JP2005297566A - 加熱されるノズル本体セグメント及び加熱されないノズル本体セグメントを有するノズル本体を備えたノズル - Google Patents

加熱されるノズル本体セグメント及び加熱されないノズル本体セグメントを有するノズル本体を備えたノズル Download PDFInfo

- Publication number

- JP2005297566A JP2005297566A JP2005110897A JP2005110897A JP2005297566A JP 2005297566 A JP2005297566 A JP 2005297566A JP 2005110897 A JP2005110897 A JP 2005110897A JP 2005110897 A JP2005110897 A JP 2005110897A JP 2005297566 A JP2005297566 A JP 2005297566A

- Authority

- JP

- Japan

- Prior art keywords

- nozzle body

- body segment

- nozzle

- injection molding

- molding apparatus

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001746 injection moulding Methods 0.000 claims abstract description 114

- 238000011144 upstream manufacturing Methods 0.000 claims description 114

- 239000004020 conductor Substances 0.000 claims description 80

- 239000000155 melt Substances 0.000 claims description 34

- 238000004891 communication Methods 0.000 claims description 12

- 238000010438 heat treatment Methods 0.000 claims description 11

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 9

- 239000010949 copper Substances 0.000 claims description 9

- 229910052802 copper Inorganic materials 0.000 claims description 9

- 239000012530 fluid Substances 0.000 claims description 9

- 238000005219 brazing Methods 0.000 claims description 7

- 238000003466 welding Methods 0.000 claims description 7

- 239000011248 coating agent Substances 0.000 claims description 6

- 238000000576 coating method Methods 0.000 claims description 6

- 230000004927 fusion Effects 0.000 claims description 6

- 239000000919 ceramic Substances 0.000 claims description 5

- 239000010410 layer Substances 0.000 claims 8

- 239000011247 coating layer Substances 0.000 claims 4

- 230000008878 coupling Effects 0.000 claims 4

- 238000010168 coupling process Methods 0.000 claims 4

- 238000005859 coupling reaction Methods 0.000 claims 4

- 239000000243 solution Substances 0.000 abstract 1

- 239000000463 material Substances 0.000 description 15

- 238000012546 transfer Methods 0.000 description 8

- 230000008859 change Effects 0.000 description 7

- 229910000881 Cu alloy Inorganic materials 0.000 description 6

- 238000009826 distribution Methods 0.000 description 6

- 238000002347 injection Methods 0.000 description 6

- 239000007924 injection Substances 0.000 description 6

- 238000009413 insulation Methods 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 230000004048 modification Effects 0.000 description 4

- 238000012986 modification Methods 0.000 description 4

- 238000000465 moulding Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- 229910001369 Brass Inorganic materials 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 2

- 229910001315 Tool steel Inorganic materials 0.000 description 2

- 239000010951 brass Substances 0.000 description 2

- 239000012212 insulator Substances 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 229910052718 tin Inorganic materials 0.000 description 2

- 229910000984 420 stainless steel Inorganic materials 0.000 description 1

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 1

- 229910001018 Cast iron Inorganic materials 0.000 description 1

- 229920000106 Liquid crystal polymer Polymers 0.000 description 1

- 239000004977 Liquid-crystal polymers (LCPs) Substances 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- DMFGNRRURHSENX-UHFFFAOYSA-N beryllium copper Chemical compound [Be].[Cu] DMFGNRRURHSENX-UHFFFAOYSA-N 0.000 description 1

- 238000005524 ceramic coating Methods 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

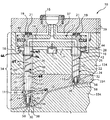

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2701—Details not specific to hot or cold runner channels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

- B29C45/2738—Heating or cooling means therefor specially adapted for manifolds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2701—Details not specific to hot or cold runner channels

- B29C2045/2717—Reconfigurable runner channels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

- B29C2045/274—Thermocouples or heat sensors

- B29C2045/2741—Plurality of independent thermocouples or heat sensors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

- B29C2045/2754—Plurality of independent heating or cooling means, e.g. independently controlling the heating of several zones of the nozzle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C2045/2766—Heat insulation between nozzle and mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C2045/2774—The nozzle head or the collar portion and central portion being made of different parts or materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C2045/2777—Means for controlling heat flow or temperature distribution in the nozzle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/28—Closure devices therefor

