EP4234840A2 - Procédé de connexion sécurisée auto-activable d'une console d'escalade avec un dispositif d'ancrage, système comprenant une console d'escalade et une console d'escalade - Google Patents

Procédé de connexion sécurisée auto-activable d'une console d'escalade avec un dispositif d'ancrage, système comprenant une console d'escalade et une console d'escalade Download PDFInfo

- Publication number

- EP4234840A2 EP4234840A2 EP23186146.9A EP23186146A EP4234840A2 EP 4234840 A2 EP4234840 A2 EP 4234840A2 EP 23186146 A EP23186146 A EP 23186146A EP 4234840 A2 EP4234840 A2 EP 4234840A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- anchoring device

- hook

- climbing bracket

- climbing

- bracket

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000009194 climbing Effects 0.000 title claims abstract description 228

- 238000004873 anchoring Methods 0.000 title claims abstract description 147

- 238000000034 method Methods 0.000 title claims description 18

- 238000003780 insertion Methods 0.000 claims abstract description 30

- 230000037431 insertion Effects 0.000 claims abstract description 30

- 238000009415 formwork Methods 0.000 claims description 47

- 238000010276 construction Methods 0.000 claims description 22

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 230000005484 gravity Effects 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- 230000001154 acute effect Effects 0.000 claims description 5

- 230000004913 activation Effects 0.000 claims description 4

- 230000014759 maintenance of location Effects 0.000 claims description 4

- 230000001960 triggered effect Effects 0.000 claims description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 2

- 238000003466 welding Methods 0.000 claims description 2

- 238000002788 crimping Methods 0.000 claims 1

- 238000009416 shuttering Methods 0.000 description 42

- 238000006073 displacement reaction Methods 0.000 description 5

- 238000005266 casting Methods 0.000 description 3

- 230000009471 action Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 230000002730 additional effect Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000005422 blasting Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 235000000396 iron Nutrition 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 210000003813 thumb Anatomy 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 230000003313 weakening effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G5/00—Component parts or accessories for scaffolds

- E04G5/06—Consoles; Brackets

- E04G5/062—Consoles; Brackets specially adapted for attachment to building walls

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G11/00—Forms, shutterings, or falsework for making walls, floors, ceilings, or roofs

- E04G11/36—Forms, shutterings, or falsework for making walls, floors, ceilings, or roofs for floors, ceilings, or roofs of plane or curved surfaces end formpanels for floor shutterings

- E04G11/365—Stop-end shutterings

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G15/00—Forms or shutterings for making openings, cavities, slits, or channels

- E04G15/04—Cores for anchor holes or the like around anchors embedded in the concrete

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G17/00—Connecting or other auxiliary members for forms, falsework structures, or shutterings

- E04G17/16—Members, e.g. consoles, for attachment to the wall to support girders, beams, or the like carrying forms or moulds for floors, lintels, or transoms

Definitions

- the invention relates to a method for automatically activatable, secure connection of a climbing bracket to an anchoring device, a system for fastening a climbing bracket to an anchoring device embedded in a substructure, a climbing bracket, an anchoring device, and a formwork panel girder.

- the subject of the invention is also a method for automatically activatable, secure connection of a climbing bracket to an anchoring device according to the preamble of patent claims 1, 6, 8.

- the subject of the invention is also a climbing bracket according to the preamble of patent claims 3, 7, 9.

- the subject of the invention is further an anchoring device according to the preamble of patent claim 12.

- Climbing brackets of the type mentioned are used in order to be able to attach slab edge formwork with little effort and to be able to carry wall formwork, in particular also large-area wall formwork panels, and/or at the same time to be able to create scaffolding along the crowns of walls, in particular partial buildings.

- the climbing brackets have the shape of a right-angled triangle, one leg of which forms the upper and load-bearing traverse, the second leg comes into contact with the wall or partial building and the hypotenuse or base of the triangle is a strut are trained.

- a hook is formed on the traverse in the region of the connection of the two legs and as an extension of the traverse, the end of which engages in an anchoring device forming a recess in the wall.

- Such anchoring devices are fastened to the formwork before the substructure (wall) is poured, in that a mounting pin is fastened to the formwork with a nail and the opening in the anchoring device is then pushed onto the mounting pin.

- the mounting pin which lies in the surface of the wall, can be removed and thus the opening of the anchoring device can be exposed.

- the anchoring device extends into the wall behind the opening and spaced a further distance downwardly from the opening so that the hook on the climbing bracket after insertion passes down through the opening and onto the lower edge of the box and on a there existing wall section can be hung.

- a climbing bracket anchoring device system constructed in this way can probably accommodate the required load capacity for the climbing bracket. However, the climbing bracket is only held by gravity and if a crane load accidentally attaches to the climbing bracket from below and lifts it, the climbing bracket is not secured and can detach from the wall.

- a rebar is inserted in the box below the opening and the hook on the climbing bracket is cranked to such an extent that the cranked section grips under the rebar, but only if the hook has previously been manually withdrawn with a wedge and the climbing bracket has been drawn up against the wall and so lifting the Climbing bracket is made more difficult, but is not sufficiently secured.

- the hook can be moved in the traverse and after the hook has been hung in the anchoring device, the climbing bracket can again be additionally secured by means of a wedge which penetrates the traverse and pulls back the hook.

- Such a climbing bracket is held relatively securely if it has been properly fastened, but the construction worker who is fastening the climbing bracket has to move over it and, unsecured, pass the wedge through the traverse and the hook outside the wall and also below its crown and strike.

