JP2005298973A - ニッケル基超合金、組成、物品、およびガスタービンエンジンブレード - Google Patents

ニッケル基超合金、組成、物品、およびガスタービンエンジンブレード Download PDFInfo

- Publication number

- JP2005298973A JP2005298973A JP2005110703A JP2005110703A JP2005298973A JP 2005298973 A JP2005298973 A JP 2005298973A JP 2005110703 A JP2005110703 A JP 2005110703A JP 2005110703 A JP2005110703 A JP 2005110703A JP 2005298973 A JP2005298973 A JP 2005298973A

- Authority

- JP

- Japan

- Prior art keywords

- less

- alloy

- weight

- ppm

- gas turbine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000203 mixture Substances 0.000 title claims abstract description 25

- 229910000601 superalloy Inorganic materials 0.000 title claims abstract description 25

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 title abstract description 9

- 229910052759 nickel Inorganic materials 0.000 title abstract description 4

- 229910045601 alloy Inorganic materials 0.000 claims abstract description 60

- 239000000956 alloy Substances 0.000 claims abstract description 60

- 230000003647 oxidation Effects 0.000 claims abstract description 28

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 28

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 12

- 229910052735 hafnium Inorganic materials 0.000 claims abstract description 10

- 229910052796 boron Inorganic materials 0.000 claims abstract description 7

- 239000012720 thermal barrier coating Substances 0.000 claims abstract description 6

- 229910052804 chromium Inorganic materials 0.000 claims abstract 7

- 229910052750 molybdenum Inorganic materials 0.000 claims abstract 5

- 229910052758 niobium Inorganic materials 0.000 claims abstract 5

- 229910052702 rhenium Inorganic materials 0.000 claims abstract 5

- 229910052721 tungsten Inorganic materials 0.000 claims abstract 5

- 229910052720 vanadium Inorganic materials 0.000 claims abstract 5

- 229910052715 tantalum Inorganic materials 0.000 claims abstract 4

- 238000000576 coating method Methods 0.000 claims description 23

- 239000011248 coating agent Substances 0.000 claims description 20

- 229910052727 yttrium Inorganic materials 0.000 claims description 16

- 239000013078 crystal Substances 0.000 claims description 13

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims description 8

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 5

- 239000000919 ceramic Substances 0.000 claims description 5

- 229910000951 Aluminide Inorganic materials 0.000 claims description 3

- 230000001464 adherent effect Effects 0.000 claims description 3

- 238000009413 insulation Methods 0.000 claims description 3

- 229910052726 zirconium Inorganic materials 0.000 claims description 3

- 239000000758 substrate Substances 0.000 claims description 2

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 12

- 238000007792 addition Methods 0.000 description 9

- 238000005260 corrosion Methods 0.000 description 6

- 230000007797 corrosion Effects 0.000 description 6

- 239000000463 material Substances 0.000 description 6

- 238000000034 method Methods 0.000 description 6

- 238000012360 testing method Methods 0.000 description 6

- 238000005328 electron beam physical vapour deposition Methods 0.000 description 5

- 239000007789 gas Substances 0.000 description 5

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 description 5

- 238000001816 cooling Methods 0.000 description 4

- 238000010438 heat treatment Methods 0.000 description 4

- 239000007921 spray Substances 0.000 description 4

- 238000005275 alloying Methods 0.000 description 3

- 238000005524 ceramic coating Methods 0.000 description 3

- 239000011162 core material Substances 0.000 description 3

- 239000011253 protective coating Substances 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 238000005495 investment casting Methods 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 239000011224 oxide ceramic Substances 0.000 description 2

- 229910052574 oxide ceramic Inorganic materials 0.000 description 2

- 238000007740 vapor deposition Methods 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical group [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000010285 flame spraying Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 229910002078 fully stabilized zirconia Inorganic materials 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 229910002077 partially stabilized zirconia Inorganic materials 0.000 description 1

- 238000007750 plasma spraying Methods 0.000 description 1

- 229910001404 rare earth metal oxide Inorganic materials 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/34—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates

- C23C28/345—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates with at least one oxide layer

- C23C28/3455—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates with at least one oxide layer with a refractory ceramic layer, e.g. refractory metal oxide, ZrO2, rare earth oxides or a thermal barrier system comprising at least one refractory oxide layer

