EP1683548A1 - Inerting method for avoiding fire - Google Patents

Inerting method for avoiding fire Download PDFInfo

- Publication number

- EP1683548A1 EP1683548A1 EP05001224A EP05001224A EP1683548A1 EP 1683548 A1 EP1683548 A1 EP 1683548A1 EP 05001224 A EP05001224 A EP 05001224A EP 05001224 A EP05001224 A EP 05001224A EP 1683548 A1 EP1683548 A1 EP 1683548A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- inert gas

- area

- oxygen

- protected area

- fresh air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims description 22

- 239000001301 oxygen Substances 0.000 claims abstract description 64

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 64

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 62

- 239000011261 inert gas Substances 0.000 claims description 76

- 239000003570 air Substances 0.000 claims description 39

- 239000000203 mixture Substances 0.000 claims description 6

- 239000012080 ambient air Substances 0.000 claims description 4

- 238000004880 explosion Methods 0.000 claims description 3

- 230000001105 regulatory effect Effects 0.000 claims description 3

- 150000002926 oxygen Chemical class 0.000 claims description 2

- 239000007789 gas Substances 0.000 description 11

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 10

- 230000008901 benefit Effects 0.000 description 8

- 230000001681 protective effect Effects 0.000 description 6

- 229910000831 Steel Inorganic materials 0.000 description 5

- 230000004941 influx Effects 0.000 description 5

- 229910052757 nitrogen Inorganic materials 0.000 description 5

- 239000010959 steel Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000012544 monitoring process Methods 0.000 description 3

- 230000002265 prevention Effects 0.000 description 3

- 238000013461 design Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 230000007257 malfunction Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 230000008033 biological extinction Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000007596 consolidation process Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000002779 inactivation Effects 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 230000011664 signaling Effects 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C99/00—Subject matter not provided for in other groups of this subclass

- A62C99/0009—Methods of extinguishing or preventing the spread of fire by cooling down or suffocating the flames

- A62C99/0018—Methods of extinguishing or preventing the spread of fire by cooling down or suffocating the flames using gases or vapours that do not support combustion, e.g. steam, carbon dioxide

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C37/00—Control of fire-fighting equipment

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C99/00—Subject matter not provided for in other groups of this subclass

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C99/00—Subject matter not provided for in other groups of this subclass

- A62C99/0009—Methods of extinguishing or preventing the spread of fire by cooling down or suffocating the flames

Definitions

- the present invention relates to an inerting method for preventing a fire or an explosion in an enclosed protective area, in which the oxygen content in the protected area is lowered relative to the ambient air in the protected area.

- Inertization procedures for fire prevention and extinguishing indoors are known from the fire extinguishing technology.

- the extinguishing effect resulting from these processes is based on the principle of oxygen displacement.

- the normal ambient air is known to be 21% by volume of oxygen, 78% by volume of nitrogen and 1% by volume of other gases.

- For extinction or fire prevention by initiating e.g. pure or 90% nitrogen as inert gas further increases the nitrogen concentration in the relevant protection area and thus reduces the oxygen content. It is known that an extinguishing effect starts when the oxygen content drops below about 15% by volume.

- a further decrease in the oxygen content to, for example, 12% by volume may be required. At this oxygen concentration, most flammable materials can no longer burn.

- the oxygen-displacing gases used in this "inert gas extinguishing technology" are usually stored in special ancillary rooms in steel cylinders in compressed form, or a device is used to generate an oxygen-displacing gas. It is also possible to use inert gas / air mixtures with a proportion of, for example, 90%, 95% or 99% nitrogen (or another inert gas). Justify the steel bottles or this device for generating the oxygen-displacing gas the so-called primary source of Inertgasfeuerlöschstrom. If necessary, then the gas is passed from this source via piping systems and corresponding outlet nozzles in the relevant protection area. In order to keep the fire risk as low as possible, even if the source fails, occasionally secondary sources of inert gas are also used.

- the reason for a high level of inertization and thus still relatively high oxygen content may be due to the fact that either humans are in the protection area or the access of people to the protection area must be enabled, even if an increased concentration of inerting gas prevents fires should be.

- the continuous influx of inerting gas into the protected area therefore not only leads to higher costs due to the permanent production of inert gas or the discharge of inert gas from primary and / or secondary sources, but also human-relevant and, in particular, vitally important issues within the protected area are affected.

- the present invention is based on the object of the present invention explained Inertmaschinesclar further develop so that too high or for certain requirements such as inspection of the protection area by staff too high inert gas concentration can be reliably reduced.

- This object is achieved according to the invention in the inertization process mentioned above in that the oxygen content in the protected area is continuously measured, compared with a threshold value (maximum inerting level) and fresh air is introduced into the protected area if the threshold value (maximum inerting level) falls below the threshold value (unintentional).

- fresh air also oxygen-reduced air with a higher oxygen content than in the protected area to understand.

- the advantages of this invention are, in particular, that an inertizing process that is easy to implement and thereby very effective for avoiding a fire in an enclosed protected area can be achieved even if the influx of inert gas has occurred uncontrollably due to an error in the inert gas production or inert gas feed system. Fresh air is always available around the protected area to a sufficient extent.

- the disadvantages of the hitherto known apparatuses and methods, which can entail a hazard to humans in the protected area, are clearly avoided.

- the threshold value for the oxygen content at which fresh air is introduced into the protected area is smaller than the value of the oxygen content of the basic inertization level.

- This type of oxygen content separation makes sense, as the oxygen content of the base inertization level is chosen to avoid fires, but people can still enter the protected area. If the oxygen content continues to decrease as a result of the incorrect excessive supply of inert gas, fires are still prevented, but the stay for persons becomes increasingly dangerous.

- the threshold value for the oxygen content in the protection range is therefore chosen so that it is below the oxygen content of the basic inertization level, but on the other hand does not fall below a dangerous value for humans.

- the inert gas content in the protected area can also be measured.

- the inert gas content is compared with a threshold value and when fresh air is exceeded in the protected area initiated.

- This process requires that a direct relationship between oxygen content and inert gas content be established in a natural atmosphere. This dependency ratio is known for typical fire avoidance situations.

- the oxygen content in the protected area is measured at several points, each with one or more sensors.

- the advantage of measuring the oxygen content at several points is that even if the concentration of the oxygen is not uniform, a drop below a point is already detected.

- Another advantage of using multiple sensors is redundancy. If a sensor is defective or the line to one sensor is interrupted, another sensor can take over the measuring task. In the event that routing cables to the different sensors poses problems, the signals from the sensors can also be wirelessly transmitted to the control unit.

- the inert gas content in the protected area can also be measured at one or more locations with one or more inert gas sensors.

- the advantages of multi-site measurement equals the benefits of multi-site oxygen concentration measurement. It is expressly pointed out that a simultaneous measurement of both the oxygen content and the inert gas content significantly increases the safety for persons who are in the protected area.

- the signals of the oxygen sensors or the inert gas sensors are supplied to a control unit.

- all electronic components for evaluating the signals of the sensors are combined in this control unit.

- different algorithms for reaction to different gas mixture concentration can be stored in the control unit.

- control unit in an advantageous development, a fresh air supply system on and off.

- the inclusion of the control logic for the fresh air supply system in the control unit also falls under the aspect of a compact design of a central consolidation of all measurement and control signals in an electronic unit.

- the fresh air supply is controlled so that a maximum inerting level is not exceeded.

- the basic inerting level is not undershot. This means that the oxygen concentration within the protected area is regulated even with fresh air supply so that fires are reliably prevented at a basic inerting level. It is important that the fresh air supply is switched on at the latest when a maximum inerting level has been reached, beyond which people who are in the protected area are endangered.

