EP3557071B1 - Pompe à vide et procédé de fonctionnement d'une telle pompe à vide - Google Patents

Pompe à vide et procédé de fonctionnement d'une telle pompe à vide Download PDFInfo

- Publication number

- EP3557071B1 EP3557071B1 EP18167557.0A EP18167557A EP3557071B1 EP 3557071 B1 EP3557071 B1 EP 3557071B1 EP 18167557 A EP18167557 A EP 18167557A EP 3557071 B1 EP3557071 B1 EP 3557071B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pump

- heating device

- sensor

- vacuum

- accordance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 20

- 238000010438 heat treatment Methods 0.000 claims description 152

- 238000005259 measurement Methods 0.000 claims description 7

- 239000007789 gas Substances 0.000 description 20

- 230000001105 regulatory effect Effects 0.000 description 12

- 239000002826 coolant Substances 0.000 description 9

- 238000005086 pumping Methods 0.000 description 6

- 238000007789 sealing Methods 0.000 description 6

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 230000015572 biosynthetic process Effects 0.000 description 4

- 238000001816 cooling Methods 0.000 description 4

- 238000013461 design Methods 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000010926 purge Methods 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 230000001143 conditioned effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000011010 flushing procedure Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D19/00—Axial-flow pumps

- F04D19/02—Multi-stage pumps

- F04D19/04—Multi-stage pumps specially adapted to the production of a high vacuum, e.g. molecular pumps

- F04D19/042—Turbomolecular vacuum pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D27/00—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids

- F04D27/001—Testing thereof; Determination or simulation of flow characteristics; Stall or surge detection, e.g. condition monitoring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D27/00—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids

- F04D27/02—Surge control

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D27/00—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids

- F04D27/02—Surge control

- F04D27/0284—Conjoint control of two or more different functions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/58—Cooling; Heating; Diminishing heat transfer

- F04D29/582—Cooling; Heating; Diminishing heat transfer specially adapted for elastic fluid pumps

- F04D29/584—Cooling; Heating; Diminishing heat transfer specially adapted for elastic fluid pumps cooling or heating the machine

Definitions

- the present invention relates to a vacuum pump, in particular a turbo molecular pump, and a method for operating a vacuum pump.

- the object of the present invention was to provide a vacuum pump which enables a particular desired temperature to be maintained with greater accuracy and at the same time can be produced with less effort.

- the task also consisted of specifying a method for operating a vacuum pump.

- a vacuum pump according to the invention can in particular be configured and / or arranged as a backing pump.

- a vacuum pump according to the invention can in particular be a turbo-molecular pump.

- a vacuum pump according to the invention has at least one pump component, a heating device for heating the pump component and a sensor for detecting a measured variable for the pump operation.

- the sensor is arranged independently of the heating device and the heating device is configured for operation as a function of the measured variable detected by the sensor.

- the sensor can thus be a component that is provided in the vacuum pump independently of the heating device, in particular it detects measured variables that are also used in other ways.

- the sensor can detect a measured variable and make it available to other devices than the heating device provided according to the invention, in particular for functionalities of the vacuum pump that are not directly related to the heating functionality of the heating device.

- the pump component can be heated with increased accuracy, since the operation takes place as a function of measurement data from an independently arranged sensor.

- the sensor which is provided independently of the heating device, the respective measured variable to be determined can be detected more closely or directly at the desired location of the vacuum pump or the respective pump component.

- the heating effect of the heating device on the critical part of the vacuum pump in each case can thus be recorded without delay or with only a slight delay.

- the heating output of the heating device can be precisely adjusted as a function of this.

- the operating precision of the heating device can be improved overall as a result.

- the heating device remains deactivated in a pump run-up mode.

- a pump run-up operation there is typically a proportional high power consumption of a pump drive, for example more than 80 watts, in particular 90 to 100 watts. Since this absorbed power is largely given off as heat loss, additional heating by the heating device can be omitted.

- the heating device can remain in a deactivated state.

- the heating device remains deactivated in a vacuum-generating mode.

- a vacuum-generating operation for example, a vacuum chamber is pumped empty so that there is a relatively high gas load.

- a pump drive consumes a relatively high power, for example more than 40 watts, in particular 50 to 60 watts.

- the correspondingly introduced heat loss can be sufficient to heat a pump component or to maintain a pump component temperature, so that no further heating by the heating device is required.

- the senor is designed to detect a measured variable for the control and / or regulation of the pump operation, in particular a pump drive.

- a measured variable for the control and / or regulation of the pump operation in particular a pump drive.

- the measured variable detected by the sensor in each case triggers an increase, maintenance or decrease in the pump drive power.

- the measured variable recorded in each case can also trigger an emergency measure such as an emergency stop.

