EP2339701B1 - Connecteur à fiche de plaquettes doté d'un dispositif de verrouillage - Google Patents

Connecteur à fiche de plaquettes doté d'un dispositif de verrouillage Download PDFInfo

- Publication number

- EP2339701B1 EP2339701B1 EP10015559A EP10015559A EP2339701B1 EP 2339701 B1 EP2339701 B1 EP 2339701B1 EP 10015559 A EP10015559 A EP 10015559A EP 10015559 A EP10015559 A EP 10015559A EP 2339701 B1 EP2339701 B1 EP 2339701B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- locking

- plug connector

- circuit board

- unlocking

- connector part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 description 10

- 230000015572 biosynthetic process Effects 0.000 description 6

- 238000005755 formation reaction Methods 0.000 description 6

- 230000000694 effects Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 210000002023 somite Anatomy 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/72—Coupling devices for rigid printing circuits or like structures coupling with the edge of the rigid printed circuits or like structures

- H01R12/73—Coupling devices for rigid printing circuits or like structures coupling with the edge of the rigid printed circuits or like structures connecting to other rigid printed circuits or like structures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/627—Snap or like fastening

- H01R13/6271—Latching means integral with the housing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/633—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances for disengagement only

- H01R13/6335—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances for disengagement only comprising a handle

Definitions

- the invention relates to a printed circuit board connector for parallel circuit boards, wherein the PCB connector consists of a first connector part and a second connector part, wherein the first connector part has a first base which is fixable on a first circuit board, and wherein the first connector part, a first locking element and the second connector part has a second locking element, wherein both locking elements each have at least one locking arm, wherein at the end of each locking arm at least one Anformung each having a locking surface is provided, and wherein in the locked state, the locking surfaces of the two locking elements are arranged counter to each other.

- Such a device is needed to electrically and mechanically connect two parallel aligned printed circuit boards, each fixed to a connector part, via the circuit board connector and to lock that connection.

- the PCB connector consists of two connectors and has locking means for blocking a vertical movement of its cover housing. Furthermore, the circuit board connector unlocking means for releasing a locking of the cover housing.

- the publication EP 1 557 908 A2 discloses a printed circuit board connector for parallel printed circuit boards, wherein the printed circuit board connector consists of a first connector part and a second connector part, wherein the first connector part has a first base which is fixable on a first circuit board, and wherein the first connector part, a first locking element and the second connector part a second locking element, wherein both locking elements each have at least one locking arm, wherein at the end of each locking arm at least one Anformung each having a locking surface is provided, and wherein in the locked state, the locking surfaces of the two locking elements are arranged interlocking.

- a drawback in the prior art is that there is no inexpensive manufacturable printed circuit board connector of the type mentioned, which is suitable for unlocking an existing lock between two parallel-aligned printed circuit boards in a simple manner.

- the invention is therefore based on the object form a printed circuit board connector of the type mentioned in that it allows easy to be carried out unlocking the circuit boards and continue to produce inexpensive.

- the second connector part has a second base, which is fixable on a second circuit board, wherein the first connector part has an unlocking, the held movably on the first connector part perpendicular to the first base surface and thereby adapted to elastically deform at least one of the two locking elements to separate the locking surfaces of the first locking element from the locking surfaces of the second locking element.

- Such a printed circuit board connector allows in a particularly comfortable way the locking and unlocking of two parallel circuit boards.

- At least one of the two locking elements consists at least partially of an elastically deformable material.

- the printed circuit board connector has an unlocking element which is provided for elastically deforming at least one of the two locking elements in order to separate the locking surfaces of the two locking elements from each other.

- the unlocking element on the first connector part is movable at right angles to the first base surface and captively associated therewith, for example by the unlocking element has unlocking arms which are positively but movably guided through openings provided for this purpose of the first base.

- An essential advantage achieved by the invention is that the respective locking element is elastically deformed only in the locking and unlocking, so is not deformed both in the locked and in the unlocked state and is therefore exposed over a longer period corresponding mechanical stresses. This has an advantageous effect on the life of the locking element according to the respective material.

- Another advantage is that assembly and disassembly of the circuit boards take place without additional tools.

- the locking process and the unlocking process are considerably simplified over the prior art.

- the PCB connector is inexpensive to manufacture.

- the locking surfaces of the locking elements are arranged almost parallel to the associated base surfaces is particularly advantageous.

- the term "almost parallel” means that an angle between the plane of the locking surface and a plane parallel to the associated base surface is not more than 10 °, in particular not more than 5.degree ..

- the almost parallel orientation of the locking surfaces ensures that On the one hand, the locking elements do not automatically unlock and, on the other hand, they can already be unlocked by means of force components which are small and parallel to the circuit board plane.

- the unlocking element which is moved at right angles to the printed circuit board plane.

- the unlocking element is U-shaped.

- the second locking element consists of an elastically deformable material and is advantageously formed V-shaped. It is furthermore of particular advantage if the second locking element has engagement bevels on its projections, which are intended to cooperate with the unlocking element in the unlocking process.

- the unlocking element presses the two locking arms of the second locking element together over these attack slopes.

- the V-shape of the second locking element has a particularly advantageous effect, since its two locking arms move toward one another with only little elastic deformation and due to a corresponding lever action with relatively little expenditure of force.

- the locking elements are located within the connector and thus protected against mechanical damage and against unintentional unlocking.

- the unlocking element is advantageously designed as a user-friendly actuator, which passes through the first base surface and a first printed circuit board fixed thereto through corresponding openings and thus allows easy to be carried out unlocking of the two connector parts. In this way, an unlocking of the fixed to the two bases printed circuit boards from the outside, i. from the side facing away from the connector of the first circuit board, be performed by a simple pushing the unlocking into the connector.

- the second locking element has a locking arm with two projections. With these projections, the second locking element is formed substantially T-shaped. This is advantageous because the holding forces thereby run parallel to its locking arm.

- the first locking element is made an elastically deformable material, is formed substantially U-shaped and the associated projections are inwardly, ie directed towards each other to lock with the projections of the second locking element.

- the projections of the first locking element on attack slopes which are on the one hand intended to cooperate with the second locking element in the locking operation. On the other hand, these attack slopes are also intended to cooperate with the unlocking in the unlocking process as follows: In the locked state, the unlocking engages around the first locking element.

- the locking arms of the second locking element are thereby pulled apart.

- the locking surfaces of the two locking elements are separated from each other and the two connector parts are unlocked from each other.

- the direction of movement of the unlocking coincides in the process of unlocking with the direction of movement of the first connector part in the separation of the second connector part. This greatly improves the handiness of operation, since the direction of movement of the unlocking and the direction of movement of the separation of the connector parts are identical and thus no opposing force components occur.

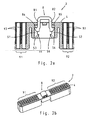

- the Fig. 1b represents the locked printed circuit board connector in a three-dimensional view from the outside.

- the first connector part 2 is as a single part in cross section through the locking plane in the Fig. 2a and as a three-dimensional representation from the outside in the Fig. 2b shown.

- the first connector part 2 has a first locking element 5, which is designed in two parts in the form of two separate locking arms 51,52 with associated projections 53,54. Accordingly, the first locking element 5 is not referred to in the drawing as a single part.

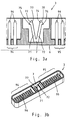

- the second connector part 3 is in a similar manner in the Fig. 3a and in the Fig. 3b shown and has a second locking element 7, which is made in one piece.

- the two locking arms 51,52 of the first locking element 5 are aligned parallel to each other and have at their ends the corresponding projections 53,54.

- the projections 53,54 are inwardly, ie directed towards each other and each having a locking surface 55,56, which is aligned parallel to the first base 4.

- the first connector part 2 further has two plug-in areas 91,92, which are equipped with contact sockets 93.

- This in Fig. 3a illustrated second locking element 7 consists of an elastically deformable material, is substantially V-shaped and accordingly has two locking arms 71,72. At their ends, these locking arms 71,72 each have a Anformung 73,74. These two projections 73, 74 are directed outwards, ie away from one another, and each have a locking surface 75, 76, which is aligned parallel to the second base surface 6. Furthermore, these two projections 73, 74 have attack slopes 77, 78 on a side facing away from their respective locking surface 75, 76.

- the second connector part further has two plug-in areas 94,95, which are equipped with pins 96.

- a U-shaped unlocking element 8 is shown in a three-dimensional representation as a single part.

- This unlocking element 8 has two unlocking arms 81,82, which, as in the Fig. 1b and Fig. 2b is shown, movably guided through openings provided for the first base 4.

- projections 83,84,85,86 are provided, of which only three projections 83,84,85 are visible in the drawing, while the fourth Anformung 86 covered by the second Entriegelungsarm 82 and in the drawing accordingly not indicated.

- the unlocking element 8 is part of the first connector part. 2

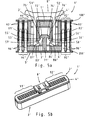

- the first connector part 2 ' has a first base 4' and a first locking element 5 'formed on this first base 4'.

- the first locking element 5 ' is made in one piece.

- the second connector part 3 ' has a second base 6' and a second locking element 7 'formed on this second base 6'.

- the second locking element 7 ' is made in one piece.

- the first locking element 5 ' consists of an elastically deformable material, has two locking arms 51', 52 'and is formed substantially U-shaped. At the ends of the two locking arms 51 ', 52', the first locking element 5 'has two projections 53', 54 '. These projections 53 ', 54' each have a locking surface 55 ', 56', which is aligned parallel to the first base 4 '. Furthermore, these two projections 53 ', 54' on one of their respective locking surface 55 ', 56' facing away from attack bevels 57 ', 58'.

- the first connector part 2 'further has two plug-in areas 91', 92 ', which are equipped with contact sockets 93'.

- the second locking element 7 ' has a locking arm 71', which is integrally formed at one end on the second base 6 and at the other end on both sides each have a Anformung 73 ', 74'.

- the second locking element 7 ' is formed substantially T-shaped.

- the two projections 73 ', 74' each have a locking surface 75 ', 76', which is aligned parallel to the second base 6 '.

- the second connector part 3 ' has two plug-in areas 94', 95 ', which are equipped with contact pins 96'.

- the locking surfaces 55 ', 56' of the first locking element 5 'and the locking surfaces 75', 76 'of the second locking element 7' are arranged counter to one another.

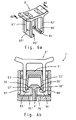

- the first connector part 2 ' has a substantially U-shaped unlocking element 8', which in Fig. 6a is shown as a single part.

- the unlocking element 8 ' has two parallel, surface unlocking arms 81', 82 ', each having a rectangular window.

- an unlocking hook 83 ', 84' each with a Entriegelungsschrägen 87 ', 88' integrally formed.

- Fig. 6b represents the unlocking process in cross section through an in Fig. 6a indicated locking plane is:

- the unlocking 8 'from the PCB connector 1' engage the Entriegelungshaken 83 ', 84' with their Entriegelungsschrägen 87 ', 88' against the bevels 57 ', 58' of the first locking element 5 '.

- the two locking arms 51 ', 52' of the first locking element 5 ' are bent apart elastically.

- the locking surfaces 55 ', 56' of the first locking element 5 ' are thus separated from the locking surfaces 75', 76 'of the second locking element 7' and the PCB connector 1 'is unlocked.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Claims (10)

- Connecteur à fiches de plaque de circuit imprimé pour des plaques de circuit imprimé parallèles, le connecteur à fiches (1, 1') de plaque de circuit imprimé étant composé d'une première pièce (2, 2') de connecteur à fiches et d'une deuxième pièce (3, 3') de connecteur à fiches, la première pièce (2, 2') de connecteur à fiches présentant une première surface de base (4, 4') qui peut être fixée sur une première plaque de circuit imprimé (100, 100'), la première pièce (2, 2') de connecteur à fiches comportant un premier élément de verrouillage (5, 5'), et la deuxième pièce (3, 3') de connecteur à fiches comportant un deuxième élément de verrouillage (7, 7'),

les deux éléments de verrouillage (5, 7, 5', 7') comportant chacun au moins un bras de verrouillage (51, 52, 71, 72, 51', 52', 71'), au moins une conformation (53, 54, 73, 74, 53', 54', 73', 74') présentant respectivement une surface de verrouillage (55, 56, 75, 76, 55', 56', 75', 76') étant prévue à l'extrémité de chaque bras de verrouillage (51, 52, 71, 72, 51', 52', 71'), et les surfaces de verrouillage (55, 56, 75, 76, 55', 56', 75', 76') des deux éléments de verrouillage (5, 7, 5', 7') étant agencées en engagement les unes contre les autres à l'état verrouillé, caractérisé en ce que

la deuxième pièce (3, 3') de connecteur à fiches présente une deuxième surface de base (6, 6') qui peut être fixée sur une deuxième plaque de circuit imprimé (200, 200'), la première pièce (2, 2') de connecteur à fiches comportant un élément de déverrouillage (8, 8') qui est retenu sur la première pièce (2, 2') de connecteur à fiches de manière à être mobile perpendiculairement à la première surface de base (4, 4') et est ainsi adapté à déformer élastiquement au moins l'un des deux éléments de verrouillage (7, 5') pour séparer les surfaces de verrouillage (55, 56, 55', 56') du premier élément de verrouillage (5, 5') des surfaces de verrouillage (75, 76, 75', 76') du deuxième élément de verrouillage (7, 7'). - Connecteur à fiches de plaque de circuit imprimé selon la revendication 1, caractérisé en ce que au moins l'un des deux éléments de verrouillage (5, 7, 5', 7') est réalisé au moins en partie en une matière élastiquement déformable.

- Connecteur à fiches de plaque de circuit imprimé selon l'une des revendications 1 à 2, caractérisé en ce que l'élement de déverrouillage (8, 8') présente au moins deux bras de déverrouillage (81, 82, 81', 82') au moyen desquels il s'engage à travers la première surface de base (4, 4') à travers des orifices prévus à cet effet.

- Connecteur à fiches de plaque de circuit imprimé selon la revendication 3, caractérisé en ce que les bras de déverrouillage (81, 82, 81', 82') comportent à leurs extrémités des conformations respectives (83, 84, 85, 86, 83', 84'), en particulier des crochets de déverrouillage (83', 84') au moyen desquels l'élément de déverrouillage (8, 8') est relié de manière imperdable à la première pièce (2, 2') de connecteur à fiches.

- Connecteur à fiches de plaque de circuit imprimé selon l'une des revendications 1 à 4, caractérisé en ce que les surfaces de verrouillage (55, 56, 75, 76, 55', 56', 75', 76') sont orientées de manière à être approximativement parallèles aux surfaces de base (4, 6, 4', 6') de la pièce (2, 3, 2', 3') de connecteur à fiches respective.

- Connecteur à fiches de plaque de circuit imprimé selon l'une des revendications 1 à 5, caractérisé en ce que le premier élément de verrouillage (5) comporte deux bras de verrouillage (51, 52) parallèles qui présentent des conformations (53, 54) orientées les unes vers les autres.

- Connecteur à fiches de plaque de circuit imprimé selon la revendication 6, caractérisé en ce que le deuxième élément de verrouillage (7) est réalisé sensiblement en forme de V et présente deux bras de verrouillage (71, 72) avec des conformations (73, 74) détournées les unes des autres.

- Connecteur à fiches de plaque de circuit imprimé selon l'une des revendications 1 à 6, caractérisé en ce que le deuxième élément de verrouillage (7') comprend un bras de verrouillage (71') avec deux conformations (73', 74'), et en ce que le deuxième élément de verrouillage (7') est réalisé ensemble avec ces conformations (73', 74') sensiblement en forme de T.

- Connecteur à fiches de plaque de circuit imprimé selon l'une des revendications précédentes, caractérisé en ce que les conformations (53, 54, 73, 74, 53', 54', 73', 74') d'au moins l'un des deux éléments de verrouillage (5, 7, 5', 7') présentent des chanfreins d'attaque (57', 58') destinés à coopérer avec l'élément de déverrouillage (8, 8').

- Connecteur à fiches de plaque de circuit imprimé selon l'une des revendications précédentes, caractérisé en ce que l'élément de déverrouillage (8, 8') est réalisé sensiblement en forme de U.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL10015559T PL2339701T3 (pl) | 2009-12-17 | 2010-12-13 | Łącznik wtykowy płytek drukowanych z urządzeniem blokującym |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009058616A DE102009058616B4 (de) | 2009-12-17 | 2009-12-17 | Leiterplattensteckverbinder mit Verriegelungsvorrichtung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2339701A2 EP2339701A2 (fr) | 2011-06-29 |

| EP2339701A3 EP2339701A3 (fr) | 2011-07-27 |

| EP2339701B1 true EP2339701B1 (fr) | 2012-10-17 |

Family

ID=43568353

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10015559A Active EP2339701B1 (fr) | 2009-12-17 | 2010-12-13 | Connecteur à fiche de plaquettes doté d'un dispositif de verrouillage |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8192221B2 (fr) |

| EP (1) | EP2339701B1 (fr) |

| CN (1) | CN102104211B (fr) |

| DE (1) | DE102009058616B4 (fr) |

| DK (1) | DK2339701T3 (fr) |

| ES (1) | ES2395234T3 (fr) |

| PL (1) | PL2339701T3 (fr) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011057294A2 (fr) * | 2009-11-09 | 2011-05-12 | Virginia Panel Corporation | Interface |

| FR2953066B1 (fr) * | 2009-11-25 | 2011-12-30 | St Microelectronics Tours Sas | Montage en boitier pour composants electroniques assembles par clip |

| FR2956527B1 (fr) * | 2010-02-15 | 2012-09-21 | Tyco Electronics France Sas | Connecteur electrique comprenant une protuberance ou une poche de guidage avec un element de fixation flexible. |

| JP5631191B2 (ja) * | 2010-12-21 | 2014-11-26 | 矢崎総業株式会社 | コネクタ |

| JP5920565B2 (ja) * | 2012-01-30 | 2016-05-18 | 第一精工株式会社 | 配線基板連結装置 |

| CN109119803B (zh) * | 2017-06-23 | 2020-09-15 | 町洋企业股份有限公司 | 连接器模块的组接结构 |

| US10355411B2 (en) * | 2017-07-18 | 2019-07-16 | Dinkle Enterprise Co., Ltd. | Assembly structures of connector module |

| US10079454B1 (en) * | 2017-07-18 | 2018-09-18 | Dinkle Enterprise Co., Ltd. | Assembly structures of connector module |

| DE102017127991B4 (de) | 2017-11-27 | 2021-06-10 | HARTING Electronics GmbH | Ver- und entriegelbarer Steckverbinder |

| CN110197974B (zh) * | 2018-02-27 | 2020-10-30 | 中航光电科技股份有限公司 | 一种锁紧连接结构及插头、插座 |

| DE102018132440B4 (de) | 2018-12-17 | 2023-05-04 | Amphenol Tuchel Industrial GmbH | Anordnung aus einem Gerätesteckverbinder und einem Adapterstecker sowie Montageverfahren |

| US11777256B2 (en) * | 2020-06-28 | 2023-10-03 | Amphenol Commercial Products (Chengdu) Co., Ltd. | Electrical connector and method for mating and unmating the same |

| DE102021118853B4 (de) | 2021-07-21 | 2023-06-15 | Amphenol Tuchel Industrial GmbH | Mehrteiliger Leiterplattenadapterstecker mit spezifischem Interface |

| DE102022111007A1 (de) | 2022-05-04 | 2023-11-09 | Amphenol Tuchel Industrial GmbH | Modularer Steckverbinder für Leiterplatten |

| DE102023101760B3 (de) | 2023-01-25 | 2024-05-29 | Amphenol-Tuchel Electronics Gesellschaft mit beschränkter Haftung | Flexible Leiterplattenbrücke, Verbindungsanordnung und Verfahren zum Herstellen einer Leiterplattenverbindung |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4637670A (en) * | 1984-04-23 | 1987-01-20 | Amp Incorporated | Dual in-line package carrier assembly |

| US5567166A (en) * | 1994-04-08 | 1996-10-22 | Berg Technology, Inc. | Low profile connector and processes for making and using the same |

| US5836773A (en) * | 1996-07-29 | 1998-11-17 | Hon Hai Precision Ind. Co., Ltd. | Board-to-board connector |

| US6220903B1 (en) * | 1999-12-13 | 2001-04-24 | Cvilux Corporation | Plastic housing structures for a board-to-board connector |

| TW555189U (en) * | 2002-09-25 | 2003-09-21 | Hon Hai Prec Ind Co Ltd | Electrical connector assembly |

| DE602004008208T2 (de) | 2004-01-05 | 2008-05-15 | Sumitomo Wiring Systems, Ltd., Yokkaichi | Verbinder |

| JP2006049036A (ja) | 2004-08-03 | 2006-02-16 | Tyco Electronics Amp Kk | ドッキングコネクタ |

-

2009

- 2009-12-17 DE DE102009058616A patent/DE102009058616B4/de active Active

-

2010

- 2010-11-29 US US12/955,623 patent/US8192221B2/en active Active

- 2010-12-13 DK DK10015559.7T patent/DK2339701T3/da active

- 2010-12-13 ES ES10015559T patent/ES2395234T3/es active Active

- 2010-12-13 PL PL10015559T patent/PL2339701T3/pl unknown

- 2010-12-13 EP EP10015559A patent/EP2339701B1/fr active Active

- 2010-12-17 CN CN201010593259.3A patent/CN102104211B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| DE102009058616A1 (de) | 2011-06-22 |

| CN102104211B (zh) | 2014-03-12 |

| DK2339701T3 (da) | 2013-02-04 |

| CN102104211A (zh) | 2011-06-22 |

| ES2395234T3 (es) | 2013-02-11 |

| US8192221B2 (en) | 2012-06-05 |

| EP2339701A3 (fr) | 2011-07-27 |

| EP2339701A2 (fr) | 2011-06-29 |

| PL2339701T3 (pl) | 2013-10-31 |

| DE102009058616B4 (de) | 2011-11-10 |

| US20110136367A1 (en) | 2011-06-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2339701B1 (fr) | Connecteur à fiche de plaquettes doté d'un dispositif de verrouillage | |

| DE69722055T2 (de) | Elektrischer Verbinder | |

| EP2839544B1 (fr) | Bornier de test | |

| EP2613220B1 (fr) | Boîtier pour système informatique et système informatique équipé d'un tel boîtier | |

| DE202010008319U1 (de) | Tragschienen- und Modulverrastung | |

| WO2017084954A1 (fr) | Cadre support servant à maintenir des modules de connecteurs à enficher | |

| DE3337511A1 (de) | Verriegelbare steckerverbindung | |

| DE102014106277B4 (de) | Ein Elektronikgehäuse mit einer Anschlussleiste für ein Elektronikgerät | |

| DE69800154T2 (de) | Elektrische Anschlussvorrichtung mit verbesserter Kontaktsicherheit | |

| DE202013012817U1 (de) | Steckverbinder umfassend eine Schutzleiterbrücke | |

| DE102016107633B4 (de) | Halterahmen zum Aufnehmen von modularen Kontakteinsätzen sowie Steckverbinderteil mit einem solchen Halterahmen | |

| DE102011002135A1 (de) | Steckerelement mit zweiter Kontaktsicherung | |

| WO1997008783A1 (fr) | Dispositif constitue de deux demi-fiches pour fixation dans une paroi | |

| DE102016108780A1 (de) | Mittel zum Montieren, Entriegeln und Demontieren eines Steckverbinders, sowie Verfahren zur Nutzung des Mittels | |

| DE69210072T2 (de) | Elektrisches Verbindergehäuse | |

| DE3015138A1 (de) | Verriegelbarer steckverbinder | |

| DE202017101632U1 (de) | Steckeranordnung und Verriegelungseinrichtung zur Verriegelung eines Gegensteckverbinders an einem Steckverbinder | |

| DE102016200363A1 (de) | Kontaktelement | |

| DE202013104941U1 (de) | Elektrische Steckverbinderanordnung und Schirmanbindungselement hierzu | |

| EP2262062B1 (fr) | Connecteur à fiches | |

| EP1891711B1 (fr) | Connecteur electrique d'un vehicule automobile | |

| DE10334071B4 (de) | Steckverbindungssystem mit integrierter Verriegelung | |

| DE102022113144A1 (de) | Steckverbinder mit einer rasteinrichtung zur verriegelung einer steckverbindung mit einem gegensteckverbinder, gegensteckverbinder sowie anordnung mit einem steckverbinder und einem gegensteckverbinder | |

| DE102020102705A1 (de) | Schnappverbindung | |

| DE4417173C2 (de) | Kupplungsvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20110822 |

|

| 17Q | First examination report despatched |

Effective date: 20111028 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 580257 Country of ref document: AT Kind code of ref document: T Effective date: 20121115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010001449 Country of ref document: DE Effective date: 20121213 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BUGNION S.A., CH |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: HARTING ELECTRONICS GMBH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502010001449 Country of ref document: DE Representative=s name: PRINZ & PARTNER PATENTANWAELTE RECHTSANWAELTE, DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2395234 Country of ref document: ES Kind code of ref document: T3 Effective date: 20130211 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20121017 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502010001449 Country of ref document: DE Representative=s name: PRINZ & PARTNER PATENTANWAELTE RECHTSANWAELTE, DE Effective date: 20130122 Ref country code: DE Ref legal event code: R081 Ref document number: 502010001449 Country of ref document: DE Owner name: HARTING ELECTRONICS GMBH, DE Free format text: FORMER OWNER: HARTING ELECTRONICS GMBH & CO. KG, 32339 ESPELKAMP, DE Effective date: 20130122 Ref country code: DE Ref legal event code: R082 Ref document number: 502010001449 Country of ref document: DE Representative=s name: PRINZ & PARTNER MBB PATENTANWAELTE RECHTSANWAE, DE Effective date: 20130122 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130118 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130218 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130117 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121231 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20130815 AND 20130821 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 580257 Country of ref document: AT Kind code of ref document: T Owner name: HARTING ELECTRONIC GMBH, DE Effective date: 20130719 |

|

| 26N | No opposition filed |

Effective date: 20130718 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121213 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010001449 Country of ref document: DE Effective date: 20130718 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E017316 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121017 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20151211 Year of fee payment: 6 Ref country code: DK Payment date: 20151210 Year of fee payment: 6 Ref country code: FI Payment date: 20151209 Year of fee payment: 6 Ref country code: NO Payment date: 20151209 Year of fee payment: 6 Ref country code: TR Payment date: 20151102 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20151210 Year of fee payment: 6 Ref country code: SE Payment date: 20151211 Year of fee payment: 6 Ref country code: AT Payment date: 20151125 Year of fee payment: 6 Ref country code: RO Payment date: 20151106 Year of fee payment: 6 Ref country code: CZ Payment date: 20151207 Year of fee payment: 6 Ref country code: HU Payment date: 20151112 Year of fee payment: 6 Ref country code: ES Payment date: 20151112 Year of fee payment: 6 Ref country code: BE Payment date: 20151207 Year of fee payment: 6 Ref country code: PL Payment date: 20151014 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20151221 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161231 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: MMEP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20161231 Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20170101 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 580257 Country of ref document: AT Kind code of ref document: T Effective date: 20161213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161231 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161214 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161231 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20161231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161214 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161213 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230603 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231219 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20231226 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231227 Year of fee payment: 14 |