- the control unit monitors a second protection area.

- a fresh air supply system for this second protection area is a fresh air supply system, at least one oxygen sensor and / or at least one inert gas sensor and a range valve for controlling the supply of the inert gas available.

- a maximum inerting level is not exceeded.

- a basic inactivation level is not undercut.

- control unit sets the basic and maximum inertization levels in the different protection areas differently high.

- the oxygen content of the basic inertization level in protection area 1a may be lower than the corresponding value in protection area 1b.

- the advantage of such a splitting would be that persons can stay in one area of protection, while in the other area the oxygen content is so low that a stay of persons in this area is not possible. It is conceivable to use such a division in the storage of highly flammable materials in a protected area and of normally flammable materials in another area of protection, which is regularly entered by persons.

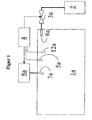

- FIG. 1 schematically shows, by way of example, the basic function of the method according to the invention, including the associated control and measuring systems.

- Pipes are fat and thick and measuring and control lines are normal and thin.

- the inert gas may be left from the inert gas source 2, through a valve 3a and one or more outlet nozzles 6a into the protection area 1a.

- the inert gas source can be designed in various ways.

- a typical embodiment is to provide the inert gas from one or more containers, for example steel bottles.

- a generator may be used to produce an inert gas (for example, nitrogen) or an inert gas-air mixture.

- a secondary inert gas source which in turn may consist either of compressed inert gas in steel cylinders or of an inert gas-producing generator.

- the concentration of the inert gas in the protected area 1 a is controlled by the control unit 4, which in turn influences the valve 3 a.

- the control unit 4 is set so that a basic inerting level in the protection area 1a is achieved. This basic inerting level reduces the risk of fire or explosion in the protection area 1a.

- inert gas is introduced from the inert gas source 2 into the protective area 1a via the valve 3a and the inert gas inlet nozzle 6a.

- the valve 3a does not close or the inert gas or the inert gas-producing air mixture generator does not switch off and thus permanently inert gas passes through the inert gas 6a into the protected area and so the inert gas concentration in the protection area increases continuously, so That the oxygen content far below the desired Grundinertmaschinescited, the following mechanism according to the invention is set in motion.

- the control unit 4 measures a too low oxygen concentration via the oxygen sensor 5a, and thus outputs a signal for closing the valve 3a or a signal for turning off the inert gas or inert gas-air mixture producing generator. If these two conditions are met, the oxygen concentration in the protective area 1a continues to decrease, which is also signaled to the control unit 4 by inert gas sensors 12a can, the fresh air supply system 8a is put into operation, passes through the additional fresh air via one or more fresh air supply inlets 7a in the protection area 1a. In this case, the volume flow of fresh air is adjusted so that even at full operation of the inert gas-producing system (either made of steel cylinders or as a generator), the inert gas concentration in the protection area 1a can not increase.

- FIG. 2 shows by way of example a possible course of the oxygen concentration in the protected area 1a.

- the oxygen concentration is regulated to a basic inertization level (setpoint), between an upper and a lower set point.

- setpoint a basic inertization level

- the inert gas source is activated and inert gas is introduced into the protective area 1a a. Triggered by this introduction of the inert gas into the protection area 1a, the oxygen concentration falls between the times t o and t 1 .

- the inert gas source is deactivated again.

- the oxygen concentration rises slowly again because, for example, some fresh air enters the protected area due to leaks in relation to the ambient air.

- the inert gas source is reactivated. However, if the inert gas source can not be deactivated due to a defect, the oxygen concentration in the protected area will continue to decrease.

- the maximum inerting concentration which is permitted in protection zone 1 and is still harmless to humans, is achieved. Due to the malfunction of the inert gas system, ie by an unimpeded further influx of inert gas into the protected area, the oxygen concentration would continue to decrease after time t 3 and prevent a safe stay of people in the protected area.

- FIG. 3 shows a further alternative of an inerting system, which in this case comprises two protective spaces 1a and 1b and area-specific inerting and monitoring components having.

- the protection area 1a is monitored in this case according to the details given in the description of FIGS. 1 and 2.

- a further protection area 1b with associated inerting and monitoring components is shown. These include the valve 3b, the inert gas inlet 6b, the oxygen sensor 5b, the fresh air supply inlet 7b, and the fresh air supply system 8b.

- the control unit 4 shown in Figure 3 could alternatively consist of two separate control units.

- the two shelters 1 a, 1 b are separated from each other by a wall 9.

- the control unit 4 shown in Figure 3 could alternatively consist of two separate control units.

- the protection area 1a which in this case is not entered by persons, has a different (higher) inerting level than the protection area 1b, which despite regularization is regularly entered by persons.

- Protective area 1a could, for example, have an inerting level at which the oxygen concentration is about 13% by volume.

- another inertization level of, for example, 17 vol.% Oxygen is ensured by the control unit 4 in the protection area 1b. Leakage of the wall 9 can lead to uncontrolled passage of inert gas from the protection area 1a to the protection area 1b. This is shown in Figure 3 by the directional arrows 10.

- Task of the control unit 4 is the different levels of inerting in the shelters 1a and 1b by supplying inert gas through the valves 3a and 3b and, if necessary, by the supply of fresh air through the fresh air systems 8a and 8b and the Frischluftzufarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarfarction 7a and 7b, as under Description to Figure 1 described to guarantee.

- the valves 3a and 3b are referred to in this case as area valves, since the different shelters 1a and 1b represent different areas of monitoring.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

- Fire-Extinguishing By Fire Departments, And Fire-Extinguishing Equipment And Control Thereof (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Fire Alarms (AREA)

- Control Of Non-Electrical Variables (AREA)

- Separation By Low-Temperature Treatments (AREA)

- Fire-Detection Mechanisms (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein Inertisierungsverfahren zur Vermeidung eines Brandes oder einer Explosion in einem umschlossenen Schutzbereich, bei dem der Sauerstoffgehalt im Schutzbereich gegenüber der Umgebungsluft im Schutzbereich abgesenkt wird.The present invention relates to an inerting method for preventing a fire or an explosion in an enclosed protective area, in which the oxygen content in the protected area is lowered relative to the ambient air in the protected area.

Inertisierungsverfahren zur Brandverhütung und- Löschung in geschlossenen Räumen sind aus der Feuerlöschtechnik bekannt. Die bei diesen Verfahren resultierende Löschwirkung beruht auf dem Prinzip der Sauerstoffverdrängung. Die normale Umgebungsluft besteht bekanntlich zu 21 Vol.-% aus Sauerstoff, zu 78 Vol.-% aus Stickstoff und zu 1 Vol.-% aus sonstigen Gasen. Zum Löschen bzw. zur Brandvermeidung wird durch Einleiten von z.B. reinem oder 90% Stickstoff als Inertgas die Stickstoffkonzentration in dem betreffenden Schutzbereich weiter erhöht und damit der Sauerstoffanteil verringert. Es ist bekannt, das eine Löschwirkung einsetzt, wenn der Sauerstoffanteil unter etwa 15 Vol.-% absinkt. Abhängig von den in dem betreffenden Schutzbereich vorhandenen brennbaren Materialien kann ferner ein weiteres Absinken des Sauerstoffanteils auf beispielsweise 12 Vol.-% erforderlich sei. Bei dieser Sauerstoffkonzentration können die meisten brennbaren Materialien nicht mehr brennen.Inertization procedures for fire prevention and extinguishing indoors are known from the fire extinguishing technology. The extinguishing effect resulting from these processes is based on the principle of oxygen displacement. The normal ambient air is known to be 21% by volume of oxygen, 78% by volume of nitrogen and 1% by volume of other gases. For extinction or fire prevention, by initiating e.g. pure or 90% nitrogen as inert gas further increases the nitrogen concentration in the relevant protection area and thus reduces the oxygen content. It is known that an extinguishing effect starts when the oxygen content drops below about 15% by volume. Depending on the flammable materials present in the relevant protection zone, a further decrease in the oxygen content to, for example, 12% by volume may be required. At this oxygen concentration, most flammable materials can no longer burn.

