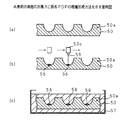

JP2005243499A - フラットディスプレイパネルの電極形成方法 - Google Patents

フラットディスプレイパネルの電極形成方法 Download PDFInfo

- Publication number

- JP2005243499A JP2005243499A JP2004053569A JP2004053569A JP2005243499A JP 2005243499 A JP2005243499 A JP 2005243499A JP 2004053569 A JP2004053569 A JP 2004053569A JP 2004053569 A JP2004053569 A JP 2004053569A JP 2005243499 A JP2005243499 A JP 2005243499A

- Authority

- JP

- Japan

- Prior art keywords

- metal

- substrate

- electrode

- plating catalyst

- partition walls

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J9/00—Apparatus or processes specially adapted for the manufacture, installation, removal, maintenance of electric discharge tubes, discharge lamps, or parts thereof; Recovery of material from discharge tubes or lamps

- H01J9/02—Manufacture of electrodes or electrode systems

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J11/00—Gas-filled discharge tubes with alternating current induction of the discharge, e.g. alternating current plasma display panels [AC-PDP]; Gas-filled discharge tubes without any main electrode inside the vessel; Gas-filled discharge tubes with at least one main electrode outside the vessel

- H01J11/20—Constructional details

- H01J11/22—Electrodes, e.g. special shape, material or configuration

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J11/00—Gas-filled discharge tubes with alternating current induction of the discharge, e.g. alternating current plasma display panels [AC-PDP]; Gas-filled discharge tubes without any main electrode inside the vessel; Gas-filled discharge tubes with at least one main electrode outside the vessel

- H01J11/10—AC-PDPs with at least one main electrode being out of contact with the plasma

- H01J11/12—AC-PDPs with at least one main electrode being out of contact with the plasma with main electrodes provided on both sides of the discharge space

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J11/00—Gas-filled discharge tubes with alternating current induction of the discharge, e.g. alternating current plasma display panels [AC-PDP]; Gas-filled discharge tubes without any main electrode inside the vessel; Gas-filled discharge tubes with at least one main electrode outside the vessel

- H01J11/20—Constructional details

- H01J11/34—Vessels, containers or parts thereof, e.g. substrates

- H01J11/36—Spacers, barriers, ribs, partitions or the like

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J9/00—Apparatus or processes specially adapted for the manufacture, installation, removal, maintenance of electric discharge tubes, discharge lamps, or parts thereof; Recovery of material from discharge tubes or lamps

- H01J9/02—Manufacture of electrodes or electrode systems

- H01J9/022—Manufacture of electrodes or electrode systems of cold cathodes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J9/00—Apparatus or processes specially adapted for the manufacture, installation, removal, maintenance of electric discharge tubes, discharge lamps, or parts thereof; Recovery of material from discharge tubes or lamps

- H01J9/24—Manufacture or joining of vessels, leading-in conductors or bases

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Gas-Filled Discharge Tubes (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004053569A JP2005243499A (ja) | 2004-02-27 | 2004-02-27 | フラットディスプレイパネルの電極形成方法 |

| TW093122277A TWI259499B (en) | 2004-02-27 | 2004-07-26 | Method of forming electrode for flat display panel |

| US10/898,335 US7138335B2 (en) | 2004-02-27 | 2004-07-26 | Method of forming electrode for flat display panel |

| KR1020040059264A KR100654200B1 (ko) | 2004-02-27 | 2004-07-28 | 플랫 디스플레이 패널의 전극 형성 방법 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004053569A JP2005243499A (ja) | 2004-02-27 | 2004-02-27 | フラットディスプレイパネルの電極形成方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005243499A true JP2005243499A (ja) | 2005-09-08 |

| JP2005243499A5 JP2005243499A5 (enExample) | 2007-02-15 |

Family

ID=34879707

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004053569A Withdrawn JP2005243499A (ja) | 2004-02-27 | 2004-02-27 | フラットディスプレイパネルの電極形成方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7138335B2 (enExample) |

| JP (1) | JP2005243499A (enExample) |

| KR (1) | KR100654200B1 (enExample) |

| TW (1) | TWI259499B (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100570750B1 (ko) * | 2004-01-29 | 2006-04-12 | 삼성에스디아이 주식회사 | 플라즈마 디스플레이 패널용 감광성 도전 조성물 |

| TWI265543B (en) * | 2005-11-22 | 2006-11-01 | Marketech Int Corp | The manufacturing method of the shadow mask of an opposed discharge plasma display panel |

| GB2432722A (en) * | 2005-11-25 | 2007-05-30 | Seiko Epson Corp | Electrochemical cell and method of manufacture |

| GB2432723B (en) * | 2005-11-25 | 2010-12-08 | Seiko Epson Corp | Electrochemical cell and method of manufacture |

| GB2432721B (en) * | 2005-11-25 | 2011-06-22 | Seiko Epson Corp | Electrochemical cell structure and method of fabrication |

| KR100901017B1 (ko) * | 2007-10-11 | 2009-06-04 | 성균관대학교산학협력단 | 기판의 금속패턴 형성방법 |

| JP5227570B2 (ja) * | 2007-11-13 | 2013-07-03 | セーレン株式会社 | 透明導電性部材の製造方法 |

| US8179032B2 (en) * | 2008-09-23 | 2012-05-15 | The Board Of Trustees Of The University Of Illinois | Ellipsoidal microcavity plasma devices and powder blasting formation |