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47F—SPECIAL FURNITURE, FITTINGS, OR ACCESSORIES FOR SHOPS, STOREHOUSES, BARS, RESTAURANTS OR THE LIKE; PAYING COUNTERS

- A47F1/00—Racks for dispensing merchandise; Containers for dispensing merchandise

- A47F1/04—Racks or containers with arrangements for dispensing articles, e.g. by means of gravity or springs

- A47F1/08—Racks or containers with arrangements for dispensing articles, e.g. by means of gravity or springs dispensing from bottom

- A47F1/10—Racks or containers with arrangements for dispensing articles, e.g. by means of gravity or springs dispensing from bottom having mechanical dispensing means, e.g. with buttons or handles

- A47F1/106—Racks or containers with arrangements for dispensing articles, e.g. by means of gravity or springs dispensing from bottom having mechanical dispensing means, e.g. with buttons or handles for nested articles, e.g. cups, cones

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47F—SPECIAL FURNITURE, FITTINGS, OR ACCESSORIES FOR SHOPS, STOREHOUSES, BARS, RESTAURANTS OR THE LIKE; PAYING COUNTERS

- A47F7/00—Show stands, hangers, or shelves, adapted for particular articles or materials

- A47F7/28—Show stands, hangers, or shelves, adapted for particular articles or materials for containers, e.g. flasks, bottles, tins, milk packs

- A47F7/281—Show stands, hangers, or shelves, adapted for particular articles or materials for containers, e.g. flasks, bottles, tins, milk packs for vertically-stacked containers; Stabilising means therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G59/00—De-stacking of articles

- B65G59/06—De-stacking from the bottom of the stack

- B65G59/061—De-stacking from the bottom of the stack articles being separated substantially along the axis of the stack

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

- C22C19/05—Alloys based on nickel or cobalt based on nickel with chromium

- C22C19/051—Alloys based on nickel or cobalt based on nickel with chromium and Mo or W

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/32—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer

- C23C28/321—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer with at least one metal alloy layer

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/32—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer

- C23C28/321—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer with at least one metal alloy layer

- C23C28/3215—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one pure metallic layer with at least one metal alloy layer at least one MCrAlX layer

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/30—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer

- C23C28/34—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates

- C23C28/345—Coatings combining at least one metallic layer and at least one inorganic non-metallic layer including at least one inorganic non-metallic material layer, e.g. metal carbide, nitride, boride, silicide layer and their mixtures, enamels, phosphates and sulphates with at least one oxide layer

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

- F01D5/288—Protective coatings for blades

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G2201/00—Indexing codes relating to handling devices, e.g. conveyors, characterised by the type of product or load being conveyed or handled

- B65G2201/02—Articles

- B65G2201/0235—Containers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2201/00—Metals

- F05C2201/04—Heavy metals

- F05C2201/0433—Iron group; Ferrous alloys, e.g. steel

- F05C2201/0466—Nickel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/20—Oxide or non-oxide ceramics

- F05D2300/21—Oxide ceramics

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Inorganic Chemistry (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Abstract

【解決手段】合金と断熱被覆との組み合わせは、他の関連する特性を維持しながら、良好な高温強度と良好な耐酸化性を有するタービン部材を作成するのに使用できる。ニッケル基超合金は、重量で、約7.5〜約12.5%のCrと、約4.5〜約5.5%のAlと、約2%以下のTiと、約3.5〜約4.5%のWと、約11.5〜約12.5%のTaと、約3〜約16%のCoと、約0.2〜約0.5%のHfと、意図的な添加なしでかつ300ppm未満のYと、意図的な添加なしでかつ500ppm未満のZrと、約0.05%以下のCと、約0.005%以下のBと、Mo、Re、NbおよびVから成る群より選択される約8.5%以下の付加的元素と、残部の実質的Niと、から実質的に構成され、P条件値が、約2500未満であり、所定の公称組成を有する合金より少なくとも約25%大きな耐酸化性を有する。

