JP2009532874A - 回路の三次元的な統合において用いられるバリヤ - Google Patents

回路の三次元的な統合において用いられるバリヤ Download PDFInfo

- Publication number

- JP2009532874A JP2009532874A JP2009503112A JP2009503112A JP2009532874A JP 2009532874 A JP2009532874 A JP 2009532874A JP 2009503112 A JP2009503112 A JP 2009503112A JP 2009503112 A JP2009503112 A JP 2009503112A JP 2009532874 A JP2009532874 A JP 2009532874A

- Authority

- JP

- Japan

- Prior art keywords

- inter

- opening

- integrated circuit

- circuit

- trace

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000004888 barrier function Effects 0.000 title claims abstract description 48

- 230000010354 integration Effects 0.000 title claims description 7

- 238000000034 method Methods 0.000 claims abstract description 42

- 239000004065 semiconductor Substances 0.000 claims abstract description 30

- 239000000463 material Substances 0.000 claims abstract description 29

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims abstract description 24

- 239000011231 conductive filler Substances 0.000 claims abstract description 15

- 229910017052 cobalt Inorganic materials 0.000 claims abstract description 13

- 239000010941 cobalt Substances 0.000 claims abstract description 13

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 claims abstract description 13

- 229910052759 nickel Inorganic materials 0.000 claims abstract description 12

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 6

- 229910052802 copper Inorganic materials 0.000 claims description 6

- 239000010949 copper Substances 0.000 claims description 6

- 239000003989 dielectric material Substances 0.000 claims description 3

- 229910052751 metal Inorganic materials 0.000 claims description 2

- 239000002184 metal Substances 0.000 claims description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 claims description 2

- 229910052721 tungsten Inorganic materials 0.000 claims description 2

- 239000010937 tungsten Substances 0.000 claims description 2

- 235000012431 wafers Nutrition 0.000 description 43

- 238000005530 etching Methods 0.000 description 14

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 4

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000003486 chemical etching Methods 0.000 description 2

- 229910052763 palladium Inorganic materials 0.000 description 2

- 238000005240 physical vapour deposition Methods 0.000 description 2

- 229910052697 platinum Inorganic materials 0.000 description 2

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- LFGFZXXKZPSRMB-UHFFFAOYSA-N [B].[Mo].[Co] Chemical compound [B].[Mo].[Co] LFGFZXXKZPSRMB-UHFFFAOYSA-N 0.000 description 1

- UYNAGLMEARBXEG-UHFFFAOYSA-N [B].[Re].[Co] Chemical compound [B].[Re].[Co] UYNAGLMEARBXEG-UHFFFAOYSA-N 0.000 description 1

- CPJYFACXEHYLFS-UHFFFAOYSA-N [B].[W].[Co] Chemical compound [B].[W].[Co] CPJYFACXEHYLFS-UHFFFAOYSA-N 0.000 description 1

- HMDDXIMCDZRSNE-UHFFFAOYSA-N [C].[Si] Chemical compound [C].[Si] HMDDXIMCDZRSNE-UHFFFAOYSA-N 0.000 description 1

- FEBFYWHXKVOHDI-UHFFFAOYSA-N [Co].[P][W] Chemical compound [Co].[P][W] FEBFYWHXKVOHDI-UHFFFAOYSA-N 0.000 description 1

- CKQGJVKHBSPKST-UHFFFAOYSA-N [Ni].P#[Mo] Chemical compound [Ni].P#[Mo] CKQGJVKHBSPKST-UHFFFAOYSA-N 0.000 description 1

- AXFKVYBBROZOGA-UHFFFAOYSA-N [P].[Mo].[Co] Chemical compound [P].[Mo].[Co] AXFKVYBBROZOGA-UHFFFAOYSA-N 0.000 description 1

- UUJLWEYRZDAJFO-UHFFFAOYSA-N [P].[Re].[Co] Chemical compound [P].[Re].[Co] UUJLWEYRZDAJFO-UHFFFAOYSA-N 0.000 description 1

- ACVSDIKGGNSZDR-UHFFFAOYSA-N [P].[W].[Ni] Chemical compound [P].[W].[Ni] ACVSDIKGGNSZDR-UHFFFAOYSA-N 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- IJIMPXOIJZHGTP-UHFFFAOYSA-N boranylidynemolybdenum nickel Chemical compound [Ni].B#[Mo] IJIMPXOIJZHGTP-UHFFFAOYSA-N 0.000 description 1

- IGLTYURFTAWDMX-UHFFFAOYSA-N boranylidynetungsten nickel Chemical compound [Ni].B#[W] IGLTYURFTAWDMX-UHFFFAOYSA-N 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 230000003197 catalytic effect Effects 0.000 description 1

- 238000001311 chemical methods and process Methods 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000009713 electroplating Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000010297 mechanical methods and process Methods 0.000 description 1

- 230000005226 mechanical processes and functions Effects 0.000 description 1

- IGDBIOSLOUHDAG-UHFFFAOYSA-N nickel phosphanylidynerhenium Chemical compound [Ni].P#[Re] IGDBIOSLOUHDAG-UHFFFAOYSA-N 0.000 description 1

- UJRJCSCBZXLGKF-UHFFFAOYSA-N nickel rhenium Chemical compound [Ni].[Re] UJRJCSCBZXLGKF-UHFFFAOYSA-N 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76898—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics formed through a semiconductor substrate

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/48—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor

- H01L23/481—Internal lead connections, e.g. via connections, feedthrough structures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/52—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/91—Methods for connecting semiconductor or solid state bodies including different methods provided for in two or more of groups H01L24/80 - H01L24/90

- H01L24/92—Specific sequence of method steps

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/93—Batch processes

- H01L24/94—Batch processes at wafer-level, i.e. with connecting carried out on a wafer comprising a plurality of undiced individual devices

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L25/00—Assemblies consisting of a plurality of individual semiconductor or other solid state devices ; Multistep manufacturing processes thereof

- H01L25/50—Multistep manufacturing processes of assemblies consisting of devices, each device being of a type provided for in group H01L27/00 or H01L29/00

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76801—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing

- H01L21/76802—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics

- H01L21/76805—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the dielectrics, e.g. smoothing by forming openings in dielectrics the opening being a via or contact hole penetrating the underlying conductor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/8319—Arrangement of the layer connectors prior to mounting

- H01L2224/83191—Arrangement of the layer connectors prior to mounting wherein the layer connectors are disposed only on the semiconductor or solid-state body

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/91—Methods for connecting semiconductor or solid state bodies including different methods provided for in two or more of groups H01L2224/80 - H01L2224/90

- H01L2224/92—Specific sequence of method steps

- H01L2224/9202—Forming additional connectors after the connecting process

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2225/00—Details relating to assemblies covered by the group H01L25/00 but not provided for in its subgroups

- H01L2225/03—All the devices being of a type provided for in the same subgroup of groups H01L27/00 - H01L33/648 and H10K99/00

- H01L2225/04—All the devices being of a type provided for in the same subgroup of groups H01L27/00 - H01L33/648 and H10K99/00 the devices not having separate containers

- H01L2225/065—All the devices being of a type provided for in the same subgroup of groups H01L27/00 - H01L33/648 and H10K99/00 the devices not having separate containers the devices being of a type provided for in group H01L27/00

- H01L2225/06503—Stacked arrangements of devices

- H01L2225/06513—Bump or bump-like direct electrical connections between devices, e.g. flip-chip connection, solder bumps

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2225/00—Details relating to assemblies covered by the group H01L25/00 but not provided for in its subgroups

- H01L2225/03—All the devices being of a type provided for in the same subgroup of groups H01L27/00 - H01L33/648 and H10K99/00

- H01L2225/04—All the devices being of a type provided for in the same subgroup of groups H01L27/00 - H01L33/648 and H10K99/00 the devices not having separate containers

- H01L2225/065—All the devices being of a type provided for in the same subgroup of groups H01L27/00 - H01L33/648 and H10K99/00 the devices not having separate containers the devices being of a type provided for in group H01L27/00

