EP2682427A1 - Polyurethan basierte expandierbare Polymerpartikel - Google Patents

Polyurethan basierte expandierbare Polymerpartikel Download PDFInfo

- Publication number

- EP2682427A1 EP2682427A1 EP12175270.3A EP12175270A EP2682427A1 EP 2682427 A1 EP2682427 A1 EP 2682427A1 EP 12175270 A EP12175270 A EP 12175270A EP 2682427 A1 EP2682427 A1 EP 2682427A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tpu

- polymerization

- polymer particles

- temperature

- expandable polymer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/16—Making expandable particles

- C08J9/20—Making expandable particles by suspension polymerisation in the presence of the blowing agent

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F112/00—Homopolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring

- C08F112/02—Monomers containing only one unsaturated aliphatic radical

- C08F112/04—Monomers containing only one unsaturated aliphatic radical containing one ring

- C08F112/06—Hydrocarbons

- C08F112/08—Styrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F283/00—Macromolecular compounds obtained by polymerising monomers on to polymers provided for in subclass C08G

- C08F283/006—Macromolecular compounds obtained by polymerising monomers on to polymers provided for in subclass C08G on to polymers provided for in C08G18/00

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/14—Manufacture of cellular products

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/48—Polyethers

- C08G18/4854—Polyethers containing oxyalkylene groups having four carbon atoms in the alkylene group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/65—Low-molecular-weight compounds having active hydrogen with high-molecular-weight compounds having active hydrogen

- C08G18/66—Compounds of groups C08G18/42, C08G18/48, or C08G18/52

- C08G18/6603—Compounds of groups C08G18/42, C08G18/48, or C08G18/52 with compounds of group C08G18/32 or polyamines of C08G18/38

- C08G18/6607—Compounds of groups C08G18/42, C08G18/48, or C08G18/52 with compounds of group C08G18/32 or polyamines of C08G18/38 with compounds of group C08G18/3203

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/65—Low-molecular-weight compounds having active hydrogen with high-molecular-weight compounds having active hydrogen

- C08G18/66—Compounds of groups C08G18/42, C08G18/48, or C08G18/52

- C08G18/6666—Compounds of group C08G18/48 or C08G18/52

- C08G18/667—Compounds of group C08G18/48 or C08G18/52 with compounds of group C08G18/32 or polyamines of C08G18/38

- C08G18/6674—Compounds of group C08G18/48 or C08G18/52 with compounds of group C08G18/32 or polyamines of C08G18/38 with compounds of group C08G18/3203

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/70—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the isocyanates or isothiocyanates used

- C08G18/72—Polyisocyanates or polyisothiocyanates

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/0061—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof characterized by the use of several polymeric components

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J9/00—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof

- C08J9/04—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent

- C08J9/12—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent by a physical blowing agent

- C08J9/14—Working-up of macromolecular substances to porous or cellular articles or materials; After-treatment thereof using blowing gases generated by a previously added blowing agent by a physical blowing agent organic

- C08J9/141—Hydrocarbons

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L25/00—Compositions of, homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Compositions of derivatives of such polymers

- C08L25/02—Homopolymers or copolymers of hydrocarbons

- C08L25/04—Homopolymers or copolymers of styrene

- C08L25/06—Polystyrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L25/00—Compositions of, homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Compositions of derivatives of such polymers

- C08L25/02—Homopolymers or copolymers of hydrocarbons

- C08L25/04—Homopolymers or copolymers of styrene

- C08L25/08—Copolymers of styrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L51/00—Compositions of graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Compositions of derivatives of such polymers

- C08L51/08—Compositions of graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Compositions of derivatives of such polymers grafted on to macromolecular compounds obtained otherwise than by reactions only involving unsaturated carbon-to-carbon bonds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L75/00—Compositions of polyureas or polyurethanes; Compositions of derivatives of such polymers

- C08L75/04—Polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2201/00—Foams characterised by the foaming process

- C08J2201/02—Foams characterised by the foaming process characterised by mechanical pre- or post-treatments

- C08J2201/026—Crosslinking before of after foaming

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2203/00—Foams characterized by the expanding agent

- C08J2203/14—Saturated hydrocarbons, e.g. butane; Unspecified hydrocarbons

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2325/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Derivatives of such polymers

- C08J2325/02—Homopolymers or copolymers of hydrocarbons

- C08J2325/04—Homopolymers or copolymers of styrene

- C08J2325/06—Polystyrene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2351/00—Characterised by the use of graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers

- C08J2351/08—Characterised by the use of graft polymers in which the grafted component is obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers grafted on to macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2375/00—Characterised by the use of polyureas or polyurethanes; Derivatives of such polymers

- C08J2375/04—Polyurethanes

- C08J2375/08—Polyurethanes from polyethers

Definitions

- the invention relates to expandable polymer particles based on thermoplastic polyurethanes (TPU) containing a styrene polymer and TPU, a process for their preparation, moldings obtainable from the polymer particles, and their use as elastomeric foam.

- TPU thermoplastic polyurethanes

- Foams based on styrene polymers have long been known and are widely used, for example, for the production of insulating materials.

- the great advantages of these materials, such as insulating properties, low density, water resistance and expandability, are offset by disadvantages in terms of chemical resistance and impact resistance.

- thermoplastic polyurethanes in foamed form are known. They are characterized for example by excellent elasticity, transparency, abrasion resistance and chemical resistance, but have disadvantages such as lack of dimensional stability and unsatisfactory foamability. So it is technically difficult to produce an expandable particle foam made of TPU, since TPU physical propellant such as pentane very quickly by diffusion back to the environment gives (poor blowing agent holding capacity). Furthermore, physical blowing agents in pure TPU can not build up sufficient foaming pressure so that pure blowing agent-containing TPU can not be expanded to an EPS prefoamer.

- thermoplastic polymer blends based on thermoplastic polyurethane and styrene polymer, foams produced therefrom and related manufacturing processes.

- the JP-A 2007-231068 discloses expandable styrene-modified TPU particles containing 100 parts by weight of TPU and 20 to 300 parts by weight of a styrenic polymer with styrene polymer particles of 0.5 ⁇ m or less dispersed in the TPU.

- Task was therefore to develop materials based on TPU, which can hold over a period of weeks a physical blowing agent (pentane), can be processed on commercially available EPS machines and still have sufficient elastomeric properties.

- a physical blowing agent pentane

- the invention therefore provides expandable polymer particles containing at least one thermoplastic polyurethane (TPU) having a Vicat softening point (according to ISO 306 / A50) of below 80 ° C and 5 to 95 wt .-%, based on the sum of TPU and by free radical polymerization of available polymer, at least one polymer obtainable by radical polymerization, wherein the polymer obtainable by radical polymerization is bonded as a comb, graft or copolymer to the TPU.

- TPU thermoplastic polyurethane

- the invention further provides expanded polymer particles according to the invention, obtainable by prefoaming the polymer particles according to the invention.

- foam moldings obtainable from the prefoamed polymer particles according to the invention.

- the foam moldings according to the invention as an elastomeric foam, preferably as insulating material for facades, living areas and / or footfall sound insulation, for floor coverings of sports facilities, shoe soles and / or bumpers for automobiles.

- TPU Thermoplastic polyurethanes

- TPU types are used with a Vicat temperature of less than 80 ° C, preferably from 60 to 79 ° C, particularly preferably from 60 to 75 ° C.

- the Vicat temperature is determined according to ISO 306 according to method ASO, i. determined with a force of 10 N and a heating rate of 50 ° C / h / ISO 306 / ASO).

- the determination of the Vicat temperature is carried out on propellant-free samples which contain no additives customary for the desired applications.

- a Vicat temperature according to the invention can be obtained by methods known to the person skilled in the art, for example by using corresponding monomer building blocks, in the preparation of the TPU (see below).

- TPU types used according to the invention preferably have a Shore A hardness in the range from 50 to 150, more preferably from 65 to 85 (measured to DIN 53505).

- the melting range is preferably in the range from -20 ° C to -60 ° C.

- the elongation at break according to DIN 53504-S2 is preferably> 550%.

- peroxide initiator such as dicumyl peroxide

- free-radically polymerizable monomers having groups (alkoxide, epoxide, amine groups) which can undergo a polyaddition reaction with isocyanates are added in the preparation of the TPU according to known methods (see below).

- the following compounds are particularly preferred as monomers: hydroxyethyl methacrylate; 1,2- and 1,3-dihydroxypropyl methacrylate; Glycidyl methacrylate, ortho-, meta- and para-hydroxystyrene, meta- and para-aminostyrene, methacrylamide, 1,4-butenediol, 1,4-butynediol and / or polybutadiene diol.

- TPU is prepared by reacting from a mixture of isocyanates (a) with isocyanate-reactive compounds (b), preferably having a molecular weight of from 0.5 kg / mol to 10 kg / mol and optionally chain extenders (c), preferably one Molecular weight of 0.05 kg / mol to 0.5 kg / mol.

- At least one chain regulator (c1), a catalyst (d) and optionally at least one filler, auxiliary and / or additive are added to the mixture for the production of TPU.

- the substance groups which may also be indicated by the lower case letters, are also addressed as components.

- the components (a), (b), (c), (c1), (d) and (e) usually used in the preparation of the TPU are described below by way of example and comprise the following substance groups: isocyanates (a), relative to isocyanates reactive compounds (b), chain extenders (c), chain regulators (c1), catalysts (d) and / or at least one customary filler, auxiliary and / or additive.

- a mixture of isocyanates (a) and isocyanate-reactive compounds (b) is required for the preparation of TPU.

- the further addition of components (c), (c1), (d) and (e) is optional and can be done individually or in all possible variations.

- component means in each case a single substance or a mixture of the substances belonging to this component.

- the components isocyanates (a), isocyanate-reactive compounds (b), and chain extenders (c) and, if used, the chain regulators (c1) are addressed as structural components.

- the organic isocyanates used are (a) aliphatic, cycloaliphatic, araliphatic and / or aromatic isocyanates, further preferred diisocyanates.

- preferred diisocyanates are tri-, tetra-, penta-, hexa-, hepta- and / or octamethylene diisocyanate, 2-methylpentamethylene diisocyanate 1, 5, 2-ethylbutylene diisocyanate-1,4, pentamethylene diisocyanate-1,5, butylene diisocyanate-1,4, 1-isocyanato-3,3,5-trimethyl-5-isocyanatomethylcyclohexane (isophorone diisocyanate , IPDI), 1,4- and / or 1,3-bis (isocyanatomethyl) cyclohexane (HXDI), 1,4-cyclohexane diisocyanate, 1-methyl-2,4- and / or 2,6

- the organic diisocyanates may optionally be present in minor amounts, e.g. B. in amounts up to 3 mol%, preferably up to 1 mol%, based on the organic diisocyanate, be replaced by a tri- or higher functional polyisocyanate, but the amount of which must be limited so that still obtain thermoplastically processable polyurethanes become.

- a greater amount of such more than difunctional isocyanates is suitably compensated by the concomitant use of less than difunctional compounds with reactive hydrogen atoms, so that too extensive chemical crosslinking of the polyurethane is avoided.

- polyetherols in preferred embodiments polyetherols, polyesterols, and / or polycarbonate diols, which are usually also included under the term "polyols", are used.

- TPU is preferably prepared from polyether alcohol, more preferably polyether diol is used.

- Suitable polyether can be prepared by known methods, for example by anionic polymerization of alkylene oxides with alkali metal hydroxides, such as sodium or potassium hydroxide, or alkali metal such as sodium, sodium or potassium or potassium isopropoxide, as catalysts and with the addition of at least one starter molecule, 2 to 3, preferably 2, containing reactive hydrogen atoms, or by cationic polymerization with Lewis acids as catalysts of one or more alkylene oxides having 2 to 4 carbon atoms in the alkylene radical.

- Suitable alkylene oxides are, for example, tetrahydrofuran, 1,3-propylene oxide and particularly preferably ethylene oxide and 1: 2-propylene oxide.

- the alkylene oxides can be used individually, alternately in succession or as mixtures.

- suitable starter molecules are: water, organic dicarboxylic acids, such as succinic acid, adipic acid and, preferably, bivalent alcohols, which are optionally bonded in an ether bridge, such as. Ethanediol, 1,2-propanediol, 1,4-butanediol, diethylene glycol, hexanediol, 1,6- and 2-methylpentanediol-1,5.

- the starter molecules can be used individually or as mixtures.

- Particularly suitable and preferred are the hydroxyl-containing polytetrahydrofurans (PTHF).

- the substantially linear polyetherols usually have average molecular weights of 500 to 8000, preferably 600 to 6000, wherein the PTHF has a preferred average molecular weight of 500 to 2500, in particular from 800 to 2000. They can be used both individually and in the form of mixtures with one another Application come.

- a particularly preferred polyether diol is polytetrahydrofuran.

- the polyether alcohols and polytetrahydrofuran having a molecular weight between 0.6 kg / mol and 2.5 kg / mol are preferably used.

- the polyether alcohols are used individually or else as a mixture of different polyether alcohols.

- TPU is made from polyester alcohol.

- polyester diol is used for this purpose.

- a preferred polyester diol is made from adipic acid and butane-1,4-diol.

- Preferred embodiments of the polyester alcohols have a molecular weight between 0.6 kg / mol and 2.5 kg / mol.

- these polyols have molecular weights of 0.5 kg / mol to 8 kg / mol, preferably 0.6 kg / mol to 6 kg / mol, in particular 0.8 kg / mol to 4 kg / mol, and in further In a particularly preferred embodiment, the polyol is a polyester alcohol, preferably synthesized from polytetrahydrofuran, and has in a further preferred embodiment a molecular weight between 0.6 kg / mol and 2.5 kg / mol.

- chain extenders (c) in preferred embodiments, aliphatic, araliphatic, aromatic and / or cycloaliphatic compounds are used, which in further preferred embodiments have a molecular weight of 0.05 kg / mol to 0.5 kg / mol.

- chain extenders (c) are compounds having two functional groups, for example diamines and / or alkanediols having 2 to 10 carbon atoms in the alkylene radical, especially butane-1,4-diol, 1,6-hexanediol and / or di-, tri -, tetra-, penta-, hexa, hepta, octa, nona and / or Dekaalkylenglykole having 3 to 8 carbon atoms and corresponding oligo- and / or polypropylene glycols.

- mixtures of the chain extenders are used to prepare TPU.

- chain regulators (c1) usually having a molecular weight of 0.03 kg / mol to 0.5 kg / mol, are used.

- Chain regulators are compounds which have only one functional group compared to isocyanates. Examples of chain regulators are monofunctional alcohols, monofunctional amines, preferably methylamine, and / or monofunctional polyols. Through chain regulators, the flow behavior of the mixtures of the individual components can be specifically adjusted.

- Chain regulators are in preferred embodiments in an amount of 0 parts by weight to 5 parts by weight, more preferably from 0.1 parts by weight to 1 parts by weight, based on 100 parts by weight of the isocyanate-reactive compound b) used. Chain regulators are used in addition to or instead of chain extenders.

- At least one catalyst (d) is used for TPU preparation, which accelerates in particular the reaction between the NCO groups of the diisocyanates (a) and the isocyanate-reactive compounds, preferably hydroxyl groups of the synthesis components (b), (c) and c1 ,

- the catalyst is selected from the group of tertiary amines, e.g. Triethylamine, dimethylcyclohexylamine, N-methylmorpholine, N, N'-dimethylpiperazine, 2- (dimethylaminoethoxy) ethanol, diazabicyclo- (2,2,2) octane and the like.

- the at least one catalyst is selected from the group of organic metal compounds and is exemplified by titanic acid esters, an iron compound such as e.g. Iron (III) acetylacetonate, a tin compound, e.g. Tin diacetate, tin dioctoate, tin dilaurate or a tin dialkyl salt of an aliphatic carboxylic acid such as dibutyltin diacetate, dibutyltin dilaurate or the like.

- an iron compound such as e.g. Iron (III) acetylacetonate

- a tin compound e.g. Tin diacetate, tin dioctoate, tin dilaurate or a tin dialkyl salt of an aliphatic carboxylic acid such as dibutyltin diacetate, dibutyltin dilaurate or the like.

- the catalysts are used individually, in other embodiments, mixtures of catalysts are used. In preferred embodiments, the catalyst or mixture of catalysts is used in amounts of 0.0001 parts by weight to 0.1 parts by weight per 100 parts by weight of the isocyanate-reactive compound (b), preferably polyhydroxyl compound.

- auxiliary and / or additive examples include hydrolysis protection agents and flame retardants.

- Other additives and auxiliaries may be standard works such as o.g. Becker and Braun (1996).

- structural components (a) to (c) and optionally (c1) may also be added with hydrolysis protectants such as, for example, polymeric and low molecular weight carbodiimides.

- the structural components (b) and (c) can be varied in relatively wide molar ratios.

- the molar ratio of component (b) to total chain extender (c) used is from 10: 1 to 1:10, preferably from 5: 1 to 1: 8, more preferably from 1: 1 to 1: 4 the hardness of TPU increases with increasing content of chain extender (c).

- Shore hardnesses of A44 to D80 can be adjusted, particularly preferred are Shore hardnesses of A44 to A84.

- the Shore hardnesses are determined according to DIN 53505.

- the conversion to TPU takes place with customary characteristic numbers.

- the index is defined by the ratio of the total isocyanate groups used in the reaction of component (a) to the isocyanate-reactive groups, ie the active hydrogens, components (b) and (c).

- an isocyanate group of component (a) has an active hydrogen atom, ie, an isocyanate-reactive function, components (b) and (c).

- characteristic numbers above 100 more isocyanate groups than groups reactive toward isocyanates, for example OH groups, are present.

- the conversion to TPU is carried out at a ratio between 60 and 120, more preferably at a ratio between 80 and 110.

- TPU is preferably carried out according to one of the known methods mentioned below.

- Preferred embodiments are the continuous process, for example with reaction extruders, the tape process, the one-shot process or the prepolymer process.

- preferred embodiments are the batch process or the prepolymer process process.

- the components (a) and (b) and, if appropriate, (c), (c1), (d) and / or (e) can be mixed successively or simultaneously with one another, the reaction of the components (a) and (b) immediate use.

- the constituent components (a) and (b) and optionally the components (c), (c1), (d) and / or (e) are introduced into the extruder singly or as a mixture, e.g. at temperatures of 100 ° C to 280 ° C, preferably at 140 C to 250 ° C reacted.

- the resulting TPU is extruded, cooled and granulated.

- Preferred TPU types have a greater proportion of the soft phase than the hard phase, preferably from 5 to 30 wt .-%, particularly preferably from 10 to 25 wt .-% soft phase on. Furthermore, the nitrogen content in the hard phase is preferably higher.

- Preferred TPU types are e.g. under the designations Elastollan®1170 AU, Elastollan®1180, Elastollan® 1175 A 10W000 and Elastollan®880 A 13N000 from BASF Polyurethane GmbH, Lemförde, Germany, are commercially available.

- Elastollan®1170 AU a TPU consisting of the polytetrahydrofuran types 1000 and 2000 (the numbers are based on the molecular weight M w , the products are commercially available, for example, from BASF SE), a small proportion of 1,4-butanediol and 4,4'-diphenylmethane diisocyanate (MDI).

- MDI 1,4-butanediol and 4,4'-diphenylmethane diisocyanate

- the polymer particles according to the invention contain, in addition to the TPU, from 5 to 95% by weight (based on the sum of TPU and styrene polymers) of one or more polymers obtainable by free-radical polymerization, which are bound to the TPU as comb, graft or copolymers.

- their proportion is 80 to 30, more preferably 75 to 50, most preferably 75 to 65%.

- Polymers based on vinylically unsaturated monomers for example (and preferably) styrene, acrylates and methacrylates, vinyl chloride, vinyl acetate and acrylonitrile and mixtures thereof, are preferably used as polymers obtainable by free-radical polymerization.

- styrene polymer comprises polymers based on styrene, alpha-methylstyrene or mixtures of styrene and alpha-methylstyrene.

- Styrene polymers according to the invention are based on at least 50% by weight of styrene and / or alpha-methylstyrene monomers.

- Styrene polymers which are preferred are polystyrene, poly- ⁇ -methylstyrene and styrene-alpha-methylstyrene copolymers, styrene-butadiene copolymers (SB), styrene-acrylonitrile copolymers (SAN), acrylonitrile-alpha-methylstyrene copolymers (AMSAN), styrene-maleic anhydride copolymers (SMA), styrene-methyl methacrylate copolymers (SMMA), styrene-N-phenylmaleimide copolymers (SPMI), acrylonitrile-styrene-acrylic esters (ASA), methyl methacrylate-butadiene-styrene (MBS), Methyl methacrylate-acrylonitrile-butadiene-styrene (MABS) polymers or mixtures thereof.

- the polymer particles according to the invention are distinguished by a special TPU phase morphology, which consists of a continuous phase of TPU homopolymer and a discontinuous phase of the graft polymer of TPU and the polymer obtainable by free-radical polymerization.

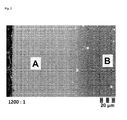

- the TPU phases ideally have an as in Fig. 1 (TEM recording) shown phase morphology, the graft polymer of TPU and the polymer obtainable by free-radical polymerization thereby forms round to elliptical discontinuous phases with a diameter between 50 and 500 nm, these are surrounded by a closed continuous TPU network.

- Fig. 1 TEM recording

- the FIG. 2 SEM shows images of expandable TPU-PS granules (50:60) with good propellant holding power: the samples were cut by cryo-histo, contrasted with RuO 4 , then spotted in SEM and visualized by SEM (margin A, center of bead B ) Positions shown. The pure TPU appears brighter on the SEM images than the styrene-modified TPU.

- An essential element of the invention is that the above-described polymer structure can be obtained by radical polymerization of one or more monomers in the TPU network swollen by these monomer (s) under suitable conditions.

- the polymer particles according to the invention may be used to improve the mechanical properties or the thermal stability, if appropriate by using compatibilizers with thermoplastic polymers such as polyamides (PA), polyolefins such as polypropylene (PP) or polyethylene (PE), polyacrylates such as polymethylmethacrylate (PMMA), polycarbonates (PC), Polyesters such as polyethylene terephthalate (PET) or polybutylene terephthalate (PBT), polyethersulfones (PES), polyether ketones or polyether sulfides (PES) or mixtures thereof in proportions of not more than 30% by weight, preferably in the range of 1 to 10% by weight, be mixed based on the polymer content.

- thermoplastic polymers such as polyamides (PA), polyolefins such as polypropylene (PP) or polyethylene (PE), polyacrylates such as polymethylmethacrylate (PMMA), polycarbonates (PC), Polyesters such as polyethylene terephthalate (PET) or polybutylene

- mixtures in the stated quantitative ranges are also possible with, for example, hydrophobically modified or functionalized polymers or oligomers, rubbers such as polyacrylates or polydienes, for example styrene-butadiene block copolymers or biodegradable aliphatic or aliphatic / aromatic copolyesters.

- rubbers such as polyacrylates or polydienes, for example styrene-butadiene block copolymers or biodegradable aliphatic or aliphatic / aromatic copolyesters.

- the polymer granules according to the invention contain a blowing agent component.

- the blowing agent component comprises one or more blowing agents in a proportion of 1 to 15 wt .-%, preferably 2 to 6 wt .-%, particularly preferably 3 to 5 wt .-%, based on.

- Suitable propellants are, for example, aliphatic hydrocarbons having 2 to 8, preferably 3 to 8 carbon atoms and mixtures of 2 or more such hydrocarbons and / or 2 or more isomers of such hydrocarbons.

- butane and pentane isomers such as isobutane, n-butane, isopentane, n-pentane and mixtures thereof, in particular pentane isomers, such as iso-pentane and n-pentane, and mixtures of such isomers.

- Suitable in particular as co-blowing agent preferably in an amount of from 0 to 3% by weight, preferably from 0.25 to 2.5% by weight, in particular from 0.5 to 2.0% by weight (based on (P) ) are (C 1 -C 4 ) carbonyl compounds such as ketones and esters, C 1 -C 4 alcohols and C 2 -C 4 ethers.

- Preferred co-propellants are ketones, particularly preferably acetone.

- the stated blowing agent amounts are those added in the production.

- the content in the product and especially after storage is correspondingly lower.

- the expanded polymer granules according to the invention generally have a bulk density of at most 300 g / l, preferably 15 to 200 g / l, particularly preferably in the range from 40 to 150 g / l.

- bulk densities in the range of 40 to 150 g / l may occur, depending on the type and amount of the filler.

- the polymer particles according to the invention preferably contain an additive component. Suitable additives are known to the person skilled in the art.

- nucleating agent for example finely divided, inorganic solids such as talc, silica, mica, clay, zeolites, calcium carbonate and / or polyethylene waxes can be used in amounts of generally 0.1 to 10 wt .-%, preferably 0.1 to 3 wt. %, particularly preferably 0.1 to 1.5 wt .-%, based on (P), are used.

- the average particle diameter of the nucleating agent is usually in the range of 0.01 to 100 ⁇ m, preferably 1 to 60 ⁇ m.

- a particularly preferred nucleating agent is talc, for example talc from Luzenac Pharma.

- the nucleating agent may be added by methods known to those skilled in the art.

- additives such as fillers (for example mineral fillers such as glass fibers), plasticizers, flame retardants, IR absorbers and athermane materials such as carbon black, cokes, graphene and / or graphite, aluminum powder and titanium dioxide, soluble and insoluble dyes, pigments, UV Stabilizers and / or thermal stabilizers are added.

- fillers for example mineral fillers such as glass fibers

- plasticizers for example plasticizers, flame retardants, IR absorbers and athermane materials

- IR absorbers and athermane materials such as carbon black, cokes, graphene and / or graphite, aluminum powder and titanium dioxide, soluble and insoluble dyes, pigments, UV Stabilizers and / or thermal stabilizers are added.

- graphite in amounts of generally from 0.05 to 25% by weight, particularly preferably in amounts of from 2 to 8% by weight, based on (P).

- Suitable particle sizes for the graphite used are in the range from 1 to 50 ⁇ m, preferably in the range from 2 to 10 ⁇ m.

- UV stabilizers has proved to be advantageous. Especially with the polymers PS1) such as SMA, strong UV irradiation leads to visible yellowing and chemical conversion of the material, which is accompanied by significant embrittlement.

- the reactivity e.g. with SMA, a crucial role.

- stabilizers based on benzotriazoles such as Tinuvin 234 can improve the UV resistance without changing the processing and foaming properties

- stabilizers based on sterically hindered amines such as Uvinul 4050 and Tinuvin 770 are suitable to a lesser extent for the material system according to the invention.

- the granules according to the invention preferably contain as additive an UV stabilizer based on benzotriazoles in amounts in the range of 0.05 to 5 parts by weight, preferably 0.1 to 1 part by weight, based on 100 parts by weight of polymer P.

- Suitable flame retardants are, for example, tetrabromobisphenol A, brominated polystyrene oligomers, brominated butadiene-polystyrene copolymers according to WO 2007/058736 , Tetrabromobisphenol A diallyl ether and hexabromocyclododecane (HBCD), in particular the technical products which essentially contain the ⁇ , ⁇ and ⁇ isomer and an addition of synergists such as dicumyl.

- tetrabromobisphenol A brominated polystyrene oligomers, brominated butadiene-polystyrene copolymers according to WO 2007/058736 , Tetrabromobisphenol A diallyl ether and hexabromocyclododecane (HBCD)

- HBCD hexabromocyclododecane

- brominated aromatics such as tetrabromobisphenol A, and brominated styrene oligomers.

- Suitable halogen-free flame retardants are, for example, expandable graphite, red phosphorus and phosphorus compounds, such as expandable graphite, red phosphorus, triphenyl phosphate and 9,10-dihydro-9-oxa-10-phosphaphenanthren-10-oxide.

- Preferred phosphorus compounds are tris (2-chloroisopropyl) phosphate, triethyl phosphite, diethyl ethyl phosphonates, cresyl diphenyl phosphates, Exolit OP560, phosphoric acid 6- (diphenoxy-phosphoryloxy) -hexahydro-furo [3,2-b] -furan-3-yl-ester- diphenyl ester, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or 6-bibenzo [c, e] [1,2] oxaphosphorine-6-oxide).

- the abovementioned flame retardants can either be dissolved in the monomers before the beginning of the polymerization or be incorporated into the TPU by extrusion.

- the polymer particles according to the invention are coated with one or more coating components, wherein these coating components may optionally be adsorbed to a porous-containing solid.

- Suitable coating components are, for example, glycerol esters, zinc stearate, esters of citric acid and in particular finely divided silicates.

- the corresponding commercial products which are generally mixtures of the corresponding mono-, di- and triesters, which may also contain small amounts of free glycerol and free fatty acids, such as glycerol tri- or glycerol monostearates.

- hydrophilic silica eg Sipernat® FK320, from Evonic

- plasticizers from the group consisting of a) one or more alkyl esters of cyclohexanecarboxylic acids having a boiling point ⁇ 160 ° C., b) one or more C 10 -C 21 -alkanesulfonic acid phenyl esters having a boiling point ⁇ 150 ° C. and c) mixtures the components a) and b).

- the mono-, di- and triglycerides which are obtainable from glycerol and stearic acid, glycerol and 12-hydroxystearic acid and glycerol and ricinoleic acid, and mixed di- and triglycerides which, in addition to stearic acid, 12-hydroxystearic acid and ricinoleic acid, comprise one or two fatty acids from the group oleic acid, linoleic acid, linolenic acid and palmitic acid are available.

- the total amount of additives is generally 0 to 5 wt .-%, preferably 0 to 0.5 wt .-%, based on the total weight of the polymers used.

- styrene is preferably used according to the above.

- other radically polymerizable monomers such as alkylstyrenes, divinylbenzene, 1,4-butanediol dimethacrylate, acrylonitrile, I, I-diphenyl ether or ⁇ -methylstyrene and acrylates can be used.

- blowing agent conventional additives such as peroxide initiators, suspension stabilizers, blowing agents, chain transfer agents, expanding aids, nucleating agents and plasticizers may be added in the suspension polymerization.

- auxiliaries and additives mentioned can be added to the suspension. Quantities of 3 to 15 wt .-%, based on the sum of monomer and TPU added. It can be added before, during or after the polymerization of the suspension.

- suspension stabilizers inorganic Pickering dispersants e.g. Magnesium pyrophosphate or calcium phosphate use.

- the TPU used before being used in the polymerization, can be processed by underwater granulation to give a miniprimulate having an average diameter of 0.5 to 1.5 mm.

- a product with a particle size is obtained, which can be processed on commercially available EPS machines.

- nucleating agents such as talc or polyethylene waxes in amounts of from 0.01 to 15 wt .-% can be incorporated by extrusion into the polyurethane used.

- a preferred embodiment of the process is characterized in that first an aqueous phase which contains 0.1 to 10% by weight of the abovementioned Pickering stabilizers, 0.1 to 0.001% by weight of a surfactant (for example sodium dodecylsulfonate) and 1 to 90% by weight.

- a surfactant for example sodium dodecylsulfonate

- TPU granules are presented in a stirrable pressure autoclave.

- the monomer which optionally contains the abovementioned auxiliaries, such as initiators and flame retardants, is metered into the stirred reactor at room temperature or below the polymerization temperature.

- the TPU is first combined at room temperature with the monomer which contains the abovementioned auxiliaries, such as initiators and optionally flame retardants, in the absence of water and for Let it swell for 0.5 to 24 hours. Subsequently, the granules which have been swollen by monomer are likewise transferred into the polymerization reactor, in which the aqueous phase is present with the abovementioned Pickering stabilizer and the surfactant.

- bead-shaped, substantially round particles having a mean diameter in the range of 0.5 to 4 mm are formed when microgranular TPU is used or 0.5 to 2 cm in size when microgranulation of the TPU is omitted.

- They can be coated with the usual coating agents, for example metal stearates, glycerol esters and finely divided silicates.

- metal stearates for example metal stearates, glycerol esters and finely divided silicates.

- the expandable polymer particles can be made into foams having densities of from 20 to 250 g / l, preferably from 50 to 100 g / l.

- the expandable preferred particles are prefoamed with steam (for example standard EPS prefoamer from Hirsch).

- the pre-expanded particles are preferably deposited for 10 to 24 hours and then preferably processed in a standard EPS machine, into blocks or molded parts.

- the resulting blocks or molded parts can be elasticized in mechanical presses by means of loading and unloading.

- a unidirectional elastification of the material has proven advantageous for such applications.

- elastification a foam body (block and molding) is compressed with a press to 10 to 50% of the original volume. After completion of compression up to a storage time (up to 24 h) of the compressed molding is cut accordingly.

- the elasticized materials have an extremely high undirectional recovery capability.

- MPP precipitation can be prepared as follows:

- the swollen TPU was placed in a 6 l pressure autoclave [EPS reactor, maximum pressure: 20 bar, paddle stirrer; Stirrer speed 300 U / min] transferred, in which 3 kg of deionized water, 803 g MPP precipitation and 42 g of 2% solution of the emulsifier E30 (manufactured from E30-40 Fa. Leuna Tenside GmbH) were.

- EPS reactor maximum pressure: 20 bar, paddle stirrer; Stirrer speed 300 U / min

- E30 manufactured from E30-40 Fa. Leuna Tenside GmbH

- 80 g of iso-pentane were metered into the reactor within 40 minutes.

- a temperature of 125 ° C was maintained for a further 6.5 hours, then cooled to room temperature.

- the propellant-containing polymer beads obtained were decanted off, dried from internal water and coated with 0.3% by weight of precipitated silica (Sipernat FK320, Evonik ).

- the material was placed in a pressure-sealed box (zinc box) for at least 2 to 5 days for equilibration.

- the nitrogen content of the polymer was determined (Kjeldahl nitrogen determination). By comparison with the TPU used, the TPU content of the polymer was calculated nitrogen analysis TPU content polymer 0.92% 33% Reference TPU 2.8% 100%

- the coated polymer was prefoamed to a density of 50 g / l (vapor pressure 0.2 bar).

- the pre-expanded material was deposited for 10 hours and processed in a standard EPS processing machine into round moldings.

- the following processing parameters have proven to be practical: product bulk density print molding Foam pressure max. demolding comment [g / L] [bar] number [bar] [s] according to Example 1 60g / L 55.5 1.1 1 1.56 281 1.3 / 1.1 bar 2 1.55 277 “ 3 1.50 278 " 4 1.58 298 "

- Example 1 was repeated except that the TPU component used was a TPU minigranulate which contains 0.5% by weight talc of Elastollan 1180A (TPU based on MDI, PolyTHF 1000, PolyTHF 2000 and butanediol) from BASF Polyurethanes GmbH.

- TPU component used was a TPU minigranulate which contains 0.5% by weight talc of Elastollan 1180A (TPU based on MDI, PolyTHF 1000, PolyTHF 2000 and butanediol) from BASF Polyurethanes GmbH.

- the batch was then introduced into a 10 l EPS reactor [pressure autoclave (20 bar) with paddle stirrer; Stirrer speed 300 rpm.]. 3.50 kg of dem. Water, 1.07 kg of MPP precipitation and 56 g of a 2% strength solution of the emulsifier E30 (alkanesulfonate, CAS68188-18-1) (from Leuna Tenside GmbH ) were initially introduced into the reactor. The suspension was heated to 50 ° C over 30 minutes and kept at 50 ° C for 3 hours to swell. Subsequently, the temperature was increased within one hour to 125 ° C, 60 minutes after reaching 125 ° C 314 g of pentane-S ( Messrs.

- Example 3 was repeated, but used as TPU but Minigranulat the type 1170AU with 0.5 wt .-% talc.

- the material from Example 2 can be pre-expanded after 19 days of storage to a density of 94 g / l, while the material of Example 1 can be prefoamed even after 53 days storage to a density of 64 g / l.

- Example 2 Analogously to the procedure described in Example 1, the styrene used for swelling was mixed with 0.3% by weight of Lumogen Red. The foam obtained after processing had a red color.

- the styrene used for swelling is mixed with 0.3% by weight of Lumogen Green.

- the foam obtained after processing had a green color.

- Example 1 was repeated with the following changes. Polymerization 1.2 used 965 g of pure TPU microgranules instead of a styrene-saturated TPU. The resulting blowing agent-containing TPU particles could no longer be prefoamed to expandable foam particles.

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Polyurethanes Or Polyureas (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Manufacture Of Porous Articles, And Recovery And Treatment Of Waste Products (AREA)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12175270.3A EP2682427A1 (de) | 2012-07-06 | 2012-07-06 | Polyurethan basierte expandierbare Polymerpartikel |

| PCT/EP2013/064248 WO2014006182A1 (de) | 2012-07-06 | 2013-07-05 | Polyurethan basierte expandierbare polymerpartikel |

| JP2015519230A JP6411338B2 (ja) | 2012-07-06 | 2013-07-05 | ポリウレタンをベースとする発泡性ポリマー粒子材料 |

| EP13734102.0A EP2870194B1 (de) | 2012-07-06 | 2013-07-05 | Polyurethan basierte expandierbare polymerpartikel |

| US14/412,233 US9447249B2 (en) | 2012-07-06 | 2013-07-05 | Polyurethane-based expandable polymer particles |

| ES13734102.0T ES2608102T3 (es) | 2012-07-06 | 2013-07-05 | Partícula expandible de polímero a base de poliuretano |

| CN201380046570.8A CN104662073B (zh) | 2012-07-06 | 2013-07-05 | 基于聚氨酯的可膨胀聚合物颗粒 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12175270.3A EP2682427A1 (de) | 2012-07-06 | 2012-07-06 | Polyurethan basierte expandierbare Polymerpartikel |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2682427A1 true EP2682427A1 (de) | 2014-01-08 |

Family

ID=48746545

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12175270.3A Ceased EP2682427A1 (de) | 2012-07-06 | 2012-07-06 | Polyurethan basierte expandierbare Polymerpartikel |

| EP13734102.0A Not-in-force EP2870194B1 (de) | 2012-07-06 | 2013-07-05 | Polyurethan basierte expandierbare polymerpartikel |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13734102.0A Not-in-force EP2870194B1 (de) | 2012-07-06 | 2013-07-05 | Polyurethan basierte expandierbare polymerpartikel |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9447249B2 (enExample) |

| EP (2) | EP2682427A1 (enExample) |

| JP (1) | JP6411338B2 (enExample) |

| CN (1) | CN104662073B (enExample) |

| ES (1) | ES2608102T3 (enExample) |

| WO (1) | WO2014006182A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2976389B1 (de) * | 2013-03-20 | 2018-05-16 | Basf Se | Polyurethan basierte polymerzusammensetzung |

Families Citing this family (48)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD953709S1 (en) | 1985-08-29 | 2022-06-07 | Puma SE | Shoe |

| USD855953S1 (en) | 2017-09-14 | 2019-08-13 | Puma SE | Shoe sole element |

| DE102012206094B4 (de) | 2012-04-13 | 2019-12-05 | Adidas Ag | Sohlen für Sportschuhe, Schuhe und Verfahren zur Herstellung einer Schuhsohle |

| US9598548B2 (en) | 2012-08-09 | 2017-03-21 | Basf Se | Producing polymer foams comprising imide groups |

| EP2882788B1 (de) | 2012-08-09 | 2016-10-12 | Basf Se | Kombinationsschaum |

| DE102013202291B4 (de) | 2013-02-13 | 2020-06-18 | Adidas Ag | Dämpfungselement für Sportbekleidung und Schuh mit einem solchen Dämpfungselement |

| DE102013002519B4 (de) | 2013-02-13 | 2016-08-18 | Adidas Ag | Herstellungsverfahren für Dämpfungselemente für Sportbekleidung |

| DE102013202306B4 (de) | 2013-02-13 | 2014-12-18 | Adidas Ag | Sohle für einen Schuh |

| US9610746B2 (en) | 2013-02-13 | 2017-04-04 | Adidas Ag | Methods for manufacturing cushioning elements for sports apparel |

| US9930928B2 (en) | 2013-02-13 | 2018-04-03 | Adidas Ag | Sole for a shoe |

| USD776410S1 (en) | 2013-04-12 | 2017-01-17 | Adidas Ag | Shoe |

| WO2015197515A1 (de) * | 2014-06-23 | 2015-12-30 | Covestro Deutschland Ag | Verwendung von thermoplastischen polyurethanpulvern |

| DE102014215897B4 (de) | 2014-08-11 | 2016-12-22 | Adidas Ag | adistar boost |

| DE102014216115B4 (de) | 2014-08-13 | 2022-03-31 | Adidas Ag | Gemeinsam gegossene 3D Elemente |

| DE102015202013B4 (de) | 2015-02-05 | 2019-05-09 | Adidas Ag | Verfahren zur Herstellung eines Kunststoffformteils, Kunststoffformteil und Schuh |

| MX2017011809A (es) * | 2015-03-13 | 2017-12-07 | Basf Se | Metodo para producir espumas en forma de particulas a base de elastomeros termoplasticos mediante enlace termico utilizando microondas. |

| JP6679363B2 (ja) | 2015-03-23 | 2020-04-15 | アディダス アーゲー | ソールおよびシューズ |

| DE102015206486B4 (de) | 2015-04-10 | 2023-06-01 | Adidas Ag | Schuh, insbesondere Sportschuh, und Verfahren zur Herstellung desselben |

| DE102015206900B4 (de) * | 2015-04-16 | 2023-07-27 | Adidas Ag | Sportschuh |

| DE102015209795B4 (de) * | 2015-05-28 | 2024-03-21 | Adidas Ag | Ball und Verfahren zu dessen Herstellung |

| USD783264S1 (en) | 2015-09-15 | 2017-04-11 | Adidas Ag | Shoe |

| CN105348665A (zh) * | 2015-12-11 | 2016-02-24 | 绍兴文理学院元培学院 | 一种复合tpu与eps的可发性树脂及其制备方法 |

| DE102016209044B4 (de) | 2016-05-24 | 2019-08-29 | Adidas Ag | Sohlenform zum Herstellen einer Sohle und Anordnung einer Vielzahl von Sohlenformen |

| DE102016209046B4 (de) | 2016-05-24 | 2019-08-08 | Adidas Ag | Verfahren zur herstellung einer schuhsohle, schuhsohle, schuh und vorgefertigte tpu-gegenstände |

| DE102016209045B4 (de) | 2016-05-24 | 2022-05-25 | Adidas Ag | Verfahren und vorrichtung zum automatischen herstellen von schuhsohlen, sohlen und schuhe |

| USD840136S1 (en) | 2016-08-03 | 2019-02-12 | Adidas Ag | Shoe midsole |

| USD840137S1 (en) | 2016-08-03 | 2019-02-12 | Adidas Ag | Shoe midsole |

| USD852475S1 (en) | 2016-08-17 | 2019-07-02 | Adidas Ag | Shoe |

| JP1582717S (enExample) | 2016-09-02 | 2017-07-31 | ||

| DE102016223980B4 (de) | 2016-12-01 | 2022-09-22 | Adidas Ag | Verfahren zur Herstellung eines Kunststoffformteils |

| USD850766S1 (en) | 2017-01-17 | 2019-06-11 | Puma SE | Shoe sole element |

| DE102017205830B4 (de) | 2017-04-05 | 2020-09-24 | Adidas Ag | Verfahren für die Nachbehandlung einer Vielzahl einzelner expandierter Partikel für die Herstellung mindestens eines Teils eines gegossenen Sportartikels, Sportartikel und Sportschuh |

| JP6912317B2 (ja) * | 2017-08-03 | 2021-08-04 | 株式会社ジェイエスピー | ウレタン系熱可塑性エラストマー発泡粒子 |

| USD975417S1 (en) | 2017-09-14 | 2023-01-17 | Puma SE | Shoe |

| JP1617832S (enExample) | 2017-09-21 | 2018-11-12 | ||

| USD899061S1 (en) | 2017-10-05 | 2020-10-20 | Adidas Ag | Shoe |

| CN111212869B (zh) * | 2017-10-10 | 2023-09-29 | 巴斯夫欧洲公司 | 弹性膜 |

| FR3073539B1 (fr) * | 2017-11-13 | 2020-05-15 | Gerflor | Panneau rigide pour la realisation d'un revetement de sol |

| US20210179847A1 (en) * | 2018-04-20 | 2021-06-17 | Basf Se | Foams based on thermoplastic elastomers |

| JP7447010B2 (ja) * | 2018-04-27 | 2024-03-11 | プーマ エス イー | 靴、特に運動靴 |

| ES2941984T3 (es) | 2018-12-18 | 2023-05-29 | Puma SE | Zapato, en particular zapato deportivo, y procedimiento para su fabricación |

| DE102019204579B4 (de) | 2019-04-01 | 2022-10-06 | Adidas Ag | Recycling eines Schuhs |

| CN111234506A (zh) * | 2020-03-19 | 2020-06-05 | 保士特(东莞)塑胶制品有限公司 | 一种可降解塑料紧固胶针及其制备方法 |

| USD944504S1 (en) | 2020-04-27 | 2022-03-01 | Puma SE | Shoe |

| CN112961399B (zh) * | 2021-03-17 | 2021-12-07 | 华东理工大学 | 一种阻燃隔热各向异性复合多孔材料及其制备方法和应用 |

| CN113621304B (zh) * | 2021-08-06 | 2022-03-18 | 浙江禾欣科技有限公司 | 一种自消光水性聚氨酯树脂及其制备方法 |

| US20240409752A1 (en) * | 2021-10-15 | 2024-12-12 | Basf Se | Thermoplastic polyurethane powders and 3d molding formed from the same |

| US12060524B2 (en) | 2022-06-23 | 2024-08-13 | Saudi Arabian Oil Company | Diverting materials for well stimulation |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3700752A (en) * | 1969-01-27 | 1972-10-24 | Ici Ltd | Gel polymerized polyurethane precursors and vinyl monomers |

| JPS5580440A (en) | 1978-12-13 | 1980-06-17 | Sekisui Plastics Co Ltd | Production of expandable polymer particle |

| WO2007082838A1 (de) | 2006-01-18 | 2007-07-26 | Basf Se | Schaumstoffe auf basis thermoplastischer polyurethane |

| JP2007231068A (ja) | 2006-02-28 | 2007-09-13 | Sekisui Plastics Co Ltd | スチレン改質熱可塑性ポリウレタン樹脂粒子、発泡性スチレン改質熱可塑性ポリウレタン樹脂粒子、スチレン改質熱可塑性ポリウレタン樹脂発泡粒子、スチレン改質熱可塑性ポリウレタン樹脂発泡成形体及びそれらの製造方法 |

| WO2010010010A1 (de) | 2008-07-25 | 2010-01-28 | Basf Se | Thermoplastische polymer blends auf der basis von thermoplastischem polyurethan und styrolpolymerisat, daraus hergestellte schaumstoffe und zugehörige herstellungsverfahren |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3705664B2 (ja) * | 1996-12-16 | 2005-10-12 | 富士写真フイルム株式会社 | 放射線像変換パネル |

| JPH10206600A (ja) * | 1997-01-23 | 1998-08-07 | Fuji Photo Film Co Ltd | 放射線像変換パネル |

| JP2001011141A (ja) * | 1999-06-29 | 2001-01-16 | Nof Corp | グラフト共重合体及びこれを含有する熱可塑性樹脂組成物 |

| JP3701514B2 (ja) * | 1999-06-30 | 2005-09-28 | 株式会社アシックス | トビナワロープ |

-

2012

- 2012-07-06 EP EP12175270.3A patent/EP2682427A1/de not_active Ceased

-

2013

- 2013-07-05 EP EP13734102.0A patent/EP2870194B1/de not_active Not-in-force

- 2013-07-05 ES ES13734102.0T patent/ES2608102T3/es active Active

- 2013-07-05 US US14/412,233 patent/US9447249B2/en not_active Expired - Fee Related

- 2013-07-05 JP JP2015519230A patent/JP6411338B2/ja not_active Expired - Fee Related

- 2013-07-05 WO PCT/EP2013/064248 patent/WO2014006182A1/de not_active Ceased

- 2013-07-05 CN CN201380046570.8A patent/CN104662073B/zh not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3700752A (en) * | 1969-01-27 | 1972-10-24 | Ici Ltd | Gel polymerized polyurethane precursors and vinyl monomers |

| JPS5580440A (en) | 1978-12-13 | 1980-06-17 | Sekisui Plastics Co Ltd | Production of expandable polymer particle |

| WO2007082838A1 (de) | 2006-01-18 | 2007-07-26 | Basf Se | Schaumstoffe auf basis thermoplastischer polyurethane |

| JP2007231068A (ja) | 2006-02-28 | 2007-09-13 | Sekisui Plastics Co Ltd | スチレン改質熱可塑性ポリウレタン樹脂粒子、発泡性スチレン改質熱可塑性ポリウレタン樹脂粒子、スチレン改質熱可塑性ポリウレタン樹脂発泡粒子、スチレン改質熱可塑性ポリウレタン樹脂発泡成形体及びそれらの製造方法 |

| WO2010010010A1 (de) | 2008-07-25 | 2010-01-28 | Basf Se | Thermoplastische polymer blends auf der basis von thermoplastischem polyurethan und styrolpolymerisat, daraus hergestellte schaumstoffe und zugehörige herstellungsverfahren |

Non-Patent Citations (2)

| Title |

|---|

| DATABASE WPI Week 200782, Derwent World Patents Index; AN 2007-888076, XP002689499 * |

| GERHARD W. BECKER; DIETRICH BRAUN: "Kunststoff Handbuch", vol. 7, 1993, CARL HANSER VERLAG, article "Polyurethane" |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2976389B1 (de) * | 2013-03-20 | 2018-05-16 | Basf Se | Polyurethan basierte polymerzusammensetzung |

Also Published As

| Publication number | Publication date |

|---|---|

| US20150344661A1 (en) | 2015-12-03 |

| CN104662073B (zh) | 2018-04-17 |

| EP2870194B1 (de) | 2016-09-14 |

| EP2870194A1 (de) | 2015-05-13 |

| ES2608102T3 (es) | 2017-04-05 |

| JP6411338B2 (ja) | 2018-10-24 |

| US9447249B2 (en) | 2016-09-20 |

| WO2014006182A1 (de) | 2014-01-09 |

| JP2015522680A (ja) | 2015-08-06 |

| CN104662073A (zh) | 2015-05-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2870194B1 (de) | Polyurethan basierte expandierbare polymerpartikel | |

| EP2976389B1 (de) | Polyurethan basierte polymerzusammensetzung | |

| EP3055353B1 (de) | Verfahren zur herstellung von expandierten thermoplastischen elastomerpartikeln | |

| EP2430097B1 (de) | Hybridschaum | |

| EP2435231B1 (de) | Wasser als treibmittel für polyurethane | |

| EP2109637B1 (de) | Hybridsysteme aus geschäumten thermoplastischen elastomeren und polyurethanen | |

| EP2496624B1 (de) | Verfahren zur herstellung eines polyurethanschaums mittels über- oder nahekritischen treibmittels | |

| DE60031290T2 (de) | Thermoplastische Polyurethane | |

| EP2882788B1 (de) | Kombinationsschaum | |

| EP2496618B1 (de) | Verfahren zur herstellung eines polyurethanschaums und hieraus erhältlicher polyurethanschaum | |

| WO2010010010A1 (de) | Thermoplastische polymer blends auf der basis von thermoplastischem polyurethan und styrolpolymerisat, daraus hergestellte schaumstoffe und zugehörige herstellungsverfahren | |

| EP1636301A1 (de) | Verfahren zur herstellung von expandierbaren thermoplastischen elastomeren | |

| EP3433295A1 (de) | Vernetztes polyurethan | |

| EP3902858A1 (de) | Etpu mit hoher festigkeit | |

| WO2013153153A1 (de) | Thermoplastische formmasse | |

| EP3931244A1 (de) | Weicher partikelschaum aus thermoplastischem polyurethan | |

| EP3274387A1 (de) | Gedächtnisschaum auf der basis von thermoplastischem polyurethan | |

| WO2022162048A1 (de) | Partikelschaum aus tpe mit einer shorehärte zwischen 20d und 90d | |

| WO2020136238A1 (de) | Partikelschäume aus aromatischem-polyester-polyurethan-multiblockcopolymer | |

| WO2022043428A1 (de) | Geschäumtes granulat aus thermoplastischem polyurethan | |

| WO2020053348A1 (de) | Verfahren zur herstellung von formkörpern aus mikrozellulären polyurethanelastomeren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 20140208 |