JP2010501339A - ベルカップ洗浄システムおよび洗浄方法 - Google Patents

ベルカップ洗浄システムおよび洗浄方法 Download PDFInfo

- Publication number

- JP2010501339A JP2010501339A JP2009525743A JP2009525743A JP2010501339A JP 2010501339 A JP2010501339 A JP 2010501339A JP 2009525743 A JP2009525743 A JP 2009525743A JP 2009525743 A JP2009525743 A JP 2009525743A JP 2010501339 A JP2010501339 A JP 2010501339A

- Authority

- JP

- Japan

- Prior art keywords

- solvent

- air

- bell cup

- coating material

- applicator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

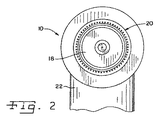

- B05B3/00—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements

- B05B3/02—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements

- B05B3/10—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements discharging over substantially the whole periphery of the rotating member

- B05B3/1092—Means for supplying shaping gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B15/00—Details of spraying plant or spraying apparatus not otherwise provided for; Accessories

- B05B15/50—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter

- B05B15/55—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter using cleaning fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B15/00—Details of spraying plant or spraying apparatus not otherwise provided for; Accessories

- B05B15/50—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter

- B05B15/55—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter using cleaning fluids

- B05B15/555—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter using cleaning fluids discharged by cleaning nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B3/00—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements

- B05B3/02—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements

- B05B3/10—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements discharging over substantially the whole periphery of the rotating member

- B05B3/1064—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements discharging over substantially the whole periphery of the rotating member the liquid or other fluent material to be sprayed being axially supplied to the rotating member through a hollow rotating shaft

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/04—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation

- B05B13/0431—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation with spray heads moved by robots or articulated arms, e.g. for applying liquid or other fluent material to three-dimensional [3D] surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B13/00—Machines or plants for applying liquids or other fluent materials to surfaces of objects or other work by spraying, not covered by groups B05B1/00 - B05B11/00

- B05B13/02—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work

- B05B13/04—Means for supporting work; Arrangement or mounting of spray heads; Adaptation or arrangement of means for feeding work the spray heads being moved during spraying operation

- B05B13/0447—Installation or apparatus for applying liquid or other fluent material to conveyed separate articles

- B05B13/0452—Installation or apparatus for applying liquid or other fluent material to conveyed separate articles the objects being vehicle components, e.g. vehicle bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B3/00—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements

- B05B3/02—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements

- B05B3/10—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements discharging over substantially the whole periphery of the rotating member

- B05B3/1007—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements discharging over substantially the whole periphery of the rotating member characterised by the rotating member

- B05B3/1014—Spraying or sprinkling apparatus with moving outlet elements or moving deflecting elements with rotating elements discharging over substantially the whole periphery of the rotating member characterised by the rotating member with a spraying edge, e.g. like a cup or a bell

Landscapes

- Electrostatic Spraying Apparatus (AREA)

- Details Or Accessories Of Spraying Plant Or Apparatus (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Nozzles (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US84008306P | 2006-08-25 | 2006-08-25 | |

| US11/830,288 US20080047591A1 (en) | 2006-08-25 | 2007-07-30 | Bell cup cleaning system and method |

| PCT/US2007/076460 WO2008024804A1 (en) | 2006-08-25 | 2007-08-22 | Bell cup cleaning system and method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010501339A true JP2010501339A (ja) | 2010-01-21 |

| JP2010501339A5 JP2010501339A5 (enExample) | 2011-10-27 |

Family

ID=38704687

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009525743A Pending JP2010501339A (ja) | 2006-08-25 | 2007-08-22 | ベルカップ洗浄システムおよび洗浄方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20080047591A1 (enExample) |

| EP (1) | EP2054164B1 (enExample) |

| JP (1) | JP2010501339A (enExample) |

| CA (1) | CA2661738A1 (enExample) |

| DE (1) | DE602007007339D1 (enExample) |

| WO (1) | WO2008024804A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018012088A (ja) * | 2016-07-22 | 2018-01-25 | トリニティ工業株式会社 | 塗装ガン洗浄装置 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009014831A1 (de) * | 2009-03-25 | 2010-09-30 | Daimler Ag | Verfahren zum Betreiben eines Reduktionsmittelversorgungssystems |

| GB2469539B (en) * | 2009-09-21 | 2011-03-09 | Dau Binh Chiu | Rotary device and method for transmitting material |

| DE102012001896A1 (de) * | 2012-02-01 | 2013-08-01 | Eisenmann Ag | Rotationszerstäuber |

