JP2012102755A - 車両用トルクリミッタ装置 - Google Patents

車両用トルクリミッタ装置 Download PDFInfo

- Publication number

- JP2012102755A JP2012102755A JP2010248919A JP2010248919A JP2012102755A JP 2012102755 A JP2012102755 A JP 2012102755A JP 2010248919 A JP2010248919 A JP 2010248919A JP 2010248919 A JP2010248919 A JP 2010248919A JP 2012102755 A JP2012102755 A JP 2012102755A

- Authority

- JP

- Japan

- Prior art keywords

- facing

- friction plate

- rotating shaft

- torque limiter

- facings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000002093 peripheral effect Effects 0.000 claims description 22

- 229910001220 stainless steel Inorganic materials 0.000 claims description 7

- 239000010935 stainless steel Substances 0.000 claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 5

- 239000002184 metal Substances 0.000 claims description 5

- 239000000853 adhesive Substances 0.000 abstract description 7

- 230000001070 adhesive effect Effects 0.000 abstract description 7

- 230000013011 mating Effects 0.000 abstract description 3

- 238000003825 pressing Methods 0.000 description 22

- 229920001971 elastomer Polymers 0.000 description 15

- 239000005060 rubber Substances 0.000 description 15

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 6

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 6

- 239000010410 layer Substances 0.000 description 6

- 239000011347 resin Substances 0.000 description 6

- 229920005989 resin Polymers 0.000 description 6

- 239000006096 absorbing agent Substances 0.000 description 5

- 239000003365 glass fiber Substances 0.000 description 5

- 230000007423 decrease Effects 0.000 description 4

- 229910000019 calcium carbonate Inorganic materials 0.000 description 3

- 210000000078 claw Anatomy 0.000 description 3

- 239000000428 dust Substances 0.000 description 3

- 239000002783 friction material Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000005011 phenolic resin Substances 0.000 description 3

- 229920001187 thermosetting polymer Polymers 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 229920000459 Nitrile rubber Polymers 0.000 description 2

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 239000011247 coating layer Substances 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 150000002989 phenols Chemical class 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000011593 sulfur Substances 0.000 description 2

- 229910052717 sulfur Inorganic materials 0.000 description 2

- 230000001629 suppression Effects 0.000 description 2

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical class [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 1

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 235000012489 doughnuts Nutrition 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 239000012783 reinforcing fiber Substances 0.000 description 1

- 239000012779 reinforcing material Substances 0.000 description 1

- 230000000452 restraining effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 229920003048 styrene butadiene rubber Polymers 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 239000005061 synthetic rubber Substances 0.000 description 1

- 238000004073 vulcanization Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

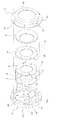

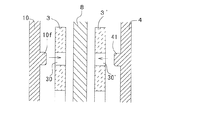

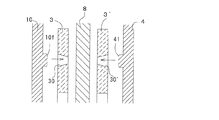

- F16D7/00—Slip couplings, e.g. slipping on overload, for absorbing shock

- F16D7/02—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type

- F16D7/024—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type with axially applied torque limiting friction surfaces

- F16D7/025—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type with axially applied torque limiting friction surfaces with flat clutching surfaces, e.g. discs

- F16D7/027—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type with axially applied torque limiting friction surfaces with flat clutching surfaces, e.g. discs with multiple lamellae

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D43/00—Automatic clutches

- F16D43/02—Automatic clutches actuated entirely mechanically

- F16D43/20—Automatic clutches actuated entirely mechanically controlled by torque, e.g. overload-release clutches, slip-clutches with means by which torque varies the clutching pressure

- F16D43/21—Automatic clutches actuated entirely mechanically controlled by torque, e.g. overload-release clutches, slip-clutches with means by which torque varies the clutching pressure with friction members

- F16D43/213—Automatic clutches actuated entirely mechanically controlled by torque, e.g. overload-release clutches, slip-clutches with means by which torque varies the clutching pressure with friction members with axially applied torque-limiting friction surfaces

- F16D43/215—Automatic clutches actuated entirely mechanically controlled by torque, e.g. overload-release clutches, slip-clutches with means by which torque varies the clutching pressure with friction members with axially applied torque-limiting friction surfaces with flat friction surfaces, e.g. discs

- F16D43/216—Automatic clutches actuated entirely mechanically controlled by torque, e.g. overload-release clutches, slip-clutches with means by which torque varies the clutching pressure with friction members with axially applied torque-limiting friction surfaces with flat friction surfaces, e.g. discs with multiple lamellae