- H01L2225/06503—Stacked arrangements of devices

- H01L2225/06541—Conductive via connections through the device, e.g. vertical interconnects, through silicon via [TSV]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L27/00—Devices consisting of a plurality of semiconductor or other solid-state components formed in or on a common substrate

- H01L27/02—Devices consisting of a plurality of semiconductor or other solid-state components formed in or on a common substrate including semiconductor components specially adapted for rectifying, oscillating, amplifying or switching and having potential barriers; including integrated passive circuit elements having potential barriers

- H01L27/04—Devices consisting of a plurality of semiconductor or other solid-state components formed in or on a common substrate including semiconductor components specially adapted for rectifying, oscillating, amplifying or switching and having potential barriers; including integrated passive circuit elements having potential barriers the substrate being a semiconductor body

- H01L27/06—Devices consisting of a plurality of semiconductor or other solid-state components formed in or on a common substrate including semiconductor components specially adapted for rectifying, oscillating, amplifying or switching and having potential barriers; including integrated passive circuit elements having potential barriers the substrate being a semiconductor body including a plurality of individual components in a non-repetitive configuration

- H01L27/0688—Integrated circuits having a three-dimensional layout

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01005—Boron [B]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01006—Carbon [C]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01019—Potassium [K]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01029—Copper [Cu]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01033—Arsenic [As]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01042—Molybdenum [Mo]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01046—Palladium [Pd]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01073—Tantalum [Ta]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01074—Tungsten [W]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01075—Rhenium [Re]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01078—Platinum [Pt]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/14—Integrated circuits

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

Abstract

Description

Claims (20)

- 半導体デバイスを形成する方法であって、

接続フィーチャを有する第1の集積回路を提供することと、

第1の集積回路に第2の集積回路を取り付けることと、第2の集積回路は回路間トレースを有することと、回路間トレースは回路間トレース開口部を有することと、

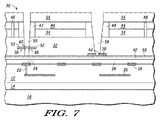

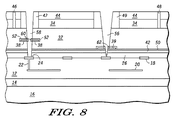

第2の集積回路を通じた開口部を形成することと、開口部は回路間トレース開口部を通じて接続パッドまで延びていることと、

開口部において回路間トレースの露出した部分上に選択的なバリヤを形成することと、

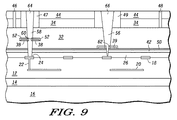

導電性充填材料を用いて開口部を充填することと、導電性充填材料は回路間トレースと接続フィーチャとを電気的に接続することと、

を含む方法。 - 選択的なバリヤはコバルトおよびニッケルから選択される材料を含む請求項1に記載の方法。

- 選択的なバリヤはコバルトを含む請求項1に記載の方法。

- 選択的なバリヤはタングステンを含む請求項3に記載の方法。

- 選択的なバリヤは開口部において回路間トレースの露出した部分上にのみ形成される請求項1に記載の方法。

- 接続パッドは、コバルトおよびニッケルから選択される材料を含む導電性バリヤ層を含む請求項1に記載の方法。

- 第1の集積回路に第2の集積回路を取り付けることは、第1の集積回路と第2の集積回路との間の1つ以上の接合層を用いて第1の集積回路に第2の集積回路を取り付けることを含む請求項1に記載の方法。

- 開口部を形成することは、

第2の集積回路および回路間トレース開口部を通じて前記1つ以上の接合層まで延びる開口部を形成することと、

前記1つ以上の接合層を通じて接続フィーチャまで同開口部を延ばすことと、接続フィーチャは接続パッドおよび金属トレースのうちの1つ以上を含むことと、

を含む請求項7に記載の方法。 - 回路間トレースは回路間トレースバリヤ層を含むことと、選択的なバリヤを形成する前に、回路間トレースバリヤ層の露出した部分を処理することと、を含む請求項1に記載の方法。