- Another known climbing bracket has a T-shaped hook firmly connected to it. In order to introduce this climbing bracket into the anchoring device, the climbing bracket must be brought into a horizontal position and inserted through the horizontally arranged opening of the anchoring device and then pivoted by 90°. Such a climbing bracket can no longer be detached from the wall by mistake or external forces, but there is no way of bringing the climbing bracket close to the surface of the wall at different distances from it.

- a climbing bracket and a formwork part for such a climbing bracket which climbing bracket comprises a frame and in this a movable hook, which can be hung in the formwork part forming a wall recess and can be secured within the formwork part against detachment from the formwork part, with the formwork part and each hook must include at least one passive safety element.

- a security part can be a safety flap, which in the Forming part is pivoted and after the insertion of the hook and lowering the same comes to rest between the upper surface of the formwork part and the upper edge of the hook and so the lifting of the hook should be prevented.

- a lever that is guided in a slot is articulated on the hook.

- this lever When the hook is inserted, this lever inclines so far that the hook can be inserted into the opening of the formwork part if the opening is very large, in particular in cross-section much larger, in particular higher.

- the lever When lowering the hook in the shuttering part, the lever should tilt into a vertical position due to a frictional force and, as in the first exemplary embodiment, prevent the hook from being lifted. Since the pivoting of the lever can only be triggered by frictional contact and no clear end position is guaranteed, the securing of the console is also not guaranteed, in particular there is no visual control of the position of the lever.

- a wedge must additionally and imperatively be driven through the upper traverse of the climbing bracket and the carrier of the hook, which is slidably mounted in the traverse, in order to prevent horizontal displacement and thus the risk of the safety lever tipping over.

- the construction worker has to bend over the wall as before and drive the wedge in below the crown of the partial structures on the climbing brackets.

- the safety lever later when the climbing bracket is to be detached from the wall, is released from the safety position and can thus be pulled out of the formwork part.

- One object of the present invention is to create a method for automatically activatable, secure connection of a climbing bracket to an anchoring device, in which the climbing bracket automatically secures itself in the anchoring device after the hook has been hooked into the anchoring device.

- Another object of the present invention is to create a system that allows the construction worker, without explanations or learning effort, to introduce the climbing bracket into the anchoring device as before and without further actions, i.e. without introducing safety elements such as a wedge, so that the climbing bracket after hanging definitely secured to the wall.

- a further object of the invention is to create a climbing bracket that is forcibly drawn onto the wall or into the anchoring device during the hanging process without any manipulation by the construction worker, at the latest when the construction worker lets go of the climbing bracket, so that a play-free hold of the climbing bracket is guaranteed immediately and without the use of a wedge.

- Another object of the invention is to provide a climbing bracket, which inevitably and automatically the inaccuracies when setting the

- Anchoring device arise, picks up or the climbing bracket is pressed snugly against the wall and held securely there, regardless of the position of the anchoring device.

- Another object of the invention is to provide a climbing bracket in which an automatic

- Securing element after the end of the lowering of the hook on the climbing bracket prevents the hook from being extended again without manual intervention being able to actively release it.

- a further object of the invention is to provide an anchoring device for installation in a wall for anchoring a climbing bracket, in which the hook of the climbing bracket is secured against being pulled out both above and below the opening.

- a further object of the invention is the creation of an anchoring device with such high strength that it can be anchored in the wall without additional reinforcing irons or the like.

- the general object of the invention is consequently the creation of a climbing bracket which secures itself or inevitably and whose securing means do not have to be activated in a separate operation.

- a further object of the invention is to create a shuttering plate carrier which is arranged on the upper leg of the climbing bracket so that it can be easily moved and fixed and with which the locking bracket for the climbing bracket can be locked during the pouring of the ceiling of the anchoring device is ensured by the fact that it cannot be loosened as long as the formwork panel carrier is pressed against the formwork, and with which the construction worker standing on the newly poured ceiling can unlock the climbing bracket and lead it out of the anchoring device after concreting is complete and the formwork panel has been removed .

- the essentially two-armed securing element on the hook can be pivoted upwards about an axis to such an extent that the first leg reaches a cross-sectional widening located above the insertion opening for the hook.

- the second leg of the two-armed safety element locks on a locking bolt in such a way that the hook together with the climbing bracket can no longer be released from the anchoring device.

- the pulling out of the climbing bracket from the anchoring device is already prevented when the hook is only partially inserted, because this When the vertical extent of the hook and the safety lever is greater than the height of the opening in the anchoring device, which is not the case with any known climbing bracket with safety elements.

- the securing element could also be articulated on the hook such that it could swing out laterally and, when inserted into the anchoring device, extend into a space located on the side of the insertion channel.

- the release of the climbing bracket after completion of its assigned tasks, namely the support of formwork panels for the further concreting of the partial structures already constructed, can only take place if the safety bolt on the traverse or the upper, horizontally running leg, which is accessible from the outside, is against pressed by the force of a spring and thereby the locking of the two-armed safety element is released in its raised or laterally extended position.

- the lock can only be released if the climbing bracket is no longer loaded by formwork and is initially lifted vertically. In other words, even if the safety bolt is actuated intentionally or unintentionally, the climbing bracket is still held securely in the anchoring device.

- the climbing bracket succeeds without the construction worker having to do anything, that it inevitably comes into close contact with the wall of the substructure, i.e. the climbing bracket is pulled horizontally towards the wall as soon as the climbing bracket is no longer from the Construction worker is kept raised. Pulling towards the wall is inevitable and independent of how far the anchoring device is placed from the surface of the wall in which it is concreted. inaccuracies when setting the anchoring device are thereby eliminated.

- the anchoring device which is advantageously made of steel, has a small width in relation to its height, the internal dimension of which corresponds substantially to the width of the hook and of the securing element placed next to it.

