EP3975815B1 - Geschirrkorb mit einem gefässhalter und haushaltsgeschirrspülmaschine - Google Patents

Geschirrkorb mit einem gefässhalter und haushaltsgeschirrspülmaschine Download PDFInfo

- Publication number

- EP3975815B1 EP3975815B1 EP20728741.8A EP20728741A EP3975815B1 EP 3975815 B1 EP3975815 B1 EP 3975815B1 EP 20728741 A EP20728741 A EP 20728741A EP 3975815 B1 EP3975815 B1 EP 3975815B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- holding

- horizontal

- section

- vessel

- holding device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000005489 elastic deformation Effects 0.000 claims description 3

- 238000005406 washing Methods 0.000 description 21

- 230000008901 benefit Effects 0.000 description 9

- 238000003780 insertion Methods 0.000 description 7

- 230000037431 insertion Effects 0.000 description 7

- 230000007704 transition Effects 0.000 description 7

- 238000004851 dishwashing Methods 0.000 description 3

- 230000014759 maintenance of location Effects 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000007792 addition Methods 0.000 description 1

- 235000013361 beverage Nutrition 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 230000035622 drinking Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000002792 vascular Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/42—Details

- A47L15/50—Racks ; Baskets

- A47L15/505—Inserts, e.g. for holding baby bottles, stemware or cups

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/42—Details

- A47L15/50—Racks ; Baskets

- A47L15/503—Racks ; Baskets with foldable parts

Definitions

- the present invention relates to a crockery basket with a container holder for a household dishwasher, the container holder comprising a base body which has a base section and a wall section connected to the base section, and the container holder comprising a holding device which is rotatably mounted on the wall section and which has a to a horizontal aligned holding position for holding a vessel and a downwardly inclined position relative to the horizontal, the holding device being adapted to move from the horizontally aligned holding position to the downwardly inclined relative to the horizontal when a vertically downward force is exerted on the same Position to move when the force exceeds a threshold.

- the present invention relates to a domestic dishwasher with such a crockery basket.

- a household dishwasher has a washing compartment and at least one crockery basket that can be moved into and out of the washing compartment.

- the domestic dishwasher can have several crockery baskets arranged one above the other, such as a lower basket, an upper basket and a cutlery drawer.

- a bottle holder can be provided inside the crockery basket.

- the pamphlet US 4,828,211A discloses an article holder mountable on an upwardly extending surface, the article holder including a back panel adapted to sit on and be supported by the upwardly extending surface.

- the article holder further includes a base panel pivotally connected to the lower end of the back panel and movable for pivotal movement between an open position oriented substantially perpendicular to the back panel and a closed position abutting the back panel.

- the article holder further includes a clamping element for engaging and holding a beverage container, which is pivotally connected to the upper end of the rear wall and which is for pivotal movement is movable between a storage position oriented generally parallel to the rear wall and an erected position generally parallel to the base wall.

- the article holder also includes an elongate rail member having means at each end pivotally attaching the elongate rail member to the rear wall, the clamping member having a pair of arms which are independent of one another. One end of each arm is slidably engaged and supported by the rail member whereby each arm can be independently moved longitudinally of the rail member for size adjustment to vary the opening width between the arms.

- the pamphlet U.S. 2006/0138064 A1 discloses a device for securing stemmed glassware during the wash and rinse cycles of a domestic dishwasher.

- the device is attached to a dish rack of the domestic dishwasher, preferably to a generally vertically disposed and plastic-coated wire prong within the upper dish rack.

- the device includes a mounting base member attached to the dish rack, a pivotable arm member attached to and extending outwardly from the mounting base member, the pivotable arm member being pivotable relative to the mounting base member, and a support member attached to the attached to or part of the outwardly extending portion of the pivotable arm member.

- the dish rack provides means for holding, supporting or otherwise securing the stemmed glassware in a preferred inverted orientation for cleaning thereof.

- the pamphlet DE 10 2018 103 585 A1 discloses a holding device for holding items to be washed in a washing basket for a dishwasher, the holding device having at least one leg which can be pivotably fastened to a pivoting device. At least two receiving devices of different sizes for items to be washed are arranged on the at least one leg.

- the holding device for holding items to be washed is fastened pivotably to the washing basket for the dishwasher, preferably to its latticed bottom area, using the pivoting device.

- the pamphlet EP 2 036 482 A1 discloses a glass holder unit for dishwashing baskets, comprising at least one support element in the form of a wire, which in its Central section having a plurality of turns to allow glasses to rest between them, the legs extending laterally with one curl at the two ends of the central section and the end sections, which in turn are formed with one curl each at the ends of the legs, and two Connection devices, which are the legs at two ends of the support element and which are attached to the mutual wires of the basket.

- a bearing is provided in the shape of a U, which extends from the front to the outside along the surface of the connecting element. In the inner space of the bearing and on the underside of the U-shape, an end section is mounted so that it can rotate about its center. Also provided is a channel surrounding the side faces of the bearing which allows arcuate rotation of the leg and which communicates with the interior of the bearing.

- the pamphlet U.S. 2008/0149149 A1 discloses a dishwasher. It comprises a washing compartment which forms an interior of the dishwasher, a crockery basket which can be brought into the washing compartment, a large number of wires and at least one vessel holder which can be detachably attached to the crockery basket, preferably to its latticed bottom area, and which makes it possible that a vessel is set in it and held therein.

- the vessel holder includes a plurality of supports which elastically hold the vessel, and an insertion part which is provided between the supports and which allows a vessel to be inserted therein.

- the pamphlet US 6,123,204A discloses a container holder for a dish rack for accommodating containers of different sizes in a dishwasher.

- the container holder includes a support element, which is designed to be attached to a depth wire of the dish rack of the dishwasher, with the support element forming a receptacle.

- the container holder further includes a plurality of resilient-flexible retention members extending inwardly from the socket of the support member into the socket.

- the plurality of resilient-flexible retention members are sized and shaped to removably retain containers of different sizes, wherein in response to receipt of a container within that receptacle, the majority of the resilient-flexible retention members exert an inward effect against the received container, so as to removably retain the received container within the receptacle.

- the pamphlet EP 3 037 028 A1 discloses a holding device for holding items to be washed in an item to be washed in a water-bearing household appliance, having a gripping section which is set up to at least partially encompass the items to be washed, the gripping section being pivotable from an initial position into a holding position and vice versa, and the gripping section being able to be pivoted with the aid of a weight force of the items to be washed can be pivoted automatically from the starting position to the holding position.

- the at least one holding device for holding items to be washed is preferably provided on a latticed rear wall of the items to be washed receptacle of the water-bearing domestic appliance.

- the pamphlet CN 204363929 U discloses a bottle holder with a panel that can be attached to a side wall of a dish rack. Furthermore, two ring elements can be attached to the plate to receive a surface therein. The ring elements can be folded up.

- an object of the present invention is to provide an improved dish rack with a vessel holder for a domestic dishwasher.

- the vessel holder comprises a base body which has a base section and a wall section connected to the base section.

- the vessel holder comprises a holding device which is rotatably mounted on the wall section and which has a holding position aligned with the horizontal for holding a vessel and a position which is inclined downward with respect to the horizontal, the holding device being set up to move from the hold position aligned with the horizontal to the inclined position downward with respect to the horizontal when the force exceeds a threshold.

- a first connecting element is provided on an underside of the base section, which can be connected to a base of the crockery basket, and a second connecting element is provided on the wall section, which can be connected to a wall of the crockery basket.

- a durable vessel holder can thus be provided.

- the vessel holder is set up to hold the holding device in the holding position, in particular with the aid of a form fit, as long as the force remains below the threshold value.

- the positive locking is preferably released or unlocked, so that the holding device moves into the inclined position.

- Such a dissolution or unlocking of the form fit can be accompanied by an unlatching, for example.

- the vessel holder is a bottle holder.

- a vessel is an elongated container for storing a liquid.

- the vessel or a part thereof is preferably rotationally symmetrical.

- the vessel is, for example, a carafe, a bottle, a sports bottle or a feeding bottle.

- the holding device is set up to encompass the vessel.

- the force is, for example, a force that a user exerts on the holding device.

- the holding device preferably has a positive angle to a horizontal line in the holding position. For example, the holding device is then inclined upwards. In the down position, this angle is negative.

- the holding device is made of plastic.

- the vessel holder is preferably made of plastic.

- the holding position is, for example, the usage position of the holding device.

- the holding device preferably comprises a ring element.

- the ring element comprises an opening through which the vessel can be passed.

- the ring element is set up, for example, to center the vessel and/or to secure it to one side against falling out of the vessel holder.

- Inclined position means that a ring plane of the ring element is inclined to a horizontal.

- the downwardly inclined position can, for example, be referred to as a snap-through position.

- the holding device can be transferred at any time from the downwardly inclined position to the holding position.

- the force is applied to an extreme free end of the ring member.

- the force is preferably between 1 and 200 N, 2 and 100 N, 3 and 80 N, 5 and 40 N or 10 and 30 N.

- the force can also be at a rest against another point of the ring segment, in which case the threshold value is larger due to the lower lever.

- the movement of the holding device is a rotational movement.

- the holding device preferably comprises a fastening element which comprises two bearing bolts projecting in opposite directions.

- the base body includes bearings, in particular bearing points, for each bearing pin.

- the bearing bolts and the bearings are preferably designed as a clip connection.

- the bearing bolts snap into the bearing when the holding device is pushed onto the base body.

- the bearing bolts and the bearings define an axis of rotation of the holding device relative to the base body.

- the base body is made of plastic.

- the wall section and the bottom section preferably form an L-shape.

- the base section comprises an outer ring section, in which an inner ring section is arranged with the aid of webs.

- Three webs preferably extend radially from the inner ring section to the outer ring section.

- the inner ring section together with the webs can also be referred to as a funnel.

- the webs preferably form a three-point support for the vessel.