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- One-Way And Automatic Clutches, And Combinations Of Different Clutches (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010248919A JP2012102755A (ja) | 2010-11-05 | 2010-11-05 | 車両用トルクリミッタ装置 |

| US13/237,161 US20120115620A1 (en) | 2010-11-05 | 2011-09-20 | Torque limiter |

| CN2011103448957A CN102454720A (zh) | 2010-11-05 | 2011-11-04 | 扭矩限制器 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010248919A JP2012102755A (ja) | 2010-11-05 | 2010-11-05 | 車両用トルクリミッタ装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2012102755A true JP2012102755A (ja) | 2012-05-31 |

| JP2012102755A5 JP2012102755A5 (enExample) | 2012-08-02 |

Family

ID=46020146

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010248919A Pending JP2012102755A (ja) | 2010-11-05 | 2010-11-05 | 車両用トルクリミッタ装置 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20120115620A1 (enExample) |

| JP (1) | JP2012102755A (enExample) |

| CN (1) | CN102454720A (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016070323A (ja) * | 2014-09-29 | 2016-05-09 | アイシン精機株式会社 | 摩擦緩衝装置 |

| CN112041577A (zh) * | 2018-06-22 | 2020-12-04 | 舍弗勒技术股份两合公司 | 带有电气绝缘保护构件的扭矩限制器以及带有扭矩限制器的动力总成系统 |

| JP2022501554A (ja) * | 2018-09-20 | 2022-01-06 | シェフラー テクノロジーズ アー・ゲー ウント コー. カー・ゲーSchaeffler Technologies AG & Co. KG | 電気駆動機械用のスリップクラッチ装置 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5604906B2 (ja) * | 2009-03-05 | 2014-10-15 | アイシン精機株式会社 | トルク変動吸収装置 |

| JP5691367B2 (ja) * | 2009-10-27 | 2015-04-01 | アイシン精機株式会社 | トルク変動吸収装置 |

| WO2012168997A1 (ja) * | 2011-06-06 | 2012-12-13 | トヨタ自動車株式会社 | 車両用トルクリミッタ装置 |

| CN109690105A (zh) * | 2016-09-13 | 2019-04-26 | 欧利生电气株式会社 | 扭矩限制器 |

| JP6870169B2 (ja) * | 2017-03-29 | 2021-05-12 | 株式会社アイシン | トルクリミッタ |

| TR201710514A1 (tr) | 2017-07-18 | 2019-02-21 | Ford Otomotiv Sanayi As | Bi̇r tork li̇mi̇tleyi̇ci̇ |

| DE102017121431A1 (de) * | 2017-09-15 | 2019-03-21 | Schaeffler Technologies AG & Co. KG | Drehmomentbegrenzer für einen Antriebsstrang |

| TR201914875A2 (tr) * | 2019-09-30 | 2021-04-21 | Valeo Otomotiv Sanayi Ve Ticaret A S | Bi̇r tork li̇mi̇törü |

| CN111173888A (zh) * | 2020-01-11 | 2020-05-19 | 华域动力总成部件系统(上海)有限公司 | 车辆用扭矩限制保护的飞轮装置 |

| DE102022100680A1 (de) * | 2022-01-13 | 2023-07-13 | Schaeffler Technologies AG & Co. KG | Drehmomentbegrenzer und Drehschwingungsdämpfer mit Drehmomentbegrenzer |

| DE102022100943A1 (de) * | 2022-01-17 | 2023-07-20 | Schaeffler Technologies AG & Co. KG | Drehmomentbegrenzer und Drehschwingungsdämpfer mit Drehmomentbegrenzer |

| CN120418548A (zh) * | 2023-01-12 | 2025-08-01 | 舍弗勒技术股份两合公司 | 滑动离合器、扭矩限制器、扭振减振器以及制造滑动离合器的金属板部件的方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5136743U (enExample) * | 1974-09-11 | 1976-03-18 | ||

| JP2002013547A (ja) * | 2000-06-29 | 2002-01-18 | Aisin Seiki Co Ltd | ハイブリッド駆動装置用ダンパ |

| JP2010230162A (ja) * | 2009-03-05 | 2010-10-14 | Aisin Seiki Co Ltd | トルク変動吸収装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3683165B2 (ja) * | 2000-07-27 | 2005-08-17 | トヨタ自動車株式会社 | トルク変動吸収装置のトルクリミッター部組付け偏芯低減構造および方法 |

