JP2015516556A - 円錐ころ軸受けの保持器セグメントおよび円錐ころ軸受け - Google Patents

円錐ころ軸受けの保持器セグメントおよび円錐ころ軸受け Download PDFInfo

- Publication number

- JP2015516556A JP2015516556A JP2015510709A JP2015510709A JP2015516556A JP 2015516556 A JP2015516556 A JP 2015516556A JP 2015510709 A JP2015510709 A JP 2015510709A JP 2015510709 A JP2015510709 A JP 2015510709A JP 2015516556 A JP2015516556 A JP 2015516556A

- Authority

- JP

- Japan

- Prior art keywords

- circumferential

- web

- cage

- cage segment

- tapered roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

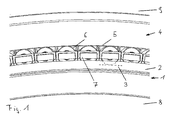

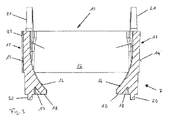

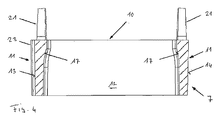

- F16C33/46—Cages for rollers or needles

- F16C33/51—Cages for rollers or needles formed of unconnected members

- F16C33/513—Cages for rollers or needles formed of unconnected members formed of arcuate segments for carrying one or more rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/22—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings

- F16C19/34—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load

- F16C19/36—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with a single row of rollers

- F16C19/364—Bearings with rolling contact, for exclusively rotary movement with bearing rollers essentially of the same size in one or more circular rows, e.g. needle bearings for both radial and axial load with a single row of rollers with tapered rollers, i.e. rollers having essentially the shape of a truncated cone

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/46—Cages for rollers or needles

- F16C33/467—Details of individual pockets, e.g. shape or roller retaining means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C43/00—Assembling bearings

- F16C43/04—Assembling rolling-contact bearings

- F16C43/06—Placing rolling bodies in cages or bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C43/00—Assembling bearings

- F16C43/04—Assembling rolling-contact bearings

- F16C43/06—Placing rolling bodies in cages or bearings

- F16C43/065—Placing rolling bodies in cages or bearings in cages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

- F16C2240/46—Gap sizes or clearances

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2300/00—Application independent of particular apparatuses

- F16C2300/10—Application independent of particular apparatuses related to size

- F16C2300/14—Large applications, e.g. bearings having an inner diameter exceeding 500 mm

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2360/00—Engines or pumps

- F16C2360/31—Wind motors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/46—Cages for rollers or needles

- F16C33/467—Details of individual pockets, e.g. shape or roller retaining means

- F16C33/4676—Details of individual pockets, e.g. shape or roller retaining means of the stays separating adjacent cage pockets, e.g. guide means for the bearing-surface of the rollers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C41/00—Other accessories, e.g. devices integrated in the bearing not relating to the bearing function as such

- F16C41/008—Identification means, e.g. markings, RFID-tags; Data transfer means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49636—Process for making bearing or component thereof

- Y10T29/49643—Rotary bearing

- Y10T29/49679—Anti-friction bearing or component thereof

- Y10T29/4968—Assembling of race, cage, and rolling anti-friction members

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49636—Process for making bearing or component thereof

- Y10T29/49643—Rotary bearing

- Y10T29/49679—Anti-friction bearing or component thereof

- Y10T29/49691—Cage making

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rolling Contact Bearings (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102012207529.1 | 2012-05-07 | ||

| DE102012207529A DE102012207529A1 (de) | 2012-05-07 | 2012-05-07 | Käfigsegment eines Kegelrollenlagers und Kegelrollenlager |

| PCT/EP2013/058257 WO2013167363A1 (de) | 2012-05-07 | 2013-04-22 | Käfigsegment eines kegelrollenlagers und kegelrollenlager |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015516556A true JP2015516556A (ja) | 2015-06-11 |

| JP2015516556A5 JP2015516556A5 (enExample) | 2016-06-16 |

Family

ID=48224804

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015510709A Withdrawn JP2015516556A (ja) | 2012-05-07 | 2013-04-22 | 円錐ころ軸受けの保持器セグメントおよび円錐ころ軸受け |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9458886B2 (enExample) |

| EP (1) | EP2847481A1 (enExample) |

| JP (1) | JP2015516556A (enExample) |

| CN (1) | CN104350297A (enExample) |

| DE (1) | DE102012207529A1 (enExample) |

| WO (1) | WO2013167363A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190048357A (ko) * | 2017-10-31 | 2019-05-09 | 셰플러코리아(유) | 조립성이 향상된 테이퍼 롤러 베어링 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013017714A1 (de) * | 2013-10-24 | 2015-04-30 | GM Global Technology Operations LLC (n. d. Ges. d. Staates Delaware) | Wälzlageranordnung mit einem Lagerkäfig sowie Verfahren zur Montage einer solchen Wälzlageranordnung |