| US8865522B2 (en) | 2010-07-15 | 2014-10-21 | Infineon Technologies Austria Ag | Method for manufacturing semiconductor devices having a glass substrate |

| US9029200B2 (en) | 2010-07-15 | 2015-05-12 | Infineon Technologies Austria Ag | Method for manufacturing semiconductor devices having a metallisation layer |

| US8202786B2 (en) * | 2010-07-15 | 2012-06-19 | Infineon Technologies Austria Ag | Method for manufacturing semiconductor devices having a glass substrate |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4349583A (en) * | 1981-07-28 | 1982-09-14 | International Business Machines Corporation | Laser enhanced maskless method for plating and simultaneous plating and etching of patterns |

| JP3022226B2 (ja) * | 1994-12-08 | 2000-03-15 | 大伸化学株式会社 | 無電解めっき法における触媒化方法 |

| US6207369B1 (en) * | 1995-03-10 | 2001-03-27 | Meso Scale Technologies, Llc | Multi-array, multi-specific electrochemiluminescence testing |

| TW353762B (en) * | 1996-10-21 | 1999-03-01 | Dainippon Printing Co Ltd | Transfer sheet, and pattern-forming method |

| US6207268B1 (en) * | 1996-11-12 | 2001-03-27 | Dai Nippon Printing Co., Ltd. | Transfer sheet, and pattern-forming method |

| JP2001043793A (ja) | 1999-08-02 | 2001-02-16 | Fujitsu Ltd | 表示パネルの隔壁形成方法 |

| JP2001236885A (ja) * | 2000-02-22 | 2001-08-31 | Matsushita Electric Ind Co Ltd | プラズマディスプレイパネルおよびその製造方法 |

| JP2002348680A (ja) * | 2001-05-22 | 2002-12-04 | Sharp Corp | 金属膜パターンおよびその製造方法 |

-

2004

- 2004-02-27 JP JP2004053569A patent/JP2005243499A/ja not_active Withdrawn

- 2004-07-26 US US10/898,335 patent/US7138335B2/en not_active Expired - Fee Related

- 2004-07-26 TW TW093122277A patent/TWI259499B/zh not_active IP Right Cessation

- 2004-07-28 KR KR1020040059264A patent/KR100654200B1/ko not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| KR100654200B1 (ko) | 2006-12-06 |

| US20050191783A1 (en) | 2005-09-01 |

| US7138335B2 (en) | 2006-11-21 |

| TW200529279A (en) | 2005-09-01 |

| KR20050087706A (ko) | 2005-08-31 |

| TWI259499B (en) | 2006-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2005243499A (ja) | フラットディスプレイパネルの電極形成方法 | |

| JPH1027542A (ja) | プラズマディスプレイパネル及びその隔壁形成方法 | |

| JP3657220B2 (ja) | プラズマディスプレイパネルおよびその製造方法 | |

| KR19980069904A (ko) | 표시 패널의 격벽 형성방법 | |

| US20050242696A1 (en) | Plasma display panel and method of fabricating the same | |

| KR100392284B1 (ko) | 플라즈마 디스플레이 패널 및 그 제조 방법 | |

| JP3652543B2 (ja) | プラズマディスプレイパネルの電極の構造及び形成方法 | |

| JP2003297584A (ja) | 配線付き基体形成用積層体、配線付き基体およびその形成方法 | |

| KR20070118220A (ko) | 플라즈마 디스플레이 패널 | |

| JP3299888B2 (ja) | プラズマディスプレイパネル及びその製造方法 | |

| JP4225800B2 (ja) | プラズマディスプレイパネルの電極形成方法 | |

| US20090149103A1 (en) | Plasma display panel and method for manufacturing the same | |

| JPH10241576A (ja) | カラープラズマディスプレイパネル | |

| KR100331815B1 (ko) | 플라즈마 디스플레이 패널의 전극 제조방법 | |

| KR100664577B1 (ko) | 플라즈마 디스플레이 패널의 배면기판 제조장치 및배면기판의 제조방법, 배면기판 | |

| JP2005105391A (ja) | 金属酸化物の成膜方法および成膜装置、有機el素子の製造方法および製造装置 | |

| KR100444516B1 (ko) | 플라즈마 디스플레이 패널의 제조방법 | |

| JPH1021837A (ja) | プラズマディスプレイパネル及びその製造方法 | |

| JP2002075178A (ja) | 表示装置およびその製造方法 | |

| KR100364540B1 (ko) | 표시소자의 전극 제조방법 | |

| JPH09283029A (ja) | プラズマディスプレイパネル | |

| KR19990054294A (ko) | 플라즈마 디스플레이 패널의 제조방법 | |

| JP2008262877A (ja) | プラズマディスプレイパネル用背面板の製造方法 | |

| KR20010004318A (ko) | 전기 도금법을 이용한 플라즈마 디스플레이 패널의 전극 및 격벽의 동시 형성 방법 | |

| KR20000007779A (ko) | 플라즈마 표시장치의 전극 형성방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20050720 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20050720 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20050914 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051206 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20051207 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061220 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061220 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20090715 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090717 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20090901 |