JP2012055152A - 駆動装置 - Google Patents

駆動装置 Download PDFInfo

- Publication number

- JP2012055152A JP2012055152A JP2011136051A JP2011136051A JP2012055152A JP 2012055152 A JP2012055152 A JP 2012055152A JP 2011136051 A JP2011136051 A JP 2011136051A JP 2011136051 A JP2011136051 A JP 2011136051A JP 2012055152 A JP2012055152 A JP 2012055152A

- Authority

- JP

- Japan

- Prior art keywords

- actuator

- moving body

- roller

- moving

- sliding plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16H—GEARING

- F16H19/00—Gearings comprising essentially only toothed gears or friction members and not capable of conveying indefinitely-continuing rotary motion

- F16H19/02—Gearings comprising essentially only toothed gears or friction members and not capable of conveying indefinitely-continuing rotary motion for interconverting rotary or oscillating motion and reciprocating motion

- F16H19/025—Gearings comprising essentially only toothed gears or friction members and not capable of conveying indefinitely-continuing rotary motion for interconverting rotary or oscillating motion and reciprocating motion comprising a friction shaft

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02N—ELECTRIC MACHINES NOT OTHERWISE PROVIDED FOR

- H02N2/00—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction

- H02N2/0005—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction producing non-specific motion; Details common to machines covered by H02N2/02 - H02N2/16

- H02N2/001—Driving devices, e.g. vibrators

- H02N2/003—Driving devices, e.g. vibrators using longitudinal or radial modes combined with bending modes

- H02N2/004—Rectangular vibrators

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02N—ELECTRIC MACHINES NOT OTHERWISE PROVIDED FOR

- H02N2/00—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction

- H02N2/0005—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction producing non-specific motion; Details common to machines covered by H02N2/02 - H02N2/16

- H02N2/005—Mechanical details, e.g. housings

- H02N2/0055—Supports for driving or driven bodies; Means for pressing driving body against driven body

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02N—ELECTRIC MACHINES NOT OTHERWISE PROVIDED FOR

- H02N2/00—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction

- H02N2/02—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction producing linear motion, e.g. actuators; Linear positioners ; Linear motors

- H02N2/026—Electric machines in general using piezoelectric effect, electrostriction or magnetostriction producing linear motion, e.g. actuators; Linear positioners ; Linear motors by pressing one or more vibrators against the driven body

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/20—Piezoelectric or electrostrictive devices with electrical input and mechanical output, e.g. functioning as actuators or vibrators

- H10N30/202—Piezoelectric or electrostrictive devices with electrical input and mechanical output, e.g. functioning as actuators or vibrators using longitudinal or thickness displacement combined with bending, shear or torsion displacement

- H10N30/2023—Piezoelectric or electrostrictive devices with electrical input and mechanical output, e.g. functioning as actuators or vibrators using longitudinal or thickness displacement combined with bending, shear or torsion displacement having polygonal or rectangular shape

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/50—Piezoelectric or electrostrictive devices having a stacked or multilayer structure

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/18—Mechanical movements

- Y10T74/18568—Reciprocating or oscillating to or from alternating rotary

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Electrical Machinery Utilizing Piezoelectricity, Electrostriction Or Magnetostriction (AREA)

Abstract

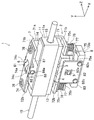

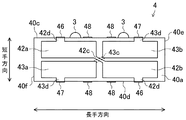

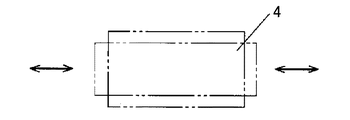

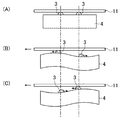

【解決手段】駆動装置1は、振動することによって駆動力を出力するアクチュエータ本体4と、アクチュエータ本体4が当接しており、アクチュエータ本体4に対して所定の移動方向に相対的に移動可能な移動体11と、移動体11を挟んでアクチュエータ本体4と対向する位置に配置され、4アクチュエータ本体と共に移動体11を挟持するローラ6とを備えている。移動体11のうち、ローラ6と当接する部分は、ローラ6よりも弾性係数が小さい。