| JP6369083B2 (ja) * | 2013-11-25 | 2018-08-08 | 株式会社ジェイテクト | 分割保持器及びころ軸受 |

| JP2015102153A (ja) * | 2013-11-25 | 2015-06-04 | 株式会社ジェイテクト | 分割保持器及びころ軸受 |

| JP6295621B2 (ja) * | 2013-11-25 | 2018-03-20 | 株式会社ジェイテクト | 分割保持器及びころ軸受 |

| JP2015135143A (ja) * | 2014-01-17 | 2015-07-27 | 株式会社ジェイテクト | 円錐ころ軸受の組立用治具および組立方法、ならびに内輪アッセンブリ |

| JP2015135142A (ja) * | 2014-01-17 | 2015-07-27 | 株式会社ジェイテクト | 円錐ころ軸受の組立用治具および組立方法、ならびに内輪アッセンブリ |

| EP3104030A4 (en) * | 2014-02-07 | 2017-10-04 | JTEKT Corporation | Segmented cage and roller bearing |

| DE102014220649A1 (de) * | 2014-10-13 | 2016-04-14 | Schaeffler Technologies AG & Co. KG | Käfigmodul und Rollenwälzlager mit einem aus diesen Käfigmodulen aufgebauten Käfig |

| DE102017211146A1 (de) * | 2017-06-30 | 2019-01-03 | Aktiebolaget Skf | Abstandshalter für Wälzlager, insbesondere zur Verwendung in einer Windturbine |

| CN110878798A (zh) * | 2019-12-27 | 2020-03-13 | 瓦房店轴承集团国家轴承工程技术研究中心有限公司 | 端面带角度坡结构的保持架 |

| US10975912B1 (en) | 2020-01-21 | 2021-04-13 | United Technologies Corporation | Roller bearing cage retention apparatus |

| CN116892571A (zh) * | 2023-07-26 | 2023-10-17 | 山东金帝精密机械科技股份有限公司 | 一种调心滚子轴承保持架 |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1585690A (en) * | 1918-10-22 | 1926-05-25 | Skf Svenska Kullagerfab Ab | Roller bearing |

| US2417559A (en) * | 1944-06-26 | 1947-03-18 | Cread Engineering And Res Comp | Antifriction bearing retainer |

| FR1559419A (enExample) | 1967-04-28 | 1969-03-07 | ||

| FR2222898A5 (enExample) * | 1973-03-20 | 1974-10-18 | Rks | |

| NL7403680A (enExample) * | 1973-03-20 | 1974-09-24 | ||

| FR2224015A1 (enExample) * | 1973-03-27 | 1974-10-25 | Rks | |

| DE3114325C2 (de) * | 1981-04-09 | 1984-02-23 | FAG Kugelfischer Georg Schäfer KGaA, 8720 Schweinfurt | Wälzlager, vorzugsweise Drehkranz |

| GB2104600A (en) * | 1981-08-26 | 1983-03-09 | Kugelfischer G Schaefer & Co | A segmented cage for a ball or roller bearing |

| SE432977B (sv) * | 1982-06-09 | 1984-04-30 | Skf Ab | Rullager med gjuten plasthallare |

| DE4027109A1 (de) * | 1990-08-28 | 1992-03-05 | Hoesch Ag | Kaefig fuer ein waelzlager |

| DE29720767U1 (de) * | 1997-11-22 | 1998-01-15 | Skf Gmbh, 97421 Schweinfurt | Massivkäfig für Rollenlager |

| JP4515589B2 (ja) * | 2000-03-21 | 2010-08-04 | Thk株式会社 | ローラ用リテーナ及びこれを用いた直動案内装置並びにローラねじ |

| DE10246825B4 (de) * | 2002-10-08 | 2019-02-14 | Aktiebolaget Skf | Käfig für ein Wälzlager |

| DE102004026291A1 (de) * | 2004-05-28 | 2005-12-15 | Fag Kugelfischer Ag & Co. Ohg | Käfig mit Rollen |

| DE102005009980B3 (de) * | 2005-03-04 | 2006-06-14 | Aktiebolaget Skf | Wälzlager |

| JP4342512B2 (ja) * | 2005-12-21 | 2009-10-14 | Ntn株式会社 | 転がり軸受、保持器セグメントおよび風力発電機の主軸支持構造 |

| JP2007205557A (ja) * | 2006-02-06 | 2007-08-16 | Ntn Corp | 転がり軸受、保持器セグメントおよび風力発電機の主軸支持構造 |

| DK2461058T3 (en) * | 2006-03-10 | 2015-07-13 | Ntn Toyo Bearing Co Ltd | Roller bearing, cage segment and main shaft support structure for wind powered generator |

| DE102006022951A1 (de) * | 2006-05-17 | 2007-11-22 | Schaeffler Kg | Käfigsegment für einen Käfig eines Wälzlagers |

| JP2008064248A (ja) * | 2006-09-08 | 2008-03-21 | Ntn Corp | 転がり軸受用保持器、転がり軸受、および風力発電機の主軸支持構造 |

| JP2008082380A (ja) | 2006-09-26 | 2008-04-10 | Ntn Corp | 転がり軸受、保持器付ころ、および風力発電機の主軸支持構造 |

