserted into the substrate molding die according to the second embodiment of the present invention

FIG. 7 is a cross-sectional view showing a substrate molding die according to a third embodiment of the present invention.

FIG. 8A is a plan view showing the arrangement of shims in a substrate molding die according to a third embodiment of the present invention.

(B): A plan view and a cross-sectional view showing the shape of the shim of the substrate molding die according to the third embodiment of the present invention.

FIG. 9 is a cross-sectional view showing a substrate molding die according to a fourth embodiment of the present invention.

FIG. 10 is a plan view showing the arrangement of shims and pins of a substrate molding die according to a fourth embodiment of the present invention.

FIG. 11A is a cross-sectional view showing a configuration of pins and shims of a substrate molding die according to a fourth embodiment of the present invention.

(B): Plan view showing shim shape of substrate molding die according to

(C): Plan view showing shim shape of substrate molding die according to

(D): Plan view showing shim shape of substrate molding die according to

(E): Plan view showing shim shape of substrate molding die according to

(F): Plan view showing shim shape of substrate molding die according to

FIG. 12 is a cross-sectional view showing a substrate molding die according to a fifth embodiment of the present invention.

FIG. 13 is a cross-sectional view showing the arrangement of recesses for providing shims of a substrate molding die according to a fifth embodiment of the present invention.

FIG. 14 is a sectional view showing a substrate molding die according to a sixth embodiment of the present invention.

FIG. 15 is a plan view showing an arrangement of abutting members of a substrate molding die according to a sixth embodiment of the present invention.

FIG. 16A is a cross-sectional view showing the configuration of the abutting member of the substrate molding die according to the sixth embodiment of the present invention.

(B): The top view which showed the groove | channel shape of the head of the butting member of the metal mold | die for board | substrate shaping | molding of

(C): The top view which showed the groove | channel shape of the head of the butting member of the metal mold | die for board | substrate shaping | molding of

(D): The top view which showed the groove | channel shape of the head of the butting member of the metal mold | die for board | substrate shaping | molding of

(E): Plan view showing the groove shape of the head of the abutting member of the substrate molding die according to the sixth embodiment of the present invention.

(F): Sectional view showing the configuration of the abutting member of the substrate molding die according to the sixth embodiment of the present invention.

(G): Plan view showing the configuration of the abutting member of the substrate molding die according to the sixth embodiment of the present invention.

FIG. 17A is a cross-sectional view of a jig for adjusting the protrusion amount of the abutting member of the substrate molding die according to the sixth embodiment of the present invention.

(B): Side view of a jig for adjusting the protruding amount of the abutting member of the mold for forming a substrate according to the sixth embodiment of the present invention.

FIG. 18 is a cross-sectional view showing a substrate molding die according to a seventh embodiment of the present invention.

FIG. 19 is a sectional view showing a conventional substrate molding die.

[Explanation of symbols]

1 Fixed mold

2 Movable mold

3 Stamper

4 Stamper holder

5 outer ring

6 Fixed mirror surface board

7, 22 Temperature control groove

8 Fixed mold base

9, 12, 30, 31 shims

10 Fixed bush

11 Sprue bush

13 Fixed abutment ring

14 Movable abutment ring

15 cavity

16 Movable mold base

17 Movable mirror

18 Movable bush

19 Ejector punch

20 Cut punch

21 Ejector pin

23 Spring

24, 28 Cover plate

25, 29 pins

26 Abutting member

27 nuts

101 Fixed mold

102 Movable mold

103 Fixed abutting ring

104 Movable abutment ring

105 Fixed mounting template

106 Sim

107 fixed mirror

108 Fixed bush

109 sprue bush

110 Stamper

111 stamper holder

112 outer ring

113 Spring

114 Movable mounting template

115 Movable mirror

116 Movable bush

117 Ejector punch

118 Cut punch

119 Ejector pin

120, 121 Temperature control groove

201 Perimeter edge of fixed mirror

202 Inner peripheral edge of fixed bush

301 substrate

302 circumference of 23mm radius

303 Circumference of radius 40mm

304 circumference of radius 58mm

401 Bonding surface

402, 403 steps

501 Outer part of fixed bush

601 recess

701 Tip

702-704 gear

Claims (23)