【選択図】図1

Description

実施形態について、以下のような構成としてもよい。

2 超音波アクチュエータ(振動型アクチュエータ)

4 アクチュエータ本体

6 ローラ(対向部材)

7 連結部材

8 支持体(支持部)

10 シャフト

11 移動体

11a 移動体本体

13 第1摺動板(摺動部材)

Claims (5)

- 振動することによって駆動力を出力するアクチュエータ本体と、

前記アクチュエータ本体が当接しており、該アクチュエータ本体に対して所定の移動方向に相対的に移動可能な移動体と、

前記移動体を挟んで前記アクチュエータ本体と対向する位置に配置され、該アクチュエータ本体と共に該移動体を挟持する対向部材とを備え、

前記移動体のうち、前記対向部材と当接する部分は、該対向部材よりも弾性係数が小さい駆動装置。 - 前記アクチュエータ本体と前記対向部材とを連結し、該アクチュエータ本体及び対向部材が前記移動体を押圧するように該アクチュエータ本体及び対向部材を付勢する連結部材をさらに備える、請求項1に記載の駆動装置。

- 前記移動体を前記移動方向に移動可能に支持するシャフトをさらに備える、請求項1又は2に記載の駆動装置。

- 前記アクチュエータ本体を、前記連結部材により付勢する方向に沿って変位可能に支持する支持部をさらに備える、請求項2に記載の駆動装置。

- 前記移動体は、移動体本体と、該移動体本体に設けられ、前記アクチュエータ本体と当接する摺動部材とを有し、

前記摺動部材は、前記移動体本体よりも弾性係数が大きい、請求項1乃至4の何れか1つに記載の駆動装置。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011136051A JP5909624B2 (ja) | 2010-08-04 | 2011-06-20 | 駆動装置 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010175021 | 2010-08-04 | ||

| JP2010175021 | 2010-08-04 | ||

| JP2011136051A JP5909624B2 (ja) | 2010-08-04 | 2011-06-20 | 駆動装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2012055152A true JP2012055152A (ja) | 2012-03-15 |

| JP5909624B2 JP5909624B2 (ja) | 2016-04-27 |

Family

ID=45555085

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011136051A Expired - Fee Related JP5909624B2 (ja) | 2010-08-04 | 2011-06-20 | 駆動装置 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US8729773B2 (ja) |

| JP (1) | JP5909624B2 (ja) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014093871A (ja) * | 2012-11-04 | 2014-05-19 | Canon Inc | 超音波モータ、及び超音波モータ付き機器駆動装置 |

| JP2014093872A (ja) * | 2012-11-04 | 2014-05-19 | Canon Inc | 超音波モータ、及び超音波モータ付き機器駆動装置 |

| JP2020205735A (ja) * | 2019-06-19 | 2020-12-24 | キヤノン株式会社 | 振動型アクチュエータ、装置、多軸ステージユニット、および多関節ロボット |

| JP2021126042A (ja) * | 2020-02-06 | 2021-08-30 | ナノモーション リミテッド | 高性能圧電モーター |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI429977B (zh) * | 2011-03-07 | 2014-03-11 | Quanta Comp Inc | 用於光學模組之調整機構 |

| JP6271963B2 (ja) * | 2013-11-21 | 2018-01-31 | キヤノン株式会社 | 振動型アクチュエータ |

| RU2624773C1 (ru) * | 2016-07-05 | 2017-07-06 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Пензенский государственный университет" (ФГБОУ ВО "Пензенский государственный университет") | Усиливающий пьезоэлектрический актюатор повышенной точности позиционирования |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0294485U (ja) * | 1989-01-09 | 1990-07-26 | ||

| JPH0393479A (ja) * | 1989-09-04 | 1991-04-18 | Brother Ind Ltd | 超音波モータ |

| JPH06319279A (ja) * | 1993-04-28 | 1994-11-15 | Olympus Optical Co Ltd | 超音波リニアアクチュエータ |

