EP2473692B1 - Vorrichtung zum dämpfen und/oder verzögern - Google Patents

Vorrichtung zum dämpfen und/oder verzögern Download PDFInfo

- Publication number

- EP2473692B1 EP2473692B1 EP10766228.0A EP10766228A EP2473692B1 EP 2473692 B1 EP2473692 B1 EP 2473692B1 EP 10766228 A EP10766228 A EP 10766228A EP 2473692 B1 EP2473692 B1 EP 2473692B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hinge

- housing

- receptacle

- cup

- piston

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000013016 damping Methods 0.000 title claims description 44

- 238000006073 displacement reaction Methods 0.000 description 3

- 239000013598 vector Substances 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000012815 thermoplastic material Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F5/00—Braking devices, e.g. checks; Stops; Buffers

- E05F5/006—Braking devices, e.g. checks; Stops; Buffers for hinges having a cup-shaped fixing part, e.g. for attachment to cabinets or furniture

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/20—Brakes; Disengaging means; Holders; Stops; Valves; Accessories therefor

- E05Y2201/21—Brakes

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/20—Brakes; Disengaging means; Holders; Stops; Valves; Accessories therefor

- E05Y2201/252—Type of friction

- E05Y2201/254—Fluid or viscous friction

- E05Y2201/256—Fluid or viscous friction with pistons or vanes

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/20—Brakes; Disengaging means; Holders; Stops; Valves; Accessories therefor

- E05Y2201/262—Type of motion, e.g. braking

- E05Y2201/264—Type of motion, e.g. braking linear

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2800/00—Details, accessories and auxiliary operations not otherwise provided for

- E05Y2800/70—Retrofitting of elements

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/20—Application of doors, windows, wings or fittings thereof for furniture, e.g. cabinets

Definitions

- the invention relates to a device for damping and / or deceleration with a housing, with a guided in the housing pressure piece and arranged in the housing and in the pressure piece, a cylinder and a piston comprising a cylinder-piston unit, which forms a part of the housing with the mounting flange a support surface and having at least two openings.

- the present invention is based on the problem to develop a retrofittable damping device that can be quickly and accurately arranged on different hinge types.

- the pressure piece is either cup-shaped and formed open on one side and the cylinder-piston unit has radial clearance to the pressure piece or the pressure piece is formed with the cylinder of the cylinder-piston unit as a common component.

- the mounting flange comprises at least two, at least approximately normal to the support surface oriented, spaced guide surfaces.

- the baffles on several sides define a receptacle which can be centered on a hinge cup, wherein both baffles are at least approximately oppositely oriented inner surfaces of the receptacle.

- At least one guide surface is arranged on a formed on the housing and projecting from this, plunging into the hinge cup centering.

- at least two openings are arranged outside of the receptacle and penetrate the support surface, so that the device can be fastened by means of fastening means outside of a hinge cup having the hinge to a piece of furniture.

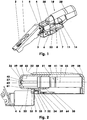

- FIG. 1 shows a dimetric representation of a hinge (1) with a device for damping and / or decelerating (10) and the FIG. 2 a partial longitudinal section of such a hinge (1) with a damping device (10).

- hinge (1) is a cup hinge (1). It has two hinge arms (2, 3), one of which (2), for example, in the furniture body and the other (3) is mounted in the hinged door of a piece of furniture.

- the two hinge arms (2, 3) are hinged together by means of two articulated levers (4, 5).

- the limited by the open and the closed end position swivel angle of the hinge (1) is in the embodiment 110 degrees.

- the one in the body the piece of furniture fastened hinge arm (2) is in the representation of FIG. 1 a mounting arm (2).

- the hinged on the door hinge arm (3) comprises a hinge cup (6) with a flange (8).

- the damping device (10) is in the FIG. 3 shown in an exploded view. It comprises a housing (20), a cylinder-piston unit (40) and a pressure piece (50). It is by means of a receptacle (32) which comprises a guide pin (33) and two guide surfaces (34, 35), centered on the hinge cup (6) and by means of a mounting flange (11), for example, outside of the hinge cup (6) in the pivotable door leaf of the furniture fixable.