- the sensor can also be designed to detect a measured variable for influencing the pump operation via a pump control and / or pump regulating device. Accordingly, the measured variable recorded in each case can be made available to a pump control and / or pump regulating device and this can be adapted to the current pump operation as a function of the respective measured value or the development of the measured value.

- the senor is designed to detect a measured variable that is only reproduced for informational purposes, so that, for example, an operator can take the current measured values of the measured variable from a display device. Depending on the measured value, an operator can thus be prompted to change or maintain the pump operation.

- the senor is arranged at a distance from the heating device, in particular in a pump interior.

- the design freedom is increased as a result, since the position of the heating device can in particular be selected independently of the position of the sensor.

- the sensor can be arranged at a critical point of the vacuum pump to detect a measured variable, so that the greatest possible precision can be achieved in the detection of the respective measured variable.

- the sensor can be set up to detect a measured variable on or in the pump component.

- the pump component in question can be, for example, the pump housing, a section of the pump housing or a component arranged within the pump housing.

- the choice of the position of the heating device can be chosen with a view to a simple overall conception, simple assembly and / or with regard to simple exchangeability of the heating device.

- the choice of the position of the heating device can be chosen with a view to a favorable transfer of a heating power to the respective pump component to be heated.

- the senor is a temperature sensor.

- the measured variable to be recorded can therefore be a temperature act, in particular a component temperature or a temperature of the respective medium to be conveyed.

- the sensor can be set up to detect a pump operating temperature and / or to detect the temperature of the pump component, in particular to detect a predefined maximum temperature of the pump component. On the one hand, this ensures a high level of operational safety. Furthermore, this creates the possibility of aligning the pump operation with a specific temperature of the pump component. For example, in order to maintain a respectively predefined temperature of the pump component, the pump drive can be controlled accordingly and / or the heating device can be operated accordingly.

- the heating device is designed without a temperature sensor.

- a heating device can therefore be provided which is completely designed without a temperature sensor, whereby the number of components of the vacuum pump can be reduced in a particularly advantageous manner. In this way, in particular, the manufacturing costs for a vacuum pump according to the invention can also be reduced.

- the heating device can be designed for connection to an external and / or separately arranged temperature sensor.

- a connection can be provided, for example, directly wired or wirelessly or also indirectly via a separate control and / or regulating device.

- a heating device can be precisely regulated during operation, as a result of which the operational reliability of a vacuum pump according to the invention can be further improved.

- the heating device can be attached externally or arranged in a pump interior.

- An external arrangement the heating device for example on a housing of the vacuum pump, enables easy-to-use assembly and also easy-to-use replacement of the heating device.

- the heating power can be transferred in a particularly effective manner to the pump component to be heated, and thus introduced directly into the temperature-critical part of the vacuum pump.

- the heating device can, for example, be arranged on a pump housing and / or be arranged for heating the pump housing.

- the heating device can directly heat the pump housing or a section of the pump housing.

- the heating device is set up for the direct heating of a pump component which is arranged within the pump housing or on it.

- the heating device can be set up to maintain a minimum temperature and / or a maximum temperature.

- a pump temperature or pump component temperature reached in pump operation by the power consumption of the pump drive can be maintained independently of the further power consumption by the pump drive.

- the heating device can be set up for heating up to a minimum temperature and / or a maximum temperature.

- the vacuum pump or the respective pump component can be conditioned before operation, so that the respectively desired temperature conditions are already present at the beginning of the respective pump operation. The operating properties of the vacuum pump can be further improved in this way.

- the heating device can be set up to be activated when the temperature falls below a predefined limit temperature and / or to be deactivated when the predefined limit temperature is exceeded.

- the heating device can be deactivated or activated.

- the limit temperature desired in each case can subsequently be maintained with relatively great precision.

- a second aspect of the present invention relates to a vacuum pump, in particular a turbomolecular pump, with a pump drive and with a heating device for heating at least one pump component, the heating device being configured to operate as a function of the power consumed by the pump drive.

- the operation of the heating device enables a particularly constant heat input as a function of the power consumed by the pump drive. This is due to the fact that turbomolecular pumps provide a relatively low delivery rate and the majority of the electrical power consumed by the pump drive occurs as heat loss. If the heating device is now configured for operation as a function of the power consumed by the pump drive, the heat loss caused by the pump drive can be supplemented in a targeted manner by the heating power of the heating element in order to ensure a constant overall loss or heat power. A predefined or desired operating temperature of the vacuum pump or of the respective pump component or also of a plurality of pump components can in this way be maintained with a high degree of reliability.

- the heating device of the vacuum pump also remains deactivated in a pump run-up mode and in a vacuum-generating mode.

- a vacuum pump described above according to the second aspect of the invention can advantageously also be designed according to the first aspect of the invention. Accordingly, the configuration according to the first aspect of the invention can be combined with the configuration according to the second aspect of the invention.