- a pull-out strength that is greater than in the prior art is achieved by embossed outwardly protruding ribs or humps.

- the anchoring device can be produced inexpensively and with high quality in a progressive press from the coil in a few stamping and deep-drawing strokes from two halves connected to one another.

- the hook on the climbing bracket is preferably composed of two parallel elements, between which the securing element is pivotably inserted. Alternatively, the securing element can also lie to the side of a simple hook.

- the anchoring device Due to the small mass and the small width of the anchoring device, there is only a negligible weakening of the partial structures and on the side of the opening of the anchoring device it is only slightly covered by the concrete mass of the wall, so that blasting off due to too thin a cover or high load can be avoided .

- the anchoring device has a relatively long channel-like insertion area, in which the guide support for the hook can lie down after the hook has been inserted and within which the securing element prevents the climbing bracket from being lifted by the securing element.

- the second leg of the securing element is prevented from pivoting upwards or the securing lever pivoted upwards, ie the first leg, cannot swing back down and allow extraction from the can.

- a climbing bracket 1 is shown schematically and in part on the left-hand side.

- the overhead leg 3 which serves as a guide and support element, visible.

- the vertical leg 5 for supporting the climbing bracket 1 on a partial structure 21 is partially shown.

- a housing 7 is arranged on the upper leg 3, in which a guide support 9 for a hook 11 is slidably mounted is.

- the guide support 9 can also be integrated into the upper leg 3 if it has a suitably large cross section.

- the guide support 9 with the hook 11 or hook-shaped end is slidably mounted on the climbing bracket 1 on guideways inclined to the horizontal at an angle of inclination of >45° to the horizontal.

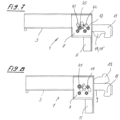

- the guideways are formed by sloping slots 13, which are formed in the guide support 9 and at least one other, preferably two more slots 41 in the Figures 7,8 are visible and embedded in the housing 7.

- the slots 13 are crossed by two bolts 15 fixedly mounted in the housing 7 and form a first longitudinal guideway for the guide support 9.

- the three or preferably four parallel slots 13; 41 consequently form the parallel guide for the guide support 9 and the hook 11 ( 6 ).

- a two-armed securing element 19 with a first arm 19' and a second arm 19" is pivotably mounted on the guide support 9 on a shaft 48.

- the two-armed securing element 19 lies with its first arm 19' essentially within the outline of the hook 11, i.e. the arm 19' does not protrude beyond the outer contour of the hook 11 at its upper edge or at its lower edge.

- the height h of the hook 11 in the area of its front end also determines the height or height extent of fuse element 19.

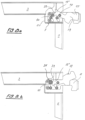

- the second arm 19" of the securing element 19 protrudes beyond the upper edge of the guide support 9 in the rest and starting position (cf. 2 + 8a).

- the second arm 19" lies entirely within the outline of the climbing bracket 1.

- FIG. 1 Also shown in vertical section is a partial structure 21, for example a wall made of concrete, in which an anchoring device 23 is concreted.

- the anchoring device 23 points to the left in Figures 1-5 an opening 25, the height H of which is slightly greater than the height h of the hook 11 or guide support 9.

- the width B of the opening 25 is slightly greater than the width of the hook 11, which is preferably constructed of two spaced plates and between which the fuse element 19 is located. These dimensions make it possible to move the hook 11 or guide support 9 and the securing element 19 lying between them horizontally in the direction X ( 1 ) to be pushed into the anchoring device 23.

- the hook 11 can also be constructed from a single sheet metal part or from two parallel sheet metal parts connected at the hook-shaped end 11 ⁇ .

- the figure 2 shows the climbing bracket 1 after the hook 11 has been inserted horizontally into the anchoring device 23 by an operator, for example the construction worker, carried on the climbing bracket or on a formwork holder slidably arranged on the carrier 3 . It can be seen that the upper edge of the guide support 9 and hook 11 lie behind the opening 25 with only a little play on the upper wall 27 and the lower one End 11 'of the hook 11 on the lower wall 29 passed now in the expanded interior or hollow body 65 of the anchoring device 23 is located.

- the positions of the elements shown are present as long as the operator is still carrying the climbing bracket 1, ie as long as the mass of the climbing bracket 1 does not move it downwards.

- the climbing bracket 1 would consequently be able to be carried out of the anchoring device 11 again in this position, carried by the construction worker.

- FIG 2 It can be seen that there is a distance A of, for example, 8 mm between the front edge of the vertical leg 5 of the climbing bracket 1 and the surface 21' of the wall 21 with the opening 25 on the anchoring device 23, after the front end of the hook 11 is close to the rear wall the anchoring device 23 of the hollow body 65 is located.

- the securing element 19 can also be slidably fastened in a linear guide on the guide support 9 and, instead of a rotary movement, perform a sliding movement upwards.

- the securing element 19 could be pivoted about a horizontal axis on the guide support 9 and could be pivoted out to the side when the hook 11 is lowered and consequently prevent the hook from being pulled out.

- the securing element 19 is pushed upwards by the right arm 19' of the securing element 19 through contact with the bottom section 29 and rotates counterclockwise about the axis of the shaft 48 until the guide beam 9 with its lower edge 9' in the area behind the hook 11 rests on the bottom section 29.

- the hook 11 As the hook 11 is further lowered, it engages in the anchoring device 23 from behind an approximately vertical section 33 at the end of the insertion channel 29 in the anchoring device 23.

- the safety element 19 is securely fixed (cf. Figures 8a, 8b ).

