EP2492405B1 - Dispositif d'élimination des déchets pour déchets de cuisine organiques et entraîneur pour un tel dispositif d'élimination des déchets - Google Patents

Dispositif d'élimination des déchets pour déchets de cuisine organiques et entraîneur pour un tel dispositif d'élimination des déchets Download PDFInfo

- Publication number

- EP2492405B1 EP2492405B1 EP11155675.9A EP11155675A EP2492405B1 EP 2492405 B1 EP2492405 B1 EP 2492405B1 EP 11155675 A EP11155675 A EP 11155675A EP 2492405 B1 EP2492405 B1 EP 2492405B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- kitchen waste

- shredding

- waste

- organic kitchen

- carrier

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/12—Plumbing installations for waste water; Basins or fountains connected thereto; Sinks

- E03C1/26—Object-catching inserts or similar devices for waste pipes or outlets

- E03C1/266—Arrangement of disintegrating apparatus in waste pipes or outlets; Disintegrating apparatus specially adapted for installation in waste pipes or outlets

- E03C1/2665—Disintegrating apparatus specially adapted for installation in waste pipes or outlets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/0084—Disintegrating by knives or other cutting or tearing members which chop material into fragments specially adapted for disintegrating garbage, waste or sewage

- B02C18/0092—Disintegrating by knives or other cutting or tearing members which chop material into fragments specially adapted for disintegrating garbage, waste or sewage for waste water or for garbage

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/16—Details

- B02C18/22—Feed or discharge means

- B02C18/2225—Feed means

- B02C18/2275—Feed means using a rotating arm

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/16—Details

- B02C18/22—Feed or discharge means

- B02C18/2225—Feed means

- B02C18/2291—Feed chute arrangements

Definitions

- the present invention relates to a driver and a disposal device for organic kitchen waste according to the preamble of claim 1 and of claim 6.

- Organic kitchen waste in the form of catering waste and equipment waste, for example, in large kitchens, canteens, hotels, communal catering and in the catering every day in large quantities.

- This organic kitchen waste can be used as a raw material for the production of renewable energy in biogas reactors.

- biogas reactors for this purpose, it is necessary to treat the organic kitchen waste so that they are storable and transportable.

- Organic kitchen waste can roughly be divided into two different categories, namely food waste and set-aside waste. The division results both from the place of origin and from the character of the respective organic kitchen waste.

- Food waste is understood as the remains of already prepared food. Food waste, for example, when returning plates and trays by the respective guests, employees or patients, before these plates or

- Trays are rinsed.

- food waste is typically incurred per patient and meal in an amount of about 250 g.

- Large quantities of catering waste are also produced in restaurants, hotels and canteens.

- Waste for example, fruit and vegetable husks, lettuce leaves and cabbage leaves, roots and other organic remains of not yet prepared food raw materials, which are prepared for the actual food preparation.

- a system For disposal and storage of organic kitchen waste, a system is known in which the organic kitchen waste is placed in a disposal device in which they are comminuted by means of a crushing device in the form of a mill, partially with the addition of water so that they subsequently in a largely homogenized form can be pumped into appropriate storage tanks. From these storage tanks, the then largely homogenized biomass is transported by means of a transport vehicle to a biogas plant, in which the biomass is fermented, wherein the fermentation resulting in fumigants, especially methane gas, is used to generate electrical energy and / or heat energy. In this way, organic kitchen waste can be recycled and recovered from this environmentally friendly renewable energy.

- the EP 0 189 379 A1 relates to a kneader for paper products and / or similar waste products.

- the JP 63-126695 A relates to a raw envelope treatment device.

- the JP 2004-298808 A relates to a device for treating garbage.

- the AU 2010 200 304 A1 concerns a system for treating garbage.

- the WO 2007/058176 A1 relates to a raw envelope treatment device.

- the JP 2001-293389 A relates to a crushing device.

- the US 4,387,858 A relates to a crushing machine for bulk material.

- the GB 1,200,842 relates to a device for comminuting solids.

- the US 2,828,083 relates to a garbage disposal device.

- the JP 10 057831 A shows a waste treatment apparatus in which waste in a cylinder is conveyed by means of a screw conveyor to a crushing device.

- the EP 1 685 906 A1 shows a device for treating food waste, which is arranged at the drain of a sink.

- the WO 2007/143853 A1 shows a crushing pump for pumping and crushing sludge or manure from a sludge or manure pit.

- a disposal device is independent of the type of organic kitchen waste, which is filled in a receiving device.

- a loading of the disposal device is possible only with loose, dry and light equipment waste, since these set-waste can now be transported by means of the driver to the crushing device or are pre-shredded by the driver so that they get into the crushing device by its own weight.

- the funnel-shaped receiving device preferably has a square cross section, a rectangular cross section, an oval cross section or a round cross section.

- the comminution device is preferably arranged such that organic kitchen waste filled from above passes by gravity to the comminuting device.

- the driver is rotatably connected to the crushing device, so that it rotates together with this. In this way, a simple conversion of existing disposal devices is possible.

- the driver so far in the Receiving device extends in that a take away of set-up waste is reliably possible. A Hereinragen the complete driver in the receiving device is not required.

- the depth by which the driver protrudes into the receiving device is determined by several factors, in particular by the pitch angle of the receiving hopper, wherein the driver must be dimensioned relative to the hopper so that even larger set-up waste between the hopper wall of the receiving device and the driver so can slip, that they can be finally captured by the driver.

- the driver has a coaxial with the axis of rotation of the crushing device arranged axis of rotation.

- the driver has a shaft extending coaxially to the axis of rotation, wherein the shaft preferably has a diameter which reduces the formation of braids and the adhesion of organic kitchen waste.

- the diameter of the shaft is in a range of 40mm to 70mm, more preferably in the range of 50mm to 60mm. In this way, not only the tendency to braid formation is reduced, but also a stability of the shaft against external disturbances improved, for example against interference from the introduction of foreign substances such as cutlery, screws or bones in the receiving device.

- the driver has at least one pre-shredder arranged perpendicular to its axis of rotation for comminuting organic kitchen waste, preferably for cutting or smashing the organic kitchen waste.

- the pre-comminuting knife is designed as a triangular knife, which has oblique knife edges directed towards the comminution device.

- the angle which the knife edges include is preferably in a range of 40 ° to 80 °, more preferably in a range of 50 ° to 70 °, particularly preferably about 60 °.

- the driver may have shaking means and / or conveying means for loosening and / or conveying the organic kitchen waste to the crushing device.

- the driver on the comminution device may have a flange, wherein the flange may preferably have at least one recess for receiving a driver of the comminuting device.

- the disposal device preferably has a pump for pumping out the organic kitchen waste shredded in the comminution device, the pump being connected to the comminuting device.

- the comminuting device can have a rotor and a blade ring surrounding the rotor.

- FIG. 1 shows in a perspective schematic representation of a disposal device 1, which for the disposal of organic kitchen waste, in particular of Food waste and from equipment waste, serves.

- the disposal device comprises a receiving device 2 in the form of a funnel, which initially serves to receive the uncut organic kitchen waste.

- the receiving device 2 is in FIG. 1 shown in the form of a funnel with rectangular cross-section.

- other cross sections may also be used, such as square cross sections, round cross sections, or oval cross sections.

- a crushing device 3 is provided, which are supplied via the receiving device 2 organic kitchen waste.

- the comminution device 3 is used for comminuting the organic kitchen waste supplied via the receiving device 2.

- the crushing device 3 may be in the form of, for example, in the Figures 5 and 6 be shown and described below mill.

- a driver 4 is arranged, which protrudes from the crushing device 3 from at least partially into the receiving device 2. In other words, the driver projects at least partially into the volume V defined by the dimensions of the receiving device 2.

- the driver 4 is used for improved supply of set-up waste to the crushing device 3.

- By feeding is here understood both the actual conveyance of organic kitchen waste, for example by means of a screw conveyor, as well as the conveyance of the organic kitchen waste by pre-crushing or mechanical shaking, to correspondingly easy , loose and dry set-up waste, which hitherto jammed in the receiving device 2, to be able to feed to the shredding device 3.

- the driver 4 prepares the organic kitchen waste so and / or moves them so that they Crushing device 3 are fed or slip into this.

- the driver 4 may be provided with pre-shredders as described below to pre-shred the typically light, loose and dry set-up scrapes so that they will slide more easily toward the shredder 3 in accordance with smaller set-up scrap and will not be able to become wedged together as much.

- the driver 4 may be provided with a vibrating device to let the light, loose and dry set-up waste by shaking further down to the crushing device 3.

- the driver 4 may be provided with a conveying device, for example in the form of a screw conveyor, by means of which the light, loose and dry set-up waste is conveyed in the direction of the comminuting device 3. The transport of food remains is not hindered by the driver 4.

- a conveying device for example in the form of a screw conveyor, by means of which the light, loose and dry set-up waste is conveyed in the direction of the comminuting device 3. The transport of food remains is not hindered by the driver 4.

- Disposal device 1 shown schematically further comprises a cover 10, by means of which the receiving device 2 can be covered.

- the receiving device 2 must be covered with the cover 10 before the crushing device 3 and the driver 4 are put into operation and start to rotate.

- the lid 10 prevents spillage of organic kitchen waste from the disposal device 1 while they are transported by the driver 4 to the crushing device 3 and during the actual crushing of organic kitchen waste in the crushing device 3. This is particularly advantageous if the crushing device 3 in shape a fast-rotating mill is provided, for example, with speeds of about 1400 U / min.

- the lid 10 is there to avoid that users engage in the receiving device 2 in when the Crushing device 3 is operated.

- the cover 10 is advantageously equipped with a safety switch such that the crushing device 3 and the driver 4 can only be operated when the flap 10 is closed.

- the disposal device 1 can be operated by a user.

- a water nozzle 14 for feeding process water into the receiving device 2 is provided in order to be able to produce sufficiently high water content in the case of dry organic kitchen waste in order to allow a subsequent pumping out of the biomass comminuted by the comminuting device 3.

- the water supply nozzle 14 can also be used for cleaning the receiving device 2 and the crushing device 3 and the driver 4. For cleaning, however, at least one further water supply nozzle may be provided at a different location in the receiving device 2.

- FIG. 2 is the disposal device 1 of FIG. 1 once again shown completely in a schematic perspective view, wherein also here the lid 10 is open. Owing to the perspective, at least the comminution unit 3 adjoining the receiving device 2 at the bottom is not visible.

- the driver 4 is arranged coaxially with the crushing unit 3, wherein the axis of rotation 400 of the driver 4 extends coaxially along the axis of rotation 300 of the crushing unit 3.

- the driver 4 is in FIG. 3 shown in a schematic perspective view.

- the driver axis 400 is surrounded by the driver shaft 40, which preferably has a diameter d, which is dimensioned so that a formation of braids from the organic kitchen waste to be processed on the shaft 40 is reduced or avoided.

- the diameter d of the shaft is about 50mm to 60mm.

- the surface of the shaft 40 of the driver 4 is advantageously equipped so that the adhesion of organic kitchen waste is largely avoided. Also by the choice of the diameter d of the shaft 40, adhesion of organic kitchen waste can be reduced, since corresponding centrifugal forces can be generated by the correspondingly higher peripheral speeds.

- a flange 42 with recesses 44 is provided, such that the driver 3 at the in the FIG. 3 not shown but from the FIG. 1 known crushing device 3 can be flanged.

- the driver 3 can be coupled via a slip clutch or a comparable coupling to the crushing device 3, in the case of introducing foreign substances such as cutlery, crockery, screws or bone, in the receiving device 2 damage to the driver 4 and to avoid the associated with this crushing device 3.

- Perpendicular to the axis of rotation 400 of the driver 4 extend as shown FIG. 3 to recognize pre-shredder 46, which serve to pre-shred loose set-up waste so that they slip in the receiving device 2 better in the direction of the crushing device 3 and this can be fed easier.

- the pre-crushing blades 46 are substantially triangular in cross section in the embodiment shown and are designed as blunt blades.

- the respective flanks of the pre-comminuting blades 46 are inclined towards the comminution device 3. To this Way, the organic kitchen waste, which is struck by the respective Vorzerklein knife 46, crushed, in particular cut and / or smashed.

- the angle a which is enclosed by the triangular shape of the pre-comminuting blade 46, is approximately 60 ° in the exemplary embodiment shown.

- the triangular design of the pre-comminuting blade 46 further enables the driver 4 to be operated in both possible directions of rotation of the comminution device 3.

- the driver 4 four pre-comminuting 46 are provided, each extending two of these Vorzerkleiners 46 on opposite sides of the shaft 40 out.

- the two pairs of pre-comminuting blades 46 are mutually perpendicular and spaced apart along the axis of rotation 400.

- the two pairs of pre-comminuting blades 46 are spaced along the axis of rotation 400 by approximately 70 mm.

- the pre-comminuting blades 46 and the shaft 40 and the flange 42 are adjusted in such a way that even high rotational speeds in the range of approximately 1400 rpm. around the rotary shaft 400 around easily possible without imbalances arise.

- FIG. 4 shows the driver 4 again in a schematic side view, wherein once again the arrangement of the pre-comminuting 46 along the axis of rotation 400 of the driver 4, as well as their triangular shape is clear.

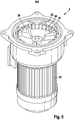

- FIG. 5 shows in a schematic perspective view of the crushing device 3.

- the crushing device 3 comprises a rotor 30 which rotates about a rotation axis 300 around and is driven by a motor 32, with the motor shaft of the rotor 30 is connected accordingly.

- the motor 32 is advantageously provided with a strong brake, which at an opening of the lid 10 during the operation of the crushing device 3 stops this immediately.

- the rotor 30 comprises differently shaped drivers 34, which carry the organic kitchen waste to be comminuted and correspondingly set in a rotational movement.

- a knife ring 36 is provided which surrounds the rotor 30 and which serves as a stator.

- the organic kitchen waste, which is rotated by the rotor 30 in a rotational movement, are accordingly pressed by the centrifugal forces against the knife rim 36 and guided along the knife ring 36 in such a way that comminution takes place in the corresponding spaces between the knives.

- the drivers 34 in turn strike along the blade ring 36 so that organic kitchen waste extending through the interspaces between the blades 36 can be cut off by the catch 34.

- Other embodiments of the crushing device 3 are also conceivable. Important for the crushing device 3 is merely that it is able to shred organic kitchen waste so that they can be subsequently pumped by a pump.

- FIG. 6 shows the shredding unit 3 again in a plan view in which the geometric arrangement of the rotor 30, the driver 34 and the blade ring 36 is clearly visible.

- FIG. 7 shows a schematic view of the disposal device 1 in a schematic sectional view, wherein the receiving device 2 is again funnel-shaped, to a targeted feeding the to get into the receiving device 2 introduced organic kitchen waste to the crushing device 3.

- the driver 4 extends clearly though not completely into the receiving device 2 and in particular extends into the volume V formed by the receiving device 2.

- the volume V formed by the receiving device 2 is defined here by the volume located between the upper edge 20 and the lower edge 22 of the funnel.

- the depth by which the driver 4 extends into the receiving device 2 depends on which organic kitchen waste to be treated. Furthermore, the depth in this embodiment is dependent on how far the pre-reduction blades 46 of the driver 4 are removed from the wall of the feed hopper 2. This distance D must be dimensioned so that even larger light equipment waste can still slip between the fast rotating Vorzerkleiner blades 46 and the wall of the receiving device 2.

- FIG. 7 Also schematically shown is a pump 5 for pumping out the biomass and a tank 6 for receiving the pumped biomass.

- the rotor of the comminution device 3 rotates advantageously at a high speed, for example 1400 revolutions / minute, in order to achieve a fine breaking of the organic kitchen waste and at the same time also to press lighter kitchen waste against the knife ring due to the generated high centrifugal force.

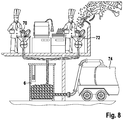

- FIG. 8 schematically shows a complete disposal system in a large kitchen, comprising a set-up station, at which set-up waste, which arise during the preparation of food, are introduced into a disposal device 70.

- a rinsing station is provided in which food waste is introduced into a corresponding disposal device 72, wherein both the set-up waste and the food waste by the disposal devices 70, 72 are comminuted and into a fine, pumpable biomass, preferably with a dry matter between 15% and 25% to be crushed.

- This pumpable biomass is pumped by the pump 5 into the tank 6, from where it can be transported by means of a tanker 74 to a biogas plant.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Environmental & Geological Engineering (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Crushing And Pulverization Processes (AREA)

- Processing Of Solid Wastes (AREA)

Claims (9)

- Entraîneur (4) pour l'apport d'un déchet de cuisine organique à un dispositif de broyage (3) d'un dispositif d'élimination (1) pour des déchets de cuisine organiques, caractérisé par un arbre (40), un axe de rotation (400) s'étendant coaxialement à l'arbre (40) et au moins un couteau de prébroyage (46) agencé perpendiculairement à son axe de rotation (400), prévu sur l'arbre (40) pour le broyage de déchets de cuisine organiques, qui est réalisé comme un couteau triangulaire avec des flancs inclinés vers le dispositif de broyage (3),

dans lequel l'entraîneur (4) peut être raccordé solidaire en rotation au dispositif de broyage (3),

dans lequel l'au moins un couteau de prébroyage (46) est agencé sur l'arbre de telle manière qu'il est agencé à distance du dispositif de broyage (3) à l'état raccordé de l'entraîneur (4) avec le dispositif de broyage (3). - Entraîneur (4) selon la revendication 1,

comprenant une bride (42) pour le bridage de l'entraîneur (4) au dispositif de broyage (3). - Entraîneur (4) selon la revendication 1 ou 2, dans lequel l'angle (a) formé par les flancs du couteau triangulaire se trouve dans une plage de 40° à 80°.

- Entraîneur (4) selon l'une quelconque des revendications précédentes, dans lequel au moins un moyen de secouage pour l'ameublissement et/ou un moyen de transport pour le transport des déchets de cuisines organiques au dispositif de broyage est prévu sur l'arbre (40).

- Entraîneur (4) selon l'une quelconque des revendications précédentes, dans lequel l'arbre (40) présente un diamètre qui réduit la réalisation de tresses ainsi que l'adhérence des déchets de cuisine organiques, dans lequel le diamètre (d) de l'arbre (40) se trouve dans une plage de 40 mm à 70 mm.

- Dispositif d'élimination (1) pour des déchets de cuisine organiques, comprenant un dispositif de broyage (3) pour le broyage de déchets de cuisine organiques ainsi qu'un dispositif de réception (2) raccordé au dispositif de broyage (3) pour la réception de déchets de cuisine organiques non broyés, dans lequel le dispositif de réception (2) est réalisé en forme d'entonnoir,

caractérisé par

un entraîneur (4) dépassant dans le dispositif de réception (2) selon l'une quelconque des revendications précédentes, pour l'apport de déchets de cuisine organiques au dispositif de broyage (3),

dans lequel l'entraîneur (4) est raccordé solidaire en rotation au dispositif de broyage (3) et est agencé avec son axe de rotation (400) coaxialement à l'axe de rotation (300) du dispositif de broyage (3). - Dispositif d'élimination (1) selon la revendication 6, dans lequel le dispositif de réception (2) présente une section transversale carrée, rectangulaire, ronde ou ovale.

- Dispositif d'élimination (1) selon l'une quelconque des revendications 6 ou 7, dans lequel une pompe (5) est prévue pour le pompage des déchets de cuisine organiques broyés dans le dispositif de broyage (3) et est raccordée au dispositif de broyage (3).

- Dispositif d'élimination (1) selon l'une quelconque des revendications 6 à 8, dans lequel le dispositif de broyage (3) présente un rotor (30) et une couronne de couteau (36) entourant le rotor (30).

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11155675.9A EP2492405B1 (fr) | 2011-02-23 | 2011-02-23 | Dispositif d'élimination des déchets pour déchets de cuisine organiques et entraîneur pour un tel dispositif d'élimination des déchets |

| DE202011050658U DE202011050658U1 (de) | 2011-02-23 | 2011-07-07 | Entsorgungsvorrichtung für organische Küchenabfälle sowie Mitnehmer für eine solche Entsorgungsvorrichtung |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11155675.9A EP2492405B1 (fr) | 2011-02-23 | 2011-02-23 | Dispositif d'élimination des déchets pour déchets de cuisine organiques et entraîneur pour un tel dispositif d'élimination des déchets |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2492405A1 EP2492405A1 (fr) | 2012-08-29 |

| EP2492405B1 true EP2492405B1 (fr) | 2018-04-11 |

Family

ID=44278681

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11155675.9A Active EP2492405B1 (fr) | 2011-02-23 | 2011-02-23 | Dispositif d'élimination des déchets pour déchets de cuisine organiques et entraîneur pour un tel dispositif d'élimination des déchets |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2492405B1 (fr) |

| DE (1) | DE202011050658U1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2873463A1 (fr) | 2013-11-18 | 2015-05-20 | BIOTrans AG | Dispositif de traitement |

| EP3467214B1 (fr) | 2017-10-05 | 2023-09-27 | MEIKO Green Waste Solutions AG | Procédé et dispositif permettant de broyer des déchets de cuisine et/ou des restes alimentaires |

| CN115625177B (zh) * | 2022-10-25 | 2024-12-10 | 宁波世茂能源股份有限公司 | 一种餐厨垃圾、生活垃圾与污泥协同处理装置 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1057831A (ja) * | 1996-08-19 | 1998-03-03 | Hitachi Ltd | 厨芥処理装置 |

| EP1685906A2 (fr) * | 2005-02-01 | 2006-08-02 | Young Ki Kim | Système de traitement de déchets alimentaires |

| WO2007143853A1 (fr) * | 2006-06-15 | 2007-12-21 | Les Equipements Pro-Jet Inc. | Broyeur de boues organiques, d'engrais et analogues |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2828083A (en) * | 1955-12-14 | 1958-03-25 | Gen Electric | Waste disposal apparatus |

| GB1200842A (en) * | 1968-02-29 | 1970-08-05 | Howard Walter Dyson | Apparatus for disintegrating solid materials |

| DE2928471C2 (de) * | 1979-07-14 | 1982-03-11 | Osnabrücker Metallwerke J.Kampschulte GmbH & Co KG, 4500 Osnabrück | Maschine zum Zerkleinern von stückigen Gegenständen |

| IT8520484V0 (it) * | 1985-01-14 | 1985-01-14 | Ica Spa | Spapolatore per prodotti cartacei e/o prodotti similari di scarto. |

| JPS63126695A (ja) * | 1986-11-14 | 1988-05-30 | Tago Kiyoutarou | 生ごみ処理装置 |

| JP2001293389A (ja) * | 2000-04-17 | 2001-10-23 | Seiichi Tsunoda | 破砕装置 |

| JP4228751B2 (ja) * | 2003-03-31 | 2009-02-25 | マックス株式会社 | 生ごみ処理装置 |

| JP4857722B2 (ja) * | 2005-11-15 | 2012-01-18 | マックス株式会社 | 生ごみ処理装置 |

| JP3160332U (ja) * | 2009-01-27 | 2010-06-24 | パイオニア ウェイスト マネジメント ホールディングス トラスト ピーティーワイ リミテッドPioneer Waste Management Holdings Trust Pty Limited | 廃棄物処理システム |

-

2011

- 2011-02-23 EP EP11155675.9A patent/EP2492405B1/fr active Active

- 2011-07-07 DE DE202011050658U patent/DE202011050658U1/de not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1057831A (ja) * | 1996-08-19 | 1998-03-03 | Hitachi Ltd | 厨芥処理装置 |

| EP1685906A2 (fr) * | 2005-02-01 | 2006-08-02 | Young Ki Kim | Système de traitement de déchets alimentaires |

| WO2007143853A1 (fr) * | 2006-06-15 | 2007-12-21 | Les Equipements Pro-Jet Inc. | Broyeur de boues organiques, d'engrais et analogues |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2492405A1 (fr) | 2012-08-29 |

| DE202011050658U1 (de) | 2012-10-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2977106B1 (fr) | Procede et dispositif destines au traitement de biomasse a l'echelon industriel | |

| EP3467214B1 (fr) | Procédé et dispositif permettant de broyer des déchets de cuisine et/ou des restes alimentaires | |

| DE2047006B2 (de) | Anlage zum Zerkleinern und teilweisen Trennen von Müll | |

| DE212020000395U1 (de) | Weizenstroh-Zerkleinerungsvorrichtung | |

| DE102018212162B4 (de) | Zufuhreinrichtung für eine Saftpresse, Küchenmaschine und Saftpresse mit Zufuhreinrichtung | |

| EP2092975B1 (fr) | Dispositif de mélange doté d'un pot de mélange fixé sur un récipient de mélange | |

| DE3221431C2 (fr) | ||

| EP2492405B1 (fr) | Dispositif d'élimination des déchets pour déchets de cuisine organiques et entraîneur pour un tel dispositif d'élimination des déchets | |

| EP3131679B1 (fr) | Appareil de traitement, système de traitement et procédé de traitement de déchets alimentaires | |

| DE1632883A1 (de) | Zerkleinerungsvorrichtung,insbesondere fuer Fleisch,Brot od.dgl. | |

| DE102014004492A1 (de) | Herstellung von Biogas aus Stroh | |

| EP1884564A1 (fr) | Préparation de boues et substances solides organiques pour une fermentation | |

| CN206881851U (zh) | 一种纤维多级滚刀粉碎机 | |

| DE2136203A1 (de) | Abfall-Zerkleinerungsmaschine | |

| EP0824966B1 (fr) | Dispositif de broyage ainsi que broyeur pour déchets solides ou pâteux dans un liquide | |

| DE102010050863B4 (de) | Vorrichtung zum Mischen von nicht pumpfähiger Biomasse mit einer Flüssigkeit | |

| EP2564930A1 (fr) | Hache | |

| DE202016106372U1 (de) | Häckselvorrichtung für die Aufbereitung von Biomassematerial | |

| WO2014173384A1 (fr) | Dispositif pour broyer des résidus en morceaux provenant de l'extraction de l'huile de palme | |

| DE102011089615A1 (de) | Zerkleinerungsvorrichtung und Verwendung einer solchenZerkleinerungsvorrichtung | |

| WO2012069595A1 (fr) | Dispositif et procédé de broyage de matière | |

| CN216654817U (zh) | 一种椰汁加工用椰肉绞碎装置 | |

| DE102006054132B4 (de) | Verfahren und Vorrichtung zur Verarbeitung von Wurzelfrüchten in eine gärfähige Suspension | |

| DE4328687A1 (de) | Nach dem Rotationsscheren-Prinzip arbeitender Shredder | |

| DE3301551A1 (de) | Einrichtung zum zerkleinern und fermentieren von restbrot |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20110923 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BIOTRANS HOLDING GMBH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502011014021 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: E03C0001266000 Ipc: B02C0018220000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B02C 18/00 20060101ALI20170926BHEP Ipc: E03C 1/266 20060101ALI20170926BHEP Ipc: B02C 18/22 20060101AFI20170926BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20171024 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BIOTRANS AG |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 987417 Country of ref document: AT Kind code of ref document: T Effective date: 20180415 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502011014021 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180711 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180711 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180712 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180813 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502011014021 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| 26N | No opposition filed |

Effective date: 20190114 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502011014021 Country of ref document: DE Representative=s name: DF-MP DOERRIES FRANK-MOLNIA & POHLMAN PATENTAN, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502011014021 Country of ref document: DE Owner name: MEIKO GREEN WASTE SOLUTIONS AG, CH Free format text: FORMER OWNER: BIOTRANS AG, BUETSCHWILL, CH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190223 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190228 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20110223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180411 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20240221 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502011014021 Country of ref document: DE Representative=s name: MAUCHER JENKINS PATENTANWAELTE & RECHTSANWAELT, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20250220 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250218 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20250218 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250301 Year of fee payment: 15 Ref country code: AT Payment date: 20250217 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250219 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250228 Year of fee payment: 15 Ref country code: GB Payment date: 20250220 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |