EP3606837B1 - Distributeur de fluide - Google Patents

Distributeur de fluide Download PDFInfo

- Publication number

- EP3606837B1 EP3606837B1 EP18716990.9A EP18716990A EP3606837B1 EP 3606837 B1 EP3606837 B1 EP 3606837B1 EP 18716990 A EP18716990 A EP 18716990A EP 3606837 B1 EP3606837 B1 EP 3606837B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- chamber

- cap

- film

- outlet

- fluid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000012530 fluid Substances 0.000 title claims description 74

- 239000000463 material Substances 0.000 claims description 21

- 238000003780 insertion Methods 0.000 claims description 20

- 230000037431 insertion Effects 0.000 claims description 20

- 230000000694 effects Effects 0.000 claims description 4

- 230000009467 reduction Effects 0.000 claims description 4

- 238000004891 communication Methods 0.000 claims description 2

- 230000001419 dependent effect Effects 0.000 claims 2

- 238000009826 distribution Methods 0.000 description 52

- 210000002445 nipple Anatomy 0.000 description 22

- -1 polypropylene Polymers 0.000 description 21

- 239000004698 Polyethylene Substances 0.000 description 19

- 229920000573 polyethylene Polymers 0.000 description 19

- 239000004743 Polypropylene Substances 0.000 description 10

- 229920001155 polypropylene Polymers 0.000 description 10

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 9

- 235000021183 entrée Nutrition 0.000 description 7

- IMROMDMJAWUWLK-UHFFFAOYSA-N Ethenol Chemical compound OC=C IMROMDMJAWUWLK-UHFFFAOYSA-N 0.000 description 6

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 6

- 229910052782 aluminium Inorganic materials 0.000 description 6

- 239000007788 liquid Substances 0.000 description 6

- 239000007787 solid Substances 0.000 description 6

- 239000007921 spray Substances 0.000 description 6

- 239000005977 Ethylene Substances 0.000 description 5

- 229920001577 copolymer Polymers 0.000 description 5

- 239000005038 ethylene vinyl acetate Substances 0.000 description 4

- 235000019589 hardness Nutrition 0.000 description 4

- 238000002347 injection Methods 0.000 description 4

- 239000007924 injection Substances 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 229920001707 polybutylene terephthalate Polymers 0.000 description 4

- 229920006344 thermoplastic copolyester Polymers 0.000 description 4

- KWKAKUADMBZCLK-UHFFFAOYSA-N 1-octene Chemical compound CCCCCCC=C KWKAKUADMBZCLK-UHFFFAOYSA-N 0.000 description 3

- 239000004411 aluminium Substances 0.000 description 3

- 239000002537 cosmetic Substances 0.000 description 3

- 239000006071 cream Substances 0.000 description 3

- 239000000499 gel Substances 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 235000005921 Cynara humilis Nutrition 0.000 description 2

- 240000002228 Cynara humilis Species 0.000 description 2

- 102000000591 Tight Junction Proteins Human genes 0.000 description 2

- 108010002321 Tight Junction Proteins Proteins 0.000 description 2

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- DQXBYHZEEUGOBF-UHFFFAOYSA-N but-3-enoic acid;ethene Chemical compound C=C.OC(=O)CC=C DQXBYHZEEUGOBF-UHFFFAOYSA-N 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000008021 deposition Effects 0.000 description 2

- 230000008020 evaporation Effects 0.000 description 2

- 238000001704 evaporation Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 229920002725 thermoplastic elastomer Polymers 0.000 description 2

- 210000001578 tight junction Anatomy 0.000 description 2

- 238000002604 ultrasonography Methods 0.000 description 2

- 241000195940 Bryophyta Species 0.000 description 1

- 229920001634 Copolyester Polymers 0.000 description 1

- 241000446313 Lamella Species 0.000 description 1

- 241001080024 Telles Species 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 229920001038 ethylene copolymer Polymers 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000011344 liquid material Substances 0.000 description 1

- 239000004579 marble Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 235000011929 mousse Nutrition 0.000 description 1

- 239000006072 paste Substances 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 230000037452 priming Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/20—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge

- B65D47/2018—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure

- B65D47/2056—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure lift valve type

- B65D47/2062—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure lift valve type in which the deformation raises or lowers the valve stem

- B65D47/2068—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure lift valve type in which the deformation raises or lowers the valve stem in which the stem is lowered by the pressure of the contents and thereby opening the valve

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D35/00—Pliable tubular containers adapted to be permanently or temporarily deformed to expel contents, e.g. collapsible tubes for toothpaste or other plastic or semi-liquid material; Holders therefor

- B65D35/02—Body construction

- B65D35/12—Connections between body and closure-receiving bush

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/0094—Containers having an external wall formed as, or with, a diaphragm or the like which is deformed to expel the contents

Definitions

- the present invention relates to a device for dispensing a fluid.

- the field of the invention is more particularly that of the distribution of fluids such as liquids, gels or creams, for example for the pharmaceutical or cosmetic or food industry.

- CN 105600140A describes a liquid dispenser, typically a cosmetic product, by pressure on a piston.

- FR 2857652A1 describes a valve tip for a dispenser of liquid cosmetic products.

- a first problem is the rigidity of the distribution valve: the distribution valve must both allow the device to be closed properly (to avoid loss or drying of the fluid) and must not be too difficult to open, for example when a single finger of a user presses on the chamber.

- a second problem is the conservation of the fluid in the chamber, in particular so as not to denature the composition of the fluid and/or avoid possible wear or chemical attack on the walls of the chamber by the fluid.

- a third problem is the simplicity of manufacturing the device and/or the reduction in the number of parts making up the device.

- the aim of the present invention is to solve at least one of the aforementioned problems.

- a device according to claim 1 is proposed.

- the device according to the invention may further comprise a chamber film delimiting at least partly the interior volume of the deformable chamber and arranged to be in contact with the support part of the cap.

- the chamber film can be arranged to be positioned between the fluid contained in the deformable chamber and the cap so that the cap is not in contact with the fluid contained in the chamber.

- the device according to the invention may further comprise, inside the chamber, a return means arranged to exert on the chamber film a return force pushing the chamber film against the support surface.

- the chamber film can be welded onto the cap.

- the chamber film can be held by clamping between the cap and the cap.

- the cap may comprise an elongated member provided with two ends, each of these ends having a periphery in contact with the chamber film so that, for each periphery, the chamber film is located between this periphery and the cap.

- the device according to the invention may comprise, among the at least one reservoir film, a reservoir film which can be held by clamping between the cap and the cap.

- the device according to the invention may comprise, among the at least one reservoir film, a reservoir film which can be held between two walls of the cap, these two walls being arranged to come together by pinching this reservoir film after insertion of the cap in the cap under the action of the force exerted by the cap on the cap.

- the chamber film and at least one of the at least one reservoir film may be the same film.

- the cap can be arranged to slide inside the cap with a tight junction between the cap and the cap over a length of at least 5 mm and even at least 6 mm and even at least 10 mm and even at least 15 mm.

- the fluid is typically a liquid, cream, paste, gel, gas or a mixture thereof.

- the fluid preferably comprises a liquid, a cream, a paste, a gel, or a mixture thereof.

- all the solid parts making up this device 100 are made of polypropylene (PP). Some parts can be more flexible than others, for example by varying the thickness of each of these parts.

- the so-called support part 37 is a deformable wall.

- the so-called support part 37 is a flexible surface.

- the device 100 includes a plug 23.

- the cap 32 and the cap 23 are arranged so that the cap 23 is mounted in the cap 32 according to an insertion assembly in the cap 32 on the side of the insertion orifice 33 and in an insertion direction 25.

- plug 23 we do not necessarily mean a solid element.

- the plug 23 can be pierced or allow fluid to pass through.

- the plug 23 can for example be a ring or a ring.

- plug 23, we mean an element inserted in the cap 32.

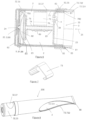

- the device 100 comprises a deformable chamber 2, an interior volume of which is arranged to contain the fluid, the deformable chamber 2 being provided with the outlet 24.

- the outlet 24 separates the interior of the chamber 2 and the exterior of the device 100.

- the device 100 comprises a distribution valve 5 which, in an open state of the valve 5, allows a passage of fluid from the interior of the chamber 2 to the exterior of the device 100 via the outlet 24 of the chamber 2 and, in a closed state of valve 5, does not allow this.

- the distribution valve 5 is typically made of rigid or semi-rigid Polypropylene (PP) or Polyethylene (PE).

- the cap 23 is inserted into the cap 32 on the side of the insertion orifice 33 so that the assembly of the cap 32 and the cap 23 forms the deformable chamber 2 whose interior volume is arranged to contain the fluid.

- the chamber 2 is provided with an inlet 38 so that the device 100 is arranged to conduct the fluid along a fluid circulation path from the inlet 38 then through the chamber 2 then to the exit 24.

- the inlet 38 is provided with a supply valve 4 (typically made of thermoplastic elastomer (TPE) or a copolymer of octene and ethylene of 75 Shore A).

- a supply valve 4 typically made of thermoplastic elastomer (TPE) or a copolymer of octene and ethylene of 75 Shore A).

- the supply valve 4 When open, the supply valve 4 allows the passage of fluid, from a reservoir 3 and into the chamber 2. When it is open, the supply valve 4 allows the passage of fluid, from a reservoir 3 and into the chamber 2. When it is closed, the supply valve 4 does not allow such passage of fluid.

- the supply valve 4 is arranged to open during an increase in the internal volume of the chamber 2 filled with fluid to be distributed or during a depression in the chamber 2 relative to a state of equilibrium of the chamber .

- the supply valve 4 is arranged to close during a reduction in the internal volume of the chamber 2 or during an excess pressure in the chamber 2 compared to the equilibrium state of the chamber.

- valve 4 is preferably closed.

- Inlet 38 passes through plug 23.

- the so-called support part 37 is arranged to be movable so as to modify the interior volume of the chamber 2.

- the distribution valve 5 comprises a nipple 90 (or a rod 90) secured to a movable member of the valve 5.

- the movable member of the valve 5 is entirely included inside the deformable chamber 2.

- the movable member of the valve 5 is arranged to move under the effect of an excess pressure of the fluid, in the interior volume of the chamber 2, greater than a pressure threshold (depending in particular on the total stiffness of the return means 96 ) relative to the state of equilibrium of the chamber 2, so as to move the pin 90 away from the outlet 24 of the chamber 2 so as to move the distribution valve 5 from its closed state to its state open.

- a pressure threshold depending in particular on the total stiffness of the return means 96

- the movable member of the valve 5 is further arranged, in other cases, to keep the valve 5 closed or to move so as to move the pin 90 towards the outlet 24 of the chamber 2 so as to move the valve distribution 5 from its open state to its closed state.

- the movable member of the valve 5 comprises at least one movable wall 91 of at least one gas pocket 92.

- Each movable wall 91 is entirely included inside the deformable chamber 2.

- Three pockets of gas 92 are represented on the figure 2 .

- Each gas pocket 92 contains a gas (typically air) without it being able to escape from this pocket 92.

- Each gas pocket 92 is arranged to isolate this gas (represented by small dots in the figures) relative to to the fluid contained in the deformable chamber 2.

- Each gas pocket 92 is completely surrounded (along a closed loop surrounding this pocket 92 at 360° around this pocket 92) by the fluid contained in the chamber 2.