- the vessel can thus be stabilized and positioned.

- a positioning aid can thereby be provided which can center and/or support vessels with different diameters.

- the first connecting element is preferably a latching element.

- the latching element and the base of the crockery basket form a detachable latching connection.

- the latching element preferably latches with a floor wire, in particular a depth wire of the crockery basket. This has the advantage that the vessel holder can be securely connected to the bottom of the crockery basket.

- the second connecting element is a latching element.

- the latching element and the wall of the crockery basket preferably form a detachable latching connection.

- the latching element preferably latches with a wall wire, in particular a depth wire, of the crockery basket.

- this allows the vessel holder to be securely connected to the wall of the crockery basket.

- the crockery basket is preferably designed as a basket structure, which is formed in particular with the aid of wires.

- the basket structure comprises a base, in particular a wire mat, and, in particular, four side walls molded onto the base.

- the basket structure includes a loading opening, through which dishes, in particular plates and vessels, can be guided into the basket structure for washing the dishes.

- the holding device has a position in which it is folded upwards relative to the holding position aligned with the horizontal.

- the holding device thus has at least three positions.

- the folded-up position can also be referred to as the folded-in position.

- a space-saving position of the vessel holder can be realized in this way, so that there is more space in the crockery basket for other crockery.

- the holding device preferably has a vertical orientation in the folded-up position.

- the holding device is preferably prestressed against the base body in the upwardly folded position.

- the holding device is thus fixed in the folded-up position, so that an unintentional movement into the holding position can be avoided.

- a smaller force is preferably required to overcome this prestress than to exceed the threshold value.

- the base body has a projection and the holding device has a contour, the contour sliding over the projection at least in sections when the holding device rotates relative to the base body.

- the holding device When the holding device is rotated, this is also accompanied by a rotational movement of the contour.

- the holding device includes a cam which includes the contour.

- the cam is formed on the fastening element of the holding device.

- the contour and the projection preferably form a positive connection when the holding device is in the holding position condition.

- the contour presses against the projection due to gravity acting on the ring element and a leverage effect when the holding device is in the holding position.

- the protrusion prevents the retainer from moving to the downwardly inclined position.

- the threshold value can advantageously be set with the aid of the contour and the projection.

- the contour comprises a first elevation which presses against the projection and prevents rotation of the holding device in the direction of the position inclined downwards from the horizontal when the holding device is in the holding position aligned with the horizontal and the force exceeds the threshold value falls below

- the pressing is, for example, the elevation resting on the projection.

- the elevation and the projection form a positive connection which prevents the holding device from rotating from the holding position to the downwardly inclined position.

- a robust mechanism can advantageously be provided in this way in order to enable the different positions of the holding device.

- the first elevation is preferably formed on the cam.

- the holding device and the base body are set up in such a way that the projection and/or the first elevation performs an evasive movement due to elastic deformation if the force exceeds the threshold value in the holding position aligned with the horizontal.

- the projection and/or the elevation is pushed away elastically.

- the elastic deformation can take place on the cam and/or a wall section of the base body.

- this may be referred to as snapping.

- This has the advantage that an inexpensive solution can be provided.

- the elevations and the projection are preferably made of plastic.

- the contour comprises a second elevation which presses against the projection and prevents rotation of the holding device in the direction of the holding position aligned with the horizontal when the holding device is in the folded-up position.

- the first and second elevations are formed on the cam.

- the second bump provides less resistance than the first bump when they press against the projection.

- the second connecting element is provided at a first height and a third connecting element is provided at a second height on the wall section, it being possible for the third connecting element to be connected to the wall of the crockery basket.

- the third connecting element is preferably a latching element.

- two connecting elements are advantageously formed on the wall section, so that the wall section can be attached to different crockery basket variants. This provides a universal vessel holder.

- the base body has a first support element and a second support element, which are designed to engage in the crockery basket in order to prevent the vessel holder from shifting in a horizontal direction.

- the supporting elements are designed as supporting flanks.

- the support elements are preferably designed as two lugs pointing in opposite directions.

- the support elements each include a curved support surface for a wire of the crockery basket, in particular a transverse wire.

- the support elements are each designed as a nose catch.

- the wall section of the base body comprises a third support element and a fourth support element, which engage in the crockery basket in order to prevent the wall section of the base body from shifting in a horizontal direction.

- the third and fourth support elements are preferably designed as two lugs pointing in opposite directions.

- the 1 shows a schematic perspective view of an embodiment of a domestic dishwasher 1.

- the domestic dishwasher 1 comprises a washing container 2, which can be closed by a door 3, in particular watertight.

- a sealing device can be provided between the door 3 and the washing container 2 .

- the washing compartment 2 is preferably cuboid.

- the washing compartment 2 can be arranged in a housing of the domestic dishwasher 1 .

- the washing compartment 2 and the door 3 can form a washing chamber 4 for washing items to be washed.

- Door 3 is in the 1 shown in their open position.

- the door 3 can be closed or opened by pivoting about a pivot axis 5 provided at a lower end of the door 3 .

