JP2004520984A - 物品を射出成形するための方法および装置 - Google Patents

物品を射出成形するための方法および装置 Download PDFInfo

- Publication number

- JP2004520984A JP2004520984A JP2003510234A JP2003510234A JP2004520984A JP 2004520984 A JP2004520984 A JP 2004520984A JP 2003510234 A JP2003510234 A JP 2003510234A JP 2003510234 A JP2003510234 A JP 2003510234A JP 2004520984 A JP2004520984 A JP 2004520984A

- Authority

- JP

- Japan

- Prior art keywords

- nozzle

- valve member

- cavity

- gate

- communication

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000001746 injection moulding Methods 0.000 title claims abstract description 20

- 238000000034 method Methods 0.000 title 1

- 239000000463 material Substances 0.000 claims description 25

- 238000007789 sealing Methods 0.000 claims description 22

- 238000004891 communication Methods 0.000 claims description 21

- 230000009969 flowable effect Effects 0.000 claims description 18

- 238000002347 injection Methods 0.000 claims description 17

- 239000007924 injection Substances 0.000 claims description 17

- 239000000155 melt Substances 0.000 claims description 6

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 5

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 5

- -1 polyethylene terephthalate Polymers 0.000 claims description 4

- 239000012530 fluid Substances 0.000 claims 6

- 239000012768 molten material Substances 0.000 description 18

- 238000001816 cooling Methods 0.000 description 7

- 238000000465 moulding Methods 0.000 description 3

- 238000012546 transfer Methods 0.000 description 3

- 108091092889 HOTTIP Proteins 0.000 description 2

- 239000012809 cooling fluid Substances 0.000 description 2

- 238000002425 crystallisation Methods 0.000 description 2

- 230000008025 crystallization Effects 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

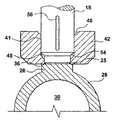

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2701—Details not specific to hot or cold runner channels

- B29C45/2708—Gates

- B29C45/2711—Gate inserts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/278—Nozzle tips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/28—Closure devices therefor

- B29C45/2806—Closure devices therefor consisting of needle valve systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/28—Closure devices therefor

- B29C45/2806—Closure devices therefor consisting of needle valve systems

- B29C2045/2879—Back flow of material into nozzle channel

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/900,083 US20030008034A1 (en) | 2001-07-06 | 2001-07-06 | Method and apparatus for injection molding articles |

| PCT/CA2002/000774 WO2003004243A1 (en) | 2001-07-06 | 2002-05-27 | Method and apparatus for injection molding articles |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004520984A true JP2004520984A (ja) | 2004-07-15 |

| JP2004520984A5 JP2004520984A5 (enExample) | 2006-04-13 |

Family

ID=25411944

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003510234A Ceased JP2004520984A (ja) | 2001-07-06 | 2002-05-27 | 物品を射出成形するための方法および装置 |

Country Status (10)

| Country | Link |

|---|---|

| US (2) | US20030008034A1 (enExample) |

| EP (1) | EP1406754B1 (enExample) |

| JP (1) | JP2004520984A (enExample) |

| CN (2) | CN100398295C (enExample) |

| AT (1) | ATE369964T1 (enExample) |

| CA (1) | CA2449179A1 (enExample) |

| DE (1) | DE60221845T2 (enExample) |

| ES (1) | ES2291468T3 (enExample) |

| TW (1) | TW590870B (enExample) |

| WO (1) | WO2003004243A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013523497A (ja) * | 2010-04-05 | 2013-06-17 | ハスキー インジェクション モールディング システムズ リミテッド | ステム先端部分に対して位置付けられる樹脂保持機構を含む金型工具アセンブリ |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6769901B2 (en) * | 2000-04-12 | 2004-08-03 | Mold-Masters Limited | Injection nozzle system for an injection molding machine |

| US7156651B2 (en) * | 2001-07-06 | 2007-01-02 | Husky Injection Molding Systems Ltd. | Apparatus for injection molding articles |