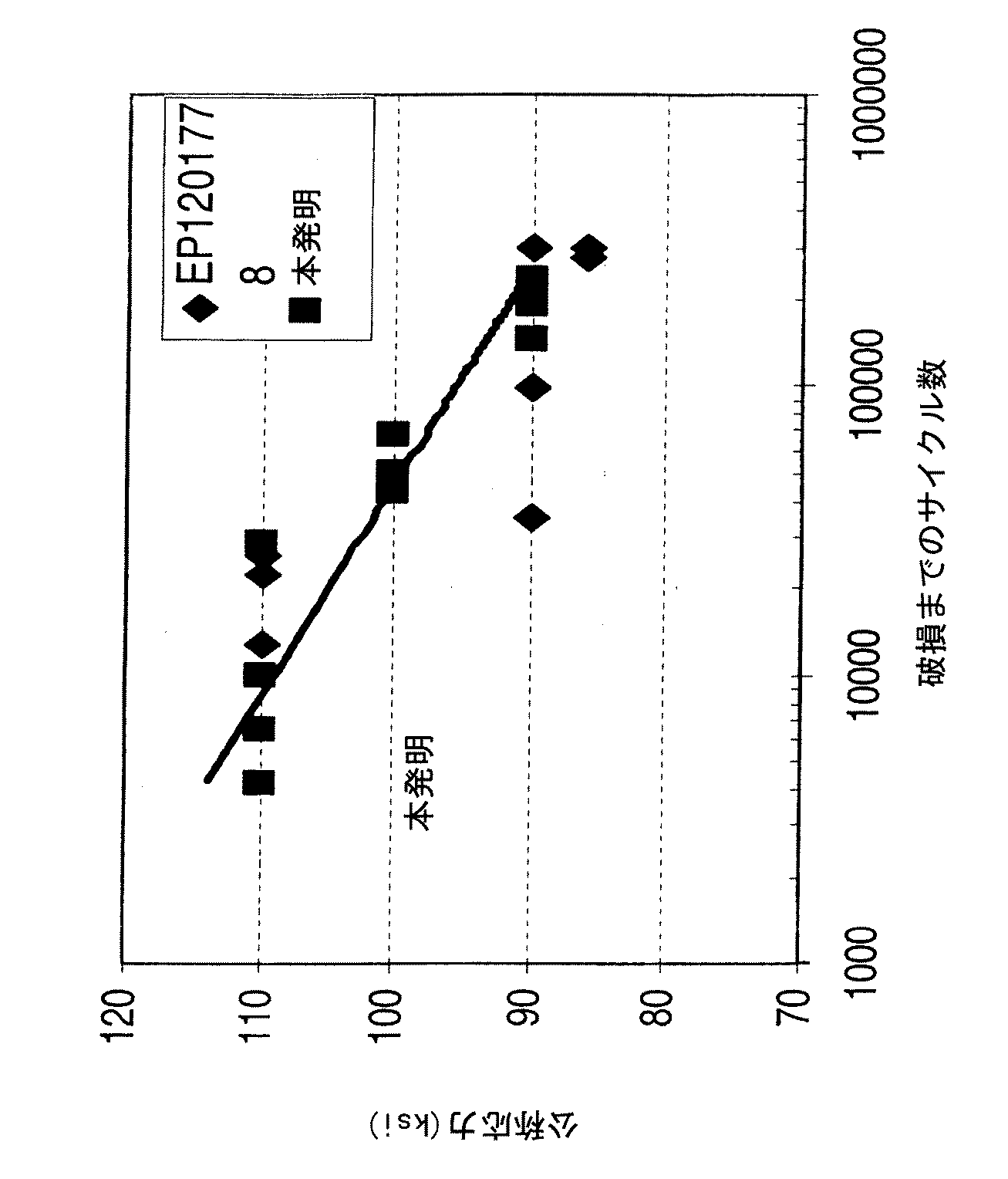

【選択図】図1

Description

本願は、2000年10月30日に出願され参照することにより本願に特に組み込まれる「接合被覆なしに断熱被覆を保持できる低密度耐酸化性超合金材料」という名称の同時係属で同一出願人による米国特許出願番号第09/699,945号の一部継続出願である。

P=−200Cr+80Mo2−250Ti2−50(TixTa)+15Nb+200W−14W2+30Ta−1.5Ta2+2.5Co+1200Al−100Al2+100Re+1000Hf−2000Hf2+700Hf3−2000V−500C−15000B−500Zr、

のようになる。

Claims (14)