- Mounting the guide support 9 in the guideways formed by the slots 13, 41, which are inclined relative to the vertical, is particularly advantageous because the hook 11 with the guide support 9 is pulled to the left when the climbing bracket 1 is lowered in the housing 7 and consequently, on the one hand, the vertical leg 5 of the climbing bracket 1 is attracted to the surface of the substructure 21 and on the other hand the hook 11 is displaced in the anchoring device 23 to the left, so that the hook 11 in the anchoring device 23 comes into close contact. The end of the hook 11 is also pulled to the left and there comes into close contact with a vertical section on the anchoring device 23.

- the climbing bracket 1 is consequently automatically and forcibly held in the anchoring device 23 on the substructure 21 automatically and forcibly without any action on the part of the construction worker, simply by being pushed into the anchoring device 23 and then lowered after being released by gravity and can no longer be held in place by external forces, which act on the climbing bracket 1 from below, from below or from above or from the side, can be solved.

- the climbing bracket 1 can only be released again by manual intervention on the safety bolt 45, as will be described later.

- the Figures 4 and 5 correspond in principle to the figure 3 . They differ in that the anchoring device 23 or the edge of its opening 25 does not lie exactly in the surface of the partial structure 21, but is set back by a few millimeters for whatever reason. The hanging of the climbing bracket 1 is still in the same way and their securing in the hooked position corresponds to that in figure 3 .

- the difference visible from the outside is that the relative displacement in the horizontal direction between the climbing bracket 1 and the anchoring device 23 is smaller. This can be seen from the fact that the bolts 15 have slid less far up in the slot 13 or the climbing bracket 1 has shifted less far down

- Another special feature, in particular another advantage of the arrangement according to the invention, is that the opening 25 on the anchoring device 23 is completely covered by the vertical leg 5 of the climbing bracket 1 and therefore no concrete or concrete water can get through the opening 25 into the interior of the anchoring device 23 during concreting get there and damage the fuse element 19 or make it unusable.

- the sliding movement of the hook 11 with the guide support 9 in the direction of the partial structure 21 could also take place horizontally, as is the case in the prior art if the slots 13, 41, 43 were arranged horizontally.

- the great disadvantage would then have to be accepted that the climbing bracket 1 would have to be pulled up to the partial structures 21 in a conventional manner, for example with a wedge. This means that the operator would have to perform an additional action in a bent and accident-prone body position, which can also be forgotten.

- the climbing bracket 1 would still be held securely on the substructure 21 because the Securing element 19 immediately after insertion inevitably when the construction worker lets go and thus begins lowering (even without pulling) the hook 11 is immovably held in the anchoring device 23 (no Fig.).

- the climbing bracket 1 is partially shown in perspective at its hook-side end. It can be seen from this figure that the horizontal leg 3 is surrounded at least laterally by the housing 7 on the hook-side end.

- the housing 7 is preferably widened at its upper edge by laterally outwardly projecting tabs 47 and also preferably also extend over the hook-side edge of the horizontal leg 3 and the vertical leg 5 in the form of a second tab 49.

- the housing 7 is preferably also closed at the rear by a wall 51 .

- the securing element 19 is fixed to the disc 35 on the securing bolt 45 by an indentation 39 on the securing element 19 ( Figure 8b ).

- the construction worker must therefore release the connection between the disc 35 on the safety bolt 45 and the safety element 19 so that the safety element 19 can pivot clockwise and thereby move back between the two plates of the hook 11.

- the climbing bracket 1 can consequently be raised and then pulled out of the anchoring device 23 .

- the release of the securing element 19 takes place in that the washer 35 is axially displaced by the securing bolt 45 so that the lower lug 53 on the securing element 19 (see 2 ) is no longer held back by the disc 35 and can slide past the shaft of the safety bolt 45.

- the securing bolt 45 or the washer 35 can only be displaced axially against the force of a spring (the spring is not shown).

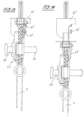

- the climbing bracket 1 serves as a temporary support for a scaffolding board and as a device for attaching a formwork panel support 55 for building the wall above the partial buildings 21.

- the in the Figures 9-21 Formwork panels, not shown, are carried by the formwork panel carrier 55, which is displaceable on the horizontal leg 3 relative to the climbing bracket 1.

- the formwork panel carrier 55 comprises a U-shaped guide shoe 57 which is pushed horizontally from the side onto the horizontal leg 3 of the climbing bracket 1 and is fixed laterally and below by suitable means.

- the guide shoe 57 ( 11 , 12 ) comprises a side wall 59, an upper guide wall 61 and a lower guide wall 63 serving as a sliding shoe, which are U-shaped relative to one another and are connected to one another.

- a safety and release plate 65 can be attached to the side wall 59 forming the base of the U. Their function and shape will be described later.

- a pivotable locking plate 69 is held in a downwardly projecting tab or in an opening 73 attached thereto. Furthermore, a first passage 75 is embedded in the upper guide wall 61 and lies above a second passage 77 formed in the lower guide wall 63 . With a slider 79, whose cross-sectional area is slightly smaller than the cross-section of the two passages 75,77, the guide shoe 57 can be closed to form a rectangular tube when this is pushed onto the upper leg 3 of the climbing bracket 1. The locking plate 69 can then be pushed through the opening 73 and a recess 81 by a slide 79 . The locking plate 69 is captively connected to the guide shoe 57 by a locking bar 83 formed at its end.

- the narrow ends are the upper ones Guide wall 61 and the lower guide wall 63 slightly bent out of their plane.

- the locking plate 69 which interacts with the slide 79, prevents a force F, which acts from the liquid concrete behind the formwork panel on the vertical arm 85 of the shuttering panel carrier 55, from being absorbed. This ensures that the shuttering plate carrier 55 can be displaced with little friction on the upper leg 3 of the climbing bracket before and after concreting as soon as the conical locking plate 69 is out of the locking position ( 15 ) to the unlocked position ( 16 and 17 ) has been withdrawn.

