JP2006181641A - 接合装置及び接合方法 - Google Patents

接合装置及び接合方法 Download PDFInfo

- Publication number

- JP2006181641A JP2006181641A JP2005332752A JP2005332752A JP2006181641A JP 2006181641 A JP2006181641 A JP 2006181641A JP 2005332752 A JP2005332752 A JP 2005332752A JP 2005332752 A JP2005332752 A JP 2005332752A JP 2006181641 A JP2006181641 A JP 2006181641A

- Authority

- JP

- Japan

- Prior art keywords

- processing chamber

- bonding

- processing

- joining

- pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims description 40

- 238000012545 processing Methods 0.000 claims abstract description 146

- 238000003825 pressing Methods 0.000 claims abstract description 13

- 238000010438 heat treatment Methods 0.000 claims abstract description 10

- 239000007789 gas Substances 0.000 claims description 66

- 238000005304 joining Methods 0.000 claims description 59

- 238000004140 cleaning Methods 0.000 claims description 26

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 claims description 26

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 claims description 15

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 claims description 13

- 235000019253 formic acid Nutrition 0.000 claims description 13

- 150000007524 organic acids Chemical class 0.000 claims description 12

- 239000011261 inert gas Substances 0.000 claims description 9

- 238000001514 detection method Methods 0.000 claims description 6

- 229910052802 copper Inorganic materials 0.000 claims description 5

- 239000010949 copper Substances 0.000 claims description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 4

- QPLDLSVMHZLSFG-UHFFFAOYSA-N Copper oxide Chemical compound [Cu]=O QPLDLSVMHZLSFG-UHFFFAOYSA-N 0.000 claims description 4

- 239000005751 Copper oxide Substances 0.000 claims description 4

- 229910000431 copper oxide Inorganic materials 0.000 claims description 4

- 238000012937 correction Methods 0.000 claims description 3

- 229910000881 Cu alloy Inorganic materials 0.000 claims description 2

- 229910000679 solder Inorganic materials 0.000 abstract description 7

- 238000007254 oxidation reaction Methods 0.000 abstract description 5

- 230000003647 oxidation Effects 0.000 abstract description 3

- 230000015556 catabolic process Effects 0.000 abstract 1

- 238000006731 degradation reaction Methods 0.000 abstract 1

- 230000008569 process Effects 0.000 description 22

- 230000007246 mechanism Effects 0.000 description 14

- 238000012546 transfer Methods 0.000 description 13

- 238000002347 injection Methods 0.000 description 8

- 239000007924 injection Substances 0.000 description 8

- 239000000758 substrate Substances 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- 229910001873 dinitrogen Inorganic materials 0.000 description 6

- 239000000463 material Substances 0.000 description 5

- 239000004065 semiconductor Substances 0.000 description 4

- 238000011109 contamination Methods 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 238000004544 sputter deposition Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 230000032258 transport Effects 0.000 description 3

- 230000009471 action Effects 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000000593 degrading effect Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 150000007522 mineralic acids Chemical class 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

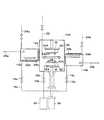

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/02—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating by means of a press ; Diffusion bonding

- B23K20/023—Thermo-compression bonding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/36—Electric or electronic devices

- B23K2101/40—Semiconductor devices

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005332752A JP2006181641A (ja) | 2004-12-02 | 2005-11-17 | 接合装置及び接合方法 |

| US11/291,838 US20060118598A1 (en) | 2004-12-02 | 2005-12-02 | Bonding apparatus and bonding method |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004349454 | 2004-12-02 | ||

| JP2005332752A JP2006181641A (ja) | 2004-12-02 | 2005-11-17 | 接合装置及び接合方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006181641A true JP2006181641A (ja) | 2006-07-13 |

| JP2006181641A5 JP2006181641A5 (enExample) | 2007-07-19 |

Family

ID=36573079

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005332752A Withdrawn JP2006181641A (ja) | 2004-12-02 | 2005-11-17 | 接合装置及び接合方法 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20060118598A1 (enExample) |

| JP (1) | JP2006181641A (enExample) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008155245A (ja) * | 2006-12-22 | 2008-07-10 | Matsushita Electric Works Ltd | 接合方法 |

| RU2397053C1 (ru) * | 2009-09-11 | 2010-08-20 | Открытое акционерное общество "Научно-исследовательский институт физических измерений" | Установка для диффузионной сварки |