- the damping device (10) can also be attached to the hinge (1).

- the damping device (10) has in the exemplary embodiment a maximum total length of 50 millimeters and a width in the region of the mounting flange (11) of 45 millimeters.

- the stroke of the pressure piece (50) relative to the housing (20) is for example 12 millimeters.

- housing (20) is an injection molded part, for example of a thermoplastic material. But it can also be made of aluminum or an aluminum alloy. It has a downwardly and to the front (22) open, semi-oval interior (21).

- the wall (23) of the interior (21) has two mutually opposite guide grooves (24). These borders on the front side (22). Their length is for example 25 millimeters and their height 1.3 millimeters.

- the guide grooves (24) are eg one millimeter deep.

- the distance between the opposing areas (26, 27) of the inner wall (23) is 12 millimeters in the exemplary embodiment.

- the closed rear wall (28) of the housing (20) has a pot-like receiving recess (29) oriented in the direction of the interior (21) and stiffening ribs (31).

- the housing (20) has a perforated bottom plate (38) which comprises the receptacle (32) including the molded, projecting from the housing (20) guide pin (33).

- the receptacle (32) formed here as a receiving channel (32) is arranged normal to the vertical center longitudinal plane of the device (10).

- the vertical center longitudinal plane is arranged normal to the support plane (15) and comprises the central axis (18).

- the receiving channel (32) is, measured in the direction of the central axis (18), for example, 6% longer than the edge (7) of the hinge cup (6), see. FIG. 2 , In the mounted state, the receiving channel (32) at least partially surrounds this edge (7).

- the guide pin (33) oriented, normal to the support plane (15) oriented inner surface of the receiving channel (32) is a guide surface (34).

- the guide pin (33) delimits the receiving channel (32) and is, for example, flush with the support plane (15) of the damping device (10).

- it has an at least approximately cuboid shape with a guide surface (35) oriented normal to the vertical center longitudinal plane of the device (10) and normal to the support plane.

- it can also have the shape of a cylinder with a circular, oval or elliptical cross-section.

- the guide surface (35) of the receiving (32) facing part of the lateral surface of the guide pin (33).

- At least the guide surface (35) of the guide pin (33) facing the rear wall (9) of the hinge cup (6) can also be formed obliquely so that the head cross-section of the guide pin (33) is smaller than the foot cross-section merging into the bottom plate (38).

- the two guide surfaces (34, 35) are at least approximately opposite oriented to each other. This means that their normal vectors point in opposite directions, whereby the single normal vector can deviate from this direction by an angle of up to 30 degrees.

- the length of the bottom plate (38) in the direction of the central axis (18) in the embodiment corresponds to half the length of the housing (20).

- the bottom plate (38) also comprises the mounting flange (11), which in the representations of Figures 3 and 4 has four through holes (13, 14).

- Two through holes (13) are in extension of the receiving channel (32), the other two through holes (14) are, for example in the longitudinal direction of the damping device (10) offset outside this channel (32).

- the through holes (13) serve as material reduction.

- the damping device (10) can also be fastened to the hinge (1) or to the door leaf outside the hinge (1), for example by means of screws which are inserted into the through-bores (13). By means of two in the through holes (14) inserted screws, the damping device (10) can be attached to the piece of furniture.

- the pressure piece (50) is a one-sided open, pot-shaped component. It is in the FIG. 5 shown as a single part.

- the pressure piece (50) has, for example, a length oriented in the direction of the longitudinal axis (58) which, for example, corresponds to 95% of the length of the guide grooves (24). Its wall thickness is for example one millimeter.

- the lateral surface (51) of the pressure piece (50) has two longitudinally oriented guide rails (52) which adjoin the opening (53). The height of these guide rails (52) is for example 0.7 millimeters and their length is half the length of the pressure piece (50). With these guide rails (52) sits the pressure piece (50) in the guide grooves (24) of the housing (20).

- This large guide length prevents tilting of the pressure piece (50) in the housing (20).

- the vertical and the lateral play of the pressure piece (50) in the housing (20) for example, each 0.5 millimeters.

- a maximum inclination of the longitudinal axis (58) of the pressure piece (50) of 2.4 degrees with respect to the central axis (18) of the damping device (10) is possible.

- a slot (55) is arranged on the underside (54) of the pressure piece (50). Its length is in the exemplary embodiment four-thirds of the maximum stroke of the pressure piece (50).

- the slot (55) is e.g. four millimeters wide. When mounted, the slot (55) forms e.g. with a housing arranged in the stop pin (39) a stroke limitation.

- the opening (53) facing away from the end wall (56) in the embodiment has a central portion (57) which is arranged normal to the longitudinal axis (58) of the pressure piece (50). Above this section (57) includes, for example, by 22 degrees to this inclined portion (59), see. FIG. 2 , In the lower area, the end wall (56) has a bent portion (61). The end wall (56) may also be curved convexly one or two axes, have an inclined plane, etc.

- the inner wall (62) of the end wall (56) has a receiving recess (63).

- the cylinder-piston unit (40) comprises a cylinder (41) and a piston, which is connected to a protruding from the cylinder (41) piston rod (42).

- spring-loaded piston defines a displacement chamber from a compensation chamber.

- the cylinder (41) sits with radial play in the receiving recess (29).

- the piston rod (42) has radial clearance for receiving recess (63).

- the cylinder-piston unit (40) can also be installed in reverse in the damping device (10). For mounting the damping device (10), for example, first the cylinder-piston unit (40) is inserted into the housing (20). Thereafter, the pressure piece (50) is inserted and locked in the stop pin (39). The assembly can also be done in a different order.

- the damping device (10) thus consists of only three parts, namely the housing (20), the cylinder-piston unit (40) and the pressure piece (50). It is thus inexpensive to produce and assembled automatically without special tool. It is also conceivable to form the pressure piece (50) and the cylinder (41) of the cylinder-piston unit (40) as a common component. For example, then the slot (55) is an oval, in the direction of the longitudinal axis (58) oriented recess of the cylinder jacket. The piston rod (42) is mounted in the housing (20) in this embodiment. This damping device (20) then consists of only two parts.

- the mounted damping device (10) can be placed with the support plane (15), for example on the door leaf.

- the damping device (10) by means of the guide surface (34) of the receptacle (32) at the edge (7) of the hinge cup (6) is aligned.

- the guide pin (33) engages in the hinge cup (6).

- the guide surface (35) of the guide pin (33) can rest on the rear wall (9) of the hinge cup (6) or, for example, have a distance of, for example, up to one millimeter from it.

- the Guide pin (33) is thus a centering pin (33), with which the position of the damping device (10) is fixed relative to the hinge (1).

- a displacement or pivoting of the damping device (10) relative to the hinge (1) is - except for the position tolerance - prevented.

- the receptacle (32) thus engages around the edge (7) of the hinge cup (6) with the guide surfaces (34, 35) delimiting them on several sides.

- the damping device (10) is fastened to the door leaf, for example, by means of screws which project through the through-bores (14).

- the two hinge arms (2, 3) pivot relative to each other.

- the pressure piece (50) approaches the mounting arm (2).

- the pressure piece (50) touches the mounting arm (2) or the outer articulated lever (4), it is inserted. It slides on the mounting arm (2) or the outer articulated lever (4).

- the pressure piece (50) pushes in the adjoining the closed end position of the hinge (1) pivot angle, the piston rod (42) with the piston.

- the slot (55) moves relative to the stop pin (39).

- the guide (24, 52) absorbs the lateral force components, so that the cylinder-piston unit (40) is loaded in only one direction parallel to the piston rod (42).

- the piston rod seal thus experiences no lateral forces that could cause leaks in the cylinder-piston unit (40).

- hydraulic or pneumatic medium is displaced throttled and delays the speed of the door leaf. For example, the higher the pan angular velocity, the greater the delay.

- the force transmitted to the cylinder-piston unit (40) is directed to the housing (20) and derived from the latter via the mounting flange (11) in the furniture door.

- the pressure piece (50) from the mounting arm (2) or the outer hinge lever (4) dissolves.