- the locking plate 69 or its wedge-shaped cross-sectional shape cf.

- the formwork panel carrier 55 can be fixed to the climbing bracket 1 in its working position, ie pushed up to a formwork panel.

- the wedge-shaped locking plate 69 By pulling out the wedge-shaped locking plate 69, the clamping effect on the slide 79 is also canceled.

- the slider 79 is pushed into the upper and lower bushings 75, 77, the formwork panel carrier 55 is held securely on the climbing bracket 1, but it can be moved.

- the backup and release plate 65 which is formed on the side wall 59 on the guide shoe 57, has two tasks. In the working position, when the formwork panel carrier 55 is pushed against the wall of the substructure 21 and is only spaced from it by a formwork panel (not shown), the securing and release panel 65 covers the bolt 45 just far enough so that it cannot be actuated unintentionally or , can be actuated and triggers the latching within the anchoring device 23 .

- the shuttering plate supports 55 arranged next to one another on the climbing brackets 1 are pushed away from the wall by knocking out the locking plate 69 on the climbing bracket 1 .

- the formwork panels are still secured by being supported on the upper leg 3 of the climbing bracket 1 so that they cannot slide down.

- the operator ie the construction worker, standing on the newly concreted ceiling, can move the formwork plate carrier 55 on the vertical arm 85 towards himself, ie in the direction of the substructures 21 .

- the offset safety and release plate 65 slides over the safety bolt 45 and presses it into the housing 7 .

- the disk 35 is disengaged from the securing element 19, 19' with the securing bolt 45 and the locking of the securing element 19, which was previously held in the raised position, is released.

- the securing element 19 now turns clockwise and disappears between the two plates forming the hook 11 .

- the climbing bracket 1 can now be raised and only then pushed or pivoted outwards, ie away from the partial structure, without the construction worker having to bend over the edge of the partial structure 21 (cf. Figures 18 to 20 ).

- backup and release plate 65 In a further embodiment of the backup and release plate 65 according to Figures 22 and 23 is the upper tab 47 at the edge or edges folded by about 90 ° and is now parallel to the wall of the housing 7. Next is the backup and release plate 65 at the front end not only with a run-up area 66 over the entire height of Safety and release plate 65 provided, but an overhead section 68 runs parallel to the side wall 59.

- both elements namely the safety and release plate 65 and their front edge regions 66 and 68, are out of contact with other elements of the device.

- the shuttering plate support 55 is in accordance with figure 23 pushed to the right and the safety and release plate 65 covers the safety bolt 45 with its run-on area 66 and thereby prevents an intentional or unintentional loosening of the locking mechanism with the hook 11.

- the section 68 is now under the area of the first flap 47 folded down and stands with this preferably in contact. So that the section 68 can easily slide under the folded flap 47, its end is bent slightly inwards.

- this further configuration of the shuttering panel support 55 is that during casting and already when the vertical arm 85 of the shuttering panel support 55 is braced, the latter, reinforced by the lever, transmits high forces to the guide shoe 57 .

- its vertical arm 85 is pivotally supported with respect to the vertical by two spaced spindles.

- the lower spindle 89 and the upper spindle 87 are connected to one another by a spindle carrier 91 .

- threaded bushings 93 and 95 are formed, in which the threads of the spindles 87 and 89 mesh.

- the output-side end of the lower spindle 89 is freely rotatably mounted in a spindle bearing 97 and axially secured against displacement of the lower spindle.

- the bore in the spindle bearing has play relative to the diameter of the spindle in the region of the bore, which offers the possibility that the axis of the lower spindle is pivotally connected to the vertical arm 85 in a certain angular range.

- the upper spindle 87 is also carried in a bearing block 99 and secured against axial displacement. However, the end of the spindle 87 is not guided in a bore, but in a U-shaped recess in the bearing block 99. This design makes it possible, after loosening a locking screw arranged at the end of the lower spindle 89, to move the two spindles 87 and 89 from the vertical arm 85 to release.

- a second embodiment of the method relates to a method according to the first embodiment of the method, wherein when the climbing bracket 1 on the hook 11 is lowered, a securing element 19 arranged on the hook 11 is pivoted out.

- a third embodiment of the method relates to a method according to the first embodiment of the method, wherein when the climbing bracket 1 is lowered, the climbing bracket 1 is automatically drawn to the anchoring device 23 .

- a first embodiment of the system relates to a system for attaching a climbing bracket 1 to an in one Anchoring device 23 embedded in substructures 21 with a safety element 19 that can be triggered when the climbing bracket 1 and anchoring device 23 are brought together for positive locking, the climbing bracket 1 having an upper leg 3 that is intended to lie horizontally and a vertical leg 5 that is vertical and parallel to the surface of the substructure 21, wherein a hook 11 is mounted on the upper leg 3 on a guide support 9 that can be displaced along the upper leg 3, the anchoring device 23 having an opening 25 intended to lie essentially in the surface of the substructure 21 , which is followed by an insertion channel 26, at the end of which facing away from the opening 25 the cross section of the anchoring device 23 is larger than at the opening 25, the securing element 19 being designed for positive locking on the guide support 9 for the hook 11.

- a second embodiment of the system relates to a system according to the first embodiment of the system, wherein the securing element 19 is articulated on the guide support 9 in such a way that after the hook 11 has been inserted through the insertion channel 26 and the climbing bracket 1 has been lowered, the securing element 19 swings out and extends beyond the cross section of the hook 11 also.

- a third embodiment of the system relates to a system according to the first embodiment of the system, wherein the safety element 19 is designed to be latched automatically to a safety bolt 45 on the climbing bracket 1 after the climbing bracket 1 is no longer held and lowered by the construction worker.