- a loading opening 6 of the washing compartment 2 can be closed or opened.

- the washing compartment 2 has a base 7, a cover 8 arranged opposite the base 7, a rear wall 9 arranged opposite the closed door 3 and two side walls 10, 11 arranged opposite one another.

- the floor 7, the ceiling 8, the rear wall 9 and the side walls 10, 11 can, for example, from a be made of stainless steel sheet.

- the bottom 7 can be made of a plastic material.

- the household dishwasher 1 also has at least one washware holder 12 to 14 .

- washware holder 12 being a lower washware holder or a lower rack

- washware holder 13 being an upper washware holder or an upper rack

- washware holder 14 being a cutlery drawer.

- the washing items receptacles 12 to 14 are arranged one above the other in the washing compartment 2 .

- Each washware holder 12 to 14 can be moved either into or out of the washing compartment 2 .

- each washware holder 12 to 14 can be pushed or moved into the washing compartment 2 in an insertion direction E (arrow) and pulled out or moved out of the washing compartment 2 in an extension direction A (arrow) counter to the insertion direction E (arrow).

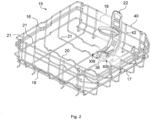

- the 2 shows a perspective view of a crockery basket 15.

- the crockery basket 15 is designed as a washware receptacle 12 (see FIG 1 ) educated.

- the crockery basket 15 has two side walls 16, 17 arranged opposite one another.

- the crockery basket 15 has two oppositely arranged side walls 18, 19 which run perpendicular to the side walls 16, 17.

- the side walls 16, 17, 18, 19 are connected to one another in the form of a frame.

- the crockery basket 15 has a base 20, in particular a wire mat, which preferably runs perpendicular to the side walls 16, 17, 18, 19.

- the bottom 20 and the side walls 16, 17, 18, 19 are formed from bent wires 21 and form a basket structure.

- a vessel holder 22 is provided, which is detachably connected at least to the base 20 and/or to the side wall 19 .

- the vessel holder 22 is a bottle holder.

- the vessel holder 22 is designed to hold a vessel, in particular a bottle, a phial, a carafe, etc., during a wash cycle.

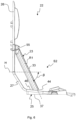

- the 3 shows a perspective view of the vessel holder 22.

- the vessel holder 22 comprises a holding device 23 which is set up to at least partially enclose the vessel.

- the vessel holder 22 comprises a base body 24, on which the holding device 23 is rotatably mounted.

- the base body 24 comprises a base section 25 and a wall section 26 connected to the base section 25.

- the base section 25 and the wall section 26 run essentially perpendicular to one another.

- the bottom section 25 and the wall section 26 are preferably connected to one another by means of a transition section 27 .

- the transition section 27 is designed as a flattening.

- the transition section 27 is formed at an angle to the wall section 26 and at an angle to the base section 25 .

- the bottom section 25, the transition section 27 and the wall section 26 form an L-shape.

- the holding device 23 is mounted on the wall section 26 .

- a centering element 28 protrudes upwards from the bottom section 25 .

- the centering element 28 is set up to center a vessel and/or to support it on the opening side. In this case, for example, the centering element 28 protrudes into an opening of the vessel. In such a case, the vessel stands, for example, upside down in the vessel holder 22.

- the centering element 28 comprises an inner ring section 29 from which the webs 30 protrude and connect this to an outer ring section 31 of the base section 25 .

- Three webs 30 are preferably connected to the ring section 29 and protrude radially from the ring section 29 .

- the centering element 28 is set up to allow water coming from below into the vessel.

- the base 25 forms a three-point support for the vessel. Vessels with different opening diameters can be supported with the aid of the webs 30 .

- the centering element 28 can be referred to as a funnel on the bottom and/or as a positioning aid for the vessel.

- representations of vessels 32 are formed in the transition section 27, in particular embossed, stamped or recessed.

- Three vessel representations 32 in particular a carafe, a sports bottle and a drinking bottle, are preferably formed on the transition section 27.

- the holding device 23 comprises a ring element 33 and a fastening element 34.

- the ring element 33 is designed to hold the vessel at least to partially enclose, center and/or fix.

- the holding device 23 is connected to the wall section 26 with the aid of the fastening element 34 .

- the 4 shows a side view of the vessel holder 22.

- the holding device 23 is in a folded-up position S3.

- the ring element 33 rests on the wall section 26 .

- the ring element 33 is preferably prestressed against the wall section 26 . This has the advantage that the ring element 33 can be prevented from being folded down unintentionally.

- the folded-up position S3 has the advantage that the vessel holder 22 can be arranged in a space-saving manner inside the crockery basket 15 if, for example, no vessel is arranged inside the vessel holder 22 .

- a ring plane R1 of ring element 33 preferably runs parallel to wall section 26. Ring element 33 is in a vertical position.

- the ring section 29 includes a ring plane R2.

- the ring plane R2 is inclined to a horizontal H. This inclination makes it possible, for example, for a vessel to be placed inclined to a vertical V in which the vessel holder 22 can be set up.