| CA2358187A1 (en) * | 2001-10-03 | 2003-04-03 | Mold-Masters Limited | Nozzle seal |

| CA2358148A1 (en) * | 2001-10-03 | 2003-04-03 | Mold-Masters Limited | A nozzle |

| US6962492B2 (en) * | 2001-10-05 | 2005-11-08 | Mold-Masters Limited | Gap seal between nozzle components |

| US7128566B2 (en) * | 2002-02-21 | 2006-10-31 | Mold-Masters Limited | Valve pin guiding tip for a nozzle |

| AU2003206525A1 (en) | 2002-02-21 | 2003-09-09 | Mold-Masters Limited | A valve pin guide for a valve-gated nozzle |

| DE10392533B4 (de) * | 2002-04-12 | 2014-07-03 | Mold-Masters (2007) Limited | Spritzgießvorrichtung mit einem Formangussöffnungseinsatz mit Wärmesperre |

| CA2492701A1 (en) * | 2002-07-30 | 2004-02-12 | Mold-Masters Limited | A valve pin guide and alignment system for a hot-runner in an injection molding apparatus |

| CA2450411C (en) * | 2002-11-21 | 2012-01-03 | Mold-Masters Limited | Hot runner nozzle with a tip, a tip surrounding piece and an alignment piece |

| CA2452112A1 (en) * | 2002-12-09 | 2004-06-09 | Mold-Masters Limited | Nozzle tip and seal |

| US7217120B2 (en) * | 2004-06-16 | 2007-05-15 | V-Tek Molding Technologies Inc. | Hot runner nozzle |

| US20070040292A1 (en) * | 2005-08-22 | 2007-02-22 | Fina Technology, Inc. | Polypropylene composition for high gloss retention |

| US7661947B2 (en) * | 2005-11-21 | 2010-02-16 | Epoch Composite Products, Inc. | Method and apparatus for molding roofing products with back gating |

| CN100553924C (zh) * | 2006-01-18 | 2009-10-28 | 鸿富锦精密工业(深圳)有限公司 | 光学元件成型模具 |

| US7458795B2 (en) * | 2006-02-24 | 2008-12-02 | Incoe Corporation | Co-injection nozzle assembly |

| US7589138B2 (en) | 2006-12-05 | 2009-09-15 | Fina Technology, Inc. | Injection molding process |

| US7566216B2 (en) | 2007-04-29 | 2009-07-28 | Husky Injection Molding Systems Ltd. | Mold assembly using inserts |

| US7568906B2 (en) | 2007-04-30 | 2009-08-04 | Husky Injection Molding Systems Ltd. | Mold assembly using inserts |

| US7513772B2 (en) * | 2007-05-09 | 2009-04-07 | Mold-Masters (2007) Limited | Injection molding nozzle with valve pin alignment |

| US7854876B2 (en) * | 2007-05-25 | 2010-12-21 | Ecovision Technologies, Llc | Apparatus and methods for modular preform mold system |

| EP1997603A1 (en) * | 2007-05-31 | 2008-12-03 | Alliance for business solutions A4BS | Modified hot runner systems for injection blow molding |

| US7866974B2 (en) * | 2008-03-18 | 2011-01-11 | Husky Injection Molding Systems Ltd. | Melt distribution apparatus for use in a hot runner |

| CN101590686B (zh) * | 2008-05-26 | 2013-08-14 | 鸿富锦精密工业(深圳)有限公司 | 阀动作的设定方法 |

| US7972132B2 (en) * | 2008-10-10 | 2011-07-05 | Mold-Masters (2007) Ltd | Injection molding valve gated hot runner nozzle |

| US8449287B2 (en) | 2010-09-10 | 2013-05-28 | Mold-Masters (2007) Limited | Valve pin for accommodating side loading |

| EP3092115B1 (en) * | 2014-01-08 | 2018-06-06 | Synventive Molding Solutions, Inc. | Valve pin and nozzle configuration and method of control |