- a fourth embodiment of the system relates to a system according to the first embodiment of the system, wherein the guide support 9 with the hook 11 is slidably mounted in at least one guide 15, 41 at an acute angle on the upper leg 3, such that during the lowering of the climbing bracket 1 the distance between the hook 11 and the vertical leg 5 is reduced and the climbing bracket 1 is thereby attracted by gravity to the anchoring device 23 in the substructure and after the climbing bracket 1 has been pulled up to the anchoring device 23, its opening 25 is completely closed by the housing 7 of the climbing bracket 1 is.

- a fifth embodiment of the system relates to a system according to the first embodiment of the system, with a shuttering panel support 55 being mounted in a displaceable and lockable manner on the upper horizontal leg 9 and means 65 being arranged on the shuttering panel support 55 with which the securing element 19 can be secured before and during the Creation of the ceiling can be protected against unlocking and can only be unlocked after the creation of the ceiling.

- a first embodiment of the climbing bracket 1 relates to a climbing bracket 1 for laying scaffolding boards and fastening shuttering plate supports 55 for the construction of ceilings on partial structures 21, comprising two horizontally and vertically aligned legs 3, 5 made of steel profiles and essentially connected at right angles to one another and the two legs 3, 5 at their other end to form a triangle connecting frame, further comprising a trained on a guide support 9 hook 11, wherein the guide support (9) is slidably mounted on the climbing bracket 1, for use in a system according to one of the embodiments 1 to 5 of the system, wherein on the guide beam 9 of the hook 11 a securing element 19 with a first arm 19' and a second longer arm 19" in its rest and starting position within the greatest vertical extent of the hook 11 next to it and wherein in a working position the longer arm 19' can be slid or pivoted into a position projecting upwards over the hook 11 and the second arm 19" can be locked automatically on a locking and release device 19 in the lowered position of the climbing bracket 1 is.

- a second embodiment of the climbing bracket 1 relates to a climbing bracket 1 according to the first embodiment of the climbing bracket, the second, longer arm 19" of the securing element 19 being able to be latched at its end in the bolt 45 designed as latching means on the climbing bracket 1 and/or the guide support 9.

- a third embodiment of the climbing bracket 1 relates to a climbing bracket 1 according to the second embodiment of the climbing bracket, an axially displaceable disc 35 which is fitted or formed on a bolt 15 being arranged as a locking means.

- a fourth embodiment of the climbing bracket relates to a climbing bracket 1 for laying scaffolding boards and for fastening a formwork panel girder 55 for the construction of ceilings on substructures 21, comprising two horizontally and vertically aligned legs 3, 5 made of steel profiles and essentially connected at right angles to each other and one of the two legs 3, 5 at the other end to form a triangle connecting frame, further comprising a trained on a guide beam 9 Hook 11, wherein the guide support 9 is mounted on the climbing bracket 1 in a displaceable and lockable manner, for use in a system according to one of the embodiments 1 to 5 of the system, the guide support 9 with the hook 11 formed at its front end in at least one guide track 13, 41 is slidably mounted on the climbing bracket 1 at an acute angle to the upper leg 3.

- a fifth embodiment of the climbing bracket 1 relates to a climbing bracket 1 according to the fourth embodiment of the climbing bracket, wherein at least one first guide slot 41 is formed on the upper leg 3, in which a screw 17 inserted in the guide support 9 or a pin can be displaced that in a second guide slot 13, which is formed in the guide beam 9, a bolt 15 is guided, which is held in the upper leg 3, such that the hook 11 with the guide beam 9 after insertion of the hook 11 in an anchoring device 23 by gravity with respect to the climbing bracket 1 at the same time Movement up and backwards in the direction of the climbing bracket 1 performs.

- a sixth embodiment of the climbing bracket 1 relates to a climbing bracket 1 according to the fifth embodiment of the climbing bracket, the first slot 41 being formed on both sides on the upper leg 3 so that the screw 17 is guided at both ends and the bolt 15 at both ends in bores in the upper leg 3 is held.

- a first embodiment of the anchoring device 23 relates to an anchoring device 23 for anchoring a climbing bracket 1 to a wall made of concrete, comprising a hollow body with an opening 25 for Insertion of a hook-shaped end 11 on a climbing bracket 1, with the opening 25 being followed by an insertion channel 26 of height H and width B with a substantially constant cross-section, which is followed by a retention area with a larger cross-section for anchoring a climbing bracket 1 according to one of the first to sixth embodiments of the climbing bracket 1, wherein the retention area at the end of the insertion channel 26 extends both upwards and downwards over the floor and ceiling section of the insertion channel 26.

- a second embodiment of the anchoring device relates to an anchoring device according to the first embodiment of the anchoring device, wherein the hollow body forming the anchoring device 23 consists of two shells made of steel or plastic connected to one another.

- a third embodiment of the anchoring device relates to an anchoring device according to the second embodiment of the anchoring device, the two shells being connected to one another by welding or flanging.

- a fourth embodiment of the anchoring device relates to an anchoring device according to one of the first to third embodiments of the anchoring device, ribs and/or humps being formed as anchor elements on the shells of the hollow body.

- a first embodiment of the formwork panel support 55 relates to a formwork panel support 55 comprising a Guide shoe 57, with which the formwork panel carrier 55 is carried on the upper leg 3 of a climbing bracket 1 according to one of the first to sixth embodiments of the climbing bracket 1, so that it can be moved and fixed, the guide shoe 57 having an essentially U-shaped cross section, the two legs of the U form a lower 63 and an upper guide wall 61 and the base of the U is a side wall 59 which lies to the side of the upper leg 3 of the climbing bracket 1 and the free edges of the two guide walls 61, 63 are connected to one another by a slide 79 so that they can be braced .