- 導電性充填材料を用いて開口部を充填する前に開口部にライナー層を形成することを含む請求項1に記載の方法。

- 回路間トレースは銅を含む請求項1に記載の方法。

- 半導体デバイスを形成する方法であって、

接続フィーチャを有する第1の集積回路を提供することと、

1つ以上の接合層を用いて第1の集積回路に第2の集積回路を取り付けることと、第2の集積回路は回路間トレースを有することと、回路間トレースは回路間トレース開口部を有することと、

第2の集積回路を通じた開口部を形成することと、開口部は回路間トレース開口部を通じて延びていることと、

開口部において回路間トレースの露出した部分上に選択的なバリヤを形成することと、選択的なバリヤはコバルトおよびニッケルから選択される1つ以上の材料を含むことと、

前記1つ以上の接合層を通じて接続フィーチャまで開口部を延ばすことと、

開口部を延ばした後、導電性充填材料を用いて開口部を充填することと、導電性充填材料は回路間トレースと接続フィーチャとを電気的に接続することと、

を含む方法。 - 1つ以上の接合層を用いて第1の集積回路に第2の集積回路を取り付けることは、

第1の集積回路上に形成された第1の接合層と第2の集積回路上に形成された第2の接合層とを取り付けることを含む請求項12に記載の方法。 - 回路間トレースは回路間トレースバリヤ層を含むことと、回路間トレースの露出した部分は回路間トレースバリヤ層のうちの少なくとも一部を含むことと、選択的なバリヤを形成する前に、回路間トレースバリヤ層うちの前記少なくとも一部を処理することと、を含む請求項12に記載の方法。

- 前記1つ以上の接合層はエッチング停止層を含むことと、第2の集積回路を通じて開口部を形成することは、同開口部がエッチング停止層まで延びるように実行されることと、を含む請求項12に記載の方法。

- 開口部を延ばした後かつ開口部を充填する前に、開口部にライナー層を形成することを含む、請求項12に記載の方法。

- 接続フィーチャはコバルトおよびニッケルから選択される材料を含む導電性バリヤ層を含むことと、前記1つ以上の接合層を通じて接続フィーチャまで開口部を延ばすことは、開口部が接続フィーチャの導電性バリヤ層を露出するように実行されることと、を含む請求項12に記載の方法。

- 接続フィーチャと、接続フィーチャの上の1つ以上の接合層とを有する第1の集積回路と、

回路間トレースと、回路間トレースの上の1つ以上の接合層とを有する第2の集積回路と、第2の集積回路の1つ以上の接合層は、第1の集積回路の前記1つ以上の接合層に取り付けられていることと、

第2の集積回路を通じて、回路間トレースの開口部を通じて、第2の集積回路の前記1つ以上の接合層を通じて、かつ第1の集積回路の前記1つ以上の接合層を通じて接続フィーチャまで延びている導電性相互接続部と、導電性相互接続部は回路間トレースを接続フィーチャに電気的に接続することと、

コバルトおよびニッケルから選択される1つ以上の材料を含む回路間トレースに隣接し、回路間トレースと導電性相互接続部との間において回路間トレースの開口部に配置されたバリヤ層と、

を含む半導体デバイス。 - 少なくとも部分的に回路間トレースを包囲する誘電体材料と、

回路間トレースに隣接した第2のバリヤ層と、第2のバリヤ層は導電性であり、第1のバリヤ層と異なることと、第2のバリヤ層は誘電体と回路間トレースとの間に配置されていることと、

を含む請求項18に記載の半導体デバイス。 - 接続フィーチャに隣接し、接続フィーチャと導電性相互接続部との間で配置された第2のバリヤ層と、接続フィーチャはコバルトおよびニッケルから選択される1つ以上の材料を含むことと、を含む請求項18に記載の半導体デバイス。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/278,042 US7378339B2 (en) | 2006-03-30 | 2006-03-30 | Barrier for use in 3-D integration of circuits |

| PCT/US2007/062538 WO2007130731A2 (en) | 2006-03-30 | 2007-02-22 | Barrier for use in 3-d integration of circuits |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009532874A true JP2009532874A (ja) | 2009-09-10 |