| JPH11136968A (ja) * | 1997-10-29 | 1999-05-21 | Kyocera Corp | 超音波駆動装置 |

| US6069420A (en) * | 1996-10-23 | 2000-05-30 | Omnific International, Ltd. | Specialized actuators driven by oscillatory transducers |

| JP2007120613A (ja) * | 2005-10-27 | 2007-05-17 | Nsk Ltd | 転がり摺動部材及び転動装置 |

| JP2008172995A (ja) * | 2006-12-15 | 2008-07-24 | Olympus Imaging Corp | 駆動装置および撮像装置 |

| JP2008246637A (ja) * | 2007-03-30 | 2008-10-16 | Tohoku Univ | 金属ガラス球体の製造方法、該方法により製造された金属ガラス球体をベアリングボールとして用いた軸受け、該金属ガラス球体をペン先に取り付けたことを特徴とするボールペン、および該金属ガラス球体を用いた装飾品 |

| JP2010161857A (ja) * | 2009-01-07 | 2010-07-22 | Panasonic Corp | 駆動装置 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3184117B2 (ja) | 1997-05-23 | 2001-07-09 | セイコーインスツルメンツ株式会社 | 超音波モータ及び超音波モータ付き電子機器 |

| US6430873B1 (en) * | 2000-03-08 | 2002-08-13 | Atoma International Corporation | Dual drum and rail window regulator drive system |

| JP2004166479A (ja) * | 2002-06-14 | 2004-06-10 | Seiko Epson Corp | 回転型駆動装置およびこれを備えた装置 |

| US7242131B2 (en) * | 2004-05-12 | 2007-07-10 | Olympus Corporation | Ultrasonic motor |

| JP4689989B2 (ja) * | 2004-08-27 | 2011-06-01 | オリンパス株式会社 | 振動波リニアモータ及びそれを用いたレンズ装置 |

| KR100880379B1 (ko) * | 2006-05-25 | 2009-01-23 | 삼성전자주식회사 | 외부로부터 제공받는 부트 코드로 부팅되는 정보기기시스템 |

| US7893598B2 (en) | 2006-12-15 | 2011-02-22 | Olympus Imaging Corp. | Driving apparatus and image pickup apparatus |

| JP2008245507A (ja) | 2007-02-28 | 2008-10-09 | Konica Minolta Opto Inc | 摩擦駆動アクチュエータ |

| US8297149B2 (en) * | 2007-02-28 | 2012-10-30 | Konica Minolta Opto, Inc. | Friction drive actuator |

| WO2008152821A1 (ja) * | 2007-06-14 | 2008-12-18 | Panasonic Corporation | 振動型アクチュエータ及びそれを備えた駆動装置 |

| JP5244727B2 (ja) * | 2009-07-27 | 2013-07-24 | パナソニック株式会社 | 振動型アクチュエータ |

| JP5979817B2 (ja) * | 2010-03-16 | 2016-08-31 | キヤノン株式会社 | 振動波駆動装置 |

| JP5810303B2 (ja) * | 2010-04-06 | 2015-11-11 | パナソニックIpマネジメント株式会社 | 駆動装置 |

-

2011

- 2011-06-20 JP JP2011136051A patent/JP5909624B2/ja not_active Expired - Fee Related

- 2011-08-03 US US13/196,992 patent/US8729773B2/en not_active Expired - Fee Related

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0294485U (ja) * | 1989-01-09 | 1990-07-26 | ||

| JPH0393479A (ja) * | 1989-09-04 | 1991-04-18 | Brother Ind Ltd | 超音波モータ |

| JPH06319279A (ja) * | 1993-04-28 | 1994-11-15 | Olympus Optical Co Ltd | 超音波リニアアクチュエータ |

| US6069420A (en) * | 1996-10-23 | 2000-05-30 | Omnific International, Ltd. | Specialized actuators driven by oscillatory transducers |

| JPH11136968A (ja) * | 1997-10-29 | 1999-05-21 | Kyocera Corp | 超音波駆動装置 |

| JP2007120613A (ja) * | 2005-10-27 | 2007-05-17 | Nsk Ltd | 転がり摺動部材及び転動装置 |

| JP2008172995A (ja) * | 2006-12-15 | 2008-07-24 | Olympus Imaging Corp | 駆動装置および撮像装置 |