Die bei dieser "Inertgaslöschtechnik" verwendeten, sauerstoffverdrängenden Gase werden in der Regel in speziellen Nebenräumen in Stahlflaschen komprimiert gelagert, oder es wird ein Gerät zur Erzeugung eines sauerstoffverdrängenden Gases eingesetzt. Dabei können auch Inertgas-Luftgemische mit einem Anteil von beispielsweise 90%, 95% oder 99% Stickstoff (oder eines anderen Inertgases) zur Anwendung kommen. Die Stahlflaschen bzw. dieses Gerät zur Erzeugung des sauerstoffverdrängenden Gases begründen die sogenannte Primärquelle der Inertgasfeuerlöschanlage. Im Bedarfsfall wird dann das Gas von dieser Quelle über Rohrleitungssysteme und entsprechende Austrittsdüsen in den betreffenden Schutzbereich geleitet. Um das Brandrisiko auch bei Ausfall der Quelle so niedrig wie möglich zu halten, wird gelegentlich auch auf sekundäre Inertgasquellen zurückgegriffen.The oxygen-displacing gases used in this "inert gas extinguishing technology" are usually stored in special ancillary rooms in steel cylinders in compressed form, or a device is used to generate an oxygen-displacing gas. It is also possible to use inert gas / air mixtures with a proportion of, for example, 90%, 95% or 99% nitrogen (or another inert gas). Justify the steel bottles or this device for generating the oxygen-displacing gas the so-called primary source of Inertgasfeuerlöschanlage. If necessary, then the gas is passed from this source via piping systems and corresponding outlet nozzles in the relevant protection area. In order to keep the fire risk as low as possible, even if the source fails, occasionally secondary sources of inert gas are also used.

Alle bisher bekannten Verfahren zur Erhöhung der Sicherheit solcher Brandverhinderungssysteme, die auf dem Prinzip der Inertisierung eines Schutzbereiches mittels eines Inertgases beruhen, konzentrieren sich darauf zu verhindern, dass der notwendige Gasstrom zur Aufrechterhaltung einer Inertisierungskonzentration erhalten bleibt. In diesem Zusammenhang sind eine Reihe von Apparaturen beschrieben, die unterschiedliche Inertgasquellen sowohl für die Primär als auch für eine potentiell vorhandene und sicherheitserhöhende sekundäre Inertgasquelle beschreiben. Die Sekundärquelle für das Inertgas springt immer dann ein, wenn die Primärquelle für das Inertgas ausgefallen ist. All diesen Apparaturen und Verfahren ist jedoch gemeinsam, dass kein Sicherheitsmechanismus vorgesehen ist für den Fall, dass der Zustrom von Inertgas unkontrolliert fortgesetzt wird, auch wenn das Inertisierungsniveau inzwischen einen Wert erreicht hat, bei dem Brände zuverlässig verhindert werden. Der Zustand einer zu hohen Inertgaskonzentration kann allerdings eintreten, wenn bedingt durch Undichtigkeiten zwischen benachbarten Räumen mit unterschiedlichen Inertisierungsniveaus ein ungewollter Inertisierungsgaskonzentrationsniveauausgleich stattfindet. Als weiterer Fehler ist denkbar, dass der Regelmechanismus für die Zuführung von Inertgas ausfällt oder der zur Inertgasproduktion eingesetzte Generator nicht abschaltet bzw. das Zuführventil nicht mehr zuverlässig schließt und kontinuierlich weiteres Inertgas in den Schutzbereich eingelassen wird.All previously known methods for increasing the safety of such fire prevention systems, which are based on the principle of inerting a protected area by means of an inert gas, focus on preventing the necessary gas flow to maintain an inerting concentration is maintained. In this context, a number of apparatuses are described which describe different sources of inert gas for both the primary and a potentially existing and safety increasing secondary source of inert gas. The secondary source of the inert gas will always start when the primary source of inert gas has failed. However, all these apparatuses and methods have in common that no safety mechanism is provided in the event that the influx of inert gas continues uncontrolled, even if the inerting has now reached a level at which fires are reliably prevented. However, the condition of an excessively high inert gas concentration can occur if, due to leaks between adjacent spaces with different inertization levels, an undesired inerting gas concentration level compensation takes place. Another error is conceivable that the control mechanism for the supply of inert gas fails or the generator used for inert gas production does not turn off or the supply valve no longer reliably closes and continuously further inert gas is admitted into the protection area.

Der Grund für ein hohes Inertisierungsniveaus und damit gleichbedeutend immer noch relativ hohen Sauerstoffgehalt kann darin begründet sein, dass sich entweder Menschen in dem Schutzbereich aufhalten, oder der Zutritt von Menschen in den Schutzbereich ermöglicht werden muss, auch wenn durch eine erhöhte Konzentration von Inertisierungsgas Brände verhindert werden sollen. Durch den kontinuierlichen Zustrom von Inertisierungsgas in den Schutzbereich entstehen also nicht nur höhere Kosten durch die permanente Produktion von Inertgas oder das Auslassen von Inertgas aus Primär- und/oder Sekundärquellen, sondern es werden auch für Menschen sicherheitsrelevante und insbesondere überlebenswichtige Fragen innerhalb des Schutzbereiches berührt. Ausgehend von den zuvor geschilderten Problemen hinsichtlich der sicherheitstechnischen Anforderungen einer Inertgasfeuerlöschanlage in Bezug auf eine zu hohe Inertgaskonzentration liegt der vorliegenden Erfindung die Aufgabe zugrunde, das eingangs erläuterte Inertisierungsverfahren derart weiter zu entwickeln, dass eine zu hohe oder für bestimmte Anforderungen wie zum Beispiel Begehung des Schutzbereiches durch Personal zu hohe Inertgaskonzentration zuverlässig abgebaut werden kann.The reason for a high level of inertization and thus still relatively high oxygen content may be due to the fact that either humans are in the protection area or the access of people to the protection area must be enabled, even if an increased concentration of inerting gas prevents fires should be. The continuous influx of inerting gas into the protected area therefore not only leads to higher costs due to the permanent production of inert gas or the discharge of inert gas from primary and / or secondary sources, but also human-relevant and, in particular, vitally important issues within the protected area are affected. Based on the problems described above with regard to the safety requirements of an inert gas fire extinguishing system with regard to an excessively high inert gas concentration, the present invention is based on the object of the present invention explained Inertisierungsverfahren further develop so that too high or for certain requirements such as inspection of the protection area by staff too high inert gas concentration can be reliably reduced.

Diese Aufgabe wird bei dem eingangs genannten Inertisierungsverfahren erfindungsgemäß dadurch gelöst, dass der Sauerstoffgehalt im Schutzbereich kontinuierlich gemessen, mit einem Schwellwert (maximalen Inertisierungsniveau) verglichen und bei einem ― unbeabsichtigten ― Unterschreiten des Schwellwerts (maximalen Inertisierungsniveaus) Frischluft in den Schutzbereich eingeleitet wird.This object is achieved according to the invention in the inertization process mentioned above in that the oxygen content in the protected area is continuously measured, compared with a threshold value (maximum inerting level) and fresh air is introduced into the protected area if the threshold value (maximum inerting level) falls below the threshold value (unintentional).

