EP1032005B1 - Installation électrique - Google Patents

Installation électrique Download PDFInfo

- Publication number

- EP1032005B1 EP1032005B1 EP00103259A EP00103259A EP1032005B1 EP 1032005 B1 EP1032005 B1 EP 1032005B1 EP 00103259 A EP00103259 A EP 00103259A EP 00103259 A EP00103259 A EP 00103259A EP 1032005 B1 EP1032005 B1 EP 1032005B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plug

- module

- electrical system

- contact

- fuse

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H85/00—Protective devices in which the current flows through a part of fusible material and this current is interrupted by displacement of the fusible material when this current becomes excessive

- H01H85/54—Protective devices wherein the fuse is carried, held, or retained by an intermediate or auxiliary part removable from the base, or used as sectionalisers

- H01H85/62—Protective devices wherein the fuse is carried, held, or retained by an intermediate or auxiliary part removable from the base, or used as sectionalisers the intermediate or auxiliary part being adapted for screwing into the base

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H9/00—Details of switching devices, not covered by groups H01H1/00 - H01H7/00

- H01H9/10—Adaptation for built-in fuses

- H01H9/102—Fuses mounted on or constituting the movable contact parts of the switch

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H85/00—Protective devices in which the current flows through a part of fusible material and this current is interrupted by displacement of the fusible material when this current becomes excessive

- H01H85/54—Protective devices wherein the fuse is carried, held, or retained by an intermediate or auxiliary part removable from the base, or used as sectionalisers

- H01H85/547—Protective devices wherein the fuse is carried, held, or retained by an intermediate or auxiliary part removable from the base, or used as sectionalisers with sliding fuse carrier

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H9/00—Details of switching devices, not covered by groups H01H1/00 - H01H7/00

- H01H9/02—Bases, casings, or covers

- H01H9/04—Dustproof, splashproof, drip-proof, waterproof, or flameproof casings

Definitions

- the invention relates to an electrical system with at least one control electronics and an attachable with this investment module, wherein in an electrical connection line between control electronics and system module at least one switching device and a fuse and terminals for connection of the system module is arranged on the electrical connection line.

- Such an electrical system must be switched off before starting maintenance, repairs or the like. This is done via a switching device that interrupts the electrical connection between the system module and control electronics. Subsequently, for example, the investment module can be serviced or replaced or other components between the security electronics and investment module can be maintained or replaced.

- US-A-1,482,958 discloses an electrical switch with a lower part and a pivotally mounted on this upper part.

- contacts for connecting external lines are provided in a connection block.

- the connection block is covered by a cover block, wherein the cover block only corresponding openings for example, has by connecting cutting edges.

- the connecting blades are arranged in a movable in the upper part switching block.

- the switching block has on its side facing the lower part of an open recess in which two fuses are held. The switching block is movable from the outside via a corresponding handle in the upper part.

- the invention is based on the object to improve an electrical system of the type mentioned in that it has a simplified structure and switching off the electrical system is avoided as much as possible, the electrical system is also cheaper to produce and operable.

- the plug-in module can be released with fuses in a simple manner from the base part, whereby already the electrical connection between the control electronics and system module is interrupted. By removing the plug-in module also only this electrical connection is interrupted and not the entire system or larger parts of the system disconnected from power.

- the arrangement of the terminals in or on the base part of this also serves for electrical connection of the system module and the control electronics, so that separately arranged terminals can be omitted. Due to this simple way of de-energizing individual modules modules for maintenance, repairs or the like can be quickly and safely separated from the electrical system.

- the plug-in module is also very compact and can be carried by maintenance personnel to prevent unintentional reconnection of the plant module. This is particularly important if the investment module is located relatively far away from the base part and plug-in module, which is usually the case.

- the plug-in module When used in potentially explosive areas, it is also important that the corresponding system module is first de-energized before the fuse is completely removed. This is done according to the invention in that the plug-in module is designed as a switching device at the same time. First, the plug-in module is moved from its connection position to the disconnected position, whereby a voltage isolation of the plant module takes place.

- Ignitable sparks which can occur during this disconnection, are flameproof encapsulated according to EN 50018 and will cool down before the actual removal of the plug-in module. Only then is the plug-in module removed from its disconnected position and separated from the base part. In this way, according to the invention, no additional arrangement of a switching device is necessary, by which, before removal of the plug-in module, a voltage release of the corresponding system module would have to take place.

- control electronics and base part as well as in this inserted plug-in module can be arranged in a cabinet. It goes without saying that a large number of such components can be contained in the control cabinet.

- the corresponding investment modules, such as sensors or the like, can be located far away from the control cabinet on site in the Ex-area and connected via appropriate connection lines, such as electrical wiring, bus systems or the like with the cabinet and accordingly with base part and control electronics.

- the base part may have at least one support terminal for the serial connection of two investment modules.

- the base part may have a base housing which can be snapped onto such a DIN rail, for example.

- Other connections between base part and base housing and rail are obvious.

- a snap fastening device can be arranged on a rear side of the base housing.

- the plug-in device can be constructed in manifold ways. In a simple embodiment example, it may have a double socket, in the plug-in module outwardly projecting pins are inserted.

- the plug-in connection between the plug-in module and the base part must be designed in the "flameproof enclosure” type of protection, since other types of protection do not permit plugging under load in the Ex area, except in "intrinsically safe” ignition protection circuits. Therefore, if the double socket or the plug-in device flameproof encapsulated (EN 50018), such a connector can be made or separated even in the presence of explosive mixture in the electrical system.

- the base part may comprise a latching device, with which the plug-in module is detachably latched in connection and disconnection position and by which both positions are determined simultaneously.

- these may have two mutually zu colldem from the base cover outwardly projecting latching arms, which arranged with arranged on opposite outer sides of the plug-in module latching projections can be brought into contact. It should be noted once again that this type of Rasteinrichung ensures that only in the disconnected position, the plant module off and then the plug-in module can be removed from the separation position of the base part.

- a simple and inexpensive constructed plug-in module can be realized that this has a box-shaped plug housing, which is closed on its forward facing away from the base part front by a lid.

- the fuse is held in a conventional manner, for example, between two resilient contacts.

- the plug housing may have in its the base part assigning rear slot recesses in which protrude the connector pins and which are attachable to the sockets in the base part.

- the terminals for connecting the system module and control electronics can be arranged directly in the base cover.

- plug-in housings and / or socket housings can have terminal covers for the terminals.

- the terminals can be reached only after removing the clamp covers, whereby the requirements of accident prevention protection are met in a simple manner. If such a terminal cover is connected to the plug housing, the terminals are released by removing the plug-in module and are then accessible.

- electrical connection lines between the terminals and the plug-in device can be arranged in the base housing.

- At least one terminal cover is formed integrally with the lid, so that when removing the plug-in module at least some of the terminals are released directly.

- the plug-in device may be formed as a pressure-resistant capsule in which the terminals electrically connectable contact elements are spaced from each other, wherein an electrical connection of the contact elements by a movable insertable into the capsule contact pin can be produced.

- An electrical connection to the fuse contained in the plug-in module can be done separately, for example in the manner described above.

- the contact pin may protrude from the plug-in module.

- the contact pin by moving the plug-in module from the connecting position into the disconnected position, the contact pin can be moved relative to the contact elements in the capsule so far that the electrical connection is disconnected.

- the plug-in module can then be carried along to avoid accidental re-insertion into the connection position.

- the contact pin In order to move the contact pin before disconnecting the plug-in module from the connection position to the disconnected position, the contact pin can be connected to a movement in particular from the front of the plug-in housing or its lid projecting actuator. About this actuator then the contact pin is adjustable relative to the contact elements so far that the electrical connection is disconnected. Then then, for example, the plug-in module can be completely removed from the base part or at least be adjusted in the above-mentioned separation position. It should be noted that the actuator may for example be an electrically insulating part of the contact pin, which part at least partially protrudes from the plug-in module.

- a simple embodiment of electrically contactable with the contact pin contact elements results, for example, when the contact elements are formed from one above the other in the cap arranged contact rings. In the voltage release position, the contact pin is only in contact with one of these contact rings and in the voltage connection position, it establishes contact between the two contact rings.

- the plug-in module can have a sleeve-shaped lower part and a detachably attachable cap, wherein the contact elements electrically connected to the terminals are arranged in the lower part and are connected with attached cap on the releasably supported in the cap fuse.

- the cap with fuse is removed, if a voltage release of the plant module is desired.

- the lower part of the plug-in module with the contact elements arranged therein can remain on the base part.

- the electrical contact to the plug-in module for example, in that the first contact element is directly connected to a terminal contact of the fuse and the second contact element via a disposed within the cap mating contact element with the other terminal contact of the fuse in combination.

- the cap may have an insertable into the lower part, downwardly open inner sleeve having at its lower end an external thread for screwing with an inner thread formed within the lower part.

- the cylindrical gap between inner sleeve and lower part forms the gap for flameproof enclosure.

- the second contact element may have a sliding contact element abutting an inner side of the inner sleeve.

- the mating contact element can be applied on the inside, extending over a part of the inner circumference Abrasive counter contact element and from this to to the other terminal contact the fuse extending connecting contact element comprise.

- the electrical connection consists of as long as the sliding contact element and the sliding counter contact element are in contact.

- connection contact element forms an elastic insertion receptacle in the region of the other terminal contact of the fuse. This is used for releasably holding one end of the fuse, whereby it is securely held even when releasing the cap from the lower part in the cap and can be handled with this.

- this can be spring-loaded in the direction of the fuse.

- the first contact element may be disposed within the lower part in a pressure-resistant chamber from which protrudes a contact pin towards the fuse. It should be noted that the smaller the volume of the flameproof enclosure, the simpler is the practical design. The interruption of the circuit is thus initially in this separate pressure-resistant chamber before the further contact between the cap and base is interrupted by their relative rotation to each other.

- the contact pin In order to disconnect the contact pin when unscrewing the cap from the first contact element and at the same time to establish a secure connection to the fuse, the contact pin can be mounted relative to the first contact element movable and spring-loaded towards the fuse. When unscrewing the cap is due to the spring loading the contact pin separated from the first contact element and finally comes into contact with a wall of the chamber, whereupon further unscrewing the cap and the contact between the contact pin and fuse is interrupted.

- a simply rotatable mounting of the terminal cover on the cap can be realized, for example, that the terminal cover has an annular flange which is at least partially rotatably inserted in an annular groove in the outer periphery of the cap.

- Plug-in module and base part according to the invention are indeed compact and relatively small. However, it is still possible, if appropriate, to arrange further electrical and / or electronic components, such as bus terminating resistor, voltage indicator, current indicator, polarity indicator or the like, in the plug-in module and / or in the base part.

- further electrical and / or electronic components such as bus terminating resistor, voltage indicator, current indicator, polarity indicator or the like

- Fig. 1 is a schematic representation of a system 1 according to the invention with at least one control electronics 2, a system module 3 and a plug-in module 9 with Sokkelteil 10, wherein plug-in module and base part simultaneously form a switching device 5.

- the electrical system 1 may have further of these components in a similar arrangement.

- Control electronics 2 and plug-in module 9 and base part 10 are usually arranged in a cabinet 13.

- the electrical connection line 4 may be formed by individual cables, a bus system or the like.

- the base part 10 is detachably mounted within the cabinet 13 and from this the plug-in module 9 with fuses 6 is separable, see line 69 in Fig. 1 ,

- first and second terminals 7, 8 are provided, can be connected to the system module 3 and control electronics 2 and are electrically connected when the plug-in module 9 is inserted.

- Another terminal 14 is provided as a so-called support terminal between each of the first and second terminals 7, 8, see Fig. 3 ,

- the electrical system 1 according to the invention is used in particular in potentially explosive areas, so-called Ex areas, in which plug-in connections in the type of protection "flameproof enclosure” are executed.

- FIG. 2 an electrical system 1 according to the prior art is shown.

- a number of different components are arranged in the electrical lines 4 between control electronics 2 and 3 investment module.

- a component is a fuse box with two fuses 6.

- Another component is a switching device 5 for interrupting the electrical connection lines 4.

- first and second terminals 7, 8 provided on the electrical connection lines 4, via which a power supply further electrical lines within the cabinet 13 takes place.

- Fig. 3 is the electrical system after Fig. 1 partially shown, wherein by means of the first terminals 7 and arranged therebetween support terminal 14, two contact modules 3, 15 are connected to the base part 10 via electrical lines. In this way, the plant modules can be selectively secured in parallel supply and separated individually from the voltage.

- FIG. 4 is a section along the line II Fig. 1 represented by a first embodiment of plug-in module 9 and base part 10. As stated above, plug-in module and base part simultaneously form a switching device 5 for interrupting the power supply.

- the base part 10 is formed by a base housing 16 of tub-like lower part 20 and base cover 21.

- the lower part 20 has on its rear side opposite the plug-in module 9 19 a snap-fastening device 18 for releasably securing the lower part 10 to a DIN rail 17.

- the base cover 21 is detachably connected to the open end of the lower part 20 with this and locked there.

- known terminals 7, 8 are arranged. These are connected via electrical connection lines 39 with contacts of a plug 22 in the form of a double socket 24.

- the Einstekk Anlagen 22 projecting from the plug-in module 9 Gegeneinsteck noticed 23 is detachably inserted.

- this plug pins 25 are arranged, which protrude from the plug-in module 9 in the direction of base part 10. Lateral spaced on both sides of the plug-in device 22 are from the base cover 21 latching arms 27, 28 as a latching device 26 from. These point towards each other and engage behind protrusions 31 projecting from outer sides 29, 30 of the plug-in module 9.

- the plug-in module 9 In the illustrated arrangement of the plug-in module 9 relative to the base part 10, the plug-in module 9 is arranged in its connection position 11. In this the furthest to the base cover 21 spaced latching projections 31 are engaged behind.

- the plug-in module 9 is formed by a box-shaped plug housing 32 with cover 34.

- the mating plug-in devices 23 are plug-like manner arranged with the Stekkerstatten 25 in plug-in recesses 36. These latch with the plug-in device 22 in plug-in module 9 arranged in connection position 11.

- the cover 34 of the plug-in module 9 has on one side a one-piece terminal cover 38, which extends in steps over the latching arm 28 and the second terminals 8 and covers them.

- a second terminal cover 37 covers the first terminals 7 opposite to the plug-in module 9, wherein both terminal covers 37, 38 may be formed integrally with the plug-in module 9.

- the latching projections 31 are from outer sides 29, 30 of the plug housing 32 from.

- plug-in module 9 and base part 10 For use of plug-in module 9 and base part 10 in hazardous areas formed by plug-in device 22 in Schmidteinsteck Pain 23 connectors in the ignition protection "flameproof enclosure" are executed. Other types of protection do not permit plugging in hazardous areas, except in "intrinsically safe” ignition protection circuits.

- the fuse (s) are detachably supported within the plug-in module 9 and connected to the plug pins 25 via electrical lines.

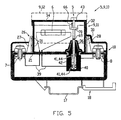

- Fig. 5 is a cut analogous to Fig. 4 represented by a second embodiment of plug-in module 9 and base part 10.

- Fig. 5 In contrast to Fig. 4 is in Fig. 5 also dashed the plug-in module 9 shown in the release position 12. In this position, the latching arms 27, 28 engage behind the latching projections 31 arranged closer to the base cover 21. In such a disconnected position, the plug-in module 9 retreats Fig. 4 so far separated from the base part 10, that the electrical connection between plug-in device 22 and Gegeneinsteck responded 23 is interrupted. In this condition, the flameproof enclosure is still preserved, as well as in FIG. 4 ,

- Fig. 5 differs further from the exemplary embodiment Fig. 4 in that the electrical connections between the fuse 6 and the first and second terminals 7, 8 are shown only in principle, these being analogous to Fig. 4 can be executed. However, these compounds can also be realized in other easily separable form.

- a particular flameproof capsule 40 is arranged, which is fixed in the base cover 21.

- spaced contact rings 44 are arranged as contact elements 41 from each other in the longitudinal direction of a contact pin.

- a lower one of these contact rings 44 is over one electrical connection line 39 connected to one end of the fuse 6 in the plug-in module 9. The other end of the fuse is connected to the first terminal 7.

- the upper contact ring 44 is connected via a further electrical connection line 39 to the second terminal 8.

- the contact pin 42 is inserted from the direction of the plug-in module 9. This is slidably mounted in the plug-in module 9.

- the contact pin 42 has at its upper end an actuator 43 which is made of an electrically insulating material.

- the actuating member 43 further has an annular shoulder 70, which limits the movement of the contact pin 42 relative to the plug-in module 9 in the direction of movement 66 by abutment against the cover 34.

- this may be formed above a marking 69 made of an electrically insulating material or be electrically separated from the remaining contact pin 42 in the region of the marking 69.

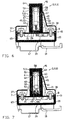

- Fig. 6 is a cut analogous to Fig. 4 represented by a third embodiment of plug-in module 9 and base part 10.

- the plug-in module 9 comprises a cap 46 and a lower part 45.

- the lower part 45 is arranged on the base cover 21 and there, for example, releasably secured.

- the cap 46 is detachably connected to the lower part 45 by screwing.

- the cap 46 has a cylindrical inner sleeve 51 which can be inserted into the lower part 45. This has at its lower end 52 on an external thread 53 which is screwed with a arranged on an inner side of the lower part 45 internal thread 54.

- the fuse 6 is arranged substantially in the longitudinal direction of the inner sleeve 51.

- a lower terminal contact 48 of the fuse 6 is connected to a first contact element 47 in Appendix. This is spring-loaded by a spring 68 in the direction of terminal contact 48 of the fuse 6.

- Cap 46 and lower part 45 form a flameproof enclosure.

- connection contact element 58 is part of a mating contact element 56, which contacts a second contact element 49 in the form of a sliding contact element 55 at the lower end 52 of the cap 46.

- First and second contact element 47, 49 are connected via corresponding electrical connecting lines 39 with first and second terminals 7, 8.

- the mating contact element 56 is formed by a sliding mating contact element 59, which extends only over a part of the circumference on an inner side 57 of the capsule 46.

- the sliding mating contact member 59 and the sliding contact member 55 slide along each other until a portion of the inner surface 57 of the cap 46 is reached where no abrasive mating contact member 59 is applied. There, the separation of the electrical connection between the first and second terminals 7, 8. After the cap 46 is rotated relative to the lower part 45 so far that the electrical connection is interrupted is, (separation position), the cap 46 can be solved by optionally further rotation relative to the lower part and removed from the base part 10.

- annular groove 63 is formed, see also Fig. 7 into which at least partially an annular flange 62 engages. This is integrally connected to the terminal cover 38 to cover the second terminals 8. When removing the cap 46 from the base part 10, this terminal cover 38 is also removable and at least the second terminals 8 are accessible.

- terminal cover 37 may be integrally formed with the terminal cover 38. In an alternative embodiment, the terminal cover 37 is detachable separately from the base member 10.

- the mating contact element 56 can be guided around into the area of the external thread 53 on an outer side of the inner sleeve 51.

- Fig. 7 is in a representation analogous to the section to 4 to 6 a fourth embodiment of plug-in module 9 and base part 10 is shown.

- a pressure-resistant chamber 60 is formed on a bottom of the lower part 45 opposite to the base cover 21, a pressure-resistant chamber 60 is formed.

- the contact pin 61 contacts the lower terminal contact 48 of the fuse 6.

- the contact pin 61 is at its opposite end of the fuse 6 with the first contact element 47 in electrical contact.

- Fig. 7 is different from the after Fig. 6

- the chamber 60 has a smaller volume compared to the interior of the cap 46. Such a smaller volume simplifies the practical implementation of the so-called "flameproof enclosure".

- the fuses 6 are preferably standardized, commercially available fuses. It should also be noted that both in the plug-in module 9 and in the base part 10 or at least in one of both additional electrical and / or electronic components may be arranged, such as bus terminators, voltage indicators, power indicators, polarity indicators or the like. Even with such additional electrical or electronic components, the unit of plug-in module / socket part is very compact and in particular the plug-in module can be easily carried by maintenance personnel or the like to protect against unintentional reconnection of the interrupted circuit. In addition, the first and second terminals 7, 8 are only accessible by the use of the terminal covers 37, 38, if at least the plug-in module 9 is removed. This fulfills the requirements of accident prevention protection in a simple manner and is particularly important when the investment module to be exchanged or serviced, such as a sensor or the like, is located far away from the control cabinet 13 or the base part 10.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Fuses (AREA)

- Control Of Linear Motors (AREA)

- Iron Core Of Rotating Electric Machines (AREA)

- Connector Housings Or Holding Contact Members (AREA)

Claims (31)

- Installation électrique (1) comportant au moins une électronique de commande (2) et un module d'installation (3) pouvant être relié à celle-ci, moyennant quoi, dans une ligne de connexion électrique (4) entre l'électronique de commande (2) et le module d'installation (3), sont au moins disposés un dispositif de couplage (5) et un fusible (6) ainsi que des bornes (7, 8) permettant le raccordement du module d'installation (3) sur la ligne de connexion électrique (4), sachant que le fusible (6) est contenu dans un module à fiches (9), qui est enfiché de manière amovible dans un élément de socle (10) qui présente des premières bornes (7) permettant le raccordement du module d'installation (3) et des deuxièmes bornes (8) permettant le raccordement de l'électronique de commande (2), une connexion électrique étant établie entre les première et deuxième bornes (7, 8) par l'intermédiaire du module à fiches (9) enfiché,

dans laquelle le module à fiches (9) peut être disposé, en tant que dispositif de couplage (5), dans au moins deux positions (11, 12) par rapport à l'élément de socle (10) dans la première position de connexion (11), le module d'installation (3) et l'électronique de commande (2) étant connectés par voie électrique et, dans la deuxième position de séparation (12), étant séparés l'un de l'autre d'un point de vue électrique, caractérisée en ce que le boîtier de socle (18) présente un élément inférieur (20) du type baignoire et un couvercle de socle (21) pouvant être fermé, en particulier pouvant être verrouillé, les bornes (7, 8) étant disposées dans le couvercle de socle (21), et au moins un dispositif d'enfichage (22) est disposé dans le couvercle de socle (21), dans lequel le module à fiches (9) peut être enfiché en établissant une connexion électrique, de manière amovible, avec un élément d'enfichage antagoniste (23), ainsi que le module d'installation (3) et l'électronique de commande (2). - Installation électrique selon la revendication 1, caractérisée en ce que l'électronique de commande (2) et l'élément de socle (10) ainsi que le module à fiches (9) sont disposés dans une armoire de commande (13).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que l'élément de socle (10) présente au moins une borne d'appui (14) permettant le raccordement parallèle de deux modules d'installation (3).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que l'élément de socle (10) présente un boîtier de socle (16), qui peut être emboîté sur un rail DIN (17).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce qu'un dispositif de fixation à déclic (18) est disposé sur une face arrière (19) du boîtier de socle (16).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que le dispositif d'enfichage (22) présente une double alvéole (24), dans laquelle peuvent être enfichées des tiges d'enfichage (25) faisant saillie vers l'extérieur à partir du module à fiches (9).

- Installation électrique selon la revendication 6, caractérisée en ce que la double alvéole (24) est encapsulée de manière résistante à la pression.

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que l'élément de socle (10) présente un dispositif d'encliquetage (26), avec lequel est encliqueté le module à fiches (9) de manière amovible, dans la position de connexion et de séparation (11, 12).

- Installation électrique selon la revendication 8, caractérisée en ce que le dispositif d'encliquetage (26) présente deux bras d'encliquetage (27, 28) orientés l'un vers l'autre, dépassant vers l'extérieur à partir du couvercle de socle (21), lesquels peuvent être mis en place avec les saillies d'encliquetage (31) apposées sur les faces externes opposées (29, 30) du module à fiches (9).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que le module à fiches (9) présente un boîtier à fiches (32) en forme de boîte, qui, sur sa face avant (33) opposée à l'élément de socle (10), peut être refermé par un couvercle (34).

- Installation électrique selon la revendication 10, caractérisée en ce que le boîtier à fiches (32) présente, dans sa face arrière (35) orientée vers l'élément de socle (10), un évidement d'enfichage (36), dans lequel peuvent faire saillie les tiges d'enfichage (25) dans le dispositif d'enfichage antagoniste, et qui peuvent être enfichées sur les alvéoles (24).

- Installation électrique selon la revendication 10, caractérisée en ce que le boîtier à fiches (32) et/ou le boîtier du socle (16) présente des recouvrements de bornes (37, 38) destinés aux bornes (7, 8).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que les lignes de connexion électriques (39) entre les bornes (7, 8) et les dispositifs d'enfichage (22) sont disposées dans le boîtier de socle (16).

- Installation électrique selon la revendication 10, caractérisée en ce qu'au moins un recouvrement de borne (37) est configuré d'un seul tenant avec le module à fiches (9), en particulier le couvercle (34).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que le dispositif d'enfichage (22) est configuré sous la forme d'une capsule (40) résistante à la pression, dans laquelle sont disposés des éléments de contact (41) connectés par voie électrique, en étant éloignés l'un de l'autre, sachant qu'une connexion électrique des éléments de contact (41) peut être établie par une tige de contact (42) pouvant être insérée de manière mobile dans la capsule (40).

- Installation électrique selon la revendication 15, caractérisée en ce que la tige de contact (42) dépasse du module à fiches (9).

- Installation selon la revendication 15, caractérisée en ce que la tige de contact (42) est reliée de manière mobile à un organe d'actionnement (43) dépassant en particulier de la face avant (33) du boîtier à fiches (32) ou de son couvercle (34).

- Installation électrique selon la revendication 15, caractérisée en ce que les éléments de contact (41) sont constitués de bagues de contact (44) disposées les unes au-dessus des autres dans la capsule (40).

- Installation électrique selon la revendication 15, caractérisée en ce que le module à fiches (9) présente une partie inférieure (45) en forme de douille et un capot (46) pouvant être posé de manière amovible sur celle-ci, sachant que les éléments de contact (41) connectés par voie électrique aux bornes (7, 8) sont disposés dans la partie inférieure (45) et, lorsque le capot (46) est posé, sont reliés par l'intermédiaire du fusible (6) maintenu de manière amovible dans le capot.

- Installation électrique selon la revendication 19, caractérisée en ce qu'un premier élément de contact (47) est directement relié à un contact de raccordement (48) du fusible (6), et un deuxième élément de contact (49) est relié par l'intermédiaire d'un élément de contact antagoniste (56) disposé à l'intérieur du capot (46) à l'autre contact de raccordement (50) du fusible (6).

- Installation électrique selon la revendication 19, caractérisée en ce que le capot (46) peut être vissé avec la partie inférieure (45).

- Installation électrique selon la revendication 19, caractérisée en ce que le capot (46) présente une douille intérieure (51) pouvant être insérée dans la partie inférieure (45), ouverte vers le bas, laquelle présente, sur son extrémité inférieure (52), un filetage externe (53) permettant le vissage avec le filetage interne (54) configuré en dessous de la partie inférieure (45).

- Installation électrique selon la revendication 20, caractérisée en ce que le deuxième élément de contact (49) est configuré sous la forme d'un élément de contact glissant (55) reposant sur une face interne (57) de la douille interne (51).

- Installation électrique selon la revendication 20, caractérisée en ce que l'élément de contact antagoniste (56) comporte un élément de contact glissant antagoniste (59) apposé sur la face interne (57), s'étendant sur une partie de la périphérie interne, et un élément de contact de raccordement (58) s'étendant à partir de celui-ci jusqu'à l'autre contact de raccordement (50) du fusible (6).

- Installation électrique selon la revendication 24, caractérisée en ce que l'élément de contact de raccordement (58) forme, dans la zone de l'autre contact de raccordement (50) du fusible (6), un logement d'enfichage élastique.

- Installation électrique selon la revendication 20, caractérisée en ce que le premier élément de contact (47) est sollicité par un ressort dans la direction du fusible (6).

- Installation électrique selon la revendication 20, caractérisée en ce que le premier élément de contact (47) est disposé à l'intérieur de la partie inférieure (45) dans une chambre (60) résistante à la pression, de laquelle fait saillie une tige de contact (61) en direction du fusible (6).

- Installation électrique selon la revendication 20, caractérisée en ce que la tige de contact (61) est logée de manière mobile par rapport au premier élément de contact (47), et sollicité par un ressort en direction du fusible (6).

- Installation électrique selon les revendications 12 ou 19, caractérisée en ce que le recouvrement de borne (37) est maintenu de manière à tourner sur le capot (46).

- Installation électrique selon les revendications 12 et 19, caractérisée en ce que le recouvrement de borne (37) présente une bride annulaire (62), qui est enfichée de manière rotative au moins en partie dans une rainure annulaire (63) dans la périphérie externe (64) du capot (46).

- Installation électrique selon au moins l'une quelconque des revendications précédentes, caractérisée en ce que d'autres composants électriques et/ou électroniques, tels qu'une résistance terminale de bus, un indicateur de tension, un indicateur de courant, un indicateur de polarité ou similaires, sont disposés dans le module à fiches (9) et/ou dans l'élément de socle (10).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29903252U | 1999-02-23 | ||

| DE29903252U DE29903252U1 (de) | 1999-02-23 | 1999-02-23 | Elektrische Anlage |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1032005A2 EP1032005A2 (fr) | 2000-08-30 |

| EP1032005A3 EP1032005A3 (fr) | 2002-04-24 |

| EP1032005B1 true EP1032005B1 (fr) | 2008-07-09 |

Family

ID=8069835

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00103259A Expired - Lifetime EP1032005B1 (fr) | 1999-02-23 | 2000-02-17 | Installation électrique |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1032005B1 (fr) |

| AT (1) | ATE400883T1 (fr) |

| DE (2) | DE29903252U1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD1006276S1 (en) | 2021-08-06 | 2023-11-28 | Western Technology, Inc. | Portable industrial light |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011007954B4 (de) | 2011-01-05 | 2022-05-05 | Friedrich Göhringer Elektrotechnik GmbH | Sammelschiene |

| DE102011056986A1 (de) * | 2011-12-23 | 2013-06-27 | Wago Verwaltungsgesellschaft Mbh | Leiteranschlussklemme |

| US11469546B2 (en) | 2020-09-29 | 2022-10-11 | Western Technology, Inc. | Electrical connector system |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1363151A (en) * | 1917-01-24 | 1920-12-21 | Thomas E Murray | Electric cut-out |

| US1482958A (en) * | 1921-05-12 | 1924-02-05 | Bryant Electric Co | Electric switch |

| US1825267A (en) * | 1930-05-19 | 1931-09-29 | Bull Dog Electric Products Com | Switching device |

| US3268692A (en) * | 1964-02-05 | 1966-08-23 | Gen Cable Corp | Fuse block for either single-pole or double-pole power supply |

| CH491492A (de) * | 1969-05-22 | 1970-05-31 | Schurter Ag H | Berührungssicherer Sicherungshalter |

| DE2052040C3 (de) * | 1970-10-23 | 1979-09-20 | R. Stahl Gmbh & Co, 7000 Stuttgart | Druckfest geschützte Sicherung |

| DE2320869C2 (de) * | 1973-04-25 | 1983-05-05 | Eckardt Ag, 7000 Stuttgart | Anschlußvorrichtung für elektrische Geräte zum Einsatz in explosionsgeschützten Räumen |

| DE3241177C2 (de) * | 1982-11-08 | 1986-10-02 | F. Wieland, Elektrische Industrie GmbH, 8600 Bamberg | Sicherungs-Reihenklemme |

| DE3303471A1 (de) * | 1983-02-02 | 1984-08-02 | Siemens AG, 1000 Berlin und 8000 München | Reihenklemme |

| DE3642728A1 (de) * | 1986-12-13 | 1988-06-23 | Bbc Brown Boveri & Cie | Explosionsgeschuetzte bzw. schlagwettergeschuetzte sicherung |

| US5559662A (en) * | 1994-05-20 | 1996-09-24 | Cooper Industries | Fused disconnect switch |

| JP3052183B2 (ja) * | 1995-07-06 | 2000-06-12 | 矢崎総業株式会社 | ヒューズ付電気接続箱 |

| JPH1083753A (ja) * | 1996-09-05 | 1998-03-31 | Yazaki Corp | サービスプラグ |

| IT1286436B1 (it) * | 1996-12-04 | 1998-07-08 | Abb Elettrocondutture Spa | Porta-fusibile sezionatore per quadro elettrico |

-

1999

- 1999-02-23 DE DE29903252U patent/DE29903252U1/de not_active Expired - Lifetime

-

2000

- 2000-02-17 DE DE50015246T patent/DE50015246D1/de not_active Expired - Lifetime

- 2000-02-17 EP EP00103259A patent/EP1032005B1/fr not_active Expired - Lifetime

- 2000-02-17 AT AT00103259T patent/ATE400883T1/de not_active IP Right Cessation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD1006276S1 (en) | 2021-08-06 | 2023-11-28 | Western Technology, Inc. | Portable industrial light |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1032005A3 (fr) | 2002-04-24 |

| DE29903252U1 (de) | 2000-08-03 |

| DE50015246D1 (de) | 2008-08-21 |

| ATE400883T1 (de) | 2008-07-15 |

| EP1032005A2 (fr) | 2000-08-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4438800C1 (de) | Anschlußklemmenblock mit Elektronikmodul | |

| EP2831957B1 (fr) | Système de fusible pour applications à haute intensité | |

| EP3122589B1 (fr) | Dispositif embrochable réalisé sous forme de prolongateur ou de fiche | |

| DE60128849T2 (de) | Sicherungsträger und Verbinder | |

| EP0678932A1 (fr) | Borne de raccordement et de connexion électrique | |

| EP1131860A1 (fr) | Dispositif de mise en contact pour cable plat | |

| DE202013003925U1 (de) | Zusatzsockel und damit herstellbare Stecksockelbaugruppe | |

| DE2900329C2 (de) | Explosionsgeschützte Schalteinrichtung | |

| EP2515380B1 (fr) | Appareils de terrain pour une meilleure sécurité | |

| EP1032005B1 (fr) | Installation électrique | |

| EP0477664A1 (fr) | Insert de protection pour réglette à bornes installée dans un équipement de télécommunication, en particulier dans un poste annexe téléphonique | |

| DE202018106082U1 (de) | Anschlussleiste | |

| DE102012007047B3 (de) | Fahrzeugseitige Dose eines Ladesteckverbinders, insbesondere für Flurförderfahrzeuge | |

| EP3127190A1 (fr) | Système d'enfichage électrique configurable | |

| DE4428687C1 (de) | Baugruppe eines elektrischen Geräts | |

| EP4348773A1 (fr) | Insert de contact pour un connecteur mâle industriel | |

| EP2988312B1 (fr) | Module de fusible | |

| DE60319326T2 (de) | Anordnung zum Anschliessen von Niederspannungsgeräten | |

| EP1356548B1 (fr) | Dispositif de contact pour la liaison liberable d'un bloc d'assemblage mobile avec des rails conducteurs fixes | |

| DE4111956A1 (de) | Mehrpolige elektrische anschlussvorrichtung | |

| WO2020011309A1 (fr) | Module de raccordement fonctionnel | |

| EP3164919B1 (fr) | Terminaison de câble pour relier une installation de commutation à un câble haute tension | |

| EP4049347B1 (fr) | Connecteur électrique doté de porte-fusible | |

| DE3412656A1 (de) | Steckvorrichtung und deren anordnung | |

| EP1307950A1 (fr) | Dispositif de raccordement antideflagrant |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20020524 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: COOPER CROUSE-HINDS GMBH |

|

| 17Q | First examination report despatched |

Effective date: 20070207 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HEINSKILL, ANTON Inventor name: HARNISCHMACHER, FRIEDHELM |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: JACOBACCI & PARTNERS S.P.A. Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50015246 Country of ref document: DE Date of ref document: 20080821 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081209 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081020 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20090121 Year of fee payment: 10 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20090414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081010 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100217 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: VIA LUGANETTO 3, 6962 LUGANO (CH) |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20170124 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20170216 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20190125 Year of fee payment: 20 Ref country code: DE Payment date: 20190122 Year of fee payment: 20 Ref country code: FR Payment date: 20190123 Year of fee payment: 20 Ref country code: IT Payment date: 20190122 Year of fee payment: 20 Ref country code: NL Payment date: 20190128 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50015246 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20200216 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20200216 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20200216 |