| JP2005344823A (ja) * | 2004-06-02 | 2005-12-15 | Ntn Corp | 逆入力遮断クラッチ |

| CN2921435Y (zh) * | 2005-12-23 | 2007-07-11 | 中煤张家口煤矿机械有限责任公司 | 摩擦限矩器 |

-

2010

- 2010-11-05 JP JP2010248919A patent/JP2012102755A/ja active Pending

-

2011

- 2011-09-20 US US13/237,161 patent/US20120115620A1/en not_active Abandoned

- 2011-11-04 CN CN2011103448957A patent/CN102454720A/zh active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5136743U (enExample) * | 1974-09-11 | 1976-03-18 | ||

| JP2002013547A (ja) * | 2000-06-29 | 2002-01-18 | Aisin Seiki Co Ltd | ハイブリッド駆動装置用ダンパ |

| JP2010230162A (ja) * | 2009-03-05 | 2010-10-14 | Aisin Seiki Co Ltd | トルク変動吸収装置 |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016070323A (ja) * | 2014-09-29 | 2016-05-09 | アイシン精機株式会社 | 摩擦緩衝装置 |

| CN112041577A (zh) * | 2018-06-22 | 2020-12-04 | 舍弗勒技术股份两合公司 | 带有电气绝缘保护构件的扭矩限制器以及带有扭矩限制器的动力总成系统 |

| CN112041577B (zh) * | 2018-06-22 | 2022-06-24 | 舍弗勒技术股份两合公司 | 带有电气绝缘保护构件的扭矩限制器以及带有扭矩限制器的动力总成系统 |

| JP2022501554A (ja) * | 2018-09-20 | 2022-01-06 | シェフラー テクノロジーズ アー・ゲー ウント コー. カー・ゲーSchaeffler Technologies AG & Co. KG | 電気駆動機械用のスリップクラッチ装置 |

| JP7147057B2 (ja) | 2018-09-20 | 2022-10-04 | シェフラー テクノロジーズ アー・ゲー ウント コー. カー・ゲー | 電気駆動機械用のスリップクラッチ装置 |

| US11920648B2 (en) | 2018-09-20 | 2024-03-05 | Schaeffler Technologies AG & Co. KG | Slip clutch device for an electric driving machine |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102454720A (zh) | 2012-05-16 |

| US20120115620A1 (en) | 2012-05-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2012102755A (ja) | 車両用トルクリミッタ装置 | |

| EP1111261B1 (en) | Multi-plate dry clutch having hub movement limiting means | |

| JP2010230162A (ja) | トルク変動吸収装置 | |

| CN101561016B (zh) | 用于扭矩限制的结构 | |

| JP6637788B2 (ja) | クラッチ装置 | |

| KR20110096486A (ko) | 건식 클러치용 환형 마찰 라이닝 | |

| JP5536609B2 (ja) | クリアランス修復装置を有するクラッチ | |

| JP2014224580A (ja) | モータサイクル用クラッチ装置 | |

| CN105240420A (zh) | 一种低刚度离合器及用于其中的从动机构 | |

| US20130192950A1 (en) | Raised bearing surface clutch friction plate machine | |

| BR102015015399A2 (pt) | disco de embreagem | |

| CN201407295Y (zh) | 用于扭矩限制的结构 | |

| JP6617031B2 (ja) | クラッチ装置 | |

| WO2011105187A1 (ja) | プレート体、同プレート体を備える摩擦クラッチ装置およびブレーキ装置 | |

| JP2015507150A (ja) | クラッチの摩擦ライニングの製造方法 | |

| JP6775574B2 (ja) | 摩擦クラッチ装置 | |

| KR101532078B1 (ko) | 분리 가능한 브레이크 디스크, 이를 구비한 휠 베어링 조립체 및 브레이크 디스크의 런아웃 규제 방법 | |

| KR20180064487A (ko) | 자용차용 클러치 장치 | |

| US9970488B2 (en) | Clutch disc with resiliently deformable damping web and method of manufacturing same | |

| KR101524423B1 (ko) | 클러치 마찰 디스크 | |

| US8770365B2 (en) | Friction damper for a transmission clutch | |

| US20070119679A1 (en) | Multiplate clutch device and clutch disk assembly | |

| JP2010223294A5 (enExample) | ||

| CN205117930U (zh) | 挡圈防脱装置 | |

| US8627937B2 (en) | Power-transmission clutch |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120613 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120613 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121023 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121025 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130307 |