- 重量で、約7.5〜約12.5%のCrと、約4.5〜約5.5%のAlと、約2%以下のTiと、約3.5〜約4.5%のWと、約11.5〜約12.5%のTaと、約3〜約16%のCoと、約0.2〜約0.5%のHfと、意図的な添加なしでかつ300ppm未満のYと、意図的な添加なしでかつ500ppm未満のZrと、約0.05%以下のCと、約0.005%以下のBと、Mo、Re、NbおよびVから成る群より選択される約8.5%以下の付加的元素と、残部の実質的Niと、

から実質的に構成されるニッケル基超合金であって、

P=−200Cr+80Mo2−250Ti2−50(TixTa)+15Nb+200W−14W2+30Ta−1.5Ta2+0.5Co+1200Al−100Al2+100Re+1000Hf−2000Hf2+700Hf3−2000V−500C−15000B−500Zr、であり、

Pは、約2500未満であり、

合金は、重量で10%のCrと、5%のCoと、4%のWと、1.5%のTiと、5%のAlと、残部のNiとから成る公称組成を有する合金より少なくとも約25%大きな耐酸化性を有する、

ことを特徴とするニッケル基超合金。 - Al+Ti+0.2Taの量が、重量で7〜10%の範囲であり、かつ、W+0.8Taの量が、重量で12〜18%の範囲であることを特徴とする請求項1記載の合金。

- 重量で、Cが0.05%未満であり、Bが0.005%未満であり、Zrが0.5%未満であり、かつ、Yが30ppm未満であることを特徴とする請求項1記載の合金。

- Pは、約1800未満であることを特徴とする請求項1記載の合金。

- 重量で、Yが50ppm未満であり、かつ、Mo、Re、NbおよびVから成る群より選択される付加的元素が1%未満であることを特徴とする請求項1記載の合金。

- 重量で、約9〜約11%のCrと、約4.75〜約5.25%のAlと、約1〜約2%のTiと、約3.5〜約4.5%のWと、約11.5〜約12.5%のTaと、約4〜約6%のCoと、約0.25〜約0.45%のHfと、意図的な添加なしでかつ300ppm未満のYと、意図的な添加なしでかつ300ppm未満のZrと、約0.01%以下のCと、約0.005%以下のBと、Mo、Re、NbおよびVから成る群より選択される約8.5%以下の付加的元素と、残部の実質的Niと、

から実質的に構成されるニッケル基超合金から実質的に構成されるニッケル基超合金組成であって、

P=−200Cr+80Mo2−250Ti2−50(TixTa)+15Nb+200W−14W2+30Ta−1.5Ta2+0.5Co+1200Al−100Al2+100Re+1000Hf−2000Hf2+700Hf3−2000V−500C−15000B−500Zr、であり、

Pは、約2500未満であり、

合金は、重量で10%のCrと、5%のCoと、4%のWと、1.5%のTiと、5%のAlと、残部のNiとから成る公称組成を有する合金より少なくとも約25%大きな耐酸化性を有する、

ことを特徴とするニッケル基超合金組成。 - Al+Ti+0.2Taの量が、重量で7〜10%の範囲であり、かつ、W+0.8Taの量が、重量で12〜18%の範囲であることを特徴とする請求項6記載の組成。

- 重量で、Cが0.05%未満であり、Bが0.005%未満であり、Zrが0.05%未満であり、かつ、Yが0.003%未満であることを特徴とする請求項6記載の組成。

- 単結晶微細構造を有することを特徴とする請求項1記載の超合金物品。

- 柱状微細構造を有することを特徴とする請求項1記載の超合金物品。

- a. 重量で、約7.5〜約12.5%のCrと、約4.5〜約5.5%のAlと、約2%以下のTiと、約3.5〜約4.5%のWと、約11.5〜約12.5%のTaと、約3〜約16%のCoと、約0.2〜約0.5%のHfと、意図的な添加なしでかつ300ppm未満のYと、意図的な添加なしでかつ500ppm未満のZrと、約0.05%以下のCと、約0.005%以下のBと、Mo、Re、NbおよびVから成る群より選択される約8.5%以下の付加的元素と、残部の実質的Niと、

から成る単結晶超合金ガスタービンエンジンブレードであって、

P=−200Cr+80Mo2−250Ti2−50(TixTa)+15Nb+200W−14W2+30Ta−1.5Ta2+0.5Co+1200Al−100Al2+100Re+1000Hf−2000Hf2+700Hf3−2000V−500C−15000B−500Zr、であり、

Pは、約2500未満であり、

合金は、重量で10%のCrと、5%のCoと、4%のWと、1.5%のTiと、5%のAlと、残部のNiとから成る公称組成を有する合金より少なくとも約25%大きな耐酸化性を有し、

ガスタービンエンジンブレードはさらに、

b. 基体上にあるアルミニウム含有被覆であって、耐久性付着性アルミナスケールを形成できる、アルミニウム含有被覆と、

c. アルミナスケールに付着するセラミック断熱被覆と、

を備えることを特徴とする単結晶超合金ガスタービンエンジンブレード。 - 断熱被覆は、柱状微細構造を有することを特徴とする請求項11記載のガスタービンブレード。

- アルミニウム含有被覆は、オーバーレイ被覆であることを特徴とする請求項11記載のガスタービンブレード。

- アルミニウム含有被覆は、アルミニドであることを特徴とする請求項11記載のガスタービンブレード。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US56028704P | 2004-04-07 | 2004-04-07 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2005298973A true JP2005298973A (ja) | 2005-10-27 |

Family

ID=34940740

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005110703A Pending JP2005298973A (ja) | 2004-04-07 | 2005-04-07 | ニッケル基超合金、組成、物品、およびガスタービンエンジンブレード |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1586669B1 (ja) |

| JP (1) | JP2005298973A (ja) |

| KR (1) | KR20060045542A (ja) |

| CN (1) | CN1680611A (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010037658A (ja) * | 2008-08-06 | 2010-02-18 | General Electric Co <Ge> | ニッケル基超合金、その一方向凝固プロセス並びに得られる鋳造品 |

| WO2015072660A1 (ko) * | 2013-11-13 | 2015-05-21 | 주식회사 엔아이비 | Ni기 초합금 및 이의 제조방법 |

| CN107177757A (zh) * | 2017-05-27 | 2017-09-19 | 湖南科技大学 | 一种NiAl基合金在二氧化碳环境中的自润滑耐磨损应用 |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7476450B2 (en) * | 2006-03-24 | 2009-01-13 | United Technologies Corporation | Coating suitable for use as a bondcoat in a thermal barrier coating system |

| US9322089B2 (en) * | 2006-06-02 | 2016-04-26 | Alstom Technology Ltd | Nickel-base alloy for gas turbine applications |

| CN101121977B (zh) * | 2006-08-09 | 2010-05-12 | 中国科学院金属研究所 | 一种定向凝固镍基高温合金及其热处理工艺 |

| EP1914327A1 (en) * | 2006-10-17 | 2008-04-23 | Siemens Aktiengesellschaft | Nickel-base superalloy |

| DE102007062417B4 (de) * | 2007-12-20 | 2011-07-14 | ThyssenKrupp VDM GmbH, 58791 | Austenitische warmfeste Nickel-Basis-Legierung |

| US20110076182A1 (en) * | 2009-09-30 | 2011-03-31 | General Electric Company | Nickel-Based Superalloys and Articles |

| CN105349811B (zh) * | 2015-11-11 | 2017-04-05 | 江西理工大学 | 提高镍基单晶高温合金铸造过程中稀土元素收得率的方法 |

| FR3057880B1 (fr) | 2016-10-25 | 2018-11-23 | Safran | Superalliage a base de nickel, aube monocristalline et turbomachine |

| DE102018204498A1 (de) * | 2018-03-23 | 2019-09-26 | Siemens Aktiengesellschaft | Keramisches Material auf der Basis von Zirkonoxid mit weiteren Oxiden |

| WO2020154494A1 (en) * | 2019-01-23 | 2020-07-30 | Crs Holdings, Inc. | Ni-based superalloy powder for additive manufacturing and an article made therefrom |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002167636A (ja) * | 2000-10-30 | 2002-06-11 | United Technol Corp <Utc> | 接合被覆なしに断熱被覆を保持できる低密度耐酸化性超合金材料 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4719080A (en) * | 1985-06-10 | 1988-01-12 | United Technologies Corporation | Advanced high strength single crystal superalloy compositions |

| US6074602A (en) * | 1985-10-15 | 2000-06-13 | General Electric Company | Property-balanced nickel-base superalloys for producing single crystal articles |

| EP0962542A1 (en) * | 1998-05-01 | 1999-12-08 | United Technologies Corporation | Stable heat treatable nickel superalloy single crystal articles and compositions |

| EP1111192B1 (en) * | 1999-12-20 | 2005-08-31 | United Technologies Corporation | Articles provided with corrosion resistant coatings |

| US6565680B1 (en) * | 1999-12-27 | 2003-05-20 | General Electric Company | Superalloy weld composition and repaired turbine engine component |

-

2005

- 2005-04-07 CN CNA2005100697810A patent/CN1680611A/zh active Pending

- 2005-04-07 JP JP2005110703A patent/JP2005298973A/ja active Pending

- 2005-04-07 EP EP05252189.5A patent/EP1586669B1/en not_active Expired - Lifetime

- 2005-04-07 KR KR1020050028762A patent/KR20060045542A/ko not_active Withdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002167636A (ja) * | 2000-10-30 | 2002-06-11 | United Technol Corp <Utc> | 接合被覆なしに断熱被覆を保持できる低密度耐酸化性超合金材料 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010037658A (ja) * | 2008-08-06 | 2010-02-18 | General Electric Co <Ge> | ニッケル基超合金、その一方向凝固プロセス並びに得られる鋳造品 |

| WO2015072660A1 (ko) * | 2013-11-13 | 2015-05-21 | 주식회사 엔아이비 | Ni기 초합금 및 이의 제조방법 |

| CN107177757A (zh) * | 2017-05-27 | 2017-09-19 | 湖南科技大学 | 一种NiAl基合金在二氧化碳环境中的自润滑耐磨损应用 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1586669B1 (en) | 2014-05-21 |

| EP1586669A1 (en) | 2005-10-19 |

| KR20060045542A (ko) | 2006-05-17 |

| CN1680611A (zh) | 2005-10-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20050271886A1 (en) | Oxidation resistant superalloy and article | |

| US5238752A (en) | Thermal barrier coating system with intermetallic overlay bond coat | |

| US5498484A (en) | Thermal barrier coating system with hardenable bond coat | |

| JP3939362B2 (ja) | 高温保護コーティング | |

| CN102816965B (zh) | 钴-镍基合金和由此制造物品的方法 | |

| JPS6354794B2 (ja) | ||

| JPH05132751A (ja) | 超合金用強化保護コ―テイング | |

| JP2007092168A (ja) | ガンマプライム相含有ニッケルアルミナイド皮膜 | |

| EP2145969A1 (en) | Economic oxidation and fatigue resistant metallic coating | |

| CN103796828B (zh) | 具有双层的MCrAlX金属层的层系统 | |

| JP5254538B2 (ja) | ケイ化ニオブを基材とした高融点金属金属間化合物複合材及びその関連する物品 | |

| JP2013127117A (ja) | ニッケル−コバルト基合金及びボンドコート並びに該合金を含むボンドコート物品 | |

| US20110287269A1 (en) | Alloy, protective layer and component | |

| US20130136948A1 (en) | Alloy, protective layer and component | |

| JP2019537672A (ja) | ニッケルをベースとする超合金、単結晶ブレード、およびターボマシン | |

| JP2005298973A (ja) | ニッケル基超合金、組成、物品、およびガスタービンエンジンブレード | |

| JP5073982B2 (ja) | ガンマプライム相含有ニッケルアルミナイド皮膜 | |

| CN101061244B (zh) | 镍基高温合金 | |

| US20140220379A1 (en) | Alloy, protective layer and component | |

| CN103298607A (zh) | 合金、保护层和构件 | |

| US20070059550A1 (en) | Nickel based superalloy | |

| JP2014198902A (ja) | ボンドコート系及び被覆部品 | |

| JP2005350771A (ja) | 改良された酸化物安定領域を備えたニッケルアルミナイド・コーティング | |

| KR101597924B1 (ko) | 2겹 금속층을 포함하는 층 시스템 | |

| US20140220384A1 (en) | Alloy, protective layer and component |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080117 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110323 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110405 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110705 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20120410 |