| CN105499027B (zh) * | 2015-11-28 | 2017-12-01 | 重庆益新阳工贸有限公司 | 一种开放式钢体表面维护机器人 |

| US11110475B2 (en) * | 2018-12-19 | 2021-09-07 | Foreman Technologies Inc. | Modular paint spraying system |

| JP7064657B2 (ja) * | 2019-12-23 | 2022-05-10 | カワサキモータース株式会社 | 塗装液混合装置及び塗装液の混合方法 |

| CN111760690A (zh) * | 2020-07-28 | 2020-10-13 | 士商(上海)机械有限公司 | 喷雾器 |

| CN111760693A (zh) * | 2020-07-28 | 2020-10-13 | 士商(上海)机械有限公司 | 喷头及喷雾器 |

| US12036577B2 (en) | 2022-04-20 | 2024-07-16 | Foreman Technologies Inc. | System for autonomously applying paint to a target surface |

| US12257590B2 (en) | 2022-04-20 | 2025-03-25 | Foreman Technologies Inc. | System for detecting thickness of a coating autonomously applied to a structure |

| CN116116625A (zh) * | 2023-01-06 | 2023-05-16 | 佛山市宝岩环保科技有限公司 | 一种静电喷涂旋杯片表面污染的自动清洗方法 |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60112364U (ja) * | 1984-01-09 | 1985-07-30 | トヨタ自動車株式会社 | 回転霧化静電塗装装置 |

| JPS62289254A (ja) * | 1986-04-18 | 1987-12-16 | ノ−ドソン コ−ポレ−シヨン | 回転式霧化液体の静電噴霧塗布装置 |

| JPH04330962A (ja) * | 1991-04-30 | 1992-11-18 | Trinity Ind Corp | 多色塗装装置の色替え洗浄方法 |

| JPH0686951A (ja) * | 1992-09-08 | 1994-03-29 | Abb Flaekt Ransburg Gmbh | 吹付け塗装装置 |

| JPH0629651U (ja) * | 1992-09-16 | 1994-04-19 | 関東自動車工業株式会社 | 塗装機用洗浄装置 |

| JPH08332417A (ja) * | 1995-06-06 | 1996-12-17 | Mazda Motor Corp | ベル型塗装装置 |

| JP2002136939A (ja) * | 2000-11-06 | 2002-05-14 | Toshimi Honda | 一般建築物や集合住宅等の給水管の洗浄車 |

| JP2005219014A (ja) * | 2004-02-09 | 2005-08-18 | Toppan Printing Co Ltd | 塗工装置 |

| JP2006035110A (ja) * | 2004-07-28 | 2006-02-09 | Shoori:Kk | 管洗浄装置 |

| JP2007069143A (ja) * | 2005-09-08 | 2007-03-22 | Toppan Printing Co Ltd | 塗工装置及びその洗浄方法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4555058A (en) * | 1983-10-05 | 1985-11-26 | Champion Spark Plug Company | Rotary atomizer coater |

| US4936510A (en) * | 1986-06-26 | 1990-06-26 | The Devilbiss Company | Rotary automizer with air cap and retainer |

| DE4201379A1 (de) * | 1992-01-20 | 1993-07-22 | Baral Karl Heinz | Reinigungseinrichtung zur reinigung von duesenbohrungen |

| DE9419641U1 (de) * | 1994-12-07 | 1995-02-02 | Dürr GmbH, 70435 Stuttgart | Rotationszerstäuber mit einem Glockenkörper |

| JP3753462B2 (ja) * | 1995-01-10 | 2006-03-08 | マツダ株式会社 | 多色回転霧化塗装装置および洗浄方法 |

| KR100265890B1 (ko) * | 1996-12-03 | 2000-09-15 | 라붸 린도베르 | 회전무화 헤드형 도장장치 |

| US6569258B2 (en) * | 2001-05-16 | 2003-05-27 | Fanuc Robotics North America, Inc. | Method and apparatus for cleaning a bell atomizer spray head |

| US20050040257A1 (en) * | 2003-08-19 | 2005-02-24 | Seitz David M. | Atomizer with dedicated cleaning fluid system |

-

2007

- 2007-07-30 US US11/830,288 patent/US20080047591A1/en not_active Abandoned

- 2007-08-22 CA CA002661738A patent/CA2661738A1/en not_active Abandoned

- 2007-08-22 EP EP07814324A patent/EP2054164B1/en not_active Expired - Fee Related