| DE102014210332A1 (de) * | 2014-06-02 | 2015-12-03 | AWETIS Engineering + Manufacturing GmbH | Einspritzdüse zum Einbringen von Spritzgut in eine Spritzgußform |

| DE102014210333A1 (de) * | 2014-06-02 | 2015-12-03 | AWETIS Engineering + Manufacturing GmbH | Spritzgussform für Spritzgut |

| US9248595B2 (en) | 2014-06-24 | 2016-02-02 | Athena Automation Ltd. | Hot runner apparatus for an injection molding machine |

| JP6792397B2 (ja) * | 2016-09-30 | 2020-11-25 | 小林製薬株式会社 | 歯間清掃具の製造方法 |

| CN106994767A (zh) * | 2017-05-05 | 2017-08-01 | 浙江思纳克热流道科技有限公司 | 自带导向定位的阀针结构 |

| IT202100031877A1 (it) * | 2021-12-20 | 2023-06-20 | Inglass S P A Con Socio Unico | “Puntale migliorato per stampaggio a iniezione” |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4108956A (en) * | 1977-01-21 | 1978-08-22 | Owens-Illinois, Inc. | Injection molding method and apparatus |

| CA1132321A (en) * | 1979-07-20 | 1982-09-28 | Mold-Masters Limited | Injection molding filter assembly |

| CA1136815A (en) * | 1980-07-15 | 1982-12-07 | Jobst U. Gellert | Injection molding nozzle seal |

| CA1261579A (en) * | 1987-03-19 | 1989-09-26 | Mold-Masters Limited | Replaceable rocker arm assembly for injection molding system |

| US5254305A (en) | 1987-12-10 | 1993-10-19 | Otto Hofstetter Ag | Injection nozzle and method for charging an injection nozzle |

| JP3222894B2 (ja) * | 1991-04-10 | 2001-10-29 | 田中貴金属工業株式会社 | 白金族金属回収方法 |

| EP0638407B1 (de) | 1993-08-13 | 1997-10-01 | AWM Werkzeugbau AG | Spritzdüse |

| CA2175634C (en) * | 1996-05-02 | 2007-08-21 | Klaus Bauer | Injection molding valve member with head and neck portions |

| EP0836925A1 (en) * | 1996-10-09 | 1998-04-22 | EUROTOOL Beheer B.V. | Valve-gated injection moulding device |

| US6056536A (en) * | 1997-03-20 | 2000-05-02 | Husky Injection Molding Systems Ltd. | Valve gating apparatus for injection molding |

| US6135757A (en) * | 1998-10-16 | 2000-10-24 | Husky Injection Systems Ltd. | Valve gated injection molding system |

| US6318990B1 (en) * | 1998-10-16 | 2001-11-20 | Mold-Masters Limited | Injection molding nozzle apparatus |

| US6168416B1 (en) | 1998-12-22 | 2001-01-02 | Husky Injection Molding Systems Ltd. | Cooling device for molded articles |

| US6220850B1 (en) * | 1999-02-16 | 2001-04-24 | Husky Injection Molding Systems Ltd. | Mold gate insert |

| US6214275B1 (en) * | 1999-06-04 | 2001-04-10 | Husky Injection Molding Systems Ltd. | Injection nozzle and method for injection molding |

| US6220891B1 (en) * | 1999-06-24 | 2001-04-24 | Zetec, Inc. | Probe connector |

-

2001

- 2001-07-06 US US09/900,083 patent/US20030008034A1/en not_active Abandoned

-

2002

- 2002-05-27 CN CNB2005100737502A patent/CN100398295C/zh not_active Expired - Fee Related

