EP2492466A2 - Procédé de fabrication de conduit de décomposition - Google Patents

Procédé de fabrication de conduit de décomposition Download PDFInfo

- Publication number

- EP2492466A2 EP2492466A2 EP12154712A EP12154712A EP2492466A2 EP 2492466 A2 EP2492466 A2 EP 2492466A2 EP 12154712 A EP12154712 A EP 12154712A EP 12154712 A EP12154712 A EP 12154712A EP 2492466 A2 EP2492466 A2 EP 2492466A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- decomposition

- sand core

- static mixer

- decomposition conduit

- mold

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features

- F01N13/18—Construction facilitating manufacture, assembly, or disassembly

- F01N13/1861—Construction facilitating manufacture, assembly, or disassembly the assembly using parts formed by casting or moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/21—Mixing gases with liquids by introducing liquids into gaseous media

- B01F23/213—Mixing gases with liquids by introducing liquids into gaseous media by spraying or atomising of the liquids

- B01F23/2132—Mixing gases with liquids by introducing liquids into gaseous media by spraying or atomising of the liquids using nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3131—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit with additional mixing means other than injector mixers, e.g. screens, baffles or rotating elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/42—Static mixers in which the mixing is affected by moving the components jointly in changing directions, e.g. in tubes provided with baffles or obstructions

- B01F25/43—Mixing tubes, e.g. wherein the material is moved in a radial or partly reversed direction

- B01F25/431—Straight mixing tubes with baffles or obstructions that do not cause substantial pressure drop; Baffles therefor

- B01F25/4316—Straight mixing tubes with baffles or obstructions that do not cause substantial pressure drop; Baffles therefor the baffles being flat pieces of material, e.g. intermeshing, fixed to the wall or fixed on a central rod

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

- B22C9/02—Sand moulds or like moulds for shaped castings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

- B22C9/10—Cores; Manufacture or installation of cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D29/00—Removing castings from moulds, not restricted to casting processes covered by a single main group; Removing cores; Handling ingots

- B22D29/001—Removing cores

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion

- F01N3/206—Adding periodically or continuously substances to exhaust gases for promoting purification, e.g. catalytic material in liquid form, NOx reducing agents

- F01N3/2066—Selective catalytic reduction [SCR]

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2892—Exhaust flow directors or the like, e.g. upstream of catalytic device

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/40—Static mixers

- B01F25/42—Static mixers in which the mixing is affected by moving the components jointly in changing directions, e.g. in tubes provided with baffles or obstructions

- B01F25/43—Mixing tubes, e.g. wherein the material is moved in a radial or partly reversed direction

- B01F25/431—Straight mixing tubes with baffles or obstructions that do not cause substantial pressure drop; Baffles therefor

- B01F25/43197—Straight mixing tubes with baffles or obstructions that do not cause substantial pressure drop; Baffles therefor characterised by the mounting of the baffles or obstructions

- B01F25/431974—Support members, e.g. tubular collars, with projecting baffles fitted inside the mixing tube or adjacent to the inner wall

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2240/00—Combination or association of two or more different exhaust treating devices, or of at least one such device with an auxiliary device, not covered by indexing codes F01N2230/00 or F01N2250/00, one of the devices being

- F01N2240/20—Combination or association of two or more different exhaust treating devices, or of at least one such device with an auxiliary device, not covered by indexing codes F01N2230/00 or F01N2250/00, one of the devices being a flow director or deflector

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2470/00—Structure or shape of exhaust gas passages, pipes or tubes

- F01N2470/28—Tubes being formed by moulding or casting x

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/02—Adding substances to exhaust gases the substance being ammonia or urea

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

- F01N2610/1453—Sprayers or atomisers; Arrangement thereof in the exhaust apparatus

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Definitions

- the present disclosure relates to diesel exhaust emissions technology and, more specifically, to a decomposition conduit fabricated with an integrated mixer and methods of manufacturing the same.

- an exemplary schematic diagram illustrates an inline six cylinder diesel engine 10 with exhaust gas recirculation (EGR) that is utilized to reduce NO x formation.

- EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders.

- the exhaust gas replaces some of the excess oxygen in the pre-combustion mixture.