| JP2008246637A (ja) * | 2007-03-30 | 2008-10-16 | Tohoku Univ | 金属ガラス球体の製造方法、該方法により製造された金属ガラス球体をベアリングボールとして用いた軸受け、該金属ガラス球体をペン先に取り付けたことを特徴とするボールペン、および該金属ガラス球体を用いた装飾品 |

| JP2010161857A (ja) * | 2009-01-07 | 2010-07-22 | Panasonic Corp | 駆動装置 |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014093871A (ja) * | 2012-11-04 | 2014-05-19 | Canon Inc | 超音波モータ、及び超音波モータ付き機器駆動装置 |

| JP2014093872A (ja) * | 2012-11-04 | 2014-05-19 | Canon Inc | 超音波モータ、及び超音波モータ付き機器駆動装置 |

| JP2020205735A (ja) * | 2019-06-19 | 2020-12-24 | キヤノン株式会社 | 振動型アクチュエータ、装置、多軸ステージユニット、および多関節ロボット |

| JP7353815B2 (ja) | 2019-06-19 | 2023-10-02 | キヤノン株式会社 | 振動型アクチュエータ、装置、多軸ステージユニット、および多関節ロボット |

| JP2021126042A (ja) * | 2020-02-06 | 2021-08-30 | ナノモーション リミテッド | 高性能圧電モーター |

| JP7720606B2 (ja) | 2020-02-06 | 2025-08-08 | ナノモーション リミテッド | 高性能圧電モーター |

Also Published As

| Publication number | Publication date |

|---|---|

| US20120031209A1 (en) | 2012-02-09 |

| US8729773B2 (en) | 2014-05-20 |

| JP5909624B2 (ja) | 2016-04-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5810303B2 (ja) | 駆動装置 | |

| JP5909624B2 (ja) | 駆動装置 | |

| KR101685362B1 (ko) | 진동 액추에이터 및 그것을 갖는 렌즈 장치 | |

| JP5244727B2 (ja) | 振動型アクチュエータ | |

| JP2008178250A (ja) | 超音波振動子の押圧機構および超音波モータ | |

| US8633632B2 (en) | Vibration actuator and method for manufacturing the same | |

| CN107710591B (zh) | 使用振动波马达的直线驱动设备和光学设备 | |

| JP2014018027A (ja) | 振動型アクチュエータ、撮像装置、及びステージ | |

| JP6049277B2 (ja) | 振動型駆動装置 | |

| JP6257224B2 (ja) | モータ及びレンズ装置 | |

| JP5202538B2 (ja) | 振動型アクチュエータ | |

| US9455394B2 (en) | Displacement member, driving member, actuator, and driving device | |

| JP2016027780A (ja) | 振動型アクチュエータ、レンズ鏡筒、撮像装置及び自動ステージ | |

| US20110095650A1 (en) | Ultrasonic motor | |

| US10924037B2 (en) | Vibration motor that prevents resonance of contact member, and electronic apparatus | |

| US7687974B2 (en) | Vibration type driving apparatus | |

| JP2010161857A (ja) | 駆動装置 | |

| JP6708472B2 (ja) | 振動波モータ及び振動波モータが搭載された光学機器 | |

| US8299683B2 (en) | Ultrasonic motor | |

| JP6479238B2 (ja) | モータ | |

| JP6774222B2 (ja) | 振動波モータ及び振動波モータを用いた光学装置 | |

| JP7130727B2 (ja) | 振動波モータ及びこれを用いた装置 | |

| JP7098438B2 (ja) | 振動波モータ及び振動波モータを用いた駆動装置 | |

| JP6525640B2 (ja) | 振動型アクチュエータ、超音波モータおよびレンズ鏡筒 | |

| JP7034770B2 (ja) | 振動波モータ及びレンズ装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140131 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20140131 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140909 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140910 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20141008 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20141110 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150623 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150820 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150908 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151106 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20160105 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160118 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5909624 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| LAPS | Cancellation because of no payment of annual fees |