- 2002-05-27 AT AT02729720T patent/ATE369964T1/de not_active IP Right Cessation

- 2002-05-27 CA CA002449179A patent/CA2449179A1/en not_active Abandoned

- 2002-05-27 WO PCT/CA2002/000774 patent/WO2003004243A1/en not_active Ceased

- 2002-05-27 EP EP02729720A patent/EP1406754B1/en not_active Expired - Lifetime

- 2002-05-27 DE DE60221845T patent/DE60221845T2/de not_active Expired - Fee Related

- 2002-05-27 JP JP2003510234A patent/JP2004520984A/ja not_active Ceased

- 2002-05-27 ES ES02729720T patent/ES2291468T3/es not_active Expired - Lifetime

- 2002-05-27 CN CNA028136454A patent/CN1537045A/zh active Pending

- 2002-05-31 TW TW091111704A patent/TW590870B/zh not_active IP Right Cessation

-

2003

- 2003-09-25 US US10/670,870 patent/US7037103B2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013523497A (ja) * | 2010-04-05 | 2013-06-17 | ハスキー インジェクション モールディング システムズ リミテッド | ステム先端部分に対して位置付けられる樹脂保持機構を含む金型工具アセンブリ |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1537045A (zh) | 2004-10-13 |

| DE60221845D1 (de) | 2007-09-27 |

| EP1406754B1 (en) | 2007-08-15 |

| CN100398295C (zh) | 2008-07-02 |

| US20040058031A1 (en) | 2004-03-25 |

| TW590870B (en) | 2004-06-11 |

| US20030008034A1 (en) | 2003-01-09 |

| ES2291468T3 (es) | 2008-03-01 |

| ATE369964T1 (de) | 2007-09-15 |

| US7037103B2 (en) | 2006-05-02 |

| EP1406754A1 (en) | 2004-04-14 |

| DE60221845T2 (de) | 2008-05-08 |

| CA2449179A1 (en) | 2003-01-16 |

| WO2003004243A1 (en) | 2003-01-16 |

| CN1680085A (zh) | 2005-10-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004520984A (ja) | 物品を射出成形するための方法および装置 | |

| KR100296953B1 (ko) | 플라스틱제품의성형방법및장치 | |

| US5871786A (en) | Tip heated hot runner nozzle | |

| US7156651B2 (en) | Apparatus for injection molding articles | |

| US4666396A (en) | Thermally insulated heated sprue bushing in plastic molding apparatus | |

| JPH10296799A (ja) | 円筒形弁部材を配置する一体的ゲートインサートを有する射出成型装置 | |

| CA2453170A1 (en) | Lateral gating injection molding apparatus | |

| KR100445948B1 (ko) | 인젝션 노즐 및 인젝션 성형 방법 | |

| JPH07148786A (ja) | 射出成形用金型装置 | |

| JPH0773867B2 (ja) | 射出成型装置 | |

| US5037598A (en) | Reciprocating heated nozzle | |

| US20070134367A1 (en) | Injection device | |

| US20060159798A1 (en) | Method for producing mould parts by injection and plugged needle nozzle for an injection mould | |

| CA1153523A (en) | Injection molding fixed pin gate | |

| KR100739013B1 (ko) | 금형조립체 | |

| HK1078528A (en) | Method and apparatus for injection molding articles | |

| CA3237443A1 (en) | Injection mold component | |

| JPH04275119A (ja) | 射出成形機 | |

| CN114555324A (zh) | 注塑成型系统 | |

| JP2000202615A (ja) | 金属射出成形方法および金属射出成形装置 | |

| CN113825613A (zh) | 射出成型装置 | |

| JP2003191290A (ja) | 射出成形用金型装置 | |

| JPH07214605A (ja) | 樹脂成形機 | |

| JP2003071880A (ja) | バルブゲート式金型装置 | |

| JP2001047468A (ja) | 射出成形用スプールブッシュおよび射出成形金型 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060227 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061017 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20061025 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20070125 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20070201 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070420 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090202 |

|

| A045 | Written measure of dismissal of application [lapsed due to lack of payment] |

Free format text: JAPANESE INTERMEDIATE CODE: A045 Effective date: 20090622 |