- NO x forms primarily when a mixture of nitrogen and oxygen is subjected to high temperature and NO x formation progresses much faster at high temperatures

- EGR reduces the amount of NO x the combustion generates. Nevertheless, NO x formation is an inherent part of combustion.

- NO x formation has been known to have significant detrimental consequences on our environment. These consequences include acid rain, smog, and creation of harmful particulate matter. In order to combat these consequences, diesel engine manufacturers have implemented technologies to reduce NO x from diesel fuel combustion. One of these technologies involves downstream treatment of the diesel exhaust through selective catalytic reduction (SCR).

- SCR selective catalytic reduction

- SCR uses a urea based diesel exhaust fluid (DEF) and a catalytic converter to significantly reduce oxides of nitrogen (NO x ) emissions.

- DEF diesel exhaust fluid

- Small quantities of diesel exhaust fluid (DEF) are injected into the exhaust upstream of a catalyst, where it vaporizes and decomposes to form ammonia and carbon dioxide.

- Ammonia (NH 3 ) is the desired product, which in conjunction with the SCR catalyst, converts the NO x to harmless nitrogen (N 2 ) and water (H 2 O).

- FIG. 1 shows a common SCR implementation.

- exhaust from the diesel engine 10 is directed through a particulate filter 12 and into a decomposition tube 14.

- DEF a blended aqueous urea solution and deionized water

- a supply tank 16 is injected into communication with the exhaust, which results in the urea decomposing to form ammonia prior to introduction to a catalytic converter 18.

- the catalytic converter 18 the ammonia and NO x components of the exhaust react in the presence of the catalyst to generate water, nitrogen gas, and oxygen gas.

- the water, nitrogen gas, and oxygen gas is thereafter conveyed to the open atmosphere via an exhaust stack or tailpipe 20.

- decomposition tubes are formed by rolling metal sheets to form a circular cross-section tube. Thereafter, the tube is modified to include an injector fitting, commonly by welding the injector fitting over a preexisting opening in the rolled tube.

- an injector fitting commonly by welding the injector fitting over a preexisting opening in the rolled tube.

- an entirely separate mixing structure is positioned within the tube and welded to the interior of the tube. The additional steps of mounting the injector fitting and mixing structure within the rolled tube add considerable cost and time to the overall fabrication process for producing a decomposition tube. At the same time, the welds may sometimes impart localized areas of weakness to the rolled tube that may eventually give way and create unintended orifices within the tube.

- the seams between the welds and the decomposition tube and mixer are subject to attack by urea that flows through the decomposition tube, causing separation between the welds and the decomposition tube and mixer. This separation leads to attachment failure between the mixer and the decomposition tube.

- the exemplary embodiments of the present disclosure include novel decomposition conduits and methods of fabricating these novel conduits.

- the sand core comprises a cylindrical sand body interposed by the static mixer, the cylindrical sand body including a projection representative of an injector adapter of the decomposition conduit housing.

- the act of molding the decomposition conduit includes suspending the sand core at least partially within the decomposition conduit housing mold.

- the static mixer includes a plurality of mixer fins distributed within a metal band having an outer circumferential face and, the act of molding the decomposition conduit housing includes overmolding material into contact with the outer circumferential face of the static mixer, where overmolding the material operates to bond the static mixer to the decomposition conduit housing.

- the method also includes the act of removing the molded decomposition housing from the mold, where at least a portion of the sand core remains within the molded decomposition housing when the decomposition housing is removed from the mold.

- the act of creating the sand core includes forming a cylindrical sand body interposed by the static mixer, the cylindrical sand body including a projection representative of an injector adapter of the decomposition conduit housing.

- the act of creating the sand core includes positioning the static mixer within a sand core mold, wherein the static mixer and the sand core mold cooperate to delineate a sand core cavity.

- the sand core mold includes prongs formed by walls of the sand core mold tapering to seat the static mixer therein.

- the static mixer includes a plurality of mixer fins distributed within a metal band having an outer circumferential face and, the act of molding the decomposition conduit housing includes overmolding material into contact with the outer circumferential face of the static mixer, where overmolding the material operates to bond the static mixer to the decomposition conduit housing.

- the sand core includes a bell and, the act of molding the decomposition conduit housing includes integrally forming the bell.

- the sand core includes a plurality of bells and, the act of molding the decomposition conduit includes integrally forming the plurality of bells.

- the sand core includes a pair of circumferential depressions formed on opposite sides of the static mixer.

- It is a third aspect of the present disclosure to provide a decomposition structure comprising a decomposition conduit including an outer housing defining a flow path between an inlet orifice and an outlet orifice, the decomposition conduit including an integral static mixer in series with the fluid flow path.

- the decomposition conduit includes at least one of a ninety degree elbow section and a straight section.

- the decomposition conduit further includes an integrated injector port.

- the decomposition conduit and the injector port comprise cast metal.

- the static mixer is embedded within the housing of the decomposition conduit.

- the decomposition conduit is at least partially filled with sand.

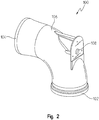

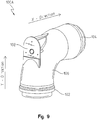

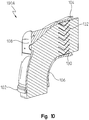

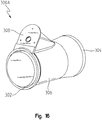

- a first exemplary decomposition conduit 100 includes an inlet bell 102 in communication with an outlet bell 104 via a ninety degree curved elbow or conduit 106.

- the bells 102, 104 are integrally formed with the curved conduit 106 and provide a female interface to accept corresponding male pipes (not shown).

- Fluid flow is adapted to pass through the inlet bell 102 in a Y-direction and be redirected in an X-direction (see FIG. 8 ), approximately perpendicular to the Y-direction, before egressing through the outlet bell 104.

- An injector fitting 108 is integrally formed with the conduit 106 in order to receive an injector 110 (see FIG. 5 ). Any commercially available DEF injectors may be used with the instant decomposition tube 100. In this exemplary embodiment, the injector is received within the injector fitting 108 and mounted thereto in order to direct the DEF fluid coaxially with the exhaust flowing in the X-direction.

- the injector 110 is connected to a DEF supply line 112 in communication with a DEF supply tank 114.

- the DEF tank supplies DEF fluid to the injector 110, where DEF fluid is injected into communication with the exhaust.

- DEF fluid decomposes to form ammonia that is mixed with exhaust prior to reaching a catalytic converter 120 downstream from the decomposition conduit 100.

- additional mixing other than inherently provided by DEF fluid and exhaust being in communication with one another is preferred.

- an in-line static mixer 130 is provided as part of the decomposition conduit 100 downstream from the injector fitting 108 and just upstream from the outlet bell 104.

- the static mixer 130 comprises a series of fixed elements or fins 132 circumscribed by a metal band integrally formed and mounted to the interior wall of the conduit.

- the fixed geometric design of the elements 132 simultaneously produces patterns of flow division and radial mixing. As a result, the ammonia and exhaust are mixed more effectively.

- One of the advantages of a static mixer 130 over a conventional mixer is the absence of moving parts that may be prone to motion stresses and corresponding fatigue failure.

- the static mixer 130 is formed as an integral unit with the curved conduit 106 and the injector fitting 108.

- an exemplary process flow 200 details how the decomposition conduit 100 is fabricated.

- the static mixer core 130 is fabricated. Those skilled in the art are familiar with fabricating static mixer cores 130 bounded by a circular wall.

- the second step 204 is to insert the static mixer core 130 into a sand mold (see FIG. 7 ) in order to form a sand core 230 (see FIG. 8 ).

- the sand mold comprises two half sections 240 each having an interior cavity 242 that is exactly one half of the size and includes the same dimensions as the interior of the decomposition conduit 100 to be fabricated.

- Each sand mold half 240 includes an elbow-shaped wall 244 that tapers to include a pair of circumferential projections 246. These circumferential projections 246 operate as boundaries or bookends to help seat the static mixer 130 within the mold.

- the taper of the wall 244 is operative to reduce the cross-section of the sand core 230. As will be discussed hereafter, this reduction in the cross-section of the sand core 230 cooperates with the decomposition mold to create a decomposition conduit with a smooth transition between its interior wall and that of the static mixer 130.

- the mold halves 240 are brought together and closed, followed by the introduction of sand to fill all of the voids on the interior of the mold that are not otherwise occupied by the static mixer core.

- the mold halves 240 are generally constructed of metal, but the mold halves may also be constructed of wood, gypsum or other material having sufficient hardness and strength.

- One exemplary technique to fill the interior of the mold involves blowing a sand-air mixture into the mold to uniformly distribute the sand (with resin) within the mold. Afterwards, the sand is packed within the mold using a combination of vibratory compacting and application of positive pressure using an inflatable bladder or application of negative pressure using a vacuum. The mold is thereafter opened and the resulting sand core 230 is released from the mold halves using gas flow. Specifically, the mold halves include air channels to permit compressed air to flow therethrough and push against the sand core 230 in order to rapidly release the sand core from the mold halves. The mold is then cleaned for reuse and the process starts again to form another sand core. The resulting sand core 230 may be finished by hand or machine to remove certain joint lines left behind by the joining of the mold halves and thereafter heat treated.

- the fourth step 208 includes inserting the sand core 230 is a unitary piece within a decomposition mold (not shown).

- the decomposition mold includes an internal cavity that has the same dimensions as the decomposition conduit 100 to be fabricated, in addition to the interior of the decomposition conduit.

- the sand core 230 is suspended within the decomposition mold and the decomposition mold is closed.

- the resulting cavity within the decomposition mold has the same dimensions as the decomposition conduit 100 to be fabricated.

- molten metal is introduced into the interior of the decomposition mold and fills the gaps between the sand core and mold.

- the result of the fifth step 210 is a cast decomposition conduit housing 100A that is formed around the sand core 230.

- the metal decomposition conduit housing 100A is integrally formed with the static mixer core 130 so that there is no seam or welded interface between the outer circumferential portion of the conduit and the circular rim of the static mixer core 130.

- the term "integral” refers to a single structure that may be comprised of multiple structures without requiring welds or other fastening devices to mount the multiple structures to one another.

- the term “integrally formed” refers to a process where multiple structures are produced to create is a single piece, where the multiple structures are mounted to one another without requiring welds or other fastening devices.

- the incidence of urea degradation causing the static mixer core 130 to separate from the decomposition conduit is substantially reduced if not eliminated.

- the decomposition conduit housing and sand core 230 are processed to remove the sand from the interior of the conduit.

- Exemplary methods of removing the sand include vibrating the sand free, using a fluid to flow through the interior of the decomposition conduit to remove the sand, and immersing the decomposition conduit in a fluid tank. The result of any one or more of these processes is the decomposition conduit shown in FIGS. 2-4 .

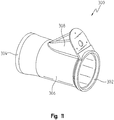

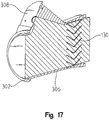

- a second exemplary decomposition conduit 300 includes an inlet bell 302 in communication with an outlet bell 304 interposing a straight conduit 306.

- the bells 302, 304 are integrally formed with the straight conduit 306 and provide a female interface to accept corresponding male pipes (not shown). Fluid flow is adapted to pass through the inlet bell 302 before egressing through the outlet bell 304.

- An injector fitting 308 is integrally formed with the conduit 306 in order to receive an injector 110 (see FIG. 5 ).

- the injector 110 is connected to a DEF supply line 112 in communication with a DEF supply tank 114.

- the DEF tank supplies DEF fluid to the injector 110, where DEF fluid is injected into communication with the exhaust.

- a static mixer 130 is provided as part of the decomposition conduit 300 downstream from the injector fitting 308 and just upstream from the outlet bell 304. Unlike prior art decomposition tubes, the static mixer 130 is formed as an integral unit with the straight conduit 306 and the injector fitting 308.

- the same or similar process flow 200 as described with respect to the first exemplary embodiment 100 may be used to fabricate the second exemplary decomposition conduit 300.

- the second exemplary embodiment includes fabricating a relatively straight sand core 430 using a sand mold 320 having an interior cavity that is exactly the same size and includes the same dimensions as the interior of the decomposition conduit 300 to be fabricated.

- the sand mold 320 has an interior cavity 322 that is exactly the same size and includes the same dimensions as the interior of the decomposition conduit 300 to be fabricated.

- the sand mold 320 includes a wall 324 that tapers to include a pair of circumferential projections 326. These circumferential projections 226 operate as boundaries or bookends to help seat the static mixer 130 within the mold. It should be noted that the taper of the wall 324 is operative to reduce the cross-section of the sand core 430.

- this reduction in the cross-section of the sand core 430 cooperates with the decomposition mold to create a decomposition conduit with a smooth transition between its interior wall and that of the static mixer 130.

- the mold is closed and sand is introduced to fill all of the voids on the interior of the mold that are not otherwise occupied by the static mixer core, thus creating the sand core 430.

- the mold halves 320 are generally constructed of metal, but the mold halves may also be constructed of wood, gypsum or other material having sufficient hardness and strength.

- the straight sand core 430 is thereafter inserted as a unitary piece within a decomposition mold (not shown).

- the decomposition mold includes an internal cavity that has the same dimensions as the decomposition conduit 300 to be fabricated, in addition to the interior of the decomposition conduit.

- the sand core 430 is suspended within the decomposition mold and the decomposition mold is closed.

- the resulting cavity within the decomposition mold has the same dimensions as the decomposition conduit 300 to be fabricated. Thereafter, molten metal is introduced into the interior of the decomposition mold and fills the gaps between the sand core and mold.

- the result of the casting step is a decomposition conduit housing 300A that is formed around the sand core 430.

- the metal decomposition conduit housing 300A is integrally formed with the static mixer core 130 so that there is no seam or welded interface between the outer circumferential portion of the conduit and the circular rim of the static mixer core 430.

- the incidence of urea degradation causing the static mixer core 130 to separate from the decomposition conduit is substantially reduced if not eliminated.

- the decomposition conduit housing and sand core 430 are processed to remove the sand from the interior of the conduit.

- Exemplary methods of removing the sand include vibrating the sand free, using a fluid to flow through the interior of the decomposition conduit to remove the sand, and immersing the decomposition fluid in a fluid tank. The result of any one or more of these processes is the decomposition conduit 300 shown in FIGS. 10 and 11 .

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Dispersion Chemistry (AREA)

- Molds, Cores, And Manufacturing Methods Thereof (AREA)

- Exhaust Silencers (AREA)

- Exhaust Gas After Treatment (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/031,824 US8689854B2 (en) | 2011-02-22 | 2011-02-22 | Decomposition conduit fabrication method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2492466A2 true EP2492466A2 (fr) | 2012-08-29 |

| EP2492466A3 EP2492466A3 (fr) | 2013-11-20 |

Family

ID=45607029

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12154712.9A Withdrawn EP2492466A3 (fr) | 2011-02-22 | 2012-02-09 | Procédé de fabrication de conduit de décomposition |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8689854B2 (fr) |

| EP (1) | EP2492466A3 (fr) |

| JP (1) | JP2012172678A (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109209581A (zh) * | 2017-07-04 | 2019-01-15 | 佛吉亚排气系统有限公司 | 用于车辆排气管线的喷射装置及相应的排气管线 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201207201D0 (en) * | 2012-04-24 | 2012-06-06 | Perkins Engines Co Ltd | Emissions cleaning module for a diesel engine |

| US9091193B2 (en) | 2013-12-13 | 2015-07-28 | Cnh Industrial America Llc | Systems and methods for cooling a diesel exhaust fluid dosing module of an agricultural vehicle |

| CN105643216B (zh) * | 2016-04-02 | 2018-02-09 | 无锡市蠡园金属容器有限公司 | 静态混合器加工工艺 |

| CN114033918B (zh) * | 2021-12-22 | 2025-01-21 | 天津市欧力诺能源技术有限公司 | 一种尿素水解分解器装置 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3729937A (en) * | 1971-12-17 | 1973-05-01 | Gen Motors Corp | Engine exhaust reactor and method of making |

| US5857328A (en) | 1997-11-24 | 1999-01-12 | General Motors Corporation | Exhaust manifold catalytic converter |

| FR2912464B1 (fr) | 2007-02-13 | 2009-04-10 | Renault Sas | Conduit d'echappement a double paroi comportant un moyen de diffusion. |

| JP4397402B2 (ja) | 2007-04-20 | 2010-01-13 | 株式会社日本自動車部品総合研究所 | 排気浄化装置 |

| DE102007020812B4 (de) | 2007-05-04 | 2010-01-14 | Audi Ag | Vorrichtung und Verfahren zur Zudosierung von fluiden schadstoffreduzierenden Medien in einen Abgaskanal einer Brennkraftmaschine |

| DE102007051510B4 (de) | 2007-10-29 | 2021-02-25 | Emcon Technologies Germany (Augsburg) Gmbh | Baugruppe zur Einbringung eines Reduktionsmittels in die Abgasleitung einer Abgasanlage einer Verbrennungskraftmaschine |

| US7976788B2 (en) | 2008-10-16 | 2011-07-12 | Cummins Filtration Ip, Inc. | Detachable decomposition reactor with an integral mixer |

-

2011

- 2011-02-22 US US13/031,824 patent/US8689854B2/en active Active

-

2012

- 2012-01-31 JP JP2012018857A patent/JP2012172678A/ja active Pending

- 2012-02-09 EP EP12154712.9A patent/EP2492466A3/fr not_active Withdrawn

Non-Patent Citations (1)

| Title |

|---|

| None |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109209581A (zh) * | 2017-07-04 | 2019-01-15 | 佛吉亚排气系统有限公司 | 用于车辆排气管线的喷射装置及相应的排气管线 |

| CN109209581B (zh) * | 2017-07-04 | 2021-01-26 | 佛吉亚排气系统有限公司 | 用于车辆排气管线的喷射装置及相应的排气管线 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20120211116A1 (en) | 2012-08-23 |

| EP2492466A3 (fr) | 2013-11-20 |

| JP2012172678A (ja) | 2012-09-10 |

| US8689854B2 (en) | 2014-04-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8689854B2 (en) | Decomposition conduit fabrication method | |

| JP5610120B2 (ja) | エンジンの排気浄化装置 | |

| CN103998760B (zh) | 具有燃料引导部的气缸盖 | |

| US20160194995A1 (en) | Flow mixing device for an exhaust after-treatment system | |

| WO2005032874A3 (fr) | Systeme de tuyau de remplissage de carburant et procede de fabrication correspondant | |

| CN110043399A (zh) | 整体进气岐管的流体输送端口 | |

| CN102209845A (zh) | 内燃机系统以及用于这种内燃机系统的微粒过滤器单元 | |

| JP5316796B2 (ja) | エンジンの排気浄化装置 | |

| CN110043387B (zh) | 具有冷凝物口的整体式气缸盖 | |

| CN110043396B (zh) | 具有排气再循环器的整体气缸盖 | |

| CN110043386B (zh) | 整体式气缸盖的流体输送端口 | |

| KR101892327B1 (ko) | 내연 엔진 및 내연 엔진 배열체를 작동하는 방법 | |

| CN102439271A (zh) | 流体混合系统 | |

| JPS63141713A (ja) | エンジン用合成樹脂製吸気管及びその製造方法 | |

| EP3075978A1 (fr) | Structure de conduit d'échappement | |

| JP6743285B2 (ja) | 還元剤供給ユニットコンパクト側方供給入口ポート | |

| JP5975217B2 (ja) | 排気管の継手構造 | |

| JP2017523336A (ja) | 触媒ユニット、触媒ユニットの製造方法、及び、排ガス触媒コンバータ | |

| JP2021053954A (ja) | 樹脂製パイプ及びその製造方法 | |

| CN221610064U (zh) | 用于还原剂喷射系统的喷嘴及内燃机排气管线 | |

| EP2931496A1 (fr) | Conduite d'air pour véhicule et procédé de fabrication de conduite d'air | |

| JP4983508B2 (ja) | 内燃機関の吸気制御装置 | |

| CN110043401A (zh) | 整体进气岐管 | |

| IT201900007740A1 (it) | Dispositivo di trattamento dei gas di scarico con iniezione di un agente riducente per un motore a combustione interna | |

| WO2020145156A1 (fr) | Culasse |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F01N 3/28 20060101AFI20131014BHEP Ipc: F01N 13/18 20100101ALI20131014BHEP Ipc: F01N 3/20 20060101ALI20131014BHEP |

|

| 17P | Request for examination filed |

Effective date: 20140520 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20160602 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170222 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20170705 |