- 2007-08-22 DE DE602007007339T patent/DE602007007339D1/de active Active

- 2007-08-22 WO PCT/US2007/076460 patent/WO2008024804A1/en not_active Ceased

- 2007-08-22 JP JP2009525743A patent/JP2010501339A/ja active Pending

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60112364U (ja) * | 1984-01-09 | 1985-07-30 | トヨタ自動車株式会社 | 回転霧化静電塗装装置 |

| JPS62289254A (ja) * | 1986-04-18 | 1987-12-16 | ノ−ドソン コ−ポレ−シヨン | 回転式霧化液体の静電噴霧塗布装置 |

| JPH04330962A (ja) * | 1991-04-30 | 1992-11-18 | Trinity Ind Corp | 多色塗装装置の色替え洗浄方法 |

| JPH0686951A (ja) * | 1992-09-08 | 1994-03-29 | Abb Flaekt Ransburg Gmbh | 吹付け塗装装置 |

| JPH0629651U (ja) * | 1992-09-16 | 1994-04-19 | 関東自動車工業株式会社 | 塗装機用洗浄装置 |

| JPH08332417A (ja) * | 1995-06-06 | 1996-12-17 | Mazda Motor Corp | ベル型塗装装置 |

| JP2002136939A (ja) * | 2000-11-06 | 2002-05-14 | Toshimi Honda | 一般建築物や集合住宅等の給水管の洗浄車 |

| JP2005219014A (ja) * | 2004-02-09 | 2005-08-18 | Toppan Printing Co Ltd | 塗工装置 |

| JP2006035110A (ja) * | 2004-07-28 | 2006-02-09 | Shoori:Kk | 管洗浄装置 |

| JP2007069143A (ja) * | 2005-09-08 | 2007-03-22 | Toppan Printing Co Ltd | 塗工装置及びその洗浄方法 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018012088A (ja) * | 2016-07-22 | 2018-01-25 | トリニティ工業株式会社 | 塗装ガン洗浄装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2661738A1 (en) | 2008-02-28 |

| US20080047591A1 (en) | 2008-02-28 |

| WO2008024804A1 (en) | 2008-02-28 |

| EP2054164B1 (en) | 2010-06-23 |

| DE602007007339D1 (de) | 2010-08-05 |

| EP2054164A1 (en) | 2009-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010501339A (ja) | ベルカップ洗浄システムおよび洗浄方法 | |

| JP4428973B2 (ja) | 回転霧化塗装装置および塗装方法 | |

| JP6492225B2 (ja) | 改良型スプレーガン洗浄装置 | |

| CN105722599B (zh) | 具有改进清洁能力的旋转钟形杯喷雾装置 | |

| JP2001079463A (ja) | 自動塗装装置 | |

| JPH08332415A (ja) | ロータリーアトマイザ | |

| US20160121372A1 (en) | Cleaning process and cleaning device for one or more parts of an application system | |

| CN101720256A (zh) | 旋转雾化头、旋转雾化涂敷装置及旋转雾化涂敷方法 | |

| CN101516524A (zh) | 钟形杯清洁系统和方法 | |

| US6899279B2 (en) | Atomizer with low pressure area passages | |

| JP5653874B2 (ja) | 塗装装置及びそれを用いた塗装方法 | |

| JPS61107976A (ja) | 回転霧化型塗装装置用噴霧ヘツドの洗浄方法及び装置 | |

| CN202539010U (zh) | 喷涂机反冲洗装置 | |

| CA2556013C (en) | Radius edge bell cup and method for shaping an atomized spray pattern | |

| US20050040257A1 (en) | Atomizer with dedicated cleaning fluid system | |

| CN100473466C (zh) | 清洗涂料枪的方法 | |

| JP3346146B2 (ja) | 回転霧化静電塗装装置の回転霧化頭裏面洗浄方法 | |

| JPH09262518A (ja) | 塗装ガン洗浄装置 | |

| JP6738929B1 (ja) | バグフィルターの濾布洗浄装置 | |

| JP4568631B2 (ja) | 静電塗装機 | |

| JP6810549B2 (ja) | 塗装ガン洗浄装置 | |

| JP5653875B2 (ja) | 塗装装置 | |

| JP4954488B2 (ja) | 霧化塗装機 | |

| JP7741560B2 (ja) | 人孔内壁洗浄装置 | |

| JPH07213954A (ja) | 偏向分配ノズル装置の汚れ防止方法及び装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100823 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100823 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120914 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121002 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20121227 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130109 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130131 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130618 |