Vorliegend ist unter dem Begriff "Frischluft" auch sauerstoffreduzierte Luft mit einem höheren Sauerstoffgehalt als im Schutzbereich zu verstehen.In the present case, the term "fresh air" also oxygen-reduced air with a higher oxygen content than in the protected area to understand.

Die Vorteile dieser Erfindung liegen insbesondere darin, dass ein einfach zu realisierendes und dabei sehr effektives Inertisierungsverfahren zur Vermeidung eines Brandes in einem umschlossenen Schutzbereich erzielbar ist auch wenn der Zustrom von Inertgas unkontrolliert durch einen Fehler in der Inertgasproduktions bzw. Inertgaszuführungsanlage aufgetreten ist. Frischluft ist in jedem Fall um den Schutzbereich herum in ausreichendem Maße zur Verfügung. Die Nachteile der bisher bekannten Apparaturen und Verfahren, die eine Gefährdung des Menschen im Schutzbereich nach sich ziehen können, werden eindeutig vermieden.The advantages of this invention are, in particular, that an inertizing process that is easy to implement and thereby very effective for avoiding a fire in an enclosed protected area can be achieved even if the influx of inert gas has occurred uncontrollably due to an error in the inert gas production or inert gas feed system. Fresh air is always available around the protected area to a sufficient extent. The disadvantages of the hitherto known apparatuses and methods, which can entail a hazard to humans in the protected area, are clearly avoided.

Weitere Ausführungsformen der Erfindung ergeben sich aus den Unteransprüchen.Further embodiments of the invention will become apparent from the dependent claims.

Vorteilhafterweise ist der Schwellwert für den Sauerstoffgehalt, bei dem Frischluft in den Schutzbereich eingeleitet wird, kleiner als der Wert des Sauerstoffgehaltes des Grundinertisierungsniveaus. Diese Art der Trennung der Sauerstoffgehalte ist sinnvoll, da der Sauerstoffgehalt des Grundinertisierungsniveaus so gewählt ist, dass Brände vermieden werden, aber Personen trotzdem den Schutzbereich weiterhin betreten können. Sinkt durch die fehlerhafte übermäßige Zufuhr von Inertgas der Sauerstoffgehalt weiter, werden zwar weiterhin Brände verhindert, aber der Aufenthalt für Personen wird zunehmend gefährlicher. Der Schwellwert für den Sauerstoffgehalt im Schutzbereich wird daher so gewählt, dass er unterhalb des Sauerstoffgehaltes des Grundinertisierungsniveaus liegt, andererseits aber nicht unter einen für Menschen gefährlichen Wert absinkt. Alternativ zur Messung des Sauerstoffgehaltes im Schutzbereich kann auch der Inertgasgehalt im Schutzbereich gemessen werden. In diesem Fall wird dann der Inertgasgehalt mit einem Schwellwert verglichen und beim Überschreiten Frischluft in den Schutzbereich eingeleitet. Dieses Verfahren setzt voraus, dass sich in natürlicher Atmosphäre ein direktes Abhängigkeitsverhältnis zwischen Sauerstoffgehalt und Inertgasgehalt einstellt. Dieses Abhängigkeitsverhältnis ist für typische Brandvermeidungssituationen bekannt.Advantageously, the threshold value for the oxygen content at which fresh air is introduced into the protected area is smaller than the value of the oxygen content of the basic inertization level. This type of oxygen content separation makes sense, as the oxygen content of the base inertization level is chosen to avoid fires, but people can still enter the protected area. If the oxygen content continues to decrease as a result of the incorrect excessive supply of inert gas, fires are still prevented, but the stay for persons becomes increasingly dangerous. The threshold value for the oxygen content in the protection range is therefore chosen so that it is below the oxygen content of the basic inertization level, but on the other hand does not fall below a dangerous value for humans. As an alternative to measuring the oxygen content in the protected area, the inert gas content in the protected area can also be measured. In this case, then the inert gas content is compared with a threshold value and when fresh air is exceeded in the protected area initiated. This process requires that a direct relationship between oxygen content and inert gas content be established in a natural atmosphere. This dependency ratio is known for typical fire avoidance situations.

In vorteilhafter Weise wird der Sauerstoffgehalt im Schutzbereich an mehreren Stellen mit jeweils einem oder mehreren Sensoren gemessen. Der Vorteil des Messens des Sauerstoffgehaltes an mehreren Stellen ist, dass auch bei einer ungleichmäßigen Konzentration des Sauerstoffes ein Unterschreiten an einer Stelle bereits detektiert wird. Ein weiterer Vorteil bei der Benutzung mehrerer Sensoren ist die Redundanz. Falls ein Sensor defekt ist oder die Leitung zu einem Sensor unterbrochen ist, kann ein anderer Sensor die Messaufgabe übernehmen.

Für den Fall, dass das Verlegen von Kabeln zu den unterschiedlichen Sensoren Probleme aufwirft, können die Signale von den Sensoren auch drahtlos an die Steuereinheit übertragen werden.Advantageously, the oxygen content in the protected area is measured at several points, each with one or more sensors. The advantage of measuring the oxygen content at several points is that even if the concentration of the oxygen is not uniform, a drop below a point is already detected. Another advantage of using multiple sensors is redundancy. If a sensor is defective or the line to one sensor is interrupted, another sensor can take over the measuring task.

In the event that routing cables to the different sensors poses problems, the signals from the sensors can also be wirelessly transmitted to the control unit.

Alternativ zur Messung des Sauerstoffgehaltes an einer oder mehreren Stellen kann auch der Inertgasgehalt im Schutzbereich an einer oder mehreren Stellen mit jeweils einen oder mehreren Inertgassensoren gemessen werden. Die Vorteile der Messung an mehreren Stellen entspricht den Vorteilen der Messung der Sauerstoffkonzentration an mehreren Stellen. Es wird ausdrücklich darauf hingewiesen, dass eine gleichzeitige Messung sowohl des Sauerstoffgehaltes als auch des Inertgasgehaltes die Sicherheit für Personen, die sich im Schutzbereich aufhalten, deutlich erhöht.As an alternative to measuring the oxygen content at one or more points, the inert gas content in the protected area can also be measured at one or more locations with one or more inert gas sensors. The advantages of multi-site measurement equals the benefits of multi-site oxygen concentration measurement. It is expressly pointed out that a simultaneous measurement of both the oxygen content and the inert gas content significantly increases the safety for persons who are in the protected area.

In einer vorteilhaften weiteren Ausführungsform der Erfindung werden die Signale der Sauerstoffsensoren bzw. der Inertgassensoren einer Steuereinheit zugeführt. Vorteilhafterweise sind in dieser Steuereinheit alle elektronischen Komponenten zur Auswertung der Signale der Sensoren zusammengefasst. Auch lassen sich in der Steuereinheit unterschiedlichen Algorithmen zur Reaktion auf unterschiedliche Gasgemischkonzentration hinterlegen.In an advantageous further embodiment of the invention, the signals of the oxygen sensors or the inert gas sensors are supplied to a control unit. Advantageously, all electronic components for evaluating the signals of the sensors are combined in this control unit. Also, different algorithms for reaction to different gas mixture concentration can be stored in the control unit.