- the base section 25 comprises a connecting element 35.

- the connecting element 35 is designed to connect the vessel holder 22 to the basket base 20, in particular a base wire 36 (see 2 ), connect to.

- the ground wire 36 can be a depth wire.

- the connecting element 35 is preferably arranged on an underside 37 of the bottom section 25 .

- the connecting element 35 is a clip connection.

- the clip connection is set up to be pressed onto the ground wire 36, to be elastically deformed in the process and then to enclose the ground wire 36 in a form-fitting manner.

- the vessel holder 22 can be detachably connected to the base 20 of the crockery basket 15 (see 2 ) get connected.

- the connecting element 35 is formed at a tip 38 of the base section 25 which faces away from the wall section 26 . This ensures that the vessel holder 22 is securely fastened to the basket base 20 (see FIG 2 ).

- the connecting element 35 can also be referred to as a latching element (here also referred to as the first latching element), which is adapted to the Bottom 20 of the dish rack 15 to lock.

- the wall section 26 comprises a connecting element 39, in particular a latching element (here also referred to as a second latching element), which is designed to connect to the wall 19 of the crockery basket 15 (see FIG 2 ) to lock.

- the connecting element 39 is designed in particular to be connected to a horizontally running wire 40, preferably a depth wire, of the wall 19.

- the connecting element 39 is formed on the wall section 26 at a first height H1.

- a further connecting element 41 in particular a latching element (here also referred to as the third latching element), is preferably provided at a second height H2.

- the connecting element 41 is designed to connect to the wall 19 of the crockery basket 15 (see FIG 2 ) to lock.

- the connecting element 41 is designed identically to the connecting element 39, for example.

- the provision of two connecting elements 39, 41 at different heights relative to the underside 37 of the base section 25 has the advantage that the vessel holder 22 can be connected to different crockery baskets 15.

- the vessel holder 22 can thus be used universally.

- a guide element 43 can be provided to guide a wire 42 (see 2 ) to be included in sections.

- the guide element 43 can also be referred to as a recess and is used to further stabilize the vessel holder 22 on the crockery basket 15.

- the height H3 is, for example, smaller than the height H2 and the height H1.

- the figure 5 shows a further side view of the vessel holder 22.

- the holding device 23 is shown in a holding position S1. In this position, the holding device 23 is set up to hold the vessel for a wash cycle.

- the ring plane R1 runs at an angle ⁇ (double arrow) to the horizontal H. Alternatively, the ring plane R1 can also run horizontally in this position.

- the angle ⁇ (double arrow) is preferably between 3° and 30°, 5° and 25°, 10° and 20°, 12° and 18° or 14° and 16°.

- the angle ⁇ (double arrow) is preferably also formed between the ring plane R2 and the horizontal H.

- the ring element 33 and the ring section 29 thus have the same inclination in the holding position.

- the angle ⁇ (double arrow) is preferably positive, so that the ring element 33 is inclined slightly upwards.

- the holding device 23 is set up to move from the holding position S1 into an inclined position S2 (see FIG 6 ) to move when the force F (arrow) exceeds a threshold.

- This has the advantage that overloading of the holding device 23 can be avoided.

- a protection mechanism against damage to the vessel holder 22 can thereby be implemented.

- the vessel holder 22 is preferably made of plastic.

- the force F (arrow) is preferably applied to an outermost free end 44 of the ring element 33 .

- the greatest possible leverage on the fastening element 34 is thus formed.

- the force F (arrow) is preferably between 2 and 100 N, 2 and 50 N, 3 and 30 N or 5 and 20 N.

- the force can also be applied at a different point on the ring segment, in which case the threshold value is greater due to the lower lever is.

- ribs 45 (see also 3 ) educated.

- the ribs face the ring member 33 .

- two parallel ribs 45 are formed.

- the ribs 45 can be designed, for example, as positioning aids for the vessel. There is preferably space between the two positioning aids 45 in order to accommodate part of the vessel, in particular a bottom section of the vessel and/or a bottom wall section of the vessel.

- the ribs 45 facilitate the vessel to slip in between the ribs 45 and then form an obstacle to prevent slipping out.

- the vessel can be positioned and stabilized with the help of the centering element 28 and the ribs 45, for example.

- the ribs 45 can also be designed as support elements for the ring element 33 in the upwardly folded position S3 in order to stabilize it.

- the wall section 26 includes windows 64, which are provided between the ribs 45 and serve as a further positioning aid.

- windows 64 are formed, which are preferably arranged one above the other and can each have different shapes.

- another window 65 can be provided on the wall section 26, which can serve as a positioning aid for shorter or small vessels.

- the 6 shows a further side view of the vessel holder 22, the holding device 23 being in an inclined position S2.

- This position takes the Holding device 23 when the force F (arrow) (see figure 5 ) exceeds the threshold.

- this position can be referred to as a latching position.

- the ring element 33 rests on an upper side 46 of the base section 25 .

- the end 44 points to the bottom section 25.