前記一対の基板成形部材の内、一方の基板成形部材を保持する固定基盤と、

前記一対の基板成形部材の内、他方の基板成形部材を保持する可動基盤と、

前記一対の基板成形部材が嵌合された際、それら一対の基板成形部材の間に、前記基板を成形する所定の隙間を設けるために互いに突き当てられる、前記固定基盤及び可動基盤に設けられ且つ前記基板成形部材より外側の位置に配置された一対の突当部材と、

前記隙間を調整するために、前記一方の基板成形部材と前記固定基盤との間及び/又は前記他方の基板成形部材と前記可動基盤との間であって、且つ、前記突当部材の内側に配置される隙間調整手段と、

を備えたことを特徴とする基板成形金型。A pair of substrate molding members for molding the substrate;

Of the pair of substrate forming members, a fixed base for holding one substrate forming member,

Of the pair of substrate forming members, a movable base for holding the other substrate forming member;

When the pair of board forming members are fitted, the fixed board and the movable board are abutted with each other to provide a predetermined gap for molding the board between the pair of board forming members, and A pair of abutting members disposed at positions outside the substrate molding member ;

In order to adjust the gap, between the one substrate molding member and the fixed base and / or between the other substrate molding member and the movable base and inside the abutting member A gap adjusting means disposed;

A substrate molding die comprising:

前記隙間調整手段が、前記蓋部材と前記固定基盤又は可動基盤との間に設けられていることを特徴とする請求項1記載の基板成形金型。Provided with a lid member for covering the groove through which the temperature adjusting medium is provided, provided in the substrate forming member,

2. The substrate molding die according to claim 1, wherein the gap adjusting means is provided between the lid member and the fixed base or the movable base.

前記基盤と前記基板成形部材との接合面の外周端が、前記突当部材の内周壁面に当たる位置に、前記基盤の段差があり、

前記隙間調整手段が、前記基盤の段差がある前記突当部材の内周壁面に隣接して配置されていることを特徴とする請求項1記載の基板成形金型。The abutting member is connected in an annular shape,

There is a step in the base at a position where the outer peripheral end of the joint surface between the base and the substrate molding member hits the inner peripheral wall surface of the abutting member,

2. The substrate molding die according to claim 1, wherein the gap adjusting means is disposed adjacent to an inner peripheral wall surface of the abutting member having a step of the base .

前記基盤と前記環状部材以外の前記基板成形部材との接合面の内周端が、前記環状部材の前記外周部の壁面に当たる位置に、前記基盤の段差があり、

前記隙間調整手段が、前記基盤の段差がある前記環状部材の前記外周部の壁面に隣接して配置されていることを特徴とする請求項1記載の基板成形金型。 The substrate molding member includes an annular member having a through hole leading to the gap in a central portion, and arranged so that an outer peripheral portion on one end side protrudes from the through hole and is fitted,

The inner peripheral edge of the joint surface between the substrate molding member other than the annular member and the foundation, the position corresponding to the wall surface of the outer peripheral portion of the annular member, there is a step of said base,

2. The substrate molding die according to claim 1, wherein the gap adjusting means is disposed adjacent to a wall surface of the outer peripheral portion of the annular member having a step of the base.

前記孔を貫通するピンが、前記シムを挟み込んでいる接合面の何れか一方の側面に設けられていることを特徴とする請求項6記載の基板成形金型。The shim is provided with a hole,

Pins, claim 6 substrate forming metal mold according to, characterized in that provided on either side of the joint surface that sandwiches the shim through said hole.

前記突出部材を回転することにより、その突出寸法が調整可能であることを特徴とする請求項1、2、4又は5に記載の基板成形金型。The gap adjusting means is a protruding member screwed into the substrate molding member or the base that is joined to the substrate molding member,

Wherein by rotating the protruding member, a substrate formed metal mold according to claim 1, 2, 4 or 5, characterized in that the projecting dimension is adjustable.

前記突出部材を回転することにより、その突出寸法が調整可能であることを特徴とする請求項3記載の基板成形金型。The gap adjusting means is a protruding member screwed into the lid member or the base joined to the lid member,

Wherein by rotating the protruding member, according to claim 3 substrate forming metal mold of, wherein that the projecting dimension is adjustable.