| JP2014188536A (ja) * | 2013-03-26 | 2014-10-06 | National Institute For Materials Science | 金属材の拡散接合方法および金属材の拡散接合装置 |

| US9236412B2 (en) | 2011-04-19 | 2016-01-12 | Sony Corporation | Semiconductor device, manufacturing method thereof, solid-state imaging device, and electronic apparatus |

| JP2017075574A (ja) * | 2015-10-15 | 2017-04-20 | トヨタ自動車株式会社 | エンジンの燃料噴射制御装置 |

| RU2646517C1 (ru) * | 2017-02-02 | 2018-03-05 | Закрытое акционерное общество "Элитрон" | Установка для диффузионной сварки |

| RU2680170C1 (ru) * | 2017-11-15 | 2019-02-18 | ООО "Авиационно-космические технологии" | Устройство диффузионной сварки |

| KR20200126269A (ko) * | 2019-04-29 | 2020-11-06 | 삼성전자주식회사 | 접합헤드 및 이를 구비하는 접합 장치 |

| RU2809742C1 (ru) * | 2023-01-24 | 2023-12-15 | Общество с ограниченной ответственностью "НОВА СПБ" | Установка для диффузионной сварки |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5263923B2 (ja) * | 2007-11-29 | 2013-08-14 | 国立大学法人 新潟大学 | 拡散接合方法及びその装置 |

| JP5424201B2 (ja) * | 2009-08-27 | 2014-02-26 | アユミ工業株式会社 | 加熱溶融処理装置および加熱溶融処理方法 |

| KR101073558B1 (ko) * | 2009-10-08 | 2011-10-17 | 삼성모바일디스플레이주식회사 | 기판 합착 장치 및 기판 합착 방법 |

| TW201301413A (zh) * | 2011-06-20 | 2013-01-01 | 華新麗華股份有限公司 | 晶片結合設備 |

| TW201301412A (zh) * | 2011-06-20 | 2013-01-01 | 華新麗華股份有限公司 | 晶片結合方法 |

| WO2013161875A1 (ja) * | 2012-04-25 | 2013-10-31 | オリジン電気株式会社 | 半田付け装置及び半田付け製品の製造方法 |

| DE112012005906A5 (de) * | 2012-05-30 | 2014-10-30 | Ev Group E. Thallner Gmbh | Vorrichtung und Verfahren zum Bonden von Substraten |

| US9576928B2 (en) * | 2015-02-27 | 2017-02-21 | Kulicke And Soffa Industries, Inc. | Bond head assemblies, thermocompression bonding systems and methods of assembling and operating the same |

| JP6625728B2 (ja) * | 2016-03-17 | 2019-12-25 | 株式会社Jcu | プラズマ生成装置 |

| CN109802030B (zh) * | 2019-01-25 | 2020-02-21 | 楼显华 | 一种led元件及其生产方法 |

| JP6879482B1 (ja) * | 2020-01-09 | 2021-06-02 | 株式会社オリジン | 酸化物除去済部材の製造方法及び酸化物除去装置 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5516031A (en) * | 1991-02-19 | 1996-05-14 | Hitachi, Ltd. | Soldering method and apparatus for use in connecting electronic circuit devices |

| US5271545A (en) * | 1993-03-31 | 1993-12-21 | Seco/Warwick Corporation | Muffle convection brazing/annealing system |

| US5573174A (en) * | 1994-08-15 | 1996-11-12 | Pekol; Robert | Automatic reflow soldering system |

| JP3693441B2 (ja) * | 1996-12-27 | 2005-09-07 | 富士通株式会社 | 記録媒体の製造方法 |

| US6152353A (en) * | 1999-01-14 | 2000-11-28 | Celestica International Inc. | Printed circuit board header attachment station |

| JP3397313B2 (ja) * | 1999-12-20 | 2003-04-14 | 富士通株式会社 | 半導体装置の製造方法及び電子部品の実装方法 |

| US7296727B2 (en) * | 2001-06-27 | 2007-11-20 | Matsushita Electric Industrial Co., Ltd. | Apparatus and method for mounting electronic components |

| US6806118B2 (en) * | 2002-02-07 | 2004-10-19 | Fujitsu Limited | Electrode connection method, electrode surface activation apparatus, electrode connection apparatus, connection method of electronic components and connected structure |