- the ring plane R1 now spans an angle ⁇ (double arrow) with the horizontal H.

- the angle ⁇ (double arrow) is negative.

- the 7 shows section VII-VII from the 3 , the holding device 23 being in the folded-up position S3 (see 4 ) having.

- the wall section 26 has a projection 47 .

- the projection 47 protrudes from the wall section 26 towards the holding device 23 .

- the fastening element 34 comprises a cam 66 with a contour 48, the contour 48 sliding over the projection 47 at least in sections when the holding device 23 is rotated relative to the wall section 26.

- Contour 48 preferably includes an elevation 49 (herein also referred to as a second elevation), which presses against projection 47 to prevent rotation of holding device 23 in the direction of holding position S1 when holding device 23 is in the folded-up position S3 located.

- the pressing can also be a slight contact.

- the contour 48 includes an elevation 50 (here also referred to as the first elevation), which presses against the projection 47 and rotates the holding device 23 in the direction of the inclined position S2 (see FIG 9 ) prevented.

- the holding device 23 and the wall section 26 are set up in such a way that the projection 47 and the elevation 50 are pushed away from one another and/or deform elastically when the force F (arrow) exceeds the threshold value.

- the wall section 26 and the contour 48 perform an evasive movement, so that the holding device 23 moves into the inclined position S2.

- the contour 48 is no longer in contact with the projection 47. If an operator moves the holding device 23 into the holding position S1, then a resistance must be overcome so that the elevation 50 and the projection 47 carry out a further evasive movement.

- the evasive movement is elastic.

- the Contour 48 is arcuately curved and has a wavy shape to form elevations 49,50.

- the bump 50 is formed at an end portion of the connecting member 34 .

- the 10 shows the holding device 23 in a top view.

- the ring member 33 includes projections 51.

- the projections 51 extend radially inward.

- the ring section 33 encloses an opening 52.

- the ring element 33 is designed as a completely closed ring.

- the ring element 33 can also be designed as an open ring.

- the ring element 33 can also be designed as a ring segment.

- the jar can be passed through the opening 52 to be placed in the jar holder 22 .

- the vessel can rest on the projections 51 so that point supports are formed.

- the projections 51 are distributed along an inner circumference of the ring member 33 .

- the connecting element 34 preferably comprises two web sections 53 on which bearing pins 54 are formed.

- two bearing journals 54 are formed which protrude from one another.

- the cam 66 is formed between the land portions 53 .

- the 11 shows section XI-XI from the figure 5 .

- This cut is designed as a partial cut.

- the wall section 26 comprises a bearing 55 for each bearing journal 54.

- the bearing 55 is set up to support the bearing journal 54 in a rotational manner.

- the bearing 55 has an insertion bevel 56 .

- the bearing pin 54 also has an insertion bevel 57.

- the insertion bevels 56 and 57 interact when the bearing pin 54 is inserted into the bearing 55 in such a way that the web section 53 is pressed outwards so that the bearing pin 54 can then snap into the bearing 55.

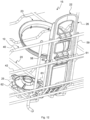

- the 12 shows a further schematic perspective view of the crockery basket 15 with the vessel holder 22.

- the crockery basket 15 comprises a transverse wire 58 and a transverse wire 59 adjacent thereto, which are curved so that they merge from the side wall 19 into the base 20.

- the transverse wires 58, 59 are immediately adjacent.

- the wall section 26 is arranged between the transverse wire 58 and the transverse wire 59 .

- the wall section 26 includes a support element 60 which rests on the transverse wire 58 .

- the wall section 26 includes a support element 61 which rests on the transverse wire 59 . With the help of the support elements 60, 61 the wall section 26 is clamped between the transverse wires 58, 59. With this, the wall portion 26 is fixed in an axial direction.

- the base section 25 can also include support elements 62 and 63, for example.

- the 13 shows section XIII-XIII from the 2 .

- the supporting elements 62, 63 of the base section 25 are designed to fix the base section 25 between the transverse wire 58 and the transverse wire 59.

- the bottom section 25 is fixed downwards and to the side.

- the support elements 62, 63 are, for example, L-shaped.

- the support elements 62, 63 can also be referred to as lugs, which point in opposite directions.

- the support elements 60, 61 (see 12 ) can also be referred to as lugs pointing in opposite directions.

- a stable fixation between the transverse wires 58, 59 and the vessel holder 22 can advantageously be realized with the aid of the supporting elements 60, 61, 62, 63.

- the support elements 60, 61, 62, 63 are set up to engage in the crockery basket 15 in order to prevent displacement of the vessel holder 22 in a horizontal direction Z (arrow), which runs perpendicular to the transverse wires 58, 59.