- a second embodiment of the shuttering panel support relates to a shuttering panel support according to the first embodiment of the shuttering panel support, wherein the bushings 75, 77 for the insertion of the slide 79 are formed at their free ends for connecting the two guide walls 61, 63 and the lower end of the slide 79 further an opening 73 is attached for inserting a wedge-shaped locking plate 69, with which the two guide walls 61, 63 can be braced against one another.

- a third embodiment of the shuttering panel support relates to a shuttering panel support according to one of the first to second embodiments of the shuttering panel support, with a securing and release plate 65 being formed on the side wall 59 of the guide leg 57, which during use of the shuttering panel support 55 during the casting of a ceiling has a securing bolt 45 for unlocking the hook 11 on the climbing bracket 1 in the anchoring device 23 protects against access and after the casting to release the safety bolt 45 this can be advanced.

- a fourth embodiment of the shuttering plate carrier relates to a shuttering plate carrier according to the third embodiment of the shuttering plate carrier, the front end of the securing and detaching plate 65 being divided horizontally into a run-on area 66 with an outwardly bent edge and a section 68 which extends slightly towards the upper leg of the climbing bracket 1 is bent out and, with the shuttering plate carrier 55 pushed forward, comes to rest under a bent-down area of a tab 47 arranged on the climbing bracket 1 .

- a fifth embodiment of the formwork panel support relates to a formwork panel support according to one of the first to fourth embodiments of the formwork panel support, comprising a guide shoe (57) with which the formwork panel support 55 is slidably and fixably supported on the upper leg (3) of a climbing bracket, the vertical arm 85 of the shuttering panel carrier 55 with two spindles 87, 89 is guided in a spindle carrier 91.

- a sixth embodiment of the shuttering panel support relates to a shuttering panel support according to the second embodiment of the shuttering panel support, the front ends of the two spindles 87, 89 being held axially and rotatably in the vertical arm 85 with play in order to move the vertical arm 85 to a position deviating from the vertical bring.

- a seventh embodiment of the shuttering plate carrier relates to a shuttering plate carrier according to one of Embodiments five to six of the shuttering plate carrier, wherein the spindle carrier 91 is rigidly connected to the guide shoe 57.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Ladders (AREA)

- Cultivation Receptacles Or Flower-Pots, Or Pots For Seedlings (AREA)

- Joining Of Building Structures In Genera (AREA)

- Moulds, Cores, Or Mandrels (AREA)

- Emergency Lowering Means (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH00368/18A CH714813A2 (de) | 2018-03-20 | 2018-03-20 | System zur temporären Befestigung einer Kletterkonsole, Konsole und eine Verankerungsdose. |

| EP19162871.8A EP3543428B1 (fr) | 2018-03-20 | 2019-03-14 | Procédé de raccordement sécurisé automatiquement activé d'une console grimpante dotée d'un dispositif d'ancrage, système avec une console grimpante et un dispositif d'ancrage, et console grimpante |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19162871.8A Division EP3543428B1 (fr) | 2018-03-20 | 2019-03-14 | Procédé de raccordement sécurisé automatiquement activé d'une console grimpante dotée d'un dispositif d'ancrage, système avec une console grimpante et un dispositif d'ancrage, et console grimpante |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4234840A2 true EP4234840A2 (fr) | 2023-08-30 |

| EP4234840A3 EP4234840A3 (fr) | 2023-11-22 |

Family

ID=65812230

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP23186146.9A Pending EP4234840A3 (fr) | 2018-03-20 | 2019-03-14 | Procédé de connexion sécurisée auto-activable d'une console d'escalade avec un dispositif d'ancrage, système comprenant une console d'escalade et une console d'escalade |

| EP19162871.8A Active EP3543428B1 (fr) | 2018-03-20 | 2019-03-14 | Procédé de raccordement sécurisé automatiquement activé d'une console grimpante dotée d'un dispositif d'ancrage, système avec une console grimpante et un dispositif d'ancrage, et console grimpante |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19162871.8A Active EP3543428B1 (fr) | 2018-03-20 | 2019-03-14 | Procédé de raccordement sécurisé automatiquement activé d'une console grimpante dotée d'un dispositif d'ancrage, système avec une console grimpante et un dispositif d'ancrage, et console grimpante |

Country Status (2)

| Country | Link |

|---|---|

| EP (2) | EP4234840A3 (fr) |

| CH (1) | CH714813A2 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2549275B (en) * | 2016-04-11 | 2018-05-09 | Tectonic Facades Ltd | Construction assembly |

| EP3848532A1 (fr) * | 2020-01-13 | 2021-07-14 | Pino Albanese | Agencement de support de plaque d'ombrage et procédé de positionnement d'un support de plaque d'ombrage sur une console |

| CH717032A2 (de) * | 2020-01-13 | 2021-07-15 | Albanese Pino | Verfahren zum selbsttätig aktivierbaren sicheren Verbinden einer Kletterkonsole mit einer Verankerungsvorrichtung, System zur Befestigung einer Kletterkonsole und Kletterkonsole. |

| DE102021115025A1 (de) * | 2021-06-10 | 2022-12-15 | Doka Gmbh | Stützkonsole zur Abstützung eines Schalungselements und/oder einer Arbeitsplattform einer Schalung |

| CN114105006B (zh) * | 2021-11-30 | 2024-01-09 | 湖南三一塔式起重机械有限公司 | 顶升横梁、爬升架和塔式起重机 |

