JP2010133482A - 転がり軸受装置 - Google Patents

転がり軸受装置 Download PDFInfo

- Publication number

- JP2010133482A JP2010133482A JP2008309632A JP2008309632A JP2010133482A JP 2010133482 A JP2010133482 A JP 2010133482A JP 2008309632 A JP2008309632 A JP 2008309632A JP 2008309632 A JP2008309632 A JP 2008309632A JP 2010133482 A JP2010133482 A JP 2010133482A

- Authority

- JP

- Japan

- Prior art keywords

- inner ring

- rotating member

- bearing device

- diameter

- fitting portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/60—Raceways; Race rings divided or split, e.g. comprising two juxtaposed rings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C35/00—Rigid support of bearing units; Housings, e.g. caps, covers

- F16C35/04—Rigid support of bearing units; Housings, e.g. caps, covers in the case of ball or roller bearings

- F16C35/06—Mounting or dismounting of ball or roller bearings; Fixing them onto shaft or in housing

- F16C35/063—Fixing them on the shaft

- F16C35/0635—Fixing them on the shaft the bore of the inner ring being of special non-cylindrical shape which co-operates with a complementary shape on the shaft, e.g. teeth, polygonal sections

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C43/00—Assembling bearings

- F16C43/04—Assembling rolling-contact bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

- F16C19/18—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls

- F16C19/181—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact

- F16C19/183—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles

- F16C19/184—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles in O-arrangement

- F16C19/186—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with two or more rows of balls with angular contact with two rows at opposite angles in O-arrangement with three raceways provided integrally on parts other than race rings, e.g. third generation hubs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2240/00—Specified values or numerical ranges of parameters; Relations between them

- F16C2240/40—Linear dimensions, e.g. length, radius, thickness, gap

- F16C2240/70—Diameters; Radii

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2326/00—Articles relating to transporting

- F16C2326/01—Parts of vehicles in general

- F16C2326/02—Wheel hubs or castors

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mounting Of Bearings Or Others (AREA)

- Rolling Contact Bearings (AREA)

Abstract

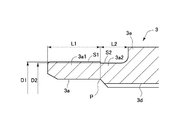

【解決手段】ハブユニット1(転がり軸受装置)は、ナックル20(車体側部材)に固定され内周部に複列の軌道面2a,2bを有する外輪2(非回転部材)と、ブレーキディスクロータ30(車輪側部材)に固定され外周部に軌道面3bを有する内軸3(回転部材)と、内軸3に一体形成された嵌め合い部3aに外嵌圧入され外周部に軌道面4aを有する内輪4と、軌道面2a,2bと軌道面4a,3b間にそれぞれ配置された転動体5を備える。内輪4が嵌め合い部3aに外嵌圧入される前の内軸3の単体状態において、嵌め合い部3aの基端側部位3a2の外径D2が嵌め合い部3aの先端側部位3a1の外径D1に比して小さく形成される。

【選択図】図2

Description

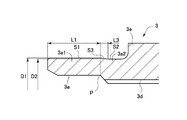

上記実施形態では、嵌め合い部3aの外周面がスプライン加工開始位置Pを境として外径の小さい基端側部位3a2の外周面S2と、外径の大きい先端側部位3a1の外周面S1とに仕切られるように構成したが、これに代えて、例えば図3に示すように、外径の小さい基端側部位3a2の外周面S2と、外径の大きい先端側部位3a1の外周面S1とが、その中間に位置する外周面S3を介して接続されるように構成してもよい。

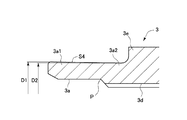

また、上記実施形態及び変形例1に代えて、例えば図4に示すように、先端側部位3a1の肉厚がスプライン加工開始位置Pに対応する基端側部位3a2の肉厚よりも大きくなるように、先端側部位3a1と基端側部位3a2とが共通のテーパ状の外周面S4を有するように構成してもよい。この変形例2によっても、上記実施形態と同様、基端側部位3a2の内径(スプライン穴3dの大径及び小径)の収縮を抑制することができる。

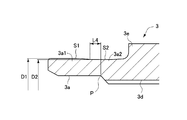

また、上記実施形態、変形例1及び2に代えて、例えば図5に示すように、外径の小さい基端側部位3a2の外周面S2の軸長を長くするとともに、外径の大きい先端側部位3a1の外周面S1の軸長を短くしてもよい。つまり、基端側部位3a2の外周面S2は、スプライン加工開始位置Pを超えて嵌め合い部3aの先端側へ軸長L4(例えば、スプライン穴3dの小径(大径)の5〜20%程度の長さ)だけ延び出した幅広の凹状面に形成されている。この変形例3のように、基端側部位3a2の外周面S2がスプライン加工開始位置Pから嵌め合い部3aの先端側へ延び出すように構成すれば、外径の大きい先端側部位3a1の外周面S1がスプライン穴3dから遠ざかることで、基端側部位3a2の内径(スプライン穴3dの大径及び小径)の収縮をより効果的に抑制することができる。

2 外輪(非回転部材)

3 内軸(回転部材)

3a 嵌め合い部

3a1 先端側部位

3a2 基端側部位

S1 外周面(先端側部位)

S2 外周面(基端側部位)

S3,S4 外周面

3d スプライン穴

3e 段部

P スプライン加工開始位置

4 内輪

5 転動体

20 ナックル(車体側部材)

30 ブレーキディスクロータ(車輪側部材)

40 等速ジョイント

41 スプライン軸

Claims (2)

- 車両インナ側にて車体側部材に固定され内周部に複列の軌道面を有する非回転部材と、車両アウタ側にて車輪側部材に固定され外周部に前記複列の軌道面の一に対応する軌道面を有する回転部材と、前記回転部材の車両インナ側端に一体形成された円筒状の嵌め合い部に外嵌圧入され外周部に前記複列の軌道面の他に対応する軌道面を有する内輪と、前記回転部材及び前記内輪の軌道面と前記非回転部材の軌道面との間にそれぞれ配置される転動体とを備えた転がり軸受装置であって、

前記内輪が前記嵌め合い部に外嵌圧入される前の前記回転部材の単体状態において、前記嵌め合い部の基端側部位の外径が該嵌め合い部の先端側部位の外径に比して小さく形成されていることを特徴とする転がり軸受装置。 - 前記内輪に対する前記嵌め合い部の基端側部位での締め代が10〜20μmに設定され、前記内輪に対する前記嵌め合い部の先端側部位での締め代が50〜70μmに設定されている請求項1に記載の転がり軸受装置。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008309632A JP2010133482A (ja) | 2008-12-04 | 2008-12-04 | 転がり軸受装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008309632A JP2010133482A (ja) | 2008-12-04 | 2008-12-04 | 転がり軸受装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010133482A true JP2010133482A (ja) | 2010-06-17 |

| JP2010133482A5 JP2010133482A5 (ja) | 2012-10-04 |

Family

ID=42344958

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008309632A Pending JP2010133482A (ja) | 2008-12-04 | 2008-12-04 | 転がり軸受装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010133482A (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2587078A1 (en) * | 2011-10-27 | 2013-05-01 | Jtekt Corporation | Wheel bearing device |

| EP4147817A1 (fr) * | 2021-09-10 | 2023-03-15 | Ntn-Snr Roulements | Procede d'assemblage d'au moins une bague cooperant par frettage avec une portee de frettage d'une piece |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002102608A1 (fr) * | 2001-06-13 | 2002-12-27 | Ntn Corporation | Dispositif de roulement a paliers pour roue motrice et procede de fabrication de ce dispositif de roulement |

| JP2003028178A (ja) * | 2001-07-18 | 2003-01-29 | Nsk Ltd | 駆動車軸用ハブユニット軸受 |

| JP2007002937A (ja) * | 2005-06-24 | 2007-01-11 | Ntn Corp | 車輪用軸受装置 |

| JP2008057717A (ja) * | 2006-09-01 | 2008-03-13 | Ntn Corp | 車輪用軸受装置 |

-

2008

- 2008-12-04 JP JP2008309632A patent/JP2010133482A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002102608A1 (fr) * | 2001-06-13 | 2002-12-27 | Ntn Corporation | Dispositif de roulement a paliers pour roue motrice et procede de fabrication de ce dispositif de roulement |

| JP2003028178A (ja) * | 2001-07-18 | 2003-01-29 | Nsk Ltd | 駆動車軸用ハブユニット軸受 |

| JP2007002937A (ja) * | 2005-06-24 | 2007-01-11 | Ntn Corp | 車輪用軸受装置 |

| JP2008057717A (ja) * | 2006-09-01 | 2008-03-13 | Ntn Corp | 車輪用軸受装置 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2587078A1 (en) * | 2011-10-27 | 2013-05-01 | Jtekt Corporation | Wheel bearing device |

| JP2013092246A (ja) * | 2011-10-27 | 2013-05-16 | Jtekt Corp | 車輪用軸受装置 |

| EP4147817A1 (fr) * | 2021-09-10 | 2023-03-15 | Ntn-Snr Roulements | Procede d'assemblage d'au moins une bague cooperant par frettage avec une portee de frettage d'une piece |

| FR3126900A1 (fr) * | 2021-09-10 | 2023-03-17 | Ntn-Snr Roulements | Procédé d’assemblage d’au moins une bague coopérant par frettage avec une portée de frettage d'une pièce |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2127902B1 (en) | Bearing device for driving wheel, and its assembling method | |

| US9656517B2 (en) | Wheel bearing and bearing device | |

| JP6320695B2 (ja) | 車輪用軸受装置及びその組立方法 | |

| JP6253909B2 (ja) | 車輪用軸受装置 | |

| JP4338095B2 (ja) | 駆動車輪用軸受ユニット | |

| US20150191044A1 (en) | Bearing module | |

| WO2007097138A1 (ja) | 車輪用軸受装置 | |

| JP4530291B2 (ja) | 駆動車輪用軸受装置の製造方法 | |

| JP2008173995A (ja) | 車輪用軸受装置 | |

| JP2010133482A (ja) | 転がり軸受装置 | |

| JP2007261577A5 (ja) | ||

| US8770852B2 (en) | Wheel bearing device | |

| JP2010127305A (ja) | 転がり軸受装置の製造方法 | |

| JP2008039106A (ja) | 車輪用軸受装置 | |

| JP4807773B2 (ja) | 駆動車輪用軸受装置 | |

| JP2008247274A (ja) | 車輪用軸受装置 | |

| JP2008155692A (ja) | 車輪用軸受装置 | |

| JP2005319889A (ja) | 駆動車輪用軸受装置 | |

| JP2004263835A (ja) | 車輪用軸受装置 | |

| JP4940566B2 (ja) | 車輪用軸受装置 | |

| JP6279237B2 (ja) | 車輪用軸受装置 | |

| JP2004098885A (ja) | 車両用転がり軸受装置 | |

| JP2005119383A (ja) | 車輪用軸受装置 | |

| JP7365769B2 (ja) | 車輪用軸受装置 | |

| JP2005255165A (ja) | 駆動輪用転がり軸受ユニット及び車輪用駆動ユニットの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110928 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120725 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120821 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20121012 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130117 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130122 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130606 |