| DE102007048655A1 (de) * | 2007-10-10 | 2008-02-07 | Schaeffler Kg | Käfigsegment eines Kunststoffkäfigs sowie Wälzlager mit dem Kunststoffkäfig |

| WO2010005007A1 (ja) * | 2008-07-08 | 2010-01-14 | 日本精工株式会社 | 円すいころ軸受用樹脂製保持器及び円すいころ軸受 |

| JP5457004B2 (ja) * | 2008-09-30 | 2014-04-02 | Ntn株式会社 | 風力発電機の主軸支持用ころ軸受の保持器セグメント間のすき間調整方法 |

| DE102009012241A1 (de) | 2009-03-07 | 2010-09-09 | Werner Beuerlein | Wälzlager mit segmentiertem Käfig |

| JP5757703B2 (ja) * | 2009-12-25 | 2015-07-29 | Ntn株式会社 | 円すいころ軸受 |

| JP2011163513A (ja) * | 2010-02-12 | 2011-08-25 | Hitachi Constr Mach Co Ltd | 旋回軸受、及びこの旋回軸受を用いた建設機械 |

| EP2677184B1 (de) * | 2012-06-21 | 2020-08-05 | Aktiebolaget SKF | Segment eines wälzlagerkäfigs |

-

2012

- 2012-05-07 DE DE102012207529A patent/DE102012207529A1/de not_active Withdrawn

-

2013

- 2013-04-22 WO PCT/EP2013/058257 patent/WO2013167363A1/de not_active Ceased

- 2013-04-22 EP EP13719288.6A patent/EP2847481A1/de not_active Withdrawn

- 2013-04-22 US US14/399,550 patent/US9458886B2/en not_active Expired - Fee Related

- 2013-04-22 CN CN201380031185.6A patent/CN104350297A/zh active Pending

- 2013-04-22 JP JP2015510709A patent/JP2015516556A/ja not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190048357A (ko) * | 2017-10-31 | 2019-05-09 | 셰플러코리아(유) | 조립성이 향상된 테이퍼 롤러 베어링 |

| KR102536309B1 (ko) * | 2017-10-31 | 2023-05-31 | 셰플러코리아 유한책임회사 | 조립성이 향상된 테이퍼 롤러 베어링 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2847481A1 (de) | 2015-03-18 |

| CN104350297A (zh) | 2015-02-11 |

| DE102012207529A1 (de) | 2013-11-07 |

| US9458886B2 (en) | 2016-10-04 |

| WO2013167363A1 (de) | 2013-11-14 |

| US20150219157A1 (en) | 2015-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2015516556A (ja) | 円錐ころ軸受けの保持器セグメントおよび円錐ころ軸受け | |

| JP2013545949A (ja) | 円錐ころ軸受のケージセグメント及び円錐ころ軸受 | |

| US8851761B2 (en) | Split cage for rolling bearing and rolling bearing using the split cage | |

| US20130078098A1 (en) | Roller bearing, retainer segment, spacer and main shaft support structure of wind-power generator | |

| JP5030072B2 (ja) | 分割された外レース及び一体の内レースを持つ2列アンギュラコンタクト転がり軸受 | |

| JP2013545949A5 (ja) | 円錐ころ軸受 | |

| EP2664808A2 (en) | Rolling bearing cage with retention means | |

| JP2014084949A (ja) | 円筒ころ軸受 | |

| JP2015516556A5 (enExample) | ||

| CN105190065B (zh) | 具有圆筒形引导接触表面和径向向外转动的向内凸缘的球形滚柱轴承保持架 | |

| KR101576072B1 (ko) | 롤링 베어링용 유지기, 이것을 구비한 내륜 조립체, 외륜 조립체, 및 롤링 베어링 | |

| CN105593547A (zh) | 滚针轴承系统 | |

| JP5531551B2 (ja) | 転がり軸受用保持器、並びにこれを備えた内輪組立体、外輪組立体、及び転がり軸受 | |

| CN101341349B (zh) | 滚动轴承、保持器构件及风力发电机主轴支承结构 | |

| JP7485948B2 (ja) | 自動調心ころ軸受用保持器 | |

| JP2019173919A (ja) | 自動調心ころ軸受用保持器 | |

| JP2011106509A (ja) | 転がり軸受およびその保持器 | |

| JP5071775B2 (ja) | 2分割外輪及びそれを用いたころ軸受 | |

| JP5218231B2 (ja) | 転がり軸受用保持器、並びにこれを備えた内輪組立体、外輪組立体、および転がり軸受 | |

| JP2012241802A (ja) | 転がり軸受 | |

| JP2010121649A (ja) | 保持器付自動調心玉軸受 | |

| JP2009074587A (ja) | ケージアンドローラ及び転がり軸受 | |

| JP2009210091A (ja) | 自動調心ころ軸受 | |

| JP2011052776A (ja) | 止め環付きころ軸受 | |

| WO2007013317A1 (ja) | 針状ころ軸受 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141114 Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150108 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160419 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160419 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20170317 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170317 |