前記一対の基板成形部材の内、一方の基板成形部材を保持する固定基盤と、

前記一対の基板成形部材の内、他方の基板成形部材を保持する可動基盤と、

前記一対の基板成形部材が嵌合された際、それら一対の基板成形部材の間に、前記基板を成形する所定の隙間を設けるために互いに突き当てられる、前記固定基盤及び可動基盤に設けられ且つ前記基板成形部材より外側の位置に配置された一対の突当部材とを備えた基板成形金型における成形基板の板厚調整方法であって、

前記隙間を調整するために、前記一方の基板成形部材と前記固定基盤との間及び/又は前記他方の基板成形部材と前記可動基盤との間であって、且つ、前記突当部材の内側に隙間調整手段を配置することを特徴とする基板成形金型における成形基板の板厚調整方法。A pair of substrate molding members for molding the substrate;

Of the pair of substrate forming members, a fixed base for holding one substrate forming member,

Of the pair of substrate forming members, a movable base for holding the other substrate forming member;

When the pair of board forming members are fitted, the fixed board and the movable board are abutted with each other to provide a predetermined gap for molding the board between the pair of board forming members, and A method for adjusting the thickness of a molded substrate in a substrate molding die comprising a pair of abutting members arranged at positions outside the substrate molded member ,

In order to adjust the gap, between the one substrate molding member and the fixed base and / or between the other substrate molding member and the movable base and inside the abutting member A method for adjusting the thickness of a molded substrate in a substrate molding die, wherein a gap adjusting means is arranged.

前記隙間調整手段を、前記複数の金型構成部材の内、全部又は一部の金型構成部材と前記基盤との間に設けることを特徴とする請求項16記載の基板成形金型における成形基板の板厚調整方法。When the substrate molding member is constituted by a combination of a plurality of mold constituent members,

The molded substrate in a substrate molding die according to claim 16, wherein the gap adjusting means is provided between all or a part of the plurality of mold constituent members and the base. Thickness adjustment method.

前記隙間調整手段を、前記蓋部材と前記固定基盤又は可動基盤との間に設けることを特徴とする請求項16記載の基板成形金型における成形基板の板厚調整方法。When a lid member for covering a groove for flowing a temperature adjusting medium provided on the substrate forming member is provided,

The method for adjusting the thickness of a molded substrate in a substrate molding die according to claim 16, wherein the gap adjusting means is provided between the lid member and the fixed base or the movable base.

前記基盤と前記基板成形部材との接合面の外周端が、前記突当部材の内周壁面に当たる位置に、前記基盤の段差がある場合、

前記隙間調整手段を、前記基盤の段差がある前記突当部材の内周壁面に隣接して配置することを特徴とする請求項16記載の基板成形金型における成形基板の板厚調整方法。The abutting member is connected in an annular shape,

When there is a step of the base at a position where the outer peripheral end of the joint surface between the base and the substrate molding member hits the inner peripheral wall surface of the abutting member,

17. The method for adjusting the thickness of a molded substrate in a substrate molding die according to claim 16, wherein the gap adjusting means is disposed adjacent to an inner peripheral wall surface of the abutting member having a step of the base .

前記基盤と前記環状部材以外の前記基板成形部材との接合面の内周端が、前記環状部材の前記外周部の壁面に当たる位置に、前記基盤の段差がある場合、

前記隙間調整手段を、前記基盤の段差がある前記環状部材の前記外周部の壁面に隣接して配置することを特徴とする請求項16記載の基板成形金型における成形基板の板厚調整方法。 The substrate molding member includes an annular member having a through hole leading to the gap in a central portion, and arranged so that an outer peripheral portion on one end side protrudes from the through hole and is fitted,

If the inner peripheral end of the junction surface between the substrate molding member other than the annular member and the foundation, that the position corresponding to the wall surface of the outer peripheral portion of the annular member, there is a step of said base,

The method for adjusting the thickness of a molded substrate in a substrate molding die according to claim 16, wherein the gap adjusting means is disposed adjacent to a wall surface of the outer peripheral portion of the annular member having a step of the base.

前記シムに耐熱粘性流体を塗布することを特徴とする請求項16〜20の何れか一つに記載の基板成形金型における成形基板の板厚調整方法。The gap adjusting means is a thin plate-shaped shim,

The method for adjusting the thickness of a molded substrate in a substrate molding die according to any one of claims 16 to 20, wherein a heat-resistant viscous fluid is applied to the shim.