Weiterhin kann die Steuereinheit in einer vorteilhaften Weiterbildung ein Frischluftzufuhrsystem ein- und ausschalten. Das Einbeziehen der Steuerlogik für das Frischluftzufuhrsystem in die Steuereinheit fällt auch unter den Gesichtspunkt einer kompakten Bauweise einer zentralen Zusammenführung aller Mess- und Steuersignale in eine elektronische Baueinheit.Furthermore, the control unit in an advantageous development, a fresh air supply system on and off. The inclusion of the control logic for the fresh air supply system in the control unit also falls under the aspect of a compact design of a central consolidation of all measurement and control signals in an electronic unit.

Vorteilhafterweise wird die Frischluftzufuhr so geregelt, dass ein maximales Inertisierungsniveau nicht überschritten wird. Außerdem wird das Grundinertisierungsniveau nicht unterschritten. Das heißt, dass die Sauerstoffkonzentration innerhalb des Schutzbereiches auch bei Frischluftzufuhr so geregelt wird, dass bei einem Grundinertisierungsniveau Brände zuverlässig verhindert werden. Wichtig dabei ist, dass die Frischluftzufuhr spätestens dann eingeschaltet wird, wenn ein maximales Inertisierungsniveau erreicht ist, ab dem Menschen, die sich im Schutzbereich befinden, gefährdet werden.Advantageously, the fresh air supply is controlled so that a maximum inerting level is not exceeded. In addition, the basic inerting level is not undershot. This means that the oxygen concentration within the protected area is regulated even with fresh air supply so that fires are reliably prevented at a basic inerting level. It is important that the fresh air supply is switched on at the latest when a maximum inerting level has been reached, beyond which people who are in the protected area are endangered.

In einer weiteren vorteilhaften Weiterbildung der Erfindung überwacht die Steuereinheit einen zweiten Schutzbereich. Auch für diesen zweiten Schutzbereich steht ein Frischluftzufuhrsystem, mindestens ein Sauerstoffsensor und/oder mindestens ein Inertgassensor und ein Bereichsventil zur Kontrolle der Zufuhr des Inertgases zur Verfügung. Auch in diesem zweiten Schutzbereich wird sichergestellt, dass ein maximales Inertisierungsniveau nicht überschritten wird. Auf der anderen Seite wird ein Grundinertisierungsniveau nicht unterschritten. Der Vorteil der Trennung von verschiedenen Schutzbereichen mit verschiedenen Inertisierungsniveaus liegt in der unterschiedlichen Möglichkeit des Betretens durch Personen. Obwohl es sich um unterschiedliche Schutzbereiche handelt, werden alle Mess- und Steuerleitungen in einer Steuereinheit zusammengefasst. Der Vorteil liegt in einer einfacheren Wartung und in einer kompakten Bauweise der gesamten Melde- und Auswerteelektronik für unterschiedliche Schutzbereiche.In a further advantageous embodiment of the invention, the control unit monitors a second protection area. Also for this second protection area is a fresh air supply system, at least one oxygen sensor and / or at least one inert gas sensor and a range valve for controlling the supply of the inert gas available. In this second protection area, too, it is ensured that a maximum inerting level is not exceeded. On the other hand, a basic inactivation level is not undercut. The advantage of the separation of different protection areas with different inertization levels lies in the different possibility of access by persons. Although these are different protection areas, all measuring and control lines are combined in one control unit. The advantage lies in simpler maintenance and in a compact construction of the entire signaling and evaluation electronics for different protection areas.

Vorteilhafterweise kann weiterhin vorgesehen sein, dass die Steuereinheit die Grund- und Maximalinertisierungsniveaus in den unterschiedlichen Schutzbereichen unterschiedlich hoch einstellt. Beispielsweise kann der Sauerstoffgehalt des Grundinertisierungsniveaus in Schutzbereich 1a niedriger sein als der entsprechende Wert im Schutzbereich 1b. Der Vorteil einer solchen Aufspaltung wäre, dass sich in einem Schutzbereich Personen aufhalten können, während im anderen Bereich der Sauerstoffgehalt so niedrig gewählt ist, dass ein Aufenthalt von Personen in diesem Bereich nicht möglich ist. Denkbar ist der Einsatz einer solchen Aufteilung bei der Verwahrung von leicht entzündlichen Materialien in einem Schutzbereich und von normal entflammbaren Materialien in einem anderen Schutzbereich, der regelmäßig von Personen betreten wird.Advantageously, it can further be provided that the control unit sets the basic and maximum inertization levels in the different protection areas differently high. For example, the oxygen content of the basic inertization level in protection area 1a may be lower than the corresponding value in

Im folgenden wird das erfindungsgemäße Verfahren anhand der Figuren näher erläutert.The method according to the invention will be explained in more detail below with reference to the figures.

Es zeigen:

- Figur 1:

- eine schematische Darstellung des Schutzbereiches mit den dazugehörigen Inertgasquellen sowie den Ventil-, Mess- und Steuer- einrichtungen sowie dem Frischluftzufuhrsystem und den Einlassdüsen für das Frischluftzufuhrsystem,

- Figur 2:

- einen beispielhaften Verlauf der Sauerstoffkonzentration im Schutzbereich,

- Figur 3:

- eine schematische Darstellung einer Inertisierungsanlage mit zwei Räumen und bereichsspezifischen Inertisierungskomponenten.

- FIG. 1:

- a schematic representation of the protected area with the associated inert gas sources and the valve, measuring and control facilities as well as the fresh air supply system and the inlet nozzles for the fresh air supply system,

- FIG. 2:

- an exemplary course of the oxygen concentration in the protected area,

- FIG. 3:

- a schematic representation of an inerting plant with two rooms and area-specific inerting.

In Figur 1 ist exemplarisch die grundsätzliche Funktion des erfindungsgemäßen Verfahrens inklusive der dazugehörigen Kontroll- und Meßsysteme schematisch dargestellt. Dabei sind Rohrleitungen fett und dick und Mess-/Steuerleitungen normal und dünn gezeigt. Das Inertgas kann aus der Inertgasquelle 2, über ein Ventil 3a und eine oder mehrere Auslassdüsen 6a in den Schutzbereich 1a gelassen werden. Dabei kann die Inertgasquelle in verschiedenartiger Weise ausgeführt sein. Eine typische Ausführung ist das Bereitstellen des Inertgases aus einem oder mehreren Behältern, beispielsweise Stahlflaschen. Alternativ kann ein Generator zur Produktion eines Inertgases (zum Beispiel Stickstoff) oder eines Inertgas-Luftgemisches eingesetzt werden. Denkbar ist auch, die Primärgasquelle zur Erhöhung der Sicherheit redundant auszulegen, d.h. bei Bedarf auf eine Sekundärinertgasquelle zurückzugreifen, die entweder wiederum aus komprimiertem Inertgas in Stahlflaschen bestehen kann oder aus einem inertgasproduzierenden Generator. Die Konzentration des Inertgases im Schutzbereich 1 a wird über die Steuereinheit 4, die wiederum Einfluss auf das Ventil 3a nimmt, geregelt. Die Steuereinheit 4 wird so eingestellt, dass ein Grundinertisierungsniveau im Schutzbereich 1a erreicht wird. Dieses Grundinertisierungsniveau vermindert das Risiko von Bränden oder Explosionen im Schutzbereich 1a. Um dieses Grundinertisierungsniveau zu halten, wird Inertgas aus der Inertgasquelle 2 über das Ventil 3a und die Inertgaseintrittsdüse 6a in den Schutzbereich 1a eingeleitet. Im Falle eines Fehlverhaltens dieser Anordnung, also wenn z.B. das Ventil 3a nicht schließt oder der das Inertgas oder das Inertgas-Luftgemisch produzierende Generator nicht abschaltet und dadurch permanent Inertgas über den Inertgaseintritt 6a in den Schutzbereich gelangt und so die Inertgaskonzentration im Schutzbereich kontinuierlich ansteigt, so dass der Sauerstoffgehalt das gewünschte Grundinertisierungsniveau weit unterschreitet, wird der folgende erfindungsgemäße Mechanismus in Gang gesetzt. Die Steuereinheit 4 misst über den Sauerstoffsensor 5a eine zu niedrige Sauerstoffkonzentration und gibt folglich ein Signal zum Schließen des Ventils 3a oder ein Signal zum Ausschalten des Inertgas- oder Inertgas-Luftgemisch produzierenden Generators ab. Sind diese beiden Bedingungen erfüllt, und sinkt die Sauerstoffkonzentration im Schutzbereich 1a weiter, was auch durch Inertgassensoren 12a an die Steuereinheit 4 signalisiert werden kann, wird das Frischluftzufuhrsystem 8a in Betrieb gesetzt, über das zusätzlich Frischluft über eine oder mehrere Frischluftzufuhreinlässe 7a in den Schutzbereich 1a gelangt. Dabei ist der Volumenzustrom von Frischluft so eingestellt, dass selbst bei Vollbetrieb des inertgasproduzierenden Systems (entweder aus Stahlflaschen oder als Generator ausgeführt) die Inertgaskonzentration im Schutzbereich 1a nicht weiter ansteigen kann. Auf diese Weise wird sichergestellt, dass eine gewünschte Sauerstoffkonzentration im Schutzbereich 1a auch beim Ausfall der Steuereinheit für den Inertgaseintritt in den Schutzbereich 1a gewährleistet ist. So werden Brände zuverlässig verhindert, und trotzdem können sich im Bedarfsfall Menschen ohne Schaden zu nehmen im Schutzbereich 1a aufhalten.FIG. 1 schematically shows, by way of example, the basic function of the method according to the invention, including the associated control and measuring systems. Pipes are fat and thick and measuring and control lines are normal and thin. The inert gas may be left from the