Landscapes

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Washing And Drying Of Tableware (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102019207812.5A DE102019207812A1 (de) | 2019-05-28 | 2019-05-28 | Gefäßhalter, Geschirrkorb und Haushaltsgeschirrspülmaschine |

| PCT/EP2020/064665 WO2020239819A1 (de) | 2019-05-28 | 2020-05-27 | Gefässhalter, geschirrkorb und haushaltsgeschirrspülmaschine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3975815A1 EP3975815A1 (de) | 2022-04-06 |

| EP3975815B1 true EP3975815B1 (de) | 2023-08-16 |

Family

ID=70861490

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20728741.8A Active EP3975815B1 (de) | 2019-05-28 | 2020-05-27 | Geschirrkorb mit einem gefässhalter und haushaltsgeschirrspülmaschine |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US11766161B2 (zh) |

| EP (1) | EP3975815B1 (zh) |

| CN (1) | CN113950275B (zh) |

| DE (1) | DE102019207812A1 (zh) |

| PL (1) | PL3975815T3 (zh) |

| WO (1) | WO2020239819A1 (zh) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102021116486A1 (de) * | 2021-06-25 | 2022-12-29 | Miele & Cie. Kg | Halter für einen Spülkorb |

| US12035865B2 (en) | 2021-09-30 | 2024-07-16 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with concentric housing members |

| US12036588B2 (en) * | 2021-09-30 | 2024-07-16 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with beverage container holder having retainer with lateral opening |

| US12022988B2 (en) | 2021-09-30 | 2024-07-02 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with slip ring for supplying power to a rotatable ultraviolet light |

| US12029369B2 (en) | 2021-09-30 | 2024-07-09 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with pop-up sprayer |

| US12011132B2 (en) | 2021-09-30 | 2024-06-18 | Midea Group Co., Ltd. | High speed reusable beverage container washing system |

| US12082761B2 (en) | 2022-06-24 | 2024-09-10 | Midea Group Co., Ltd. | Heated wash fluid circulation system for high speed reusable beverage container washing system |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4828211A (en) * | 1988-04-28 | 1989-05-09 | Itc, Incorporated | Foldable support for beverage container |

| US5014956A (en) * | 1989-03-02 | 1991-05-14 | Nk Innovations, Inc. | Adjustable drink holder |

| US4887784A (en) * | 1989-03-02 | 1989-12-19 | Nk Innovations, Inc. | Adjustable drink holder |

| US5072909A (en) * | 1990-05-10 | 1991-12-17 | Huang Tzu Ping | Adjustable cup holder in the car |

| DE4224700A1 (de) * | 1992-07-25 | 1994-01-27 | Euwe Eugen Wexler Gmbh | Haltevorrichtung für Getränkebehälter |

| US5249590A (en) * | 1992-08-18 | 1993-10-05 | General Electric Company | Article retaining mechanism |

| US6047937A (en) * | 1998-08-14 | 2000-04-11 | Huang; Pei-Hsiu | Vehicle-use foldable beverage holder |

| US6123204A (en) * | 1999-07-12 | 2000-09-26 | Belden Enterprises, Inc. | Dishwasher-rack container holder |

| US7458471B2 (en) * | 2004-12-29 | 2008-12-02 | Crudgington Jr Cleveland B | Stemware saver for dishwasher |

| KR101184455B1 (ko) * | 2006-12-22 | 2012-09-20 | 삼성전자주식회사 | 용기홀더 및 이를 포함하는 식기세척기 |

| DE102007029130B4 (de) * | 2007-06-25 | 2010-11-25 | Faurecia Innenraum Systeme Gmbh | Halter für Gebrauchs-Gegenstände |

| EP2036482A1 (en) * | 2007-09-13 | 2009-03-18 | Vestel Beyaz Esya Sanayi Ve Ticaret A.S. | Support for glasses for dishwasher baskets |

| DE202007013288U1 (de) * | 2007-09-21 | 2007-12-27 | Dr. Schneider Kunststoffwerke Gmbh | Vorrichtung zum Halten von Getränkebehältern |

| ITRN20080010A1 (it) * | 2008-02-26 | 2009-08-27 | Indesit Co Spa | Cestello per lavastoviglie e lavastoviglie comprendente il cestello. |

| EP2215956B1 (en) * | 2009-02-10 | 2020-05-27 | Electrolux Home Products Corporation N.V. | Adjustable rack assembly for a dishwasher basket |

| ES2388725T3 (es) | 2010-02-09 | 2012-10-18 | Miele & Cie. Kg | Elemento insertable para un cesto de un lavavajillas |

| DE202012103340U1 (de) * | 2012-08-31 | 2012-10-11 | Exquisit Baby Ag | Flaschenhalter |

| DE102013004184A1 (de) * | 2013-03-12 | 2014-09-18 | Premark Feg L.L.C. | Spülkorb für Spülmaschinen, insbesondere gewerbliche Spülmaschinen |

| CN204363929U (zh) * | 2014-10-08 | 2015-06-03 | 佛山市顺德区美的洗涤电器制造有限公司 | 洗碗机、用于洗碗机的碗篮组件、奶瓶支撑架 |

| DE102014226808A1 (de) * | 2014-12-22 | 2016-06-23 | BSH Hausgeräte GmbH | Haltevorrichtung, Spülgutaufnahme und wasserführendes Haushaltsgerät |