-

2005

- 2005-11-17 JP JP2005332752A patent/JP2006181641A/ja not_active Withdrawn

- 2005-12-02 US US11/291,838 patent/US20060118598A1/en not_active Abandoned

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008155245A (ja) * | 2006-12-22 | 2008-07-10 | Matsushita Electric Works Ltd | 接合方法 |

| RU2397053C1 (ru) * | 2009-09-11 | 2010-08-20 | Открытое акционерное общество "Научно-исследовательский институт физических измерений" | Установка для диффузионной сварки |

| US9236412B2 (en) | 2011-04-19 | 2016-01-12 | Sony Corporation | Semiconductor device, manufacturing method thereof, solid-state imaging device, and electronic apparatus |

| US11948833B2 (en) | 2011-04-19 | 2024-04-02 | Sony Group Corporation | Multilayer light detecting device and electronic apparatus |

| JP2014188536A (ja) * | 2013-03-26 | 2014-10-06 | National Institute For Materials Science | 金属材の拡散接合方法および金属材の拡散接合装置 |

| JP2017075574A (ja) * | 2015-10-15 | 2017-04-20 | トヨタ自動車株式会社 | エンジンの燃料噴射制御装置 |

| RU2646517C1 (ru) * | 2017-02-02 | 2018-03-05 | Закрытое акционерное общество "Элитрон" | Установка для диффузионной сварки |

| RU2680170C1 (ru) * | 2017-11-15 | 2019-02-18 | ООО "Авиационно-космические технологии" | Устройство диффузионной сварки |

| KR20200126269A (ko) * | 2019-04-29 | 2020-11-06 | 삼성전자주식회사 | 접합헤드 및 이를 구비하는 접합 장치 |

| KR102707392B1 (ko) | 2019-04-29 | 2024-09-20 | 삼성전자주식회사 | 접합헤드 및 이를 구비하는 접합 장치 |

| RU2809742C1 (ru) * | 2023-01-24 | 2023-12-15 | Общество с ограниченной ответственностью "НОВА СПБ" | Установка для диффузионной сварки |

| RU239163U1 (ru) * | 2025-03-25 | 2025-11-25 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Саратовский государственный технический университет имени Гагарина Ю.А." | Устройство для диффузионной сварки |

Also Published As

| Publication number | Publication date |

|---|---|

| US20060118598A1 (en) | 2006-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006181641A (ja) | 接合装置及び接合方法 | |

| TWI482254B (zh) | Bonding system, bonding method and computer memory media | |

| KR100809126B1 (ko) | 피처리체 처리 장치 | |

| TW201933427A (zh) | 接合系統及接合方法 | |

| JP4027072B2 (ja) | 減圧プラズマ処理装置及びその方法 | |

| JP2005039185A5 (enExample) | ||

| JP2005294800A (ja) | 接合方法及びこの方法により作成されるデバイス並びに表面活性化装置及びこの装置を備えた接合装置 | |

| CN100440475C (zh) | 算出搬送机构的搬送偏差的方法及半导体处理装置 | |

| JP4669600B2 (ja) | 実装装置 | |

| TWI360195B (enExample) | ||

| JP4377035B2 (ja) | 実装方法および装置 | |

| JP3948325B2 (ja) | フィルム基板処理方法 | |

| JP7268931B2 (ja) | 接合方法、基板接合装置および基板接合システム | |

| JP2008004601A (ja) | 基板搬送装置およびそれを用いた基板搬送方法 | |

| JP6120749B2 (ja) | 接合方法、プログラム、コンピュータ記憶媒体、接合装置及び接合システム | |

| JPS63141342A (ja) | 半導体ウエハ処理方法及びその装置 | |

| JP2004231331A (ja) | 基板の搬送方法及び基板の搬送装置 | |

| JP2006287181A5 (enExample) | ||

| TW202326897A (zh) | 半導體製造裝置及其製造方法 | |

| JP5385024B2 (ja) | 半導体製造装置及び半導体製造方法 | |

| JP3970732B2 (ja) | 接合方法および装置 | |

| JP4440284B2 (ja) | 減圧プラズマ処理装置及びその方法 | |

| TWI905426B (zh) | 接合方法及接合裝置 | |

| JP4701933B2 (ja) | プラズマcvd装置 | |

| JP2006024697A (ja) | ハンドリングツール及びこのツールを用いた部品搬送装置並びに方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070605 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070605 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20090807 |