- the heating device for operation as a function of a power consumed by the pump drive and, at the same time, as a function of a measured variable detected by a sensor arranged independently of the heating device. Consequently, both the power consumed by the pump drive and the measured variable detected by the sensor can be decisive for the operation of the heating device.

- the operational safety and heating accuracy can be further improved in this way.

- the heating device is preferably configured for operation as a function of predefined process steps or at least one further sensor.

- the further sensor can be a sensor provided in addition to a temperature sensor, for example a pressure sensor or a flow rate sensor. As a result, the operational reliability of the vacuum pump can be further improved.

- the heating device when the power consumption of a pump drive increases, the heating device is set up to reduce the heating power and / or to maintain a deactivated state. In this way, the heat input can be limited to the heat loss from the pump drive, which can reduce the risk of overheating.

- the heating device when the power consumption of a pump drive is reduced, the heating device is set up to activate the heating mode and / or to increase the heating output.

- the heat loss introduced by the pump drive can in this way be supplemented in a targeted manner by the heat output of the heating device, whereby the risk of undesired cooling of the vacuum pump or the respective pump component can be reduced.

- the heating device can be set up to be activated in a vacuum-maintaining operation or to increase the respective heating output.

- a vacuum-maintaining operation the respective vacuum chamber is already pumped empty and the vacuum pump can be operated at an operating point without gas load.

- the The power consumed by the pump drive is relatively low, so that there is also a correspondingly low heat loss.

- the heating device can be activated or the heating power can be increased in this operating state.

- the pump drive can consume only 20 watts or less of power, so that a heating output of around 80 watts can be provided.

- an available total power of about 100 W can be divided into 20 watts for the pump drive and about 80 watts for the heating device.

- a pump drive with a power supply unit is provided and the heating device is set up to draw power from the power supply unit of the pump drive.

- This enables a more efficient use of existing components, so that overall the number of required components can be reduced.

- valves and / or fans can be set up for drawing power from the power supply unit.

- the available power of the power supply unit can be divided at least between the pump drive and the heating device.

- the available power of the power supply unit can be completely divided, in particular between all consumers that are connected to the power supply unit of the pump drive. This way it becomes independent of the a substantially constant heating achieved in each case by the power consumed by the pump drive. This enables an overall simple and compact structure with a high level of operational reliability at the same time.

- the pump control and / or pump regulating device can preferably be set up to control all consumers connected to the power supply unit of the pump drive as a function of a pump operating state, in particular an electrical power consumed by the pump drive and / or a measured variable detected by the sensor . This ensures an overall safe and efficient pump operation.

- Another aspect of the present invention relates to a method for operating a vacuum pump, in particular a vacuum pump described above, in which a measured variable for the pump operation is detected by a sensor, and in which a pump component is provided by a heating device arranged independently of the sensor as a function of the the measured variable recorded by the sensor is heated.

- Yet another aspect of the invention relates to a method for operating a vacuum pump, in particular a vacuum pump described above, in which a pump drive consumes power from a power supply unit and in which a heating device heats at least one pump component depending on the power consumed by the pump drive.

- the heating device of the vacuum pump remains deactivated in a pump run-up mode and in a vacuum-generating mode.

- the above-mentioned methods for operating a vacuum pump can be combined with one another. Accordingly, there is the possibility that a pump component is heated by a heating device arranged independently of the sensor as a function of the measured variable detected by the sensor and as a function of the power consumed by the pump drive.

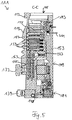

- the turbo molecular pump 111 shown comprises a pump inlet 115 which is surrounded by an inlet flange 113 and to which a recipient (not shown) can be connected in a manner known per se.

- the gas from the recipient can be sucked out of the recipient via the pump inlet 115 and conveyed through the pump to a pump outlet 117 to which a backing pump, such as a rotary vane pump, can be connected.

- the inlet flange 113 forms according to FIG Fig. 1 the upper end of the housing 119 of the vacuum pump 111.

- the housing 119 comprises a lower part 121 on which an electronics housing 123 is arranged laterally. Electrical and / or electronic components of the vacuum pump 111 are accommodated in the electronics housing 123, for example for operating an electric motor 125 arranged in the vacuum pump. A plurality of connections 127 for accessories are provided on the electronics housing 123.

- a data interface 129 for example in accordance with the RS485 standard, and a power supply connection 131 are arranged on the electronics housing 123.

- a flood inlet 133 in particular in the form of a flood valve, is provided on the housing 119 of the turbo molecular pump 111, via which the vacuum pump 111 can be flooded.

- a sealing gas connection 135, which is also referred to as a purge gas connection via which purge gas to protect the electric motor 125 from the gas conveyed by the pump into the engine compartment 137, in which the electric motor 125 in the vacuum pump 111 is housed, can be brought.

- Two coolant connections 139 are also arranged in the lower part 121, one of the coolant connections being provided as an inlet and the other coolant connection being provided as an outlet for coolant, which can be passed into the vacuum pump for cooling purposes.

- the lower side 141 of the vacuum pump can serve as a standing surface, so that the vacuum pump 111 can be operated standing on the lower side 141.

- the vacuum pump 111 can, however, also be attached to a recipient via the inlet flange 113 and can thus be operated in a suspended manner, as it were.

- the vacuum pump 111 can be designed in such a way that it can also be put into operation when it is oriented in a different way than in FIG Fig. 1 is shown.

- Embodiments of the vacuum pump can also be implemented in which the underside 141 cannot be arranged facing downwards, but facing to the side or facing upwards.

- various screws 143 are also arranged by means of which components of the vacuum pump not specified here are attached to one another.

- a bearing cap 145 is attached to the underside 141.

- Fastening bores 147 are also arranged on the underside 141, via which the pump 111 can be fastened to a support surface, for example.

- a coolant line 148 is shown, in which the coolant introduced and discharged via the coolant connections 139 can circulate.

- the vacuum pump comprises several process gas pump stages for conveying the process gas present at the pump inlet 115 to the pump outlet 117.

- a rotor 149 is arranged in the housing 119 and has a rotor shaft 153 rotatable about an axis of rotation 151.

- the turbo-molecular pump 111 comprises several turbo-molecular pump stages connected in series with one another with several radial rotor disks 155 fastened to the rotor shaft 153 and stator disks 157 arranged between the rotor disks 155 and fixed in the housing 119.

- a rotor disk 155 and an adjacent stator disk 157 each form a turbomolecular one Pumping stage.

- the stator disks 157 are held at a desired axial distance from one another by spacer rings 159.

- the vacuum pump also comprises Holweck pump stages which are arranged one inside the other in the radial direction and are connected in series with one another for effective pumping.

- the rotor of the Holweck pump stages comprises a rotor hub 161 arranged on the rotor shaft 153 and two cylinder-jacket-shaped Holweck rotor sleeves 163, 165 which are attached to the rotor hub 161 and carried by the latter, which are oriented coaxially to the axis of rotation 151 and nested in one another in the radial direction.

- two cylinder jacket-shaped Holweck stator sleeves 167, 169 are provided, which are also oriented coaxially to the axis of rotation 151 and, viewed in the radial direction, are nested inside one another.

- the active pumping surfaces of the Holweck pump stages are formed by the jacket surfaces, that is to say by the radial inner and / or outer surfaces, of the Holweck rotor sleeves 163, 165 and the Holweck stator sleeves 167, 169.

- the radial inner surface of the outer Holweck stator sleeve 167 lies opposite the radial outer surface of the outer Holweck rotor sleeve 163 with the formation of a radial Holweck gap 171 and with this forms the first Holweck pump stage following the turbomolecular pumps.

- the radial inner surface of the outer Holweck rotor sleeve 163 faces the radial outer surface of the inner Holweck stator sleeve 169 with the formation of a radial Holweck gap 173 and forms with this a second Holweck pumping stage.

- the radial inner surface of the inner Holweck stator sleeve 169 lies opposite the radial outer surface of the inner Holweck rotor sleeve 165 with the formation of a radial Holweck gap 175 and with this forms the third Holweck pumping stage.

- a radially running channel can be provided, via which the radially outer Holweck gap 171 is connected to the central Holweck gap 173.

- a radially running channel can be provided at the upper end of the inner Holweck stator sleeve 169, via which the middle Holweck gap 173 is connected to the radially inner Holweck gap 175.

- a connecting channel 179 to the outlet 117 can also be provided at the lower end of the radially inner Holweck rotor sleeve 165.

- the aforementioned pump-active surfaces of the Holweck stator sleeves 163, 165 each have a plurality of Holweck grooves running spirally around the axis of rotation 151 in the axial direction, while the opposite lateral surfaces of the Holweck rotor sleeves 163, 165 are smooth and the gas for operating the Drive vacuum pump 111 in the Holweck grooves.

- a roller bearing 181 is provided in the area of the pump outlet 117 and a permanent magnetic bearing 183 in the area of the pump inlet 115.

- a conical injection molded nut 185 is provided on the rotor shaft 153 with an outer diameter that increases towards the roller bearing 181.

- the injection-molded nut 185 is in sliding contact with at least one stripper of an operating medium reservoir.

- the operating medium reservoir comprises several absorbent disks 187 stacked on top of one another, which are impregnated with an operating medium for the roller bearing 181, e.g. with a lubricant.

- the operating medium is transferred by capillary action from the operating medium reservoir via the scraper to the rotating injection nut 185 and, as a result of the centrifugal force, is conveyed along the injection nut 185 in the direction of the increasing outer diameter of the injection nut 92 to the roller bearing 181, where it eg fulfills a lubricating function.

- the roller bearing 181 and the operating medium store are enclosed in the vacuum pump by a trough-shaped insert 189 and the bearing cover 145.

- the permanent magnetic bearing 183 comprises a rotor-side bearing half 191 and a stator-side bearing half 193, each of which comprises a ring stack of several permanent magnetic rings 195, 197 stacked on top of one another in the axial direction.

- the ring magnets 195, 197 are opposite one another with the formation of a radial bearing gap 199, the rotor-side ring magnets 195 being arranged radially on the outside and the stator-side ring magnets 197 being arranged radially on the inside.

- the magnetic field present in the bearing gap 199 causes magnetic repulsive forces between the ring magnets 195, 197, which cause the rotor shaft 153 to be supported radially.

- the rotor-side ring magnets 195 are carried by a carrier section 201 of the rotor shaft 153 which surrounds the ring magnets 195 radially on the outside.

- the stator-side ring magnets 197 are carried by a stator-side carrier section 203 which extends through the ring magnets 197 and is suspended from radial struts 205 of the housing 119.

- the ring magnets 195 on the rotor side are fixed parallel to the axis of rotation 151 by a cover element 207 coupled to the carrier section 203.

- the stator-side ring magnets 197 are fixed parallel to the axis of rotation 151 in one direction by a fastening ring 209 connected to the carrier section 203 and a fastening ring 211 connected to the carrier section 203.

- a plate spring 213 can also be provided between the fastening ring 211 and the ring magnet 197.

- An emergency or backup bearing 215 is provided inside the magnetic bearing, which runs empty during normal operation of the vacuum pump 111 without contact and only comes into engagement with an excessive radial deflection of the rotor 149 relative to the stator in order to provide a radial stop for the rotor 149 form, since a collision of the rotor-side structures with the stator-side structures is prevented.

- the backup bearing 215 is designed as an unlubricated roller bearing and forms a radial gap with the rotor 149 and / or the stator, which has the effect that the backup bearing 215 is disengaged during normal pumping operation.

- the radial deflection at which the backup bearing 215 engages is dimensioned large enough that the backup bearing 215 does not come into engagement during normal operation of the vacuum pump, and at the same time small enough that a collision of the rotor-side structures with the stator-side structures under all circumstances is prevented.

- the vacuum pump 111 comprises the electric motor 125 for rotatingly driving the rotor 149.

- the armature of the electric motor 125 is formed by the rotor 149, the rotor shaft 153 of which extends through the motor stator 217.

- a permanent magnet arrangement can be embedded radially on the outside or embedded in the section of the rotor shaft 153 extending through the motor stator 217 be arranged.

- the motor stator 217 is fixed in the housing within the motor compartment 137 provided for the electric motor 125.

- a sealing gas which is also referred to as a flushing gas and which can be air or nitrogen, for example, can enter the engine compartment 137 via the sealing gas connection 135.

- the electric motor 125 can be protected from process gas, e.g. from corrosive components of the process gas, via the sealing gas.

- the engine compartment 137 can also be evacuated via the pump outlet 117, i.e. the vacuum pressure produced by the backing pump connected to the pump outlet 117 is at least approximately in the engine compartment 137.

- a so-called and known labyrinth seal 223 can also be provided between the rotor hub 161 and a wall 221 delimiting the engine compartment 137, in particular to achieve better sealing of the motor compartment 217 from the Holweck pump stages located radially outside.

- the turbo molecular pump of the Figs. 1 to 5 forms a vacuum pump according to the invention.

- the Fig. 6 shows details which are also used in a turbo molecular pump according to FIGS Figs. 1 to 5 can be provided, even if they are not expressly shown there.

- FIG. 11 shows a schematic block diagram of a turbo molecular pump 111 according to an embodiment of the present invention.

- the one in the Fig. 6 The turbo molecular pump 111 shown has a plurality of pump components 225, a heating device 227 for heating at least one of the pump components 225 and a sensor 229 for detecting a measured variable for the pump operation.

- a sensor 229 for detecting a measured variable for the pump operation.

- several sensors 229 can also be provided, for example one sensor 229 per pump component 225.

- the senor 229 is arranged independently of the heating device 227.

- the sensor 229 is not arranged as part of the heating device 227 or within the heating device 227, but rather at a distance therefrom.

- the sensor 227 can, for example, be arranged in a pump interior, in particular in or on a pump component 225, and can thus be set up to detect a measured variable directly in or on the pump component 225. As a result, the respective measured variable can be recorded in critical areas or adjacent to critical areas of the turbo molecular pump 111.

- the sensor 229 can be designed to detect a measured variable for the control and / or regulation of the pump operation, in particular a pump drive 231.

- the pump drive 231 can correspond to or have the electric motor 125 described above.

- the sensor 229 can furthermore be designed to influence the pump operation, in particular the pump drive 231, via a pump control and / or pump regulating device 233.

- the sensor 229 can be connected to the pump control and / or pump regulating device 233, in particular via a wired or wireless data connection.

- the sensor 229 can in particular be designed as a temperature sensor. Accordingly, the sensor 229 can be set up to detect a pump operating temperature and / or to detect the temperature of the pump component 225, in particular to detect a predefined maximum temperature of the pump component 225.

- the heating device 227 is now configured for operation as a function of the measured variable detected by the sensor 225, in particular a detected temperature.

- the heating operation of the heating device 227 accordingly takes place as a function of sensor data, in particular temperature data, which are detected by the sensor 229.

- the heating device 227 can thus be designed without its own sensors, as a result of which the number of components can be reduced.

- the sensor 229 can be connected directly to the heating device 227, in particular via a data connection.

- the sensor 229 can be indirectly connected to the heating device 227 via the pump control and / or pump regulation device 233.

- the latter applies in particular in the case of the control and / or regulation of the heating device 227 via the pump control and / or pump regulation device 233.

- the data connections can be wired or wireless.

- the heating device 227 can be set up to maintain a minimum temperature and / or maximum temperature and / or to heat up to a minimum temperature and / or maximum temperature.

- This can be a temperature detected by the sensor 229 on the pump component 225, wherein the respective minimum or maximum temperature can be predefined, in particular with regard to the desired operating properties of the turbo-molecular pump 111 and / or with regard to the material and wear properties of the respective Pump component 225.

- the minimum temperature can be selected with regard to a low tendency to condensation and the maximum temperature can be selected with regard to permissible material stress.

- the heating device 227 can also be set up to be activated when falling below a predefined limit temperature and / or to be deactivated when the predefined limit temperature is exceeded. Furthermore, the heating power of the heating device 227 can be adjusted and / or regulated when the temperature falls below or exceeds the limit temperature.

- the predefined limit temperature can be a maximum or minimum temperature. The heating device 227 can thus be set up to be switched on and off completely in pump operation. The heating device 227 can also be controlled by means of pulsed, linearly variable or discrete intermediate values.

- the turbo molecular pump 111 has a pump drive 231.

- the heating device 227 can be configured for operation as a function of the power consumed by the pump drive 231. For example, when the power consumption of the pump drive 231 increases, the heating device 227 can be set up to maintain a deactivated state and / or to reduce the heating output.

- the heating device 227 can be set up to activate the heating mode and / or to increase the heating output. Furthermore, the heating device 227 is set up to remain deactivated in a pump run-up mode and in a vacuum-generating mode. In a vacuum-maintaining operation, the heating device can be activated. The heating power can be activated and / or deactivated and / or changed by the pump control and / or pump regulating device 233 or by a separate unit correspondingly provided in the heating device 227.

- the pump drive 231 has a power supply unit 235.

- the power supply unit 235 can - unlike in Fig. 6 shown - be arranged outside the pump drive 231 and connected to it.

- the heating device 227 is set up to draw power from the power supply unit 235 of the pump drive 231.

- the heating device 227 therefore does not need its own power supply unit, so that the number of components of the turbo molecular pump 111 can be further reduced.

- Further components and / or devices of the vacuum pump can also be set up to draw power from the power supply unit 235 of the pump drive 231, such as the pump control and / or pump regulating device 233.

- all consumers of the turbo molecular pump 111 can be used to draw power from the power supply unit 235 of the pump drive 231 be set up.

- the available power of the power supply unit 235 can be divided at least between the pump drive 231 and the heating device 227.

- the available power of the power supply unit 235 can be completely divided between the respective connected consumers.

- available 100 watts from a power supply unit 235 designed as a power supply unit can essentially be divided between the pump drive 231 and the heating device 227.

- the division can be made depending on the operating status. For example, 90 watts can be required by the pump drive 231 in a pump run-up operation.

- the heater 227 remains deactivated. In an operation that generates a vacuum, for example, a vacuum chamber is pumped empty so that there is a relatively high gas load.

- the pump drive 231 can here, for example, require 50 watts.

- the heating device 227 remains deactivated.

- a vacuum chamber In a vacuum-maintaining operation, a vacuum chamber is already pumped empty, so that there is a relatively low or no gas load.

- the turbo-molecular pump 111 is therefore operated at an operating point with no or only a low gas load, so that the pump drive 231 requires, for example, 20 watts or less.

- the heating device 227 can be operated with 80 watts in order to prevent the pump component 225 from cooling down too much.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Non-Positive Displacement Air Blowers (AREA)

Claims (15)

- Pompe à vide, en particulier pompe turbomoléculaire (111), comportant au moins un composant de pompe (225), un dispositif de chauffage (227) pour chauffer le composant de pompe (225), et un capteur (229) pour détecter une grandeur de mesure pour le fonctionnement de la pompe, le capteur (229) étant disposé indépendamment du dispositif de chauffage (227), et le dispositif de chauffage (227) étant configuré pour fonctionner en fonction de la grandeur de mesure détectée par le capteur (229),

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour rester désactivé dans un mode de montée en puissance de la pompe et/ou dans un mode de génération de vide. - Pompe à vide selon la revendication 1,

caractérisée en ce que

le capteur (229) est réalisé pour détecter une grandeur de mesure pour commander et/ou réguler le fonctionnement de la pompe, en particulier un entraînement de pompe (231), et/ou pour influencer le fonctionnement de la pompe par l'intermédiaire d'un dispositif de commande et/ou de régulation de pompe (233). - Pompe à vide selon la revendication 1 ou 2,

caractérisée en ce que

le capteur (229) est disposé à distance du dispositif de chauffage (227), en particulier dans un espace intérieur de la pompe, et/ou en ce que le capteur (229) est conçu pour détecter une grandeur de mesure sur ou dans le composant de pompe (225). - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

le capteur (229) est un capteur de température et/ou est conçu pour détecter une température de fonctionnement de la pompe et/ou pour détecter la température du composant de pompe (225), en particulier pour détecter une température maximale prédéfinie du composant de pompe (225). - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce quele dispositif de chauffage (227) est dépourvu de capteur de température et/ou est réalisé pour être relié à un capteur de température (229) externe et/ou disposé séparément, et/ou en ce quele dispositif de chauffage (227) est monté à l'extérieur ou est disposé dans un espace intérieur de la pompe. - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour maintenir une température minimale et/ou une température maximale et/ou pour chauffer jusqu'à une température minimale et/ou une température maximale. - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour être activé lorsque la température tombe en dessous d'une température limite prédéfinie, et/ou pour être désactivé lorsque la température limite prédéfinie est dépassée, et/ou pour ajuster et/ou réguler la puissance de chauffage lorsque la température tombe en dessous de la température limite ou dépasse celle-ci. - Pompe à vide, en particulier selon l'une des revendications précédentes, comprenant un entraînement de pompe (231) et un dispositif de chauffage (227) pour chauffer au moins un composant de pompe (225), le dispositif de chauffage (227) étant configuré pour fonctionner en fonction d'une puissance encaissée par l'entraînement de pompe (231),

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour rester désactivé dans un mode de montée en puissance de la pompe et/ou dans un mode de génération de vide. - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour maintenir un état désactivé et/ou pour réduire la puissance de chauffage lorsque la puissance encaissée par un entraînement de pompe (231) est augmentée. - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour activer le fonctionnement de chauffage et/ou pour augmenter la puissance de chauffage lorsque la puissance encaissé par un entraînement de pompe (231) est réduite. - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

le dispositif de chauffage (227) est conçu pour être activé dans un mode de maintien du vide. - Pompe à vide selon l'une au moins des revendications précédentes,

caractérisée en ce que

il est prévu un entraînement de pompe (231) ayant une unité d'alimentation en puissance (235), et le dispositif de chauffage (227) est cornu pour tirer de la puissance de l'unité d'alimentation en puissance (235) de l'entraînement de pompe. - Pompe à vide selon la revendication 12,

caractérisée en ce que

la puissance électrique disponible de l'unité d'alimentation en puissance (235) est partagée, en particulier complètement partagée, au moins entre l'entraînement de pompe (231) et le dispositif de chauffage (227). - Procédé de fonctionnement d'une pompe à vide, en particulier selon l'une des revendications précédentes,- dans lequel une grandeur de mesure pour le fonctionnement de la pompe est détectée par un capteur (229), et- dans lequel un composant de pompe (225) est chauffé par un dispositif de chauffage (227), disposé indépendamment du capteur, en fonction de la grandeur de mesure détectée par le capteur (229),caractérisé en ce que

le dispositif de chauffage (227) reste désactivé dans un mode de montée en puissance de la pompe et dans un mode de génération de vide. - Procédé de fonctionnement d'une pompe à vide, en particulier selon l'une des revendications précédentes 1 à 13 et/ou conformément à un procédé selon la revendication 14,- dans lequel un entraînement de pompe (231) encaisse de la puissance électrique d'une unité d'alimentation en puissance (235), et- dans lequel un dispositif de chauffage (227) chauffe au moins un composant de pompe (225) en fonction de la puissance encaissée par l'entraînement de pompe (231),caractérisé en ce que

le dispositif de chauffage (227) reste désactivé dans un mode de montée en puissance de la pompe et/ou dans un mode de génération de vide.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP18167557.0A EP3557071B1 (fr) | 2018-04-16 | 2018-04-16 | Pompe à vide et procédé de fonctionnement d'une telle pompe à vide |

| JP2019041548A JP2019183831A (ja) | 2018-04-16 | 2019-03-07 | 真空ポンプおよびこれを作動させるための方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP18167557.0A EP3557071B1 (fr) | 2018-04-16 | 2018-04-16 | Pompe à vide et procédé de fonctionnement d'une telle pompe à vide |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3557071A1 EP3557071A1 (fr) | 2019-10-23 |

| EP3557071B1 true EP3557071B1 (fr) | 2021-09-22 |

Family

ID=62002562

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP18167557.0A Active EP3557071B1 (fr) | 2018-04-16 | 2018-04-16 | Pompe à vide et procédé de fonctionnement d'une telle pompe à vide |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3557071B1 (fr) |

| JP (1) | JP2019183831A (fr) |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3557608B2 (ja) * | 1996-05-30 | 2004-08-25 | 株式会社島津製作所 | ターボ分子ポンプの電源装置 |

| JP2002048088A (ja) * | 2000-07-31 | 2002-02-15 | Seiko Instruments Inc | 真空ポンプ |

| JP2003172292A (ja) * | 2001-12-04 | 2003-06-20 | Shimadzu Corp | ターボ分子ポンプ駆動用電源装置 |

| CN102472288B (zh) * | 2009-08-21 | 2015-03-25 | 埃地沃兹日本有限公司 | 真空泵 |

| JP2013079602A (ja) * | 2011-10-04 | 2013-05-02 | Shimadzu Corp | ターボ分子ポンプ |

| JP6287475B2 (ja) * | 2014-03-28 | 2018-03-07 | 株式会社島津製作所 | 真空ポンプ |

-

2018

- 2018-04-16 EP EP18167557.0A patent/EP3557071B1/fr active Active

-

2019

- 2019-03-07 JP JP2019041548A patent/JP2019183831A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019183831A (ja) | 2019-10-24 |

| EP3557071A1 (fr) | 2019-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2826999B1 (fr) | Pompe à vide | |

| EP3444478B1 (fr) | Pompe à vide | |

| EP3657021B1 (fr) | Pompe à vide | |

| EP2310687B1 (fr) | Pompe à vide | |

| EP3660317A1 (fr) | Appareil à vide | |

| EP3557071B1 (fr) | Pompe à vide et procédé de fonctionnement d'une telle pompe à vide | |

| EP3112687B1 (fr) | Détection de la circulation d'un gaz auxiliaire qui est injecté dans une pompe à vide | |

| EP3438460B1 (fr) | Pompe à vide | |

| EP3683447A1 (fr) | Pompe à vide | |

| EP3653885B1 (fr) | Procédé de détermination d'une information d'état dans un appareil sous vide | |

| EP4108932A1 (fr) | Reciate et pompe à vide élevé | |

| EP3034882B1 (fr) | Pompe à vide | |

| EP3683449B1 (fr) | Palier magnétique et appareil sous vide | |

| DE102020116770B4 (de) | Vakuumpumpe mit integriertem miniaturventil | |

| EP3611383B1 (fr) | Réglage de vitesse de rotation d'un rotor d'une pompe à vide | |

| EP3636933B1 (fr) | Procédé de détermination d'une température utilisant un capteur infrarouge | |

| EP3536966B1 (fr) | Appareil à vide | |

| EP2927501B1 (fr) | Procédé et système pour la détermination et l'évaluation du sens d'encastrement d'un dispositif | |

| EP3650702B1 (fr) | Utilisation d'une huile synthétique dans une pompe à vide et pompe à vide | |

| EP3473858B1 (fr) | Procédé d'optimisation de durée de vie des paliers à rouleaux d'une pompe à vide | |

| EP3926174B1 (fr) | Pompe à vide | |

| EP3327293B1 (fr) | Pompe à vide avec une pluralté d'entrées | |

| EP3051141A1 (fr) | Roulement de rotor | |

| EP4174321B1 (fr) | Pompe à vide | |

| EP3633204B1 (fr) | Pompe à vide |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20200416 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20201005 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20210429 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502018007136 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1432542 Country of ref document: AT Kind code of ref document: T Effective date: 20211015 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210922 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20211222 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20211222 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20211223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220122 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220124 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502018007136 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20220623 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20220430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220416 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220430 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220416 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20180416 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1432542 Country of ref document: AT Kind code of ref document: T Effective date: 20230416 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240419 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240626 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230416 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20240405 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230416 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240424 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210922 |