| JP2009532874A5 JP2009532874A5 (ja) | 2010-03-11 |

Family

ID=38559646

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009503112A Pending JP2009532874A (ja) | 2006-03-30 | 2007-02-22 | 回路の三次元的な統合において用いられるバリヤ |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US7378339B2 (ja) |

| JP (1) | JP2009532874A (ja) |

| KR (1) | KR101352732B1 (ja) |

| TW (1) | TWI416691B (ja) |

| WO (1) | WO2007130731A2 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012054450A (ja) * | 2010-09-02 | 2012-03-15 | Sony Corp | 半導体装置、および、その製造方法、電子機器 |

| JP2020053701A (ja) * | 2018-08-08 | 2020-04-02 | キヤノン株式会社 | 半導体デバイスの製造方法 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101030299B1 (ko) | 2008-08-08 | 2011-04-20 | 주식회사 동부하이텍 | 반도체 소자 및 그의 제조 방법 |

| JP5985136B2 (ja) | 2009-03-19 | 2016-09-06 | ソニー株式会社 | 半導体装置とその製造方法、及び電子機器 |

| US9406561B2 (en) * | 2009-04-20 | 2016-08-02 | International Business Machines Corporation | Three dimensional integrated circuit integration using dielectric bonding first and through via formation last |

| US9293366B2 (en) * | 2010-04-28 | 2016-03-22 | Taiwan Semiconductor Manufacturing Company, Ltd. | Through-substrate vias with improved connections |

| US9142581B2 (en) | 2012-11-05 | 2015-09-22 | Omnivision Technologies, Inc. | Die seal ring for integrated circuit system with stacked device wafers |

| US10367031B2 (en) * | 2016-09-13 | 2019-07-30 | Imec Vzw | Sequential integration process |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005043584A2 (en) * | 2003-10-21 | 2005-05-12 | Ziptronix, Inc. | Single mask via method and device |

| WO2007021639A2 (en) * | 2005-08-11 | 2007-02-22 | Ziptronix, Inc. | 3d ic method and device |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4433845A1 (de) * | 1994-09-22 | 1996-03-28 | Fraunhofer Ges Forschung | Verfahren zur Herstellung einer dreidimensionalen integrierten Schaltung |

| US5756395A (en) * | 1995-08-18 | 1998-05-26 | Lsi Logic Corporation | Process for forming metal interconnect structures for use with integrated circuit devices to form integrated circuit structures |

| US6902987B1 (en) * | 2000-02-16 | 2005-06-07 | Ziptronix, Inc. | Method for low temperature bonding and bonded structure |

| JP2001291720A (ja) * | 2000-04-05 | 2001-10-19 | Hitachi Ltd | 半導体集積回路装置および半導体集積回路装置の製造方法 |

| KR20020010974A (ko) * | 2000-07-31 | 2002-02-07 | 박종섭 | 금속배선 형성 단계를 감소시킬 수 있는 강유전체 메모리소자 제조 방법 |

| US6656748B2 (en) * | 2002-01-31 | 2003-12-02 | Texas Instruments Incorporated | FeRAM capacitor post stack etch clean/repair |

| US20030143853A1 (en) * | 2002-01-31 | 2003-07-31 | Celii Francis G. | FeRAM capacitor stack etch |

| US6642081B1 (en) * | 2002-04-11 | 2003-11-04 | Robert Patti | Interlocking conductor method for bonding wafers to produce stacked integrated circuits |

| TWI225899B (en) * | 2003-02-18 | 2005-01-01 | Unitive Semiconductor Taiwan C | Etching solution and method for manufacturing conductive bump using the etching solution to selectively remove barrier layer |

| US20040262772A1 (en) * | 2003-06-30 | 2004-12-30 | Shriram Ramanathan | Methods for bonding wafers using a metal interlayer |

| US6924232B2 (en) * | 2003-08-27 | 2005-08-02 | Freescale Semiconductor, Inc. | Semiconductor process and composition for forming a barrier material overlying copper |

| US7176128B2 (en) * | 2004-01-12 | 2007-02-13 | Infineon Technologies Ag | Method for fabrication of a contact structure |