前記突出部材の突出寸法を調整する場合、その突出部材を回転させることにより行うことを特徴とする請求項16,17,19,又は20に記載の基板成形金型における成形基板の板厚調整方法。The gap adjusting means is a protruding member screwed into the substrate molding member or the base that is joined to the substrate molding member,

21. The method for adjusting a thickness of a molded substrate in a substrate molding die according to claim 16, 17, 19 or 20, wherein the protruding dimension of the protruding member is adjusted by rotating the protruding member. .

前記突出部材の突出寸法を調整する場合、その突出部材を回転させることにより行うことを特徴とする請求項18に記載の基板成形金型における成形基板の板厚調整方法。The gap adjusting means is a protruding member screwed into the lid member or the base joined to the lid member,

19. The method for adjusting the thickness of a molded substrate in a substrate molding die according to claim 18, wherein the projecting dimension of the projecting member is adjusted by rotating the projecting member.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP14022698A JP3877870B2 (en) | 1997-05-30 | 1998-05-21 | Substrate molding die and method for adjusting thickness of molded substrate in substrate molding die |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP14265397 | 1997-05-30 | ||

| JP9-142653 | 1997-05-30 | ||

| JP14022698A JP3877870B2 (en) | 1997-05-30 | 1998-05-21 | Substrate molding die and method for adjusting thickness of molded substrate in substrate molding die |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPH1142648A JPH1142648A (en) | 1999-02-16 |

| JP3877870B2 true JP3877870B2 (en) | 2007-02-07 |

Family

ID=26472823

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP14022698A Expired - Fee Related JP3877870B2 (en) | 1997-05-30 | 1998-05-21 | Substrate molding die and method for adjusting thickness of molded substrate in substrate molding die |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3877870B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| HK1027253A2 (en) * | 2000-07-31 | 2000-12-08 | Ning Lok Tse | Mould for injection moulding |

-

1998

- 1998-05-21 JP JP14022698A patent/JP3877870B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1142648A (en) | 1999-02-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR19990078021A (en) | Mold for fabricating semiconductor devices and a method of fabricating a semiconductor device using a press-molding process | |

| US6095786A (en) | Substrate forming mold, and plate thickness adjusting method of formed substrate in substrate forming mold | |

| JP3877870B2 (en) | Substrate molding die and method for adjusting thickness of molded substrate in substrate molding die | |

| US9579835B2 (en) | Locating ring and method for positioning parts | |

| JPH0828615A (en) | Friction pad | |

| JP4293715B2 (en) | Hub mounting device | |

| JP3429828B2 (en) | Method for attaching die and female die to punching machine, and member for positioning die and female die | |

| JPS6240142B2 (en) | ||

| JP4057176B2 (en) | Optical member polishing tool, pitch segment used therefor, and mold for the pitch segment | |

| JPS5921099B2 (en) | Large-area tape guide device for magnetic tape device and its manufacturing method | |

| KR100602000B1 (en) | Mold for molding disk substrate | |

| US11554407B2 (en) | Method for manufacturing brake disc and brake disc | |

| JP3409215B2 (en) | Disc substrate mold | |

| JPH08156036A (en) | Information recording disk molding injection mold | |

| JP2014162012A (en) | Microstructure molding method and microstructure molding die | |

| JP2949067B2 (en) | Injection mold for thin molded products such as information recording boards | |

| US6500512B2 (en) | Apparatus and method for use in the manufacture of multiple layer optical discs | |

| JPH0543327U (en) | Optical disk substrate mold | |

| JPH02182323A (en) | Manufacture of precision metallic disk | |

| JPH0636486Y2 (en) | Head mounting mechanism for hard disk inspection equipment | |

| KR20080012297A (en) | Mold for disc molding, mirror plate, and process for producing mold for disc molding | |

| JP3836024B2 (en) | Disc molding die and disc molding method | |

| JP3524595B2 (en) | Injection mold | |

| JPH05116186A (en) | Balance adjusting molding die | |

| CN111390021A (en) | Phase adjusting assembly of mold |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050316 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050316 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060424 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060509 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060707 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060801 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060928 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061024 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20061101 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |