EP2831957B1 - Système de fusible pour applications à haute intensité - Google Patents

Système de fusible pour applications à haute intensité Download PDFInfo

- Publication number

- EP2831957B1 EP2831957B1 EP13714208.9A EP13714208A EP2831957B1 EP 2831957 B1 EP2831957 B1 EP 2831957B1 EP 13714208 A EP13714208 A EP 13714208A EP 2831957 B1 EP2831957 B1 EP 2831957B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plug connector

- high current

- electrical

- current

- connector

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000013011 mating Effects 0.000 claims description 49

- 238000012423 maintenance Methods 0.000 claims description 11

- 230000000295 complement effect Effects 0.000 claims description 7

- 239000004020 conductor Substances 0.000 description 8

- 238000007789 sealing Methods 0.000 description 5

- 230000001747 exhibiting effect Effects 0.000 description 4

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 230000005672 electromagnetic field Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010292 electrical insulation Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/66—Structural association with built-in electrical component

- H01R13/70—Structural association with built-in electrical component with built-in switch

- H01R13/713—Structural association with built-in electrical component with built-in switch the switch being a safety switch

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H71/00—Details of the protective switches or relays covered by groups H01H73/00 - H01H83/00

- H01H71/10—Operating or release mechanisms

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/52—Dustproof, splashproof, drip-proof, waterproof, or flameproof cases

- H01R13/5219—Sealing means between coupling parts, e.g. interfacial seal

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/53—Bases or cases for heavy duty; Bases or cases for high voltage with means for preventing corona or arcing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/64—Means for preventing incorrect coupling

- H01R13/645—Means for preventing incorrect coupling by exchangeable elements on case or base

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/648—Protective earth or shield arrangements on coupling devices, e.g. anti-static shielding

- H01R13/658—High frequency shielding arrangements, e.g. against EMI [Electro-Magnetic Interference] or EMP [Electro-Magnetic Pulse]

- H01R13/6581—Shield structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R2201/00—Connectors or connections adapted for particular applications

- H01R2201/26—Connectors or connections adapted for particular applications for vehicles

Definitions

- the invention relates to a security system for high-current applications, such a security system exhibiting connector system and such a connector system exhibiting electrical system.

- a power source e.g., battery pack

- a consumer e.g., electrical refrigerant compressor

- the battery unit and the electric traction motor comprehensive electrical (high current) system is operated with a comparatively high voltage, which is in particular higher than 12 V, 24 V or 48V, with the On-board network of conventional motor vehicles is operated.

- the known vehicles with electrified powertrain still still a conventional electrical system, which - as in conventional motor vehicles - based on an electrical voltage of 12 V, 24 V or 48V.

- the vehicle electrical system of conventional and of vehicles with electrified powertrain on the same components be used, thereby saving development and production costs.

- maintenance and repair work on the electrical system can also be carried out by "normal" workshops, since even a malfunction during maintenance due to the weak electrical voltage does not lead to a significant risk to the maintenance personnel.

- the high-current system of electric or hybrid vehicles due to the high voltage is a significant hazard.

- it is therefore intended to design individual components or whole units of the high-current system so that they are not accessible by maintenance personnel. This happens, for example, in that the components or units of the high-current system are installed in housings that can not be opened, at least not nondestructively.

- the components or units of the high-current system are installed in housings that can not be opened, at least not nondestructively.

- the maintenance staff which can be done largely without risk as a result of the electrical insulation of the housing.

- the replacement of functional components which are integrated with a component that is no longer functional in one unit, involves considerable and, in principle, unnecessary costs.

- fuses are also integrated into the high-current system of motor vehicles with electrified drivetrain, which fail ("burn out") at a temporarily inadmissibly high current intensity and thereby permanently interrupt the current flow. This is intended to protect the other high-quality components of the high current system from damage.

- document US5316502 shows a high current protection system with a high current fuse and a housing surrounding the high current fuse, which has an opening which is greater the greater the current provided by the high current fuse.

- the present invention seeks to provide an improved way to hedge high current systems against overcurrent.

- a possibility should be pointed out, in the case of a defect of a high-current fuse of the high-current system, only to replace the high-current fuse, whereby, however, a risk to the replacement maintenance personnel should be excluded.

- a security system according to independent claim 1 A such a security system exhibiting connector system and such a connector system exhibiting electrical system are the subject of the independent claims.

- Advantageous embodiments of the security system according to the invention, the connector system according to the invention and the electrical system according to the invention are the subject of the respective dependent claims and will become apparent from the following description of the invention.

- An inventive safety system for high-current applications comprises a high-current fuse and a high-current fuse surrounding, electrically insulating housing, wherein the housing forms a connector for electrical contacting and mechanical connection with a mating connector.

- the housing forms a connector for electrical contacting and mechanical connection with a mating connector, it can be achieved that the high current fuse can be quickly and easily integrated into an electrical (high current) system.

- An inventive connector system in addition to a security system according to the invention at least one complementary to the connector of the security system mating connector.

- An electrical system comprises an electrical (high current) energy source, an electrical (high current) consumer and a conduit system that connects the energy source and the consumer in an electrically conductive manner, wherein the conduit system comprises at least one connector system according to the invention.

- the housing of the security system is designed to be permanently closed, i. that opening of the housing is not possible nondestructive. This ensures that a removal or replacement of the built-in high-current fuse can not be made in the housing.

- the connector of the housing has a coding which is designed individually, at least in terms of hedged by the high-current fuse amperage. Accordingly, it can be provided, for example, a coding of the connector for a security system that integrates a high-current fuse that secures a current to 20 A, to design differently than in a backup system in which the high-current fuse protects a current up to 40 A.

- individual coding can thus be ensured that a defective security system can be replaced with a blown high current fuse only by a security system with the same current fuse hedging high current fuse.

- the Coding may in particular be formed by one or more individually shaped projections or depressions which cooperate with corresponding complementary recesses / projections of the mating connector. Possibly. is additionally or alternatively a color coding available.

- the coding of the security system according to the invention or the connector system according to the invention can be configured individually not only in terms of the fused current, but it can also - additionally or alternatively - be provided that encodings, which are provided for fuse systems according to the invention in an electrical system according to the invention, distinguish from codes of other connector units used in the electrical system. This may be particularly useful if - as preferably provided - the plug-in interface of the connector system according to the invention - with the exception of the coding - the plug-in interface of the other connector units of the electrical system corresponds.

- the lines of the line system connecting the energy source and the consumer can be connected via corresponding connector units.

- the use of identical as possible connectors in the entire electrical system can help to keep the manufacturing costs for the electrical system low.

- the housing comprises a shield which (at least) surrounds the high-current fuse (preferably completely). By shielding a coupling or decoupling of electromagnetic fields is to be prevented.

- the security system of the connector system serves as a maintenance disconnector, so that in a separation of the security system of the electrical system, the electrical system (at least partially) is de-energized. Accordingly, it may be provided to remove before a maintenance or repair of the electrical system, only the integrated via a plug-in connection in the electrical system backup system, thereby possibly the entire electrical system is de-energized.

- the connector of the fuse system according to the invention and the mating connector of the connector system according to the invention in addition to (at least) two with the high current fuse electrically connected high-current contact elements additionally (at least) have two (low current) contact elements.

- the low-current contact elements may constitute a portion of a low power circuit. An interruption of the weak circuit due to a withdrawal of the security system from the mating connector can then cause the power source of the electrical system according to the invention is de-energized.

- the high-current contact elements and the low-current contact elements are formed or integrated into the security system and the mating connector that contact the mating connector and mating connector first, the high-current contact elements and then the low-current contact elements of connectors and mating connectors.

- the contact of the low-current contact elements and then that of the high current contact elements is repealed. This ensures that at the time of contacting or lifting the contact of the high current contact elements of connector and mating connector no high voltage is applied to this.

- an electrical flashover between not yet or no longer completely contacting high-current contact elements can be avoided.

- a high level of security with appropriate protection of operating or maintenance personnel from unintentional contact with electrical high voltage is achieved by the mating connector with a protection against contact for the high current contact elements and / or the low-current contacts in the unplugged state of the connector system with the class IP1X, ie protected against access with the back of the hand, the class IP2X, ie protected against access with one finger, the class IP3X, ie protected against access with a tool, the class IP4X, ie protected against access with a wire, the class IP5X , ie complete protection against contact, or the class IP6X, ie complete protection against contact, is formed.

- the protection against contact is preferably designed according to DIN EN 60529 in the German version EN 60529: 1991 + A1: 2000.

- the connector between the connector and mating connector is waterproof.

- one or more sealing elements may be provided.

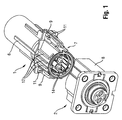

- FIG. 1 an embodiment of a connector system according to the invention is shown.

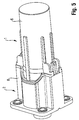

- This includes an inventive security system 1 and a mating connector 2 complementary thereto.

- the mating connector 2 is intended to be fixedly attached to a component.

- passage openings are provided, via which the mating connector can be screwed to the component, for example.

- the mating connector 2 may also be formed as an angle connector.

- the security system 1 comprises a high-current fuse 3 with a substantially conventional construction. Between two end-side cylindrical contact elements 4, a fuse body 5 is arranged, which fails at a strength of the current passed through the high-current fuse 3, which exceeds the maximum fused current, thereby interrupting the circuit in which the high-current fuse 3 is integrated.

- the amount of current through the high-current fuse 3 maximum amperage can be, for example, for use in the electrified powertrain of a motor vehicle - depending on the place of use - either 20 A, 40 A or 60 A.

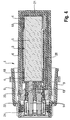

- the security system 1 further comprises a housing 6 made of an electrically insulating plastic, within which the high-current fuse 3 is arranged.

- the housing 6 forms at one end of a connector, with the mating connector 2 of the connector system through Plugged together electrically contacted and can be mechanically connected.

- the plug-in interface of the connector comprises a hollow cylindrical portion 7 of the housing 6, which can be inserted into a corresponding receiving opening of a housing 8 of the mating connector 2.

- On the outside of the housing 6 also two diagonally opposite locking tabs 9 are provided, the plug-side ends are fixed to the hollow cylindrical housing portion 7.

- a plurality of extending in the insertion direction projections 12 are provided on the outside of the hollow cylindrical housing portion 7, a plurality of extending in the insertion direction projections 12 are provided. These engage in the assembled state of the connector system in complementary recesses 13 on the inside of the housing 8 of the mating connector 2 a.

- the projections 12 in combination with the recesses 13 serve as coding, which ensures that on the one hand, the security system 1 with only one orientation in the mating connector 2 can be plugged in, and that on the other hand only the inclusion of a particular embodiment of the security system 1 in the Mating connector 2 is possible.

- the different versions of the security system 1 - in addition to the coding - only differ in the height of the maximum of the high current fuse 3 secured Amperage.

- the plug-in interface of the connector further comprises two electrically isolated high-current contact elements 14 in the form of pins that are plugged in mating the connector system in complementary (electrically isolated) high current contact elements 15 in the form of contact sockets of the mating connector 2 and then contact electrically conductive.

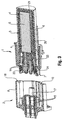

- the high current fuse is integrated into a (high) circuit in order to protect it against overcurrent. This is, for example, a circuit via which an electric traction motor of a motor vehicle is supplied with energy by a battery unit.

- the plug-in interface of the connector still comprises two low-current contact elements in the form of contact pins, which are plugged in mating the connector system in complementary low-current contact elements 16 in the form of contact sockets of the mating connector and then contact electrically conductive.

- the contact sockets are arranged in a female housing 17 of the mating connector 2.

- the function of the low-current contact elements of the connector system is basically a switch, with a low voltage (eg 12 V) operated (weak) circuit is closed when mated connector system and this is interrupted by pulling out of the security system 1 from the mating connector 2.

- the weak circuit may be connected to a control device which interrupts the high-current circuit when the low-current circuit is interrupted, preferably in such a way that as many components of the high-current circuit as possible, including the high-current contact elements 16 of the mating connector, are de-energized are.

- the electrically conductive connection between the high-current contact elements 14, 15 of the security system 1 and the two end-side cylindrical contact elements 4 of the high current fuse takes place at the proximally arranged contact element 4 via a trained as a spring cage 18 contact element, which surrounds the contact element 4 of the high current fuse 3.

- a contact pin 19 connects, which engages in a bush-shaped receptacle of the associated high-current contact element 14.

- a contact element designed as a spring cage 18 is used which surrounds the contact element 4 of the high-current fuse 3.

- this spring basket 18 is located on a portion of a conductor rail 26 which extends to the associated high-current contact element 14 and is screwed thereto.

- the security system 1 within the housing 6 comprises a first outer conductor 20 (made of an electrically conductive material), which surrounds the high-current fuse 3 and a portion of the high-current contact elements 14, but is electrically insulated from these.

- a cover 21 also electrically conductive material.

- the first outer conductor 20 radially contacts a second outer conductor 22, which is designed in the form of a spring cage.

- an electrically conductive connection with a (third) outer conductor 23 is realized, which surrounds the local high current contact elements 15 within the housing 8 of the mating connector 2, but is electrically isolated from these.

- annular sealing element 24 is provided on the inside of the housing 6, which is pushed upon mating of security system 1 and mating connector 2 on an outer surface of an annular extension 25 of the mating connector 2, wherein the sealing member 24 is radially deformed to achieve the desired sealing effect.

- the sealing element 24 is formed by the housings 6, 8 of the security system 1 and mating connector 2, the high-current contact elements 14, 15 and the low-current contact elements 16 receiving contact space sealed against the environment, in particular to prevent ingress of moisture.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Fuses (AREA)

- Connector Housings Or Holding Contact Members (AREA)

Claims (11)

- Système de sécurisation (1) pour applications à courants forts comportant un fusible (3) pour courants forts et un boîtier (6) entourant le fusible (3) pour courants forts, le boîtier (6) formant un connecteur enfichable pour la mise en contact électrique et le raccordement mécanique avec un connecteur enfichable antagoniste (2), le connecteur enfichable présentant un codage individuel pour l'intensité de courant maximale sécurisée par le fusible (3) pour courants forts, caractérisé en ce que le connecteur enfichable comprend au moins deux éléments de contact pour courants forts (14) et au moins deux éléments de contact pour courants faibles.

- Système de sécurisation selon la revendication 1, caractérisé en ce que le boîtier (6) reçoit le fusible (3) pour courants forts de manière à le refermer en permanence.

- Système de sécurisation selon la revendication 1 ou 2, caractérisé en ce que le boîtier (6) comprend un blindage.

- Système de connecteur enfichable comportant un système de sécurisation (1) selon l'une des revendications précédentes et un connecteur enfichable antagoniste (2) complémentaire au connecteur enfichable du système de sécurisation (1).

- Système de connecteur enfichable selon la revendication 4, caractérisé en ce que la connexion enfichée du connecteur enfichable et du connecteur enfichable antagoniste (2) est réalisée de façon étanche à l'eau.

- Système de connecteur enfichable selon la revendication 4 ou 5, caractérisé en ce que le connecteur enfichable et le connecteur enfichable antagoniste (2) sont réalisés de telle sorte que lors d'un assemblage par enfichage, tout d'abord les éléments de contact sécurisation (14, 15) du connecteur enfichable et du connecteur enfichable antagoniste (2) viennent en contact, et ensuite les éléments de contact pour courants faibles (16).

- Système de connecteur enfichable selon l'une des revendications 4 à 6, caractérisé en ce que le connecteur enfichable antagoniste (2) est réalisé avec une protection contre le contact physique avec les éléments de contact pour courants forts (14, 15) et/ou les contacts pour courants faibles (16) dans l'état non enfiché du système de connecteur enfichable selon la classe IP1X (IP - Ingress Protection), c'est-à-dire avec protection contre l'accès par le dos de la main, selon la classe IP2X, c'est-à-dire avec protection contre l'accès par le doigt, selon la classe IP3X, c'est-à-dire avec protection contre l'accès par un outil, selon la classe IP4X, c'est-à-dire avec protection contre l'accès par un fil, selon la classe IP5X, c'est-à-dire avec protection complète contre le contact physique, ou selon la classe IP6X, c'est-à-dire avec protection complète contre le contact physique.

- Système de connecteur enfichable selon la revendication 7, caractérisé en ce que la protection contre le contact physique est réalisée selon la norme DIN EN 60529 dans la version allemande EN 60529 : 1991 + A1 : 2000.

- Système électrique comportant une source d'énergie électrique, un consommateur électrique et un système conducteur qui relie la source d'énergie et le consommateur de façon électriquement conductrice, le système conducteur comprenant au moins un système de connecteur enfichable selon l'une des revendications 4 à 8.

- Système électrique selon la revendication 9, caractérisé en ce qu'au moins une ligne du système conducteur est intégrée dans le système conducteur au moyen d'un ensemble connecteur enfichable, et sur le plan de l'interface d'enfichage, l'ensemble connecteur enfichable de la ligne correspond au système de connecteur enfichable, exception faite de codages individuels.

- Système électrique selon la revendication 10, caractérisé en ce que le système de sécurisation du système de connecteur enfichable sert de sectionneur de maintenance, de sorte que lors d'un sectionnement du système de sécurisation (1) par rapport au connecteur enfichable antagoniste (2), le système électrique est mis hors tension.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202012003170U DE202012003170U1 (de) | 2012-03-28 | 2012-03-28 | Sicherungssystem für Hochstromanwendungen |

| PCT/EP2013/000900 WO2013143682A1 (fr) | 2012-03-28 | 2013-03-25 | Système de fusible pour applications à haute intensité |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2831957A1 EP2831957A1 (fr) | 2015-02-04 |

| EP2831957B1 true EP2831957B1 (fr) | 2016-08-03 |

Family

ID=46512703

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13714208.9A Active EP2831957B1 (fr) | 2012-03-28 | 2013-03-25 | Système de fusible pour applications à haute intensité |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US9923311B2 (fr) |

| EP (1) | EP2831957B1 (fr) |

| JP (1) | JP6401697B2 (fr) |

| KR (1) | KR101910462B1 (fr) |

| CN (2) | CN110364878A (fr) |

| CA (1) | CA2867196C (fr) |

| DE (1) | DE202012003170U1 (fr) |

| TW (1) | TWM456934U (fr) |

| WO (1) | WO2013143682A1 (fr) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5981294B2 (ja) * | 2012-10-12 | 2016-08-31 | 矢崎総業株式会社 | 充電インレット装置 |

| DE102013022064B4 (de) * | 2013-12-23 | 2015-11-26 | Amphenol-Tuchel Electronics Gmbh | Steckverbindungsanordnung zur Aufnahme von elektrischen Sicherungen, ausgebildet mit einer Mehrfachkodierung als Sicherheitsvorrichtung |

| DE202015000753U1 (de) * | 2015-01-30 | 2015-02-16 | Rosenberger Hochfrequenztechnik Gmbh & Co. Kg | Steckverbinderanordnung mit Hülsenteil |

| EP3211727B1 (fr) | 2016-02-26 | 2019-06-26 | ODU GmbH & Co KG. | Connecteur enfichable avec élément de verrouillage et procédés de connexion et de déconnexion |

| DE102016005508A1 (de) * | 2016-05-04 | 2017-11-09 | Rosenberger Hochfrequenztechnik Gmbh & Co. Kg | Hochvoltverbinder |

| US10256580B2 (en) * | 2016-10-03 | 2019-04-09 | Superwinch, Llc | Power connectors with integrated fuse supports, and associated systems and methods |

| CN106299829B (zh) * | 2016-10-10 | 2018-07-20 | 泰兴市八达电连接器有限公司 | 电动汽车电池包正负极单芯大电流自锁连接器 |

| US10781086B2 (en) | 2016-10-31 | 2020-09-22 | Westin Automotive Products, Inc. | Winches with dual mode remote control, and associated systems and methods |

| CN109650232B (zh) * | 2017-10-10 | 2020-06-02 | 上海三菱电梯有限公司 | 电梯层门门锁装置及电梯层门装置 |

| USD880427S1 (en) | 2017-11-13 | 2020-04-07 | Pure Watercraft, Inc. | Cable connector |

| USD884644S1 (en) | 2017-11-13 | 2020-05-19 | Pure Watercraft, Inc. | Power connector |

| US11183739B2 (en) | 2017-11-13 | 2021-11-23 | Pure Watercraft, Inc. | Batteries for electric marine propulsion systems, and associated systems and methods |

| USD891362S1 (en) | 2017-11-13 | 2020-07-28 | Pure Watercraft, Inc. | Battery pack |

| CN111344908B (zh) * | 2017-11-13 | 2022-07-05 | 纯船舶公司 | 用于海洋推进的电缆连接组件以及相关的系统和方法 |

| DE102018100831A1 (de) * | 2018-01-16 | 2019-07-18 | Dr. Ing. H.C. F. Porsche Aktiengesellschaft | Ladestecker für Elektroautos und dessen Herstellung |

| DE102018121400A1 (de) * | 2018-09-03 | 2020-03-05 | Rosenberger Hochfrequenztechnik Gmbh & Co. Kg | Elektrischer Steckverbinder, Hochvoltleitungssatz, Hochvoltsystem und Verfahren zum Anbringen eines elektrischen Steckverbinders |

| JP2020072064A (ja) * | 2018-11-02 | 2020-05-07 | ヒロセ電機株式会社 | インターロック機能を有する電源用コネクタ、及び、該電源用コネクタを用いた電源コネクタ装置 |

| DE102020134688A1 (de) * | 2020-12-22 | 2022-06-23 | Lisa Dräxlmaier GmbH | Multifunktionsträger und hochvolt-schütz für ein batteriesystem eines elektrischen fahrzeugs |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2008050A (en) | 1932-03-19 | 1935-07-16 | Tampier Rene Jean Camille | Ball joint |

| US3612953A (en) * | 1969-10-16 | 1971-10-12 | Alvin S Gittin | Electrical wiring system and ejectable devices therein |

| US4455056A (en) * | 1980-04-23 | 1984-06-19 | Amp Incorporated | Multi-pin high voltage connector |

| US4759730A (en) * | 1983-02-18 | 1988-07-26 | Cooper Industries, Inc. | Polarized fuseholder assembly |

| US4762509A (en) * | 1986-11-12 | 1988-08-09 | Littelfuse, Inc. | Shock-safe fuseholder assembly |

| US5316502A (en) * | 1992-04-10 | 1994-05-31 | Union Connector Co., Inc. | Electrical connector with circuit protection |

| JP3314956B2 (ja) * | 1992-07-28 | 2002-08-19 | 松下電工株式会社 | ハーネスプラグ |

| CH689029A5 (de) * | 1995-11-13 | 1998-07-31 | Anton Warmelinger | Sicherheitssteckverbindung mit einem Sicherheitsstecker und einer Sicherheitsbuchse mit durchgehender Isolation. |

| US5662500A (en) * | 1996-04-08 | 1997-09-02 | Yeah; Solomon | Plug-and-socket power connector |

| EP0821440A1 (fr) | 1996-07-22 | 1998-01-28 | Multi-Contact Ag | Dispositif de raccordement électrique |

| JPH11144813A (ja) * | 1997-10-22 | 1999-05-28 | Keiken Chin | ヒューズ入り差込みプラグ |

| US6790067B2 (en) * | 2002-12-17 | 2004-09-14 | Tyco Electronics Corporation | Finger proof power connector |

| JP2004031349A (ja) | 2003-06-20 | 2004-01-29 | Energy Support Corp | コネクタ |

| GB0420666D0 (en) * | 2004-09-17 | 2004-10-20 | Smiths Group Plc | Electrical connectors |

| US7081003B1 (en) * | 2005-03-29 | 2006-07-25 | Molex Incorporated | Electrical connector with improved latching system |

| CN101079355B (zh) * | 2005-06-20 | 2012-04-25 | 力特保险丝有限公司 | 一种防水内嵌式熔断器固定器 |

| TW200711235A (en) | 2005-06-20 | 2007-03-16 | Littelfuse Inc | Water resistant in-line fuse holder |

| DE102006033323A1 (de) | 2006-07-17 | 2008-01-24 | Kostal Kontakt Systeme Gmbh | Elektrischer Verbinder |

| WO2008109109A1 (fr) * | 2007-03-06 | 2008-09-12 | Tyco Electronics Corporation | Ensemble connecteur électrique blindé à haute tension |

| DE102008049574A1 (de) * | 2008-09-30 | 2010-04-01 | Phoenix Contact Gmbh & Co. Kg | Elektrisches Steckverbindungssystem |

| US7985098B2 (en) * | 2008-11-20 | 2011-07-26 | Tyco Electronics Corporation | Fuse connector assembly |

| US8221165B2 (en) * | 2009-12-22 | 2012-07-17 | Tyco Electronics Corporation | Connector assembly with an integrated fuse |

| KR101699576B1 (ko) * | 2009-12-24 | 2017-01-24 | 델파이 커넥션 시스템즈 홀딩 프랑스 | 전기 커넥터 조립체 |

| DE102010002681B4 (de) * | 2010-03-09 | 2018-10-18 | Te Connectivity Germany Gmbh | Elektrischer Steckverbinder, elektrische Steckverbindung sowie konfektioniertes elektrisches Kabel |

| ES2576828T3 (es) * | 2010-08-13 | 2016-07-11 | Tyco Electronics Amp Italia S.P.A. | Protección de dedos para un cabezal de 90º |

| DE102013001391A1 (de) * | 2012-01-26 | 2013-07-25 | Lear Corporation | Verbinder mit integrierter Sicherung |

-

2012

- 2012-03-28 DE DE202012003170U patent/DE202012003170U1/de not_active Expired - Lifetime

-

2013

- 2013-03-25 EP EP13714208.9A patent/EP2831957B1/fr active Active

- 2013-03-25 JP JP2015502135A patent/JP6401697B2/ja active Active

- 2013-03-25 US US14/388,423 patent/US9923311B2/en active Active

- 2013-03-25 KR KR1020147029069A patent/KR101910462B1/ko active IP Right Grant

- 2013-03-25 CN CN201910623287.6A patent/CN110364878A/zh active Pending

- 2013-03-25 CN CN201380017002.5A patent/CN104205516A/zh active Pending

- 2013-03-25 CA CA2867196A patent/CA2867196C/fr not_active Expired - Fee Related

- 2013-03-25 WO PCT/EP2013/000900 patent/WO2013143682A1/fr active Application Filing

- 2013-03-27 TW TW102205668U patent/TWM456934U/zh not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| TWM456934U (zh) | 2013-07-11 |

| EP2831957A1 (fr) | 2015-02-04 |

| CN110364878A (zh) | 2019-10-22 |

| CN104205516A (zh) | 2014-12-10 |

| KR20140143407A (ko) | 2014-12-16 |

| CA2867196A1 (fr) | 2013-10-03 |

| KR101910462B1 (ko) | 2018-10-22 |

| DE202012003170U1 (de) | 2012-05-03 |

| US20150325961A1 (en) | 2015-11-12 |

| JP2015518237A (ja) | 2015-06-25 |

| CA2867196C (fr) | 2018-07-17 |

| WO2013143682A1 (fr) | 2013-10-03 |

| JP6401697B2 (ja) | 2018-10-10 |

| US9923311B2 (en) | 2018-03-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2831957B1 (fr) | Système de fusible pour applications à haute intensité | |

| EP1830437B1 (fr) | Contact électrique | |

| EP3433907B1 (fr) | Connecteur comprenant un élément de connecteur complémentaire | |

| DE102014017081A1 (de) | Anschlussanordnung zum elektrischen Kontaktieren eines Batteriemoduls, Koppelelement zum elektrischen Verbinden von Batteriemodulen, Batteriemodul, Batterie für ein Kraftfahrzeug und Kraftfahrzeug | |

| DE112013006397T5 (de) | Manueller Service-Trennschalter für Batteriesysteme | |

| EP3122589B1 (fr) | Dispositif embrochable réalisé sous forme de prolongateur ou de fiche | |

| DE60303341T2 (de) | Elektrische Steckverbinderanordnung mit Kurzschlusselement | |

| DE102008022840B3 (de) | Akkumulator für Hybrid-Fahrzeuge mit einer Sicherheitseinrichtung zum Unterbrechen eines Hochspannungskreises | |

| EP3427343B1 (fr) | Connecteur haute tension | |

| DE102016213757B4 (de) | Steckverbindung zum Koppeln von Hochvoltanschlüssen und System mit einer derartigen Steckverbindung | |

| EP2780986B1 (fr) | Connexion enfichable | |

| DE112009001573B4 (de) | Hochvolt-Steckverbindung sowie Verwendung einer solchen | |

| DE202013011708U1 (de) | Steckvorrichtung | |

| DE102012007047B3 (de) | Fahrzeugseitige Dose eines Ladesteckverbinders, insbesondere für Flurförderfahrzeuge | |

| EP3108545B1 (fr) | Connexion enfichable | |

| EP3504760B1 (fr) | Connecteur multi-contact avec élément intégré à court-circuit | |

| WO2012052184A1 (fr) | Fiche d'une prise | |

| CH689029A5 (de) | Sicherheitssteckverbindung mit einem Sicherheitsstecker und einer Sicherheitsbuchse mit durchgehender Isolation. | |

| EP1032005B1 (fr) | Installation électrique | |

| EP1716623B1 (fr) | Connecteur a fiches de securite | |

| DE102021107137B4 (de) | Elektrischer Anschlussverbinder und elektrische Steckverbinderanordnung hierfür | |

| EP2759024A1 (fr) | Élément à enfichage | |

| DE202016106821U1 (de) | Netzanschlusssystem und Elektrowerkzeug | |

| DE102013000393B4 (de) | Hochvolt-Steckverbindung | |

| EP4049347B1 (fr) | Connecteur électrique doté de porte-fusible |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140912 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01R 13/52 20060101ALI20160129BHEP Ipc: H01R 13/6581 20110101ALI20160129BHEP Ipc: H01H 71/10 20060101ALI20160129BHEP Ipc: H01R 13/645 20060101ALI20160129BHEP Ipc: H01R 13/713 20060101ALI20160129BHEP Ipc: H01R 13/53 20060101AFI20160129BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20160303 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 817881 Country of ref document: AT Kind code of ref document: T Effective date: 20160815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502013003936 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160803 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161103 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161203 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161104 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161205 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502013003936 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161103 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170504 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170325 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 817881 Country of ref document: AT Kind code of ref document: T Effective date: 20180325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160803 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20230323 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20230317 Year of fee payment: 11 Ref country code: IT Payment date: 20230321 Year of fee payment: 11 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230524 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502013003936 Country of ref document: DE Representative=s name: KANDLBINDER, MARKUS, DIPL.-PHYS., DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240328 Year of fee payment: 12 Ref country code: GB Payment date: 20240319 Year of fee payment: 12 |