-

2006

- 2006-03-30 US US11/278,042 patent/US7378339B2/en active Active

-

2007

- 2007-02-22 WO PCT/US2007/062538 patent/WO2007130731A2/en active Application Filing

- 2007-02-22 JP JP2009503112A patent/JP2009532874A/ja active Pending

- 2007-02-22 KR KR1020087023823A patent/KR101352732B1/ko active IP Right Grant

- 2007-03-16 TW TW096109128A patent/TWI416691B/zh active

-

2008

- 2008-04-25 US US12/110,009 patent/US20080197497A1/en not_active Abandoned

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005043584A2 (en) * | 2003-10-21 | 2005-05-12 | Ziptronix, Inc. | Single mask via method and device |

| WO2007021639A2 (en) * | 2005-08-11 | 2007-02-22 | Ziptronix, Inc. | 3d ic method and device |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012054450A (ja) * | 2010-09-02 | 2012-03-15 | Sony Corp | 半導体装置、および、その製造方法、電子機器 |

| CN102386196A (zh) * | 2010-09-02 | 2012-03-21 | 索尼公司 | 半导体器件、其制造方法和电子装置 |

| US8809983B2 (en) | 2010-09-02 | 2014-08-19 | Sony Corporation | Semiconductor device, manufacturing method therefor, and electronic apparatus |

| JP2020053701A (ja) * | 2018-08-08 | 2020-04-02 | キヤノン株式会社 | 半導体デバイスの製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20090004895A (ko) | 2009-01-12 |

| US7378339B2 (en) | 2008-05-27 |

| WO2007130731A2 (en) | 2007-11-15 |

| KR101352732B1 (ko) | 2014-01-16 |

| WO2007130731A3 (en) | 2008-09-18 |

| TWI416691B (zh) | 2013-11-21 |

| TW200742022A (en) | 2007-11-01 |

| US20070231950A1 (en) | 2007-10-04 |

| US20080197497A1 (en) | 2008-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10804147B2 (en) | Semiconductor device with reduced via resistance | |

| US9978708B2 (en) | Wafer backside interconnect structure connected to TSVs | |

| CN101527278B (zh) | 通孔制程及形成晶片堆栈的方法 | |

| JP5366833B2 (ja) | 電気メッキを利用した導電ビア形成 | |

| US9165883B2 (en) | Interconnection structure for an integrated circuit | |

| JP2009532874A (ja) | 回路の三次元的な統合において用いられるバリヤ | |

| KR101577959B1 (ko) | 보이드 형성을 방지하는 무전해 도금법을 이용한 전기 배선의 형성 방법 | |

| JPWO2017150146A1 (ja) | 半導体装置及びその製造方法 | |

| TW201715620A (zh) | 傳導阻障直接混合型接合 | |

| US20110260284A1 (en) | Method for Producing a Semiconductor Component, and Semiconductor Component | |

| KR20100100629A (ko) | 3차원 SIP(System―in―Package) 구조물 | |

| CN101930965A (zh) | 用于半导体器件的电网结构及其制造方法 | |

| KR101427015B1 (ko) | 반도체 기판들의 비아들 및 도전성 루팅층들 | |

| US9418933B2 (en) | Through-substrate via formation with improved topography control | |

| KR20100044134A (ko) | 확산 배리어층의 무전해 도금법을 이용한 집적 회로 콘택 패드의 형성 방법 | |

| KR20170118203A (ko) | 금속 규화물을 사용하여 형성된 마이크로전자 조립체 및 제조 방법 | |

| US20070099394A1 (en) | Semiconductor device and manufacturing method thereof | |

| TW201351587A (zh) | 穿矽通孔及其製作方法 | |

| US8980738B2 (en) | Integrated circuit chip and fabrication method | |

| US9343359B2 (en) | Integrated structure and method for fabricating the same | |

| CN111261578A (zh) | 半导体结构的互连方法与半导体互连结构 | |

| TW201324726A (zh) | 穿矽電極及其製作方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100120 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100120 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100518 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120214 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20120228 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120724 |