- the spring disposed in the cylinder (41) pushes the piston outward with the piston rod (42) and the pressure piece (50).

- the slot (55) in this case migrates along the stop pin (39) until its rear edge (64) abuts the stop pin (39).

- the stop pin (39) now prevents further extension of the pressure piece (50). It thus forms a stop for the extended position of the damping device (10).

- the damping device (10) can be arranged on all cup hinges (1) whose edge (7) in the direction of the central axis (18) is shorter than the length of the receptacle (32) measured in this direction.

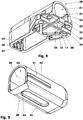

- the FIG. 6 shows a further embodiment of a hinge (1) with a damping device (10).

- the hinge cup (6) has, for example, a rear wall (9) with a recess.

- the damping device (10) has two centering pins (33, 36) which are arranged laterally of the frontal opening (25) of the housing (20). For example, they stand out in the direction of the end wall (56) of the pressure piece (50) by three millimeters.

- the length of the centering pins (33, 36) normal to the support plane (15) corresponds to the length of the centering pins (33) in the first embodiment.

- FIG. 7 is a bottom-dimensional view of a damping device (10) with a receptacle (32) with two eccentric centering pins (33, 36) shown.

- the cylinder-piston unit (40) is mounted in the housing (20).

- the piston rod (42) is mounted in the pressure piece (50), as in the FIG. 2 shown.

- the pressure piece (50) is displaceably mounted in guide grooves (24) of the housing (20) in the direction of the central axis (18). On its underside (54) has the pressure piece (50) has a slot (55) into which a in the housing (20) integrated stop pin (39) engages.

- the mounting flange (11) of the damping device (10) has four through holes (13; 14), of which two (13) in the receiving channel (32) and the other two (14) outside the receiving channel (32) are arranged.

- the assembly and assembly of the damping device (10) takes place as described above.

- the damping device (10) is door leaf side e.g. arranged on the cup hinge (1).

- the receptacle (32) and the centering pins (33) engage around the edge (7) of the hinge cup (6) adjoining the rear wall (9) in a form-fitting manner.

- the damping device (10) without adjustment work on the hinge (1) can be recognized.

- This damping device (10) can thus be used for cup hinges (1), the mounting arm (2) in the pivoted state of the hinge (1) fills the length of the hinge cup (6) in the direction of the central axis (18) to more than 90%.

- this damping device (10) can also be used for other types of cup hinges (1).

- the receptacle (32) engages outside the edge (7) of the hinge cup (6).

- it then comprises, for example, three guide surfaces, one of which is arranged, for example, like the guide surface (34) in the first exemplary embodiment.

- the two others Guiding surfaces are then arranged opposite one another on the edge regions oriented in the longitudinal direction of the hinge (1).

- a delay device upon the actuation of which, for example, air is displaced from the displacement space into the environment.

- the provision of the delay device is effected for example by means of a spring.

- the device for damping and / or decelerating (10) may also be at the open end position of two relatively moving parts, e.g. be arranged a sliding or pivoting door.

Landscapes

- Hinges (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009039559A DE102009039559A1 (de) | 2009-09-01 | 2009-09-01 | Vorrichtung zum Dämpfen und/oder Verzögern |

| PCT/DE2010/001012 WO2011026466A1 (de) | 2009-09-01 | 2010-08-30 | Vorrichtung zum dämpfen und/oder verzögern |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2473692A1 EP2473692A1 (de) | 2012-07-11 |

| EP2473692B1 true EP2473692B1 (de) | 2017-08-02 |

Family

ID=43302510

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10766228.0A Not-in-force EP2473692B1 (de) | 2009-09-01 | 2010-08-30 | Vorrichtung zum dämpfen und/oder verzögern |

Country Status (6)

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009039560A1 (de) * | 2009-09-01 | 2011-03-03 | Zimmer, Günther | Einstellbare Vorrichtung zum Dämpfen und/oder Verzögern |

| ITMI20131542A1 (it) * | 2013-09-19 | 2015-03-20 | Salice Arturo Spa | Cerniera decelerata per mobili |

| WO2015145364A2 (en) * | 2014-03-25 | 2015-10-01 | Ol.Mi S.R.L. | Hydraulic hinge, in particular concealed hinge for doors |

| US9163447B1 (en) * | 2014-09-18 | 2015-10-20 | King Slide Works Co., Ltd. | Hinge with damping device |

| DE102015106919A1 (de) * | 2015-05-04 | 2016-11-10 | Samet Kalip Ve Maden Esya San. Ve Tic. A.S. | Möbelscharnier mit einem Dämpfer |

| US9523227B1 (en) * | 2015-07-30 | 2016-12-20 | Nan Juen International Co., Ltd. | Anti-drop safety device assembly |

| TWI597432B (zh) * | 2015-11-26 | 2017-09-01 | 川湖科技股份有限公司 | 鉸鏈及其緩衝裝置 |

| TWI555487B (zh) * | 2015-11-26 | 2016-11-01 | 川湖科技股份有限公司 | 鉸鏈及其緩衝裝置 |

| US9874049B1 (en) * | 2016-08-11 | 2018-01-23 | Hardware Resources, Inc. | Compact hinge apparatus and method of use |

| EP3650728B1 (en) * | 2018-10-12 | 2024-11-06 | BSH Hausgeräte GmbH | A damping unit and a home appliance with the damping unit |

| US10947766B2 (en) * | 2019-05-07 | 2021-03-16 | B/E Aerospace, Inc. | Dampening hinges and table assemblies including the same |

| DE102019113335A1 (de) * | 2019-05-20 | 2020-11-26 | Samet Kalip Ve Maden Esya San. Ve Tic. A.S. | Möbelbeschlag |

| CN111719976B (zh) * | 2019-06-20 | 2025-03-28 | 广东精诺五金实业有限公司 | 一种阻尼器承载座及缓冲铰链 |

| GB2602285A (en) * | 2020-12-22 | 2022-06-29 | Titus D O O Dekani | Hinge Assembly |

| US11920401B2 (en) | 2021-05-03 | 2024-03-05 | Kohler Co. | Slow close mechanism for sliding applications |

| EP4450744A3 (en) * | 2023-04-20 | 2024-12-04 | LG Electronics Inc. | Refrigerator |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT250443Y1 (it) * | 2000-09-19 | 2003-09-10 | Salice Arturo Spa | Dispositivo per la chiusura decelerata di parti di mobile scorrevoli |

| DE20115250U1 (de) * | 2001-07-06 | 2002-11-14 | Lautenschlaeger Mepla Werke | Dämpfungsvorrichtung |

| TWI231344B (en) * | 2004-02-24 | 2005-04-21 | Lushridge Inc | Fastening structure of buffering rod |

| DE202004011636U1 (de) * | 2004-03-12 | 2004-09-23 | MEPLA-WERKE LAUTENSCHLäGER GMBH & CO. KG | Dämpfungsvorrichtung für Möbelscharniere |

| SI21971A (sl) * | 2005-02-18 | 2006-08-31 | Lama D.D. Dekani | Oplemeniteni pohistveni sarnir |

| DE202005011752U1 (de) * | 2005-07-22 | 2006-11-30 | Hettich-Oni Gmbh & Co. Kg | Dämpfungselement |

| AT502486B1 (de) * | 2005-09-01 | 2007-04-15 | Blum Gmbh Julius | Anordnung mit einem scharnier, insbesondere möbelscharnier |

| WO2008020682A1 (en) * | 2006-08-18 | 2008-02-21 | Samsung Precision Industrial Co., Ltd | Door hinge device for absorbing the closing impact of furniture doors |

| JP3129172U (ja) * | 2006-11-24 | 2007-02-08 | 川湖科技股▲分▼有限公司 | 蝶番の緩衝装置 |

| CN201087643Y (zh) * | 2007-08-30 | 2008-07-16 | 伍志勇 | 家具铰链的缓冲装置 |

| US20130055528A1 (en) * | 2011-09-07 | 2013-03-07 | Mark Jeffrey Lowe | Detachable hinge damper |

-

2009

- 2009-09-01 DE DE102009039559A patent/DE102009039559A1/de not_active Withdrawn

-

2010

- 2010-08-30 CA CA2772673A patent/CA2772673A1/en not_active Abandoned

- 2010-08-30 EP EP10766228.0A patent/EP2473692B1/de not_active Not-in-force

- 2010-08-30 WO PCT/DE2010/001012 patent/WO2011026466A1/de active Application Filing

- 2010-08-30 JP JP2012527203A patent/JP5871799B2/ja not_active Expired - Fee Related

-

2012

- 2012-02-29 US US13/407,862 patent/US8621713B2/en not_active Expired - Fee Related

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102009039559A1 (de) | 2011-03-10 |

| EP2473692A1 (de) | 2012-07-11 |

| JP2013503988A (ja) | 2013-02-04 |

| WO2011026466A1 (de) | 2011-03-10 |

| JP5871799B2 (ja) | 2016-03-01 |

| US8621713B2 (en) | 2014-01-07 |

| CA2772673A1 (en) | 2011-03-10 |

| US20120180262A1 (en) | 2012-07-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2473692B1 (de) | Vorrichtung zum dämpfen und/oder verzögern | |

| EP2473693B1 (de) | Einstellbare vorrichtung zum dämpfen und/oder verzögern | |

| DE10254375C1 (de) | Vorrichtung zum Dämpfen von Schwenkbewegungen | |

| DE102006058639B4 (de) | Kombinierte Verzögerungs- und Beschleunigungsvorrichtung | |

| EP2247812B1 (de) | Beschleunigungs- und verzögerungsvorrichtung mit zwei mitnahmeelementen | |

| EP1404938B2 (de) | Dämpfungsvorrichtung | |

| EP2013434B1 (de) | Führungssystem mit beschleunigungs- und verzögerungsvorrichtung | |

| EP2841668B1 (de) | Schlepptürbeschlag | |

| AT506756B1 (de) | Möbelscharnier | |

| EP2673443B1 (de) | Beschleunigungs- und verzögerungsvorrichtung mit mitnahmelement-schwenkgelenk | |

| EP1725727B1 (de) | Dämpfungsvorrichtung für möbelscharniere | |

| DE102017126367A1 (de) | Klappenbeschlag für ein Möbel, Seitenwand eines Möbelkorpus und Möbel mit einer Seitenwand | |

| EP3494270B1 (de) | Dämpfereinrichtung | |

| EP2796650A1 (de) | Möbelscharnier | |

| DE202004021727U1 (de) | Scharnier | |

| EP3581746B1 (de) | Kombinierte dämpfungs- und zuziehvorrichtung für eine mitteltür | |

| EP2617336A2 (de) | Duschabtrennung | |

| EP4064935B1 (de) | Möbelelement | |

| EP3380693B1 (de) | Dämpferbaugruppe eines topfscharniers | |

| DE10227078B4 (de) | Vorrichtung zum Dämpfen von Schwenkbewegungen | |

| DE102009035682A1 (de) | Scharnier mit hydraulischer Dämpfungsvorrichtung | |

| EP2492427B1 (de) | Beschlagvorrichtung für ein bewegliches Möbelteil | |

| EP1907658B1 (de) | Dämpfungseinrichtung | |

| EP2949845B1 (de) | Verstellbares klappenlager | |

| EP3478917B1 (de) | Mitteltür-zuziehvorrichtung mit übertragungsschlitten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20120320 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20150226 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170314 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 914667 Country of ref document: AT Kind code of ref document: T Effective date: 20170815 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010013950 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20170821 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170817 Year of fee payment: 8 Ref country code: FR Payment date: 20170822 Year of fee payment: 8 Ref country code: GB Payment date: 20170929 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20170925 Year of fee payment: 8 Ref country code: AT Payment date: 20170825 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171102 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171202 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171102 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171103 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20171026 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010013950 Country of ref document: DE Ref country code: BE Ref legal event code: MM Effective date: 20170831 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170830 |

|

| 26N | No opposition filed |

Effective date: 20180503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010013950 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20180901 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 914667 Country of ref document: AT Kind code of ref document: T Effective date: 20180830 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180901 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180830 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180830 Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180830 |