- B29C45/2806—Closure devices therefor consisting of needle valve systems

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US55997704P | 2004-04-07 | 2004-04-07 | |

| US61899604P | 2004-10-18 | 2004-10-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005297566A true JP2005297566A (ja) | 2005-10-27 |

| JP2005297566A5 JP2005297566A5 (enExample) | 2008-05-22 |

Family

ID=35329674

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005110897A Pending JP2005297566A (ja) | 2004-04-07 | 2005-04-07 | 加熱されるノズル本体セグメント及び加熱されないノズル本体セグメントを有するノズル本体を備えたノズル |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US7462030B2 (enExample) |

| JP (1) | JP2005297566A (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009539640A (ja) * | 2006-06-08 | 2009-11-19 | ギュンター・ハイスカナルテヒニク・ゲゼルシヤフト・ミト・ベシユレンクテル・ハフツング | 射出成形ノズル、特に射出成形工具に設置するためのホットランナーノズル |

| JP2009539641A (ja) * | 2006-06-08 | 2009-11-19 | ギュンター・ハイスカナルテヒニク・ゲゼルシヤフト・ミト・ベシユレンクテル・ハフツング | 射出成形鋳型内に配置するための射出成形ノズル、特にホットチャネルノズル |

| KR101005275B1 (ko) | 2008-07-08 | 2011-01-04 | 유도실업주식회사 | 사출 성형기용 핫 런너 시스템에 장착되는 히터고정용 튜브 |

| KR20220048308A (ko) * | 2020-10-12 | 2022-04-19 | 주식회사 유도 | 이중 사출용 핫 런너 시스템 |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

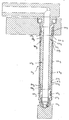

| US7160100B2 (en) | 2004-01-06 | 2007-01-09 | Mold-Masters Limited | Injection molding apparatus having an elongated nozzle incorporating multiple nozzle bodies in tandem |

| CA2482254A1 (en) * | 2004-04-07 | 2005-10-07 | Mold-Masters Limited | Modular injection nozzle having a thermal barrier |

| EP1724090B1 (en) * | 2005-05-19 | 2010-07-21 | Mold-Masters (2007) Limited | Injection nozzle with a thermal shroud and method of making the same |

| US7462031B2 (en) | 2005-11-25 | 2008-12-09 | Mold-Masters (2007) Limited | Injection molding nozzle with recessed terminal |

| US7810549B2 (en) * | 2007-01-05 | 2010-10-12 | Ford Global Technologies, Llc | Adaptive and universal hot runner manifold for die casting |

| CA2764096C (en) * | 2009-07-17 | 2015-12-22 | Husky Injection Molding Systems Ltd. | Modular manifold system |

| EP2673127A4 (en) * | 2011-02-09 | 2014-10-15 | Husky Injection Molding | MOLDING SYSTEM WITH HEAT TRANSFER INHIBITION |

| WO2014085008A1 (en) * | 2012-11-27 | 2014-06-05 | Husky Injection Molding Systems Ltd. | Molding material distribution device |

| CA2939358C (en) * | 2013-02-14 | 2020-02-18 | Nathan Y. Li | Molded dental root canal filling points/cones and process of making same |

| WO2014133702A1 (en) * | 2013-02-27 | 2014-09-04 | Husky Injection Molding Systems Ltd. | Hot runner and components thereof with a melt conditioning zone |

| LT3157351T (lt) * | 2014-06-20 | 2019-09-10 | Live-Tech S.R.L. | Riebalų sudėtyje turinčio produkto liejimo slegiant sistema |

| ITUB20154577A1 (it) | 2015-10-12 | 2017-04-12 | Inglass Spa | Iniettore per apparecchiature di stampaggio ad iniezione di materie plastiche e apparecchiatura di stampaggio ad iniezione |

| DE102016203995A1 (de) * | 2016-03-10 | 2017-09-14 | Otto Männer Innovation GmbH | Heißkanalsystem und damit verbundene Düsenheizeinrichtungen |

| CN107813466A (zh) * | 2017-12-05 | 2018-03-20 | 东泰精密注塑(天津)有限公司 | 一种胶口分离设备 |

| DE102019106975A1 (de) * | 2019-03-19 | 2020-09-24 | EWIKON Heißkanalsysteme GmbH | Heiß- oder Kaltkanalvorrichtung für ein Spritzgießwerkzeug mit einem wechselbaren Umlenk- und Verteileinsatz |