- each gas pocket 92 has a contact surface 97 arranged to be entirely in contact with the fluid contained in the chamber 2.

- each pocket 92 is defined as being the surface of the wall 91 (typically of thickness less than 1mm or preferably less than 500 ⁇ m) which is on a first side arranged to be in contact with the fluid contained in chamber 2 and on another side opposite the first in contact with the gas of this pocket 92; the surface of the nipple 90 is therefore not counted.

- the sum of the areas of the contact surfaces 97 of the gas pocket(s) 92 is at least thirty-five times (and even at least forty-five times) greater than a minimum area 99 of fluid passage through the outlet 24 of chamber 2.

- This minimum area 99 is the smallest plane passage area of the fluid through outlet 24 towards the outside of chamber 2 and of device 100.

- the sum of the areas of the contact surfaces 97 of the gas pocket(s) 92 is at least 50mm 2 and even greater than 70 mm 2 and even greater than 90 mm 2 .

- Each contact surface 97 is convex on the side of the fluid contained in the deformable chamber 2.

- the device 100 comprises several movable walls 91 of several gas pockets 92 aligned along an axis of elongation of the stud 90, this axis of elongation also being an axis of movement of the stud 90 between the open position and the closed position of valve 5.

- the distribution valve 5 and the at least one gas bag 92 are part of a module 93 inserting into the device 100 from the outside of the device 100.

- the module 93 is welded, preferably by ultrasound, to the rest of the device 100, more precisely to the cap 32.

- the pin 90 and/or the movable member of the valve 5 are arranged to be in contact with the fluid contained in the deformable chamber 2.

- the pin 90 is only arranged to be partially in contact with this fluid contained in the chamber 2: in fact, in the closed position of the valve 5, the end of the pin 90 is hidden from the inside of the chamber 2 via exit 24.

- each movable wall 91 has one of its sides in contact with the gas from its pocket 92.

- the device 100 comprises at least one return means 96 arranged to exert a return force on the pin 90 so as to push the pin 90 towards the outlet 24 of the chamber 2 so as to return the dispensing valve 5 from its open position to its closed position.

- the at least one return means 96 comprises each movable wall 91 (convex and flexible) of gas pocket 92.

- Each movable wall 91 is arranged to deform during its movement.

- the return means 96 (here the movable walls 91) of the different pockets 92 combine their effects and add their stiffnesses for a greater return force or closing force.

- Each wall 91 forms a dome.

- Each gas pocket 92 facilitates, for a user, the passage of the valve 5 from its closed state to its open state, while ensuring good closure of the valve 5 in its closed state.

- the interior volume of the deformable chamber 2 is delimited at least in part by the cap 32.

- the interior volume of the deformable chamber 2 is delimited at least in part by the plug 23.

- the dispensing seat is formed by all the contact points, on the cap 32 and/or the module 93, between the dispensing valve 5 and the cap 32 and/or the module 93 when the valve 5 is in its state farm.

- the distribution seat is stationary.

- each movable wall 91 is rigid.

- Each movable wall 91 is arranged so as not to deform during its movement.

- Each wall 91 forms a piston.

- Each movable wall 91 is not part of the at least one return means 96.

- the at least one return means 96 comprises, for each gas pocket 92, a spring inside this gas pocket 92 and in contact with the movable wall 91 of this gas pocket 92.

- This second variant only includes one gas pocket 92.

- the area of the contact surface 97 of the gas pocket 92 is at least thirty-five times (and even at least forty-five times) greater than the minimum area 99 of fluid passage through the outlet 24 of the bedroom 2.

- the area of the contact surface 97 is at least 50mm 2 and even greater than 70 mm 2 and even greater than 90 mm 2 .

- the movable wall 91 is mounted movable substantially perpendicular to the axis of movement or elongation of the pin 90, preferably by means of a slope 98 by sliding between the pin 90 and the wall 91

- the device 100 is arranged to return a translation movement of the wall 91 different from the elongation axis of the pin 90 in a translation movement of the elongation axis of the pin 90 during the opening/closing phases of valve 5.

- the at least one gas pocket 92 is not part of the module 93.

- the nipple 90 is more rigid or harder than the flexible part and the rigid part (the compared hardnesses being measured in the same unit among Shore A or Shore D).

- the nipple 90 is flush (as illustrated) or protrudes less than 1 mm from the outlet 24.

- the end of the nipple 90 is less than 1 mm from the outlet 24 (in front or behind the outlet 24).

- the TPEE and PBT pair can be replaced by a pair respectively of polypropylene (PP) and octene and ethylene copolymer.

- the end of the stud 90 is in contact with the flexible part 94 along a first contact line, preferably along an edge 51 of the stud 90.

- This first contact line is a closed contact line going around the nipple 90.

- the edge 51 in section view of the pin 90, forms an angle less than 150° on the side of the pin 90.

- the end of the stud 90 is also in contact with the rigid part 95 along a second contact line, preferably along an edge 52 of the cap 32.

- This second contact line is a closed contact line going around the nipple 90.

- the edge 52 in section view of the cap 32, forms an angle less than 150° on the side of the cap 32.

- the pin 90 is arranged so that, when the valve 5 moves from its open position to its closed position, the first contact line is formed before the second contact line.

- the maximum distance between the first contact line and the outside of chamber 2 on the outlet side 24 is less than 6 mm or even 4 mm.

- the maximum distance between the second contact line and the outside of chamber 2 on the outlet side 24 is less than 6 mm or even 4 mm.

- compensation wall 89 is arranged so that a movement of wall 89 inside chamber 2 does not cause movement of pin 90 and therefore of valve 5.

- the compensation wall 89 makes it possible to absorb variations experienced by the fluid in the chamber 2 (for example temperature variation) without such variations opening the valve 5.

- the wall 89 is thinner and/or more flexible or less hard than each wall 91 (the two hardnesses compared being measured in the same unit among Shore A or Shore D).

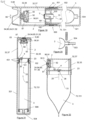

- the device 200 further comprises a chamber film 71 delimiting at least partly the interior volume of the deformable chamber 2 and arranged to be in contact with the support part 37 of the cap 32.

- the chamber film 71 is in contact with the support part 37 at least when a user presses on this support part 37 to reduce the internal volume of the chamber 2.

- the chamber film 71 is positioned between the fluid contained in the deformable chamber 2 and the cap 32 so that at least part of the cap 32 (preferably at least the support part 37) is not in contact with the fluid contained in chamber 2.

- the film 71 is in two parts: a part surrounding the plug 23 and a part placed at the bottom of the cap 32, that is to say opposite the insertion orifice 33.

- the chamber film 71 is positioned between the fluid contained in the deformable chamber 2 and the cap 32 so that the cap 32 is not in contact with the fluid contained in the chamber 2.

- the chamber film 71 is positioned between the fluid contained in the deformable chamber 2 and the cap 32 so that any junction between the cap 32 and the plug 23 is not in contact with the fluid contained in the chamber 2.

- the device 200 further comprises (particularly in the case of a film 71 assembled in the solid state), inside the chamber 2, a return means 73 arranged to exert on the chamber film 71 a force of return pushing the chamber film 71 against the support surface 37.

- the plug 23 comprises an elongated member 74 provided with two ends respectively 75, 76, each of these ends having a periphery respectively 750, 760 in contact with the chamber film 71 so that, for each periphery respectively 750, 760, the film of chamber 71 is located between this perimeter respectively 750, 760 and the cap 32.

- the chamber film 71 forms a tight seal preventing any passage of fluid between the plug 23 and the cap 32 at the level of each periphery 750, 760.

- the end 75 comprises at least one orifice 65 allowing fluid to pass through the end 75.

- Each perimeter 750, 760 forms a 360° closed loop around the elongated member 74.

- the chamber film 71 is welded to the plug 23, more precisely to the end 75 or to the periphery 750 located furthest at the bottom of the cap 32 relative to the orifice 33; particularly in the case of a film 71 assembled in the solid state.

- the chamber film 71 is held, preferably by clamping, between the cap 32 and the plug 23; particularly in the case of a film 71 assembled in the solid state. More precisely, the chamber film 71 is held, preferably by clamping, between the cap 32 and the end 76 or the periphery 760 located least at the bottom of the cap 32 relative to the orifice 33.

- the device 200 further comprises at least one reservoir film 72, extending outwards from the cap 32 so as to form the fluid reservoir 3 in communication with the deformable chamber 2 via the inlet 38 .

- the at least one reservoir film 72 is held in the device 200 at least in part by a force exerted by the plug 23 on the cap 32.

- the device 200 illustrated on the Figure 6 includes two tank films 721, 722.

- each film 72 is welded along a weld line 56 which is preferably common to all of the films 72 (721, 722 ).

- the device 200 naturally comprises a layer of gas (preferably air) between the two films 721 and 722 which avoids a delamination process.

- a layer of gas preferably air

- Films 721 and 722 are two tubes fitted one inside the other.

- the first reservoir film 72, 721 is held by clamping between the cap 32 and the plug 23, more precisely between the cap 32 and the end 76 or the periphery 760 located least at the bottom of the cap 32 relative to at port 33.

- the second reservoir film 72, 722 is held between two walls 81, 82 of the cap 32, these two walls 81, 82 being arranged to come together by pinching the reservoir film 72, 722 after insertion of the plug 23 into the cap 32 under the action of the force exerted by the plug 23 on the cap 32.

- the two walls 81, 82 are concentric and each form a closed loop.

- the second 82 of these walls is an external ring.

- the cap 32 comprises two parts: a part comprising the wall 81 and a part comprising the ring 82.

- the ring 82 is an attached part.

- the first 81 of these walls is a wall of the cap 32 located inside the external ring 82.

- tank film 721 and the chamber film 71 are the same film.

- the 722 film is made of Polyethylene (PE).

- the tank film 721 and/or 722 can be made from a rolled film laminate or an extruded or coextruded tube.

- the film 722 comprises at least one hole 55 hidden under the wall 82 allowing gas or air to enter and exit the space between the two films 721 722, for example during retraction or expansion of the film 721 during a temperature variation.

- the two films 721, 722 are concentric except at the level of the weld 56, that is to say that, except at the level of the weld 56, each of these films 721, 722 form a closed wall surrounding the same axis (common to these two films 721, 722) located inside the reservoir 3.

- the two films 721 and 722 are located on either side of the cap 32.

- the two films 721 and 722 are located on either side of the wall 81 of the cap 32.

- chamber film 71 makes it possible to improve the conservation of the fluid in chamber 2 and avoids chemical attack by the fluid, in particular of the walls of the cap 32 and of the junctions between the cap 32 and the plug 23.

- the chamber film 71 also makes it possible to form a barrier to light and/or air outside the device 200, to avoid evaporation of the fluid contained in the chamber 2, and to avoid denaturing the composition. of the fluid contained in chamber 2.

- reservoir film 72 makes it possible to simplify the manufacturing process of the device 200 according to the invention and/or to reduce the number of parts making up the device 200 according to the invention.

- the interior volume of the deformable chamber 2 is delimited at least in part by the film 71 placed between the surface 37 and the chamber 2.

- the interior volume of the deformable chamber 2 is delimited at least in part by the plug 23.

- the movable wall 91 is not convex and does not form a dome, but forms a piston.

- the at least one return means 96 does not include the movable wall 91 but comprises, for each gas pocket 92, a spring inside this gas pocket 92 and in contact with the movable wall 91 of this gas pocket. gas 92.

- This variant does not include the 721 tank film.

- the wall 82 is not a ring. There is no material discontinuity between walls 81 and 82.

- This embodiment 300 will only be described for its differences compared to the second mode 200 of the figures 6 to 11 .

- the device 300 does not include the compensation wall 89 (but may include it in a variant).

- Valve 5 does not include a nipple 90 or return means 96.

- the valve 5 is located in a distribution housing 8.

- Valve 5 is held by clamping in housing 8.

- the dispensing valve 5 comprises a part 11 held (preferably by clamping or clipping) between internal walls of the housing 8.

- Part 11 is immobile between the open and closed states of the distribution valve 5.

- the dispensing valve 5 comprises a movable part 12 which, in the closed state of this dispensing valve 5, is pressed against a dispensing seat 105 so as to block this dispensing seat 105, and in the open state of this distribution valve 5, moves away from the distribution seat 105 so as to open this distribution seat 105.

- This part 12 is a membrane or lamella.

- Part 12 is movable between the open and closed states of the distribution valve 5.

- the dispensing seat 105 is a lateral part of the internal walls of the housing 8, that is to say that this seat 105 is limited to one face, preferably flat (or curved), of the internal walls of the housing 8, and does not go all the way around a section of housing 8 which would be produced in a plane perpendicular to the direction of elongation of the part of housing 8 containing the valve 5.

- the chamber film 71 delimiting at least partly the interior volume of the deformable chamber 2 and arranged to be in contact with the support part 37 of the cap 32 (at least when a user presses on this support part 37 to reduce the internal volume of the chamber 2) is integral with the part of the plug 23 carrying the inlet 38.

- the film 71 is made of the same material as the part of the plug 23 carrying the inlet 38.

- the film 71 and the part of the cap 23 carrying the inlet 38 form a single piece without material discontinuity.

- Film 71 can be produced by injection.

- the flexibility of the film 71 is obtained by a thickness thinner than the part of the plug 23 carrying the inlet 38.

- the device 300 does not include the return means 73 (even if it could be present in a variant).

- the film 71 (mostly 0.3 mm thick) includes a circumferential extra thickness (approximately 0.8 mm total thickness) inside which the front part 93 is accommodated.

- the front part or module 93 comprises a projecting part 305 relative to the chamber 2 and towards the outlet 24.

- This part 305 extends over a length of at least 3 mm.

- This projecting part 305 extends over at least 3 or even at least 5 or even at least 10 mm in length.

- these two front and rear pieces are joined into a single piece without material discontinuity.

- the reservoir film 72 is integral with the part of the cap 23 carrying the inlet 38.

- the film 72 is made of the same material as the part of the plug 23 carrying the inlet 38.

- the film 72 and the part of the cap 23 carrying the inlet 38 form a single piece without material discontinuity.

- the flexibility of the film 72 is obtained by a thickness thinner than the part of the plug 23 carrying the inlet 38.

- these two front and rear pieces are joined into a single piece without material discontinuity.

- This plug thus forms an exchangeable refill of the device 300.

- This refill integrates the chamber 2.

- This chamber 2 is produced at least in part by the thin cylindrical wall 71.

- the plug 23 may include a portion (pointed) towards the reservoir 3 in order to avoid pinching of the reservoir 3 during its retraction (not illustrated).

- the cover 32 is equipped, on the outside of the cover 32, with an accessory 302 (for example clipped or screwed onto the cover 32) having an orifice which communicates with the outlet 24.

- an accessory 302 for example clipped or screwed onto the cover 32

- the refill 23, 5, 8, 71, 72 (more precisely the front part in which the housing 8 is formed) has a sealing zone 301 with the cap 32 so that the outgoing product does not enter into the cap 32, for example does not fit between the cap 32 and the wall 71 of the deformable chamber.

- the refill 23, 5, 8, 71, 72 is held in the cap 32 by a lateral fitting 304 and the slight tightening in the sealing zone 301.

- the protruding zone 305 emerges from the plug 23 over a length of at least 3 mm or even at least 8 mm.

- the dead zone 306 in the orifice of the accessory 302 communicating with the outlet 24 before the applicator element 309 is less than 15mm and even preferably less than 10mm, ideally less than 5mm in length.

- the distance 307 between the closure of valve 5 and the center of the support zone 37 is more than 20mm.

- Valve 5 enters accessory 302.

- the accessory 302 can be directly integrated into the cap 32.

- Module 93 (including valve 5) is inserted into a nozzle 310 oriented towards the inside of cap 32.

- the interface between module 93 and nozzle 310 is tight to the product to be dispensed.

- This nozzle 310 is part of the cap 32.

- the chamber 2 (more precisely the module 93) comprises a chamber channel 320 which starts at the intersection of the front face 319 of the wall of the chamber 2 and the projecting part 305.

- the distribution seat is in the chamber channel 320 or at most 1 mm after the chamber channel 320.

- the nozzle 310 there are two openings in the nozzle 310: one smaller (P) than the other and one larger (G) than the other.

- a nipple of the valve 5 at the end of the projecting part 12, preferably cylindrical.

- the tightness of this (round) socket is sufficient.

- This protruding part is off-center.

- the device 300 includes indexing means for orienting the cartridge or refill within the device 300.

- This embodiment 400 will only be described for its differences compared to the second mode 200 of the figures 6 to 11 .

- the distribution valve 5 and the at least one gas pocket 92 are part of a module 93 inserting into the device 400 from the inside of the device 400 (more precisely from the inside of the cover 32, more precisely from inside the chamber 2).

- Module 93 is welded, preferably by ultrasound, to the rest of device 400, more precisely to cap 32.

- the module 93 includes a cover 403 fixed (typically welded or fitted) to the tank 402 and delimiting the interior of the pocket 92 with the wall 91.

- the module 93 (more precisely the tank 402) comprises a double wall 404 and is fixed to the rest of the device 400, preferably to the cap 32, by clamping (of the cap 32) between the two walls of this double wall which surround the nipple 90.

- the cap 32 comprises a double wall and is fixed to the module 93 (more precisely to the tank 402) by clamping (of the module 93, more precisely of the tank 402) between the two walls of this double wall which surround the nipple 90.

- the device 400 does not include the compensation wall 89 (but may include it in a variant).

- the device 400 does not include a chamber film 71.

- the interior volume of the deformable chamber 2 is delimited at least in part by the cap 32.

- the interior volume of chamber 2 is delimited at least in part by the so-called support part 37.

- the interior volume of the chamber 2 is also delimited at least in part by the so-called shell part 35.

- the interior volume of the deformable chamber 2 is delimited at least in part by the plug 23.

- the device 400 includes the two reservoir films 721, 722.

- the reservoir film 721 is held in the device 400 at least in part by a force exerted by the plug 23 on the cap 32.

- the film 721 can retract on contact with the product in tank 3.

- the reservoir film 722 is integral with the cap 32.

- Film 722 is made of the same material as cap 32.

- the film 722 and the cap 32 form only one piece without material discontinuity.

- the film 722 can help hide the deformation of the film 721.

- the flexibility of the film 722 is obtained by a thickness thinner than the cap 32 or than the rest of the cap 32.

- each film 721, 722 is welded along one or two weld line(s) 56 which may be common to the whole from films 721, 722.

- the device 400 naturally comprises a layer of gas (preferably air) between the two films 721 and 722.

- a layer of gas preferably air

- Films 721 and 722 are two tubes fitted one inside the other.

- the reservoir film 72, 721 is held by clamping between two walls 181, 182 of the cap 23.

- the two inner walls 181 and outer 182 are concentric and each form a closed loop.

- Wall 181 is integral with wall 182.

- Wall 181 is made of the same material as wall 182.

- the wall 181 and the wall 182 form only one piece without material discontinuity.

- the tank film 721 can protrude from the cap 32, 722 then be welded and pressed into the cap 32 after filling the tank 3 by sliding the cap 23 (for example between 1 and 2 centimeters) forward in direction 25.

- the cap 23 for example between 1 and 2 centimeters

- a spacing element comprising fins 401 of the plug 23 in contact with the cap 32, 35 and preferably emerging from the outer wall 182 arranged to space the films 721 and 722 as illustrated on the Figure 18 in order to allow wall 721 to be pushed towards the inside of cap 32.

- the film 722 is preferably pierced (for example laser drilling) to allow air to pass between the two films 721 and 722.

- the device 400 only includes film 721 but not 722 or only film 722 but not film 721.

- each support surface 37 is arranged to receive a so-called lateral support force, and that the outlet 24 is arranged to distribute fluid according to a direction of distribution perpendicular or substantially perpendicular to each support force.

- the plug 23 is arranged to slide inside the cap 32 with a tight junction between the plug and the cap over a length of at least 5 mm and even at least 6 mm and even at least 10 mm and even at least 15 mm.

- the chamber 2 (more precisely the module 93) comprises a chamber channel 320 which starts at the intersection of the front face 319 of the wall of the chamber 2 and the projecting part 305.

- the distribution seat is in the chamber channel 320 or at most 1 mm after the chamber channel 320.

- This embodiment 500 will only be described for its differences compared to the fourth mode 400 of the figures 17 and 18 .

- This variant of device 500 includes the valve 4 previously described.

- the walls 181 and 182 can be made of the same material or different materials.

- Wall 181 and wall 182 form two distinct parts with a material discontinuity between wall 181 and 182.

- the tube 500 has the base 321 of the housing which can be clipped to the cap 32 (not shown) or to the cap 23.

- Side buttons 501 flexible preferably formed in overmolding or dual injection with the deformable wall 37 make it possible to hide the clips 502. These clips 502 can be made on the cap 23.

- the cover 32 includes feet 508 arranged to place the device 500 upright with its entrance 24 downwards.

- the cap 23 comprises a perforator 505 arranged to pierce a cover of the reservoir 3 pressed into the cap 23 so that the cover thus pierced forms the inlet 38.

- a cartridge formed by the film 72, 721 and a cover can be pressed and pierced on the cap 23, more precisely by the perforator 505.

- Wall 181 is integral with wall 182.

- Wall 181 is made of the same material as wall 182.

- the wall 181 and the wall 182 form only one piece without material discontinuity.

- this variant of device 500 comprises, to pass a tool, a spacing element (comprising fins 401 of the plug 23 in contact with the cap 32,35 and preferably emerging from the outer wall 182) arranged to space the films 721 and 722 as illustrated in the Figure 21 in order to allow wall 721 to be pushed towards the inside of cap 32.

- a spacing element comprising fins 401 of the plug 23 in contact with the cap 32,35 and preferably emerging from the outer wall 182

- the films 721 and 722 as illustrated in the Figure 21 in order to allow wall 721 to be pushed towards the inside of cap 32.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Tubes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1753003A FR3064986B1 (fr) | 2017-04-06 | 2017-04-06 | Distributeur de fluide |

| PCT/EP2018/058610 WO2018185165A1 (fr) | 2017-04-06 | 2018-04-04 | Distributeur de fluide |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3606837A1 EP3606837A1 (fr) | 2020-02-12 |

| EP3606837B1 true EP3606837B1 (fr) | 2024-02-21 |

Family

ID=59745987

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP18716990.9A Active EP3606837B1 (fr) | 2017-04-06 | 2018-04-04 | Distributeur de fluide |

Country Status (7)

| Country | Link |

|---|---|

| US (3) | US11027896B2 (ru) |

| EP (1) | EP3606837B1 (ru) |

| JP (1) | JP7277375B2 (ru) |

| KR (1) | KR102634156B1 (ru) |

| CN (1) | CN110709330A (ru) |

| FR (1) | FR3064986B1 (ru) |

| WO (1) | WO2018185165A1 (ru) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3064986B1 (fr) | 2017-04-06 | 2019-06-28 | Gb Developpement | Distributeur de fluide |

| FR3068265B1 (fr) * | 2017-06-28 | 2022-02-25 | Gb Dev | Distributeur de fluide par pression sur une paroi deformable du contenant |

| USD882409S1 (en) * | 2018-10-25 | 2020-04-28 | Yuangdong Electrical Industry (Shenzhen) Co., Ltd. | Travel bottle |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3008611A (en) * | 1958-03-31 | 1961-11-14 | Chapman Machine Company Inc | Sealing and dispensing device |

| FR2857652A1 (fr) * | 2003-07-15 | 2005-01-21 | Rexam Dispensing Sys | Embout a clapet pour distributeur de produits cosmetiques liquides |

| CN105600140A (zh) * | 2015-11-17 | 2016-05-25 | 周晓青 | 一种吸液式挤液装置 |

| WO2018138231A1 (fr) * | 2017-01-25 | 2018-08-02 | Gb Developpement | Dispositif de distribution de produit a recharge ou module |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2107106A (en) * | 1937-04-30 | 1938-02-01 | James M Crook | Closure for containers of liquid or semiliquid substances |

| US2562317A (en) * | 1946-05-16 | 1951-07-31 | Leo W Krall | Liquid dispenser with a resilient wall pump |

| US2589743A (en) * | 1950-09-25 | 1952-03-19 | Thomas W Snaith | Combination duplex collapsible container and dispensing means |

| FR2597551B1 (fr) * | 1986-04-16 | 1993-11-12 | Alpha Systemes | Pompe distributrice jetable pour des produits liquides ou pateux |

| CH684082A5 (de) * | 1991-12-19 | 1994-07-15 | Sika Robotics Ag | Behälter. |

| IT1256628B (it) * | 1992-12-04 | 1995-12-12 | Distributore di sostanze fluide, con testa deformabile | |

| US5871126A (en) * | 1996-01-22 | 1999-02-16 | Chesebrough-Pond's Usa Co., Division Of Conopco, Inc. | Pump dispenser |

| IT1282759B1 (it) * | 1996-05-29 | 1998-03-31 | Ter Srl | Distributore di sostanze cremose |

| IT1298131B1 (it) * | 1998-01-15 | 1999-12-20 | Capsol S P A Stampaggio Resine | Erogatore di sostanze pastose o cremose |

| JP2002522305A (ja) * | 1998-08-03 | 2002-07-23 | ベレスク バイオシステムズ リミテッド | 容器バルブ |

| CA2367409A1 (en) * | 1999-03-12 | 2000-09-21 | Glaxo Group Limited | Metering valve |

| AUPQ855800A0 (en) * | 2000-07-04 | 2000-07-27 | Brennan, James William | Dispenser head |

| US6675845B2 (en) * | 2001-06-05 | 2004-01-13 | The Procter & Gamble Company | Package and method for controlled metered dose dispensing of a fluid product |

| US7997453B1 (en) * | 2006-07-09 | 2011-08-16 | Yuri Gallegos | Fluid pumping dispenser |

| US8132695B2 (en) * | 2006-11-11 | 2012-03-13 | Medical Instill Technologies, Inc. | Multiple dose delivery device with manually depressible actuator and one-way valve for storing and dispensing substances, and related method |

| US8083103B2 (en) * | 2007-03-14 | 2011-12-27 | Sealed Air Corporation (Us) | Dispenser with dual pump system |

| FR2926116B1 (fr) * | 2008-01-09 | 2012-12-21 | Capital Innovation | Pompe pour produit liquide ou visqueux |

| US8499981B2 (en) * | 2008-02-08 | 2013-08-06 | Gojo Industries, Inc. | Bifurcated stem foam pump |

| WO2009104993A1 (en) * | 2008-02-18 | 2009-08-27 | Sca Hygiene Products Ab | A disposable pump, a dispensing system comprising a pump and a method for dispensing liquid |

| US7861895B2 (en) * | 2008-03-18 | 2011-01-04 | Gojo Industries, Inc. | High velocity foam pump |

| CN102452524A (zh) * | 2010-10-26 | 2012-05-16 | 杜宪勇 | 一种气囊式乳液泵 |

| FR2967141B1 (fr) * | 2010-11-04 | 2014-02-21 | Valois Sas | Tete de distribution de produit fluide et distributeur comprenant une telle tete de distribution. |

| DE102011007396A1 (de) * | 2011-04-14 | 2012-10-18 | Ing. Erich Pfeiffer Gmbh | Austragkopf für eine Tube und Tube mit Austragkopf |

| FR2976981B1 (fr) | 2011-06-27 | 2013-07-05 | Promens Sa | Systeme de fermeture d'un dispositif de distribution a basse pression d'un produit liquide a pateux |

| US8925766B2 (en) * | 2012-01-05 | 2015-01-06 | Gojo Industries, Inc. | Peroxide powered product dispensing system |

| US8875952B2 (en) * | 2012-03-12 | 2014-11-04 | Gojo Industries, Inc. | Air-activated sequenced valve split foam pump |

| FR2999959B1 (fr) * | 2012-12-20 | 2015-08-07 | Aptar France Sas | Distributeur de produit fluide. |

| FR3001719B1 (fr) * | 2013-02-07 | 2016-02-05 | Gb Dev | Dispositif distributeur de fluide et procede de fabrication d'un tel dispositif. |

| US20140231462A1 (en) * | 2013-02-18 | 2014-08-21 | Gojo Industries, Inc. | Metered dose squeeze dispenser |

| FR3019763B1 (fr) * | 2014-04-10 | 2019-11-29 | Gb Developpement | Dispositif distributeur de fluide et valve munie d'un moyen de rappel |

| FR3064986B1 (fr) | 2017-04-06 | 2019-06-28 | Gb Developpement | Distributeur de fluide |

-

2017

- 2017-04-06 FR FR1753003A patent/FR3064986B1/fr active Active

-

2018

- 2018-04-04 EP EP18716990.9A patent/EP3606837B1/fr active Active

- 2018-04-04 WO PCT/EP2018/058610 patent/WO2018185165A1/fr unknown

- 2018-04-04 JP JP2019554872A patent/JP7277375B2/ja active Active

- 2018-04-04 CN CN201880037205.3A patent/CN110709330A/zh active Pending

- 2018-04-04 US US16/603,161 patent/US11027896B2/en active Active

- 2018-04-04 KR KR1020197032959A patent/KR102634156B1/ko active IP Right Grant

-

2021

- 2021-04-29 US US17/244,654 patent/US11365032B2/en active Active

-

2022

- 2022-05-23 US US17/750,474 patent/US11577891B2/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3008611A (en) * | 1958-03-31 | 1961-11-14 | Chapman Machine Company Inc | Sealing and dispensing device |

| FR2857652A1 (fr) * | 2003-07-15 | 2005-01-21 | Rexam Dispensing Sys | Embout a clapet pour distributeur de produits cosmetiques liquides |

| CN105600140A (zh) * | 2015-11-17 | 2016-05-25 | 周晓青 | 一种吸液式挤液装置 |

| WO2018138231A1 (fr) * | 2017-01-25 | 2018-08-02 | Gb Developpement | Dispositif de distribution de produit a recharge ou module |

Also Published As

| Publication number | Publication date |

|---|---|

| FR3064986B1 (fr) | 2019-06-28 |

| US11577891B2 (en) | 2023-02-14 |

| KR102634156B1 (ko) | 2024-02-05 |

| US11365032B2 (en) | 2022-06-21 |

| JP7277375B2 (ja) | 2023-05-18 |

| FR3064986A1 (fr) | 2018-10-12 |

| CN110709330A (zh) | 2020-01-17 |

| BR112019021068A2 (pt) | 2020-05-12 |

| US20220281655A1 (en) | 2022-09-08 |

| EP3606837A1 (fr) | 2020-02-12 |

| US11027896B2 (en) | 2021-06-08 |

| WO2018185165A1 (fr) | 2018-10-11 |

| JP2020512956A (ja) | 2020-04-30 |

| KR20200002896A (ko) | 2020-01-08 |

| US20200031537A1 (en) | 2020-01-30 |

| US20210245938A1 (en) | 2021-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0721573B1 (fr) | Dispositif doseur destine a delivrer des doses unitaires constantes | |

| CA2507610C (fr) | Pompe doseuse a actionnement manuel | |

| EP2841206B1 (fr) | Dispositif de conditionnement et de distribution de produits fluides à pompe manuelle. | |

| EP3606837B1 (fr) | Distributeur de fluide | |

| EP2511196B1 (fr) | Flacon de distribution d'un produit fluide équipé d'une soupape de remplissage | |

| FR2989600A1 (fr) | Tete de distribution et d'application. | |

| WO2003053814A1 (fr) | Dispositif a recipient rigide et poches multiples souples pour le conditionnement et la distribution de fluides. | |

| EP1165246B1 (fr) | Poche et ensemble de conditionnement et de distribution | |

| CA2896254C (fr) | Valve doseuse | |

| EP3645171A1 (fr) | Dispositif pour distribuer un fluide, cartouche pour un dispositif, procédé de fabrication et procédé d'amorçage | |

| WO2018138231A1 (fr) | Dispositif de distribution de produit a recharge ou module | |

| EP0960829B1 (fr) | Valve et ensemble de conditionnement et de distribution équipé d'une telle valve | |

| EP2953724B1 (fr) | Dispositif distributeur de fluide et procede de fabrication d'un tel dispositif | |

| FR2928357A1 (fr) | Obturateur d'organe de distribution de produit fluide. | |

| EP0850851B1 (fr) | Valve pour la distribution de fluides sous pression | |

| WO2019002517A1 (fr) | Dispositif pour distribuer un fluide, cartouche pour un dispositif, procédé de fabrication et procédé d'amorçage | |

| FR3037048B1 (fr) | Valve doseuse | |

| FR3123231A1 (fr) | Valve de distribution d’un produit liquide ou pateux | |

| CA2297765C (fr) | Valve pour dispositif des fluides sous pression | |

| EP4380733A1 (fr) | Distributeur de fluide muni de moyens d'amorcage | |

| FR3118954A1 (fr) | «Distributeur de fluide muni d’un bouton de dosage» | |

| FR3088223A1 (fr) | Procédé de fabrication d'un dispositif distributeur de produit | |

| FR2918965A1 (fr) | Distributeur de produit fluide,notamment d'un echantillon, presentant une zone d'appui entouree d'une zone charniere,et procede de conditionnement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20191031 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20201125 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20230405 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20230905 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602018065498 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240430 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240522 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1658959 Country of ref document: AT Kind code of ref document: T Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240521 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240521 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240521 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240621 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240522 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240430 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240621 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240221 |