| US20230374775A1 (en) * | 2022-05-19 | 2023-11-23 | Urban Redwood | Methods and apparatuses for constructing high-rise buildings |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3032002A1 (fr) | 2014-12-12 | 2016-06-15 | Mägert & Co. Innovation | Console grimpante et son element de coffrage |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1435689A (en) * | 1972-02-01 | 1976-05-12 | Lecormex Ltd | Device for securing scaffolding to building constructions |

| DE9301494U1 (de) * | 1993-02-04 | 1993-04-15 | Mägert Bautechnik AG, Frutigen | Kletterkonsole |

| DE20220101U1 (de) * | 2002-12-23 | 2003-04-03 | Wilhelm Layher Vermögensverwaltungs-GmbH, 74363 Güglingen | Justierabschalstütze |

| CH705280B1 (de) * | 2005-01-19 | 2013-01-31 | Pino Albanese | Abschalplattenträger für eine Konsole. |

| EP1696085B1 (fr) * | 2005-02-24 | 2016-10-05 | Pino Albanese | Douille d'ancrage pour ancrer des consoles sur un mur en béton |

| KR101365059B1 (ko) * | 2011-06-30 | 2014-02-19 | 임종준 | 가설 난간지주 |

| CH713434A2 (de) * | 2017-02-01 | 2018-08-15 | Albanese Pino | Verankerungsdose für die temporäre Befestigung einer Konsole für Gerüst- und Abschalungsplatten an einer Teilbaute und Einsteckdeckel zum temporären Verschliessen einer Verankerungsdose. |

-

2018

- 2018-03-20 CH CH00368/18A patent/CH714813A2/de unknown

-

2019

- 2019-03-14 EP EP23186146.9A patent/EP4234840A3/fr active Pending

- 2019-03-14 EP EP19162871.8A patent/EP3543428B1/fr active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3032002A1 (fr) | 2014-12-12 | 2016-06-15 | Mägert & Co. Innovation | Console grimpante et son element de coffrage |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3543428A3 (fr) | 2019-11-13 |

| EP4234840A3 (fr) | 2023-11-22 |

| EP3543428A2 (fr) | 2019-09-25 |

| CH714813A2 (de) | 2019-09-30 |

| EP3543428C0 (fr) | 2023-07-19 |

| EP3543428B1 (fr) | 2023-07-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3543428B1 (fr) | Procédé de raccordement sécurisé automatiquement activé d'une console grimpante dotée d'un dispositif d'ancrage, système avec une console grimpante et un dispositif d'ancrage, et console grimpante | |

| DE102006026201B4 (de) | Selbstklettersystem | |

| WO2019161824A1 (fr) | Équipement comprenant un dispositif anti-soulèvement et procédé pour empêcher un plancher d'échafaudage de se soulever | |

| EP0390128B1 (fr) | Support télescopique de longueur réglable | |

| EP0034819A2 (fr) | Echafaudage mobile | |

| DE102018203612A1 (de) | Absenkeinrichtung sowie Stützvorrichtung und Deckenschalung mit einer solchen Absenkeinrichtung | |

| WO2008128937A1 (fr) | Sabot de guidage et combinaison d'un sabot de guidage avec un profilé d'escalade | |

| EP3854964A1 (fr) | Procédé de liaison sécurisée automatiquement activée d'une console grimpante dotée d'un dispositif d'ancrage, système de fixation d'une console grimpante, console grimpante sur un dispositif d'ancrage et support de plaques de coffrage | |

| EP3032002B1 (fr) | Console grimpante et son element de coffrage | |

| EP3848532A1 (fr) | Agencement de support de plaque d'ombrage et procédé de positionnement d'un support de plaque d'ombrage sur une console | |

| DE10243356A1 (de) | Zerlegbares Gerüst | |

| DE3605045A1 (de) | Vorrichtung mit einem haltearm zum halten einer an einem gebaeude herabhaengenden last | |

| DE102004039470B4 (de) | Betonschalungsschloss und Betonschalelement | |

| DE19502225C2 (de) | Anhängevorrichtung zum Anhängen wenigstens einer Schaltafel an ein Hebezeug | |

| CH696403A5 (de) | Verankerungsbüchse für die Verankerung einer Konsole in einer Betonwand und eine Konsole. | |

| EP4051472B1 (fr) | Dispositif de coffrage | |

| EP4056785B1 (fr) | Dispositif d'appui, élément d'appui du plafond, système de coffrage du plafond et procédé de décoffrage d'un panneau de coffrage du plafond | |

| CH717033A2 (de) | Abschalplattenträger und Verfahren zum Positionieren eines Abschalplattenträgers auf einer Konsole. | |

| AT500579B1 (de) | Verankerungsbüchse für die verankerung einer konsole in einer betonwand, ein verankerungsmittel, ein halte- und verschlussdeckel und eine konsole | |

| DE3306789A1 (de) | Stuetze fuer wohnwagen od. dgl. | |

| DE10351255B4 (de) | Absenkvorrichtung für eine Tragkonstruktion | |

| EP4069919A1 (fr) | Coffrage | |

| DE102021100608A1 (de) | Verriegelungsanordnung zur Verriegelung zweier Gerüstelemente bezüglich einander | |

| DE2256658A1 (de) | Vorrichtung zum heben und senken von vorgefertigten, kastenfoermigen werkstuecken mit geschlossenem boden | |

| DE29501062U1 (de) | Anhängevorrichtung zum Anhängen wenigstens einer Schaltafel an ein Hebezeug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 3543428 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E04G 15/04 20060101ALI20231016BHEP Ipc: E04G 15/06 20060101ALI20231016BHEP Ipc: E04G 11/36 20060101ALI20231016BHEP Ipc: E04G 5/06 20060101AFI20231016BHEP |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20240522 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20240905 |