| US9241554B1 (en) * | 2015-04-02 | 2016-01-26 | Joy Tong | Combination luggage and drink holder assembly |

| DE102018103585A1 (de) * | 2017-03-02 | 2018-09-06 | Miele & Cie. Kg | Haltevorrichtung und Schwenkvorrichtung zur Halterung und Verstellung von Spülgut im Spülkorb und Spülkorb für eine Spülmaschine |

| CN108542330B (zh) | 2018-05-03 | 2023-11-03 | 华帝股份有限公司 | 一种用于洗碗机的多功能碗篮 |

| US10531755B1 (en) * | 2018-12-27 | 2020-01-14 | Pei-Hsiu Huang | Drink holder mounting structure for attaching to various tubular objects |

| US11547230B2 (en) * | 2020-05-21 | 2023-01-10 | Sunflow, Inc. | Cup holder |

-

2019

- 2019-05-28 DE DE102019207812.5A patent/DE102019207812A1/de not_active Withdrawn

-

2020

- 2020-05-27 US US17/609,799 patent/US11766161B2/en active Active

- 2020-05-27 EP EP20728741.8A patent/EP3975815B1/de active Active

- 2020-05-27 PL PL20728741.8T patent/PL3975815T3/pl unknown

- 2020-05-27 CN CN202080039589.XA patent/CN113950275B/zh active Active

- 2020-05-27 WO PCT/EP2020/064665 patent/WO2020239819A1/de unknown

Also Published As

| Publication number | Publication date |

|---|---|

| PL3975815T3 (pl) | 2024-02-19 |

| US20220240750A1 (en) | 2022-08-04 |

| WO2020239819A1 (de) | 2020-12-03 |

| CN113950275B (zh) | 2024-02-09 |

| DE102019207812A1 (de) | 2020-12-03 |

| CN113950275A (zh) | 2022-01-18 |

| US11766161B2 (en) | 2023-09-26 |

| EP3975815A1 (de) | 2022-04-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3975815B1 (de) | Geschirrkorb mit einem gefässhalter und haushaltsgeschirrspülmaschine | |

| DE102005056258B4 (de) | Geschirrspülergestell | |

| DE112005000123B4 (de) | Besteckkorb für eine Geschirrspülmaschine | |

| EP2096979B1 (de) | Geschirrspülmaschine mit einem aufbewahrungsbehälter für zu reinigendes gut | |

| EP3092937B1 (de) | Geschirrspülmaschine mit einer spülgutaufnahme und einer hebevorrichtung für die spülgutaufnahme | |

| EP3357398B1 (de) | Tassenauflage mit einer klemmeinrichtung | |

| DE3022484A1 (de) | Vorrichtung fuer geschirrkoerbe von haushaltgeschirrspuelmaschinen | |

| DE102010042409B4 (de) | Geschirrspülmaschine mit einem ausziehbaren Rahmen und daran abstützbaren Einsätzen | |

| DE102019216603A1 (de) | Etagere, Spülgutaufnahme und Haushalts-Geschirrspülmaschine | |

| EP3037028B1 (de) | Haltevorrichtung, spülgutaufnahme und wasserführendes haushaltsgerät | |

| DE102018103585A1 (de) | Haltevorrichtung und Schwenkvorrichtung zur Halterung und Verstellung von Spülgut im Spülkorb und Spülkorb für eine Spülmaschine | |

| DE60130882T2 (de) | Geschirrspülmaschine mit einem zusätzlichen Besteckkorb | |

| CH646321A5 (de) | Abtropfstaender fuer tafelgeschirr und bestecke. | |

| WO2006058572A1 (de) | Geschirrkorb mit schwenkbarer geschirrhaltevorrichtung | |

| DE102015219620B3 (de) | Spülgutaufnahme für ein flächiges Spülgut in einer Geschirrspülmaschine | |

| EP3266362A1 (de) | Spülgutaufnahme, geschirrkorb und haushalts-geschirrspülmaschine | |

| DE1628594A1 (de) | Geschirrkorbanordnung und -aufhaengung fuer Geschirrspuelmaschinen | |

| EP4003132B1 (de) | Halter, anordnung und haushaltsgeschirrspülmaschine | |

| DE102017201227B3 (de) | Haushaltsgeschirrspülmaschine | |

| EP3195767B1 (de) | Getränkebereiter mit tassentisch | |

| EP4076126B1 (de) | Spülgutaufnahme | |

| DE102014208667A1 (de) | Glashalter zum Halten eines Glases und Anordnung | |

| WO2011006765A2 (de) | Kühlgutträger für ein kältegerät | |

| DE102015106906A1 (de) | Besteckschublade für eine Geschirrspülmaschine | |

| EP3606395B1 (de) | Besteckkorb und haushaltsgeschirrspülmaschine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20220103 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20230404 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502020004759 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20230816 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231216 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231218 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231116 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231216 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231117 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502020004759 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240531 Year of fee payment: 5 |

|

| 26N | No opposition filed |

Effective date: 20240517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230816 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20240515 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240516 Year of fee payment: 5 |