| CA3136017A1 (en) * | 2020-10-27 | 2022-04-27 | Mold-Masters (2007) Limited | VALVE PIN PLATE INJECTION MOLDING MACHINE |

| US11931937B2 (en) * | 2021-05-07 | 2024-03-19 | The Gillette Company Llc | Method and system for molding an article |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02210668A (ja) * | 1989-02-10 | 1990-08-22 | Nec Corp | 磁気テープ制御装置 |

| JPH038512U (enExample) * | 1989-06-14 | 1991-01-28 | ||

| JP2002011764A (ja) * | 2000-06-28 | 2002-01-15 | Mitsubishi Materials Corp | 成形方法およびこれに用いるバルブゲート式金型装置 |

| JP2002331552A (ja) * | 2001-05-09 | 2002-11-19 | Mitsubishi Materials Corp | バルブゲート式金型装置 |

| JP2004148551A (ja) * | 2002-10-28 | 2004-05-27 | Mitsubishi Materials Corp | バルブゲート式金型装置 |

Family Cites Families (43)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU452137B2 (en) | 1971-09-24 | 1974-08-29 | Bischoff Chemical Corporation | Injection nozzle of adjustable length |

| US3812323A (en) | 1972-11-03 | 1974-05-21 | Ford Motor Co | Electrical heating bands for a feeding system |

| US3843295A (en) | 1973-05-24 | 1974-10-22 | Bischoff Chemical Corp | Injection molding machine with adjustable nozzle length means |

| NL7804984A (nl) | 1978-05-09 | 1979-11-13 | Beek Ter Hengelo Bv | Inwendig verwarmbaar mondstuk met een deelbaar huis en een deelbare kern. |

| JPS59142124A (ja) | 1983-02-02 | 1984-08-15 | Shigeru Tsutsumi | 合成樹脂射出成形機用ホツトチツプブシング |

| CA1206311A (en) * | 1983-09-12 | 1986-06-24 | Jobst U. Gellert | Injection molding system having an insulation sleeve |

| EP0171398B1 (de) | 1984-02-06 | 1987-11-04 | STAUBER, Bernard | Transfer-düse in einem heisskanal-werkzeug |

| JPS61134218A (ja) | 1984-12-05 | 1986-06-21 | Shigeru Tsutsumi | 熱可塑性合成樹脂射出成形システムにおけるホツトランナ−の温度制御表示装置 |

| DE8620956U1 (de) | 1986-08-05 | 1986-11-27 | Jetform Heißkanalnormalien und Zubehör GmbH, 7255 Rutesheim | Vorrichtung zur elektrischen Beheizung von Heißkanaldüsen |

| JPS63202418A (ja) | 1987-02-18 | 1988-08-22 | Fuji Kikai Seizo Kk | ホットランナ式射出成形装置 |

| FR2625133B1 (fr) | 1987-12-24 | 1990-09-21 | Delta Projet | Buse de moule pour injection de matiere plastique |

| CA1265909A (en) | 1988-02-16 | 1990-02-20 | Jobst Ulrich Gellert | Injection molding heated gate insert and method |

| CA1261575A (en) | 1988-04-13 | 1989-09-26 | Jobst U. Gellert | Injection molding valve gating one of two nozzles in tandem |

| CA1266359A (en) * | 1988-04-13 | 1990-03-06 | Harald H. Schmidt | Injection molding system with nozzles in tandem |

| US4892474A (en) | 1989-02-21 | 1990-01-09 | Gellert Jobst U | Profiled plate heaters for injection molding nozzles |

| CA2008171C (en) | 1990-01-19 | 1997-05-20 | Jobst Ulrich Gellert | Method of making a selected size injection molding nozzle |

| DE4005437A1 (de) | 1990-02-21 | 1991-08-29 | Dangelmaier Sfr Formbau | Beheizte duese, sogenannte langduese fuer ein kunststoff-spritzgiesswerkzeug |

| JPH0753394B2 (ja) | 1990-07-16 | 1995-06-07 | 日精エー・エス・ビー機械株式会社 | 多層成形用ホットランナー金型 |

| CA2022124A1 (en) | 1990-07-27 | 1992-01-28 | Jobst Ulrich Gellert | Insulated injection molding nozzle |

| CA2022123C (en) | 1990-07-27 | 1998-02-03 | Jobst Ulrich Gellert | Injection molding insulative and resilient spacer member |

| JPH0753395B2 (ja) | 1990-09-12 | 1995-06-07 | 日本電装株式会社 | ホットランナ式射出成形装置 |

| DE4032509C2 (de) | 1990-10-12 | 1993-10-21 | Gellert Jobst U | Spritzgießdüse für eine Spritzgießeinrichtung |

| CA2030287C (en) | 1990-11-19 | 2000-12-19 | Jobst Ulrich Gellert | Injection molding apparatus having separate heating element in the cavity forming insert |

| CA2030286C (en) | 1990-11-19 | 2000-11-21 | Jobst Ulrich Gellert | Injection molding nozzle having tapered heating element adjacent the bore |

| CA2079390C (en) | 1991-10-16 | 1996-08-27 | Akira Nonomura | Multi-cavity mold, method of fabricating same and molding control method using said mold |

| US5320513A (en) * | 1992-12-10 | 1994-06-14 | Husky Injection Molding Systems Ltd. | Printed circuit board for an injection molding apparatus |

| DE4324027A1 (de) | 1993-07-17 | 1995-01-19 | Goetze Ag | Vorrichtung für Spritzgieß- und Spritzpreßmaschinen |

| DE4404894C1 (de) | 1994-02-16 | 1995-01-05 | Dangelmaier Sfr Formbau | Beheizte Düse zur Zuführung einer Kunststoffschmelze in die Formhöhlung eines Kunststoff-Spritzgießwerkzeuges |

| US5507637A (en) | 1995-03-02 | 1996-04-16 | Husky Injection Molding Systems Ltd. | Hot runner sliding nozzle |

| WO1997002129A1 (de) | 1995-06-30 | 1997-01-23 | Christian Stern | Düse zur spritzgussverarbeitung von kunststoffen |

| US5871786A (en) | 1997-04-04 | 1999-02-16 | Kona Corporation | Tip heated hot runner nozzle |

| CA2233433C (en) | 1998-03-27 | 2007-07-31 | Mold-Masters Limited | Injection molding cylindrical manifold insert and method |

| US6305923B1 (en) | 1998-06-12 | 2001-10-23 | Husky Injection Molding Systems Ltd. | Molding system using film heaters and/or sensors |

| DE19848188A1 (de) | 1998-10-20 | 2000-04-27 | Incoe Int Inc | Düsen für Spritzgießanlagen |

| DE50000786D1 (de) | 1999-02-04 | 2003-01-02 | Stern Christian | Düse zum spritzgiessen von kunststoff |

| CA2273517C (en) | 1999-06-01 | 2008-04-01 | Jobst Ulrich Gellert | Injection molding heater with melt bore therethrough |

| NL1012925C2 (nl) | 1999-08-27 | 2001-02-28 | Franciscus Antonius Jozef Van | Spuitgietinrichting. |

| CA2311829A1 (en) | 2000-06-16 | 2001-12-16 | Jonathon Fischer | Thermally balanced hot runner nozzle |

| DE20215960U1 (de) | 2002-09-13 | 2003-01-16 | Türk & Hillinger GmbH, 78532 Tuttlingen | Elektrische Heizpatrone für zylindrische Körper |

| CA2463402C (en) | 2003-04-07 | 2013-01-15 | Mold-Masters Limited | Hot runner nozzle with melt sealing |

| CA2545068C (en) | 2003-11-11 | 2012-08-14 | Plastic Engineering & Technical Services, Inc. | Valve gate assembly |

| CA2482254A1 (en) | 2004-04-07 | 2005-10-07 | Mold-Masters Limited | Modular injection nozzle having a thermal barrier |

| KR100744596B1 (ko) | 2006-03-27 | 2007-08-01 | 허남욱 | 이중 노즐바디로 길이조절이 가능한 플라스틱스 성형용핫런너 밸브 노즐 |

-

2005

- 2005-04-07 US US11/100,506 patent/US7462030B2/en active Active

- 2005-04-07 JP JP2005110897A patent/JP2005297566A/ja active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02210668A (ja) * | 1989-02-10 | 1990-08-22 | Nec Corp | 磁気テープ制御装置 |

| JPH038512U (enExample) * | 1989-06-14 | 1991-01-28 | ||

| JP2002011764A (ja) * | 2000-06-28 | 2002-01-15 | Mitsubishi Materials Corp | 成形方法およびこれに用いるバルブゲート式金型装置 |

| JP2002331552A (ja) * | 2001-05-09 | 2002-11-19 | Mitsubishi Materials Corp | バルブゲート式金型装置 |

| JP2004148551A (ja) * | 2002-10-28 | 2004-05-27 | Mitsubishi Materials Corp | バルブゲート式金型装置 |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009539640A (ja) * | 2006-06-08 | 2009-11-19 | ギュンター・ハイスカナルテヒニク・ゲゼルシヤフト・ミト・ベシユレンクテル・ハフツング | 射出成形ノズル、特に射出成形工具に設置するためのホットランナーノズル |

| JP2009539641A (ja) * | 2006-06-08 | 2009-11-19 | ギュンター・ハイスカナルテヒニク・ゲゼルシヤフト・ミト・ベシユレンクテル・ハフツング | 射出成形鋳型内に配置するための射出成形ノズル、特にホットチャネルノズル |

| US8007271B2 (en) | 2006-06-08 | 2011-08-30 | Guenther Heisskanal Technik Gmbh | Injection nozzle, in particular hot-runner nozzle, for arrangement in an injection mould |

| JP4791575B2 (ja) * | 2006-06-08 | 2011-10-12 | ギュンター・ハイスカナルテヒニク・ゲゼルシヤフト・ミト・ベシユレンクテル・ハフツング | 射出成形工具に設置するためのホットランナーノズル |

| KR101005275B1 (ko) | 2008-07-08 | 2011-01-04 | 유도실업주식회사 | 사출 성형기용 핫 런너 시스템에 장착되는 히터고정용 튜브 |

| KR20220048308A (ko) * | 2020-10-12 | 2022-04-19 | 주식회사 유도 | 이중 사출용 핫 런너 시스템 |

| KR102399584B1 (ko) * | 2020-10-12 | 2022-05-19 | 주식회사 유도 | 이중 사출용 핫 런너 시스템 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20050226956A1 (en) | 2005-10-13 |

| US7462030B2 (en) | 2008-12-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2005297566A (ja) | 加熱されるノズル本体セグメント及び加熱されないノズル本体セグメントを有するノズル本体を備えたノズル | |

| US7802983B2 (en) | Configurable manifold | |

| EP1386717B1 (en) | Threaded removable heater for a hot runner nozzle | |

| US7559760B2 (en) | Modular injection nozzle having a thermal barrier | |

| CA2258642C (en) | Hot runner heating clamp | |

| US6045742A (en) | Method for applying a differential heating to injection nozzle | |

| USRE41536E1 (en) | Injection molding apparatus having an elongated nozzle incorporating multiple nozzle bodies in tandem | |

| US20080022999A1 (en) | Indirectly heated capillary aerosol generator | |

| KR100536548B1 (ko) | 개선된 핫 러너 밀봉 장치 및 방법 | |

| CN1976793B (zh) | 具有热隔离的熔化物通道的热流道共注射喷嘴 | |

| US7131833B2 (en) | Nozzle with thermally conductive device | |

| JPH0434488B2 (enExample) | ||

| US6712597B1 (en) | Injection-moulding device | |

| US5804231A (en) | Expandable hot runner manifold | |

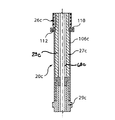

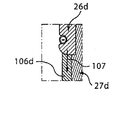

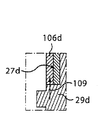

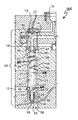

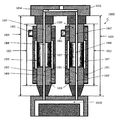

| CA2503665C (en) | Nozzle having a nozzle body with heated and unheated nozzle body segments | |

| KR102054943B1 (ko) | 사출성형기용 노즐 히터 | |

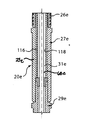

| EP1584442B1 (en) | Nozzle having a nozzle body with heated and unheated nozzle body segments | |

| CN112313060A (zh) | 侧浇口注射模制设备和侧浇口喷嘴组件 | |

| EP1584443A1 (en) | Nozzle having a nozzle body with heated and unheated nozzle body segments | |

| US20050281906A1 (en) | Hot runner nozzle | |

| EP1428646A1 (en) | Nozzle and method for making a nozzle with a removable and replaceable heating device | |

| JP7063160B2 (ja) | 射出成形用ホットランナのマニホールド | |

| HK1100338B (en) | Hot runner coinjection nozzle with thermally separated melt channels |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080407 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080407 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20081003 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110126 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110128 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110715 |