Figur 2 zeigt exemplarisch einen möglichen Verlauf der Sauerstoffkonzentration im Schutzbereich 1a. Die Sauerstoffkonzentration wird auf ein Grundinertisierungsniveau (Sollwert) geregelt, und zwar zwischen einem oberen und einem unteren Sollwert. Zum Zeitpunkt to wird die Inertgasquelle aktiviert und Inertgas in den Schutzbereich 1a a eingeleitet. Ausgelöst durch dieses Einleiten des Inertgases in den Schutzbereich 1a fällt die Sauerstoffkonzentration zwischen den Zeiten to und t1. Zum Zeitpunkt t1 wird die Inertgasquelle wieder deaktiviert. Bis zum Zeitpunkt t2 steigt die Sauerstoffkonzentration langsam wieder an, weil z.B. etwas Frischluft durch Undichtigkeiten gegenüber der Umgebungsluft in den Schutzbereich eintritt. Zum Zeitpunkt t2 wird die Inertgasquelle wieder aktiviert. Falls die Inertgasquelle wegen eines Defekts nicht mehr deaktiviert werden kann, sinkt die Sauerstoffkonzentration im Schutzbereich allerdings weiter. Zum Zeitpunkt t3 wird die maximale Inertisierungskonzentration, die im Schutzbereich 1 zugelassen ist und für Menschen noch unschädlich ist, erreicht. Durch die Fehlfunktion des Inertgassystems d.h. durch einen ungehinderten weiteren Zustrom von Inertgas in den Schutzbereich würde die Sauerstoffkonzentration nach dem Zeitpunkt t3 kontinuierlich weiter sinken und einen sicheren Aufenthalt von Menschen im Schutzbereich verhindern. Durch den erfindungsgemäß kontrollierten Zustrom von Frischluft, beginnend ab dem Zeitpunkt t3, wird das maximale Inertisierungsniveau nicht unterschritten, d.h. die Sauerstoffkonzentration im Schutzbereich verbleibt oberhalb des maximalen Inertisierungsniveaus. Zum Zeitpunkt t3 kann auch die Auslösung einer Notalarmierung (in den Figuren nicht dargestellt) vorgesehen werden. Zum Zeitpunkt t4 wird das Grundinertisierungsniveau wieder erreicht, unter dem Brände zuverlässig verhindert werden. Um den Brandschutz aufrechtzuerhalten, wird zum Zeitpunkt t4 die Frischluftzufuhr wieder ausgeschaltet.FIG. 2 shows by way of example a possible course of the oxygen concentration in the protected area 1a. The oxygen concentration is regulated to a basic inertization level (setpoint), between an upper and a lower set point. At time t o , the inert gas source is activated and inert gas is introduced into the protective area 1a a. Triggered by this introduction of the inert gas into the protection area 1a, the oxygen concentration falls between the times t o and t 1 . At time t 1 , the inert gas source is deactivated again. Until the time t 2 , the oxygen concentration rises slowly again because, for example, some fresh air enters the protected area due to leaks in relation to the ambient air. At time t 2 , the inert gas source is reactivated. However, if the inert gas source can not be deactivated due to a defect, the oxygen concentration in the protected area will continue to decrease. At time t 3 , the maximum inerting concentration, which is permitted in

Figur 3 zeigt eine weitere Alternative einer Inertisierungsanlage, die in diesem Fall zwei Schutzräume 1a und 1b und bereichsspezifische Inertisierungs- und Überwachungskomponenten aufweist. Der Schutzbereich 1a wird in diesem Fall entsprechend den Details, die bei der Beschreibung der Figuren 1 und 2 angegeben wurden, überwacht. Zusätzlich ist ein weiterer Schutzbereich 1b mit zugehörigen Inertisierungs- und Überwachungskomponenten dargestellt. Diese umfassen das Ventil 3b, den Inertgaseintritt 6b den Sauerstoffsensor 5b, den Frischluftzufuhreinlass 7b und das Frischluftzufuhrsystem 8b. Die in Figur 3 dargestellte Steuereinheit 4 könnte alternativ auch aus zwei getrennten Steuereinheiten bestehen. Die beiden Schutzräume 1a, 1b sind durch eine Wand 9 voneinander getrennt. Die in Figur 3 dargestellte Steuereinheit 4 könnte alternativ auch aus zwei getrennten Steuereinheiten bestehen. Der Schutzbereich 1a, der in diesem Fall nicht von Personen betreten wird, weist ein anderes (höheres) Inertisierungsniveau als Schutzbereich 1b auf, der trotz Inertisierung regelmäßig von Personen betreten wird. Schutzbereich 1a könnte beispielsweise ein Inertisierungsniveau haben, bei dem die Sauerstoffkonzentration ca. 13 Vol.% beträgt. Im Gegensatz dazu wird im Schutzbereich 1b ein anderes Inertisierungsniveau von zum Beispiel 17 Vol.% Sauerstoff durch die Steuereinheit 4 gewährleistet. Durch Undichtigkeiten der Wand 9 kann es zu unkontrolliertem Inertgasübertritt von Schutzbereich 1a auf Schutzbereich 1b kommen. Dieser ist in Figur 3 durch die Richtungspfeile 10 dargestellt. Aufgabe der Steuereinheit 4 ist es, die unterschiedlich hohen Inertisierungsniveaus in den Schutzräumen 1a und 1b durch Zufuhr von Inertgas über die Ventile 3a und 3b und nötigenfalls durch die Zufuhr von Frischluft über die Frischluftsysteme 8a und 8b und die Frischluftzufuhreinlässe 7a und 7b, wie unter der Beschreibung zu Figur 1 beschrieben, zu garantieren. Die Ventile 3a und 3b werden in diesem Fall auch als Bereichsventile bezeichnet, da die unterschiedlichen Schutzräume 1a und 1b unterschiedliche Bereiche der Überwachung darstellen.FIG. 3 shows a further alternative of an inerting system, which in this case comprises two

- 1a1a

- Erster SchutzbereichFirst protection area

- 1b1b

- Zweiter SchutzbereichSecond protection area

- 22

- Inertgasquelleinert gas

- 3a3a

- Bereichsventilarea valve

- 3b3b

- Bereichsventilarea valve

- 44

- Steuereinheitcontrol unit

- 5a5a

- Sauerstoffsensoroxygen sensor

- 5b5b

- Sauerstoffsensoroxygen sensor

- 6a6a

- InertgaseintrittInertgaseintritt

- 6b6b

- InertgaseintrittInertgaseintritt

- 7a7a

- FrischluftzufuhreinlassFresh air intake

- 7b7b

- FrischluftzufuhreinlassFresh air intake

- 8b8b

- FrischluftzufuhrsystemFresh air supply system

- 99

- Trennwandpartition wall

- 1010

- Richtungspfeile des InertgasflussesDirectional arrows of the inert gas flow

- 1111

- Personen im SchutzbereichPersons in the protection area

- 12a12a

- InertgassensorInertgassensor

- 12b12b

- InertgassensorInertgassensor

Claims (10)

dadurch gekennzeichnet, dass

der Sauerstoffgehalt im Schutzbereich (1a, 1b) gemessen, mit einem Schwellwert (maximalen Inertisierungsniveau) verglichen und bei einem Unterschreiten des Schwellwertes (des maximalen Inertisierungsniveaus) Frischluft in den Schutzbereich (1a, 1b) eingeleitet wird.Inertisation method for preventing a fire or an explosion in a first enclosed protection area (1a) and / or a second enclosed protection area (1b), in which the oxygen content in the protection area (1a, 1b) is lowered to a basic inerting level with respect to the ambient air,

characterized in that

the oxygen content in the protected area (1a, 1b) is measured, compared with a threshold value (maximum inerting level), and fresh air is introduced into the protected area (1a, 1b) when the threshold value (of the maximum inerting level) is undershot.

dadurch gekennzeichnet, das s

der Schwellwert für den Sauerstoffgehalt kleiner als der Wert des Sauerstoffgehaltes des Grundinertisierungsniveaus ist.Method according to claim 1,

characterized in that s

the oxygen content threshold is less than the oxygen content value of the base inertization level.

dadurch gekennzeichnet, das s

der Inertgasgehalt im Schutzbereich (1a, 1b) gemessen, mit einem Schwellwert verglichen und bei Überschreitung des Schwellwerts Frischluft in den Schutzbereich (1a, 1b) eingeleitet wird.Method according to the preamble of claim 1, wherein the decrease in the oxygen content in the protected area (1a, 1b) takes place by introducing oxygen-displacing inert gases or inert gas-air mixtures,

characterized in that s

the inert gas content in the protected area (1a, 1b) is measured, compared with a threshold value and when the fresh air threshold value is exceeded in the protected area (1a, 1b) is initiated.

dadurch gekennzeichnet, dass

der Sauerstoffgehalt im Schutzbereich (1a, 1b) an einer oder mehreren Stellen mit jeweils einem oder mehreren Sauerstoffsensoren (5a, 5b) gemessen wird.Method according to claim 1 or 2,

characterized in that

the oxygen content in the protected area (1a, 1b) is measured at one or more points, each with one or more oxygen sensors (5a, 5b).

dadurch gekennzeichnet, dass

der Inertgasgehalt im Schutzbereich (1a, 1b) an einer oder mehreren Stellen mit jeweils einem oder mehreren Inertgassensoren (12a, 12b) gemessen wird.Method according to claim 3,

characterized in that

the inert gas content in the protected area (1a, 1b) is measured at one or more points, each with one or more inert gas sensors (12a, 12b).

dadurch gekennzeichnet, dass

die Messwerte des Sauerstoffgehaltes bzw. des Inertgasgehaltes einer Steuereinheit (4) zugeführt werden.Method according to claim 4 or 5

characterized in that

the measured values of the oxygen content or the inert gas content are fed to a control unit (4).

dadurch gekennzeichnet, dass

die Steuereinheit (4) das Frischluftzufuhrsystem (8a, 8b) an- und ausschalten kann.Method according to claim 6,

characterized in that

the control unit (4) can switch the fresh air supply system (8a, 8b) on and off.

dadurch gekennzeichnet, dass

die Frischluftzufuhr so geregelt wird, dass ein voreinstellbares maximales Inertisierungsniveau nicht unterschritten und das Grundinertisierungsniveau nicht überschritten wird.Method according to one of the preceding claims,

characterized in that

the supply of fresh air is regulated so that a presettable maximum inerting level does not fall below and the basic inerting level is not exceeded.

dadurch gekennzeichnet, dass

die Steuereinheit (4) einen zweiten Schutzbereich (1b) mittels eines Frischluftsystems (8b), mindestens eines Sauerstoffsensors (5b), mindestens eines Inertgassensors (12b), eines Bereichsventils (3b), eines Inertgaseintrittes (6b) und eines Frischlufteintrittes (7b) auf eine Sauerstoffkonzentration hin überwacht, die ein maximales Inertisierungsniveau nicht unterschreitet und ein Grundinertisierungsniveau nicht überschreitet.Method according to one of claims 6 to 8,

characterized in that

the control unit (4) has a second protected area (1b) by means of a fresh air system (8b), at least one oxygen sensor (5b), at least one inert gas sensor (12b), a range valve (3b), an inert gas inlet (6b) and a fresh air inlet (7b) monitored for an oxygen concentration that does not fall below a maximum inerting level and does not exceed a Grundinertisierungsniveau.

dadurch gekennzeichnet, dass

die Steuereinheit (4) die Sauerstoffkonzentration in den Schutzbereichen (1a, 1b) so regelt, dass diese Sauerstoffkonzentration beim maximalen Inertisierungsniveau im zweiten Schutzbereich (1b) höher ist als im ersten Schutzbereich (1a).Method according to claim 9,

characterized in that

the control unit (4) controls the oxygen concentration in the protection areas (1a, 1b) such that this oxygen concentration is higher at the maximum inertization level in the second protection area (1b) than in the first protection area (1a).

Priority Applications (17)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL05001224T PL1683548T3 (en) | 2005-01-21 | 2005-01-21 | Inerting method for avoiding fire |

| ES05001224T ES2398958T3 (en) | 2005-01-21 | 2005-01-21 | Inerting procedure for fire prevention |

| EP05001224A EP1683548B1 (en) | 2005-01-21 | 2005-01-21 | Inerting method for avoiding fire |

| DK05001224.4T DK1683548T3 (en) | 2005-01-21 | 2005-01-21 | Method of inertization to avoid fire |

| MX2007008702A MX2007008702A (en) | 2005-01-21 | 2005-11-03 | Inertization method for avoiding fires. |

| UAA200708372A UA91041C2 (en) | 2005-01-21 | 2005-11-03 | Inertization method in order to avoid a fire |

| AU2005325609A AU2005325609B2 (en) | 2005-01-21 | 2005-11-03 | Inertization method for avoiding fires |

| PCT/EP2005/011773 WO2006076936A1 (en) | 2005-01-21 | 2005-11-03 | Inertization method for avoiding fires |

| CNA2005800467253A CN101102820A (en) | 2005-01-21 | 2005-11-03 | Inertization method for avoiding fires |

| US11/795,798 US8517116B2 (en) | 2005-01-21 | 2005-11-03 | Inertization method for preventing fires |

| CA2594663A CA2594663C (en) | 2005-01-21 | 2005-11-03 | Inertization method for avoiding fires |

| JP2007551550A JP2008528073A (en) | 2005-01-21 | 2005-11-03 | Deactivation method for fire prevention |

| BRPI0519823A BRPI0519823B1 (en) | 2005-01-21 | 2005-11-03 | fire prevention inerting method |

| RU2007131661/12A RU2372954C2 (en) | 2005-01-21 | 2005-11-03 | Method of inertisation for fire prevention |

| HK06111778.9A HK1091152A1 (en) | 2005-01-21 | 2006-10-25 | Inerting method for avoiding fire |

| KR1020077015831A KR101179786B1 (en) | 2005-01-21 | 2007-07-11 | Inertization method for avoiding fires |

| NO20074265A NO20074265L (en) | 2005-01-21 | 2007-08-21 | Inertization method for avoiding fire |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP05001224A EP1683548B1 (en) | 2005-01-21 | 2005-01-21 | Inerting method for avoiding fire |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1683548A1 true EP1683548A1 (en) | 2006-07-26 |

| EP1683548B1 EP1683548B1 (en) | 2012-12-12 |

Family

ID=34933401

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05001224A Active EP1683548B1 (en) | 2005-01-21 | 2005-01-21 | Inerting method for avoiding fire |

Country Status (17)

| Country | Link |

|---|---|

| US (1) | US8517116B2 (en) |

| EP (1) | EP1683548B1 (en) |

| JP (1) | JP2008528073A (en) |

| KR (1) | KR101179786B1 (en) |

| CN (1) | CN101102820A (en) |

| AU (1) | AU2005325609B2 (en) |

| BR (1) | BRPI0519823B1 (en) |

| CA (1) | CA2594663C (en) |

| DK (1) | DK1683548T3 (en) |

| ES (1) | ES2398958T3 (en) |

| HK (1) | HK1091152A1 (en) |

| MX (1) | MX2007008702A (en) |

| NO (1) | NO20074265L (en) |

| PL (1) | PL1683548T3 (en) |

| RU (1) | RU2372954C2 (en) |

| UA (1) | UA91041C2 (en) |

| WO (1) | WO2006076936A1 (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1913980A1 (en) * | 2006-10-19 | 2008-04-23 | Amrona AG | Inerting device with safety device |

| EP1913979A1 (en) * | 2006-10-19 | 2008-04-23 | Amrona AG | Inerting device with nitrogen generator |

| EP1913978A1 (en) | 2006-10-19 | 2008-04-23 | Amrona AG | Inerting device with nitrogen generator |

| EP1930048A1 (en) * | 2006-12-08 | 2008-06-11 | Amrona AG | Method and device for regulated feeding of supply air |

| WO2009016168A1 (en) | 2007-08-01 | 2009-02-05 | Amrona Ag | Device and method for fire-prevention and for extinguishing a fire that has broken out in an enclosed area |

| NL2006405C2 (en) * | 2011-03-16 | 2012-09-18 | Storex B V | OXYGEN REDUCTION SYSTEM IN A SPACE IN A BUILDING. |

| RU2712378C2 (en) * | 2015-12-22 | 2020-01-28 | Амрона Аг | Oxygen reduction system and method of oxygen reduction system operation |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005002172A1 (en) * | 2005-01-17 | 2006-07-27 | Amrona Ag | Inertization process for fire prevention |

| EP1683548B1 (en) | 2005-01-21 | 2012-12-12 | Amrona AG | Inerting method for avoiding fire |

| US9526933B2 (en) * | 2008-09-15 | 2016-12-27 | Engineered Corrosion Solutions, Llc | High nitrogen and other inert gas anti-corrosion protection in wet pipe fire protection system |

| RU2465512C1 (en) * | 2011-04-19 | 2012-10-27 | Российская Федерация, от имени которой выступает Государственная корпорация по атомной энергии "Росатом" | Device for maintaining air medium composition in sealed container |

| RU2465513C1 (en) * | 2011-04-21 | 2012-10-27 | Российская Федерация, от имени которой выступает Государственная корпорация по атомной энергии "Росатом" | Device for forced gas exchange in sealed container |

| KR101244426B1 (en) | 2012-12-03 | 2013-03-18 | (유)성문 | Apparatus for protecting and repressing fire |

| CN104210667A (en) * | 2014-09-22 | 2014-12-17 | 中国商用飞机有限责任公司 | Inerting system control method and device for monitoring oxygen concentration |

| EP3011999B1 (en) * | 2014-10-24 | 2017-08-16 | Amrona AG | System and method for reducing the oxygen in a target space |

| TR201802143T4 (en) * | 2015-07-02 | 2018-03-21 | Amrona Ag | An oxygen abatement system and a method for constructing an oxygen abatement system. |

| FR3054795B1 (en) * | 2016-08-03 | 2018-07-20 | Zodiac Aerotechnics | METHOD AND SYSTEM FOR INERTING A FUEL TANK |

| WO2018130644A1 (en) * | 2017-01-12 | 2018-07-19 | Fire Eater A/S | Interlinked fire inerting gas systems |

| EP3569290B1 (en) | 2018-05-14 | 2024-02-14 | Wagner Group GmbH | Control and regulating system for an oxygen reducing installation |

| CN110807265A (en) * | 2019-11-08 | 2020-02-18 | 重庆科技学院 | Closed fire area combustion explosion risk judgment method based on atmospheric disturbance |

| US20230288298A1 (en) * | 2020-07-14 | 2023-09-14 | Cast Environmental, Llc | Gas Monitoring Systems and Methods |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19811851A1 (en) * | 1998-03-18 | 1999-09-23 | Wagner Alarm Sicherung | Fire fighting nitrogen generator for closed room oxygen concentration reduction, to halt combustion |

| EP1312392A1 (en) * | 2001-11-15 | 2003-05-21 | Wagner Alarm- und Sicherungssysteme GmbH | Method and device for extinguishing fires in tunnels |

| US20030226669A1 (en) * | 2001-01-11 | 2003-12-11 | Wagner Ernst Werner | Inert rendering method with a nitrogen buffer |

| WO2004080540A1 (en) * | 2003-03-11 | 2004-09-23 | Basf Coatings Ag | Fire and explosion protection method in a high-bay warehouse in which chemical hazardous materials are stored, and fire/explosion-protected high-bay warehouse |

| EP1475128A1 (en) * | 2003-05-08 | 2004-11-10 | Vesta Srl | Inert gas fire-fighting apparatus and relative method for extinguishing fires |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1385122A (en) | 1972-03-13 | 1975-02-26 | Bridgett C D S | Process for the degassing and cleaning of fuel tanks and tankers and rendering them safe for repair |

| JPS521997A (en) | 1975-06-16 | 1977-01-08 | Kimimichi Monma | Quick system for extinguishing fire of a multistorey building |

| SU955946A1 (en) | 1981-03-30 | 1982-09-07 | за вители | Method of preventing fire in sealed inhabited sections |

| SU1151246A1 (en) | 1983-03-21 | 1985-04-23 | Испытательная Пожарная Лаборатория Управления Пожарной Охраны Управления Внутренних Дел Алтайского Крайисполкома | Installation for gas fire-fighting |

| US5090482A (en) | 1990-01-03 | 1992-02-25 | Spectronix Ltd. | Method and apparatus for extinguishing fires |

| DE4223781A1 (en) | 1992-07-18 | 1994-01-20 | Bayerische Motoren Werke Ag | Output air filtration method - prevents fire in filter unit and adsorbs harmful material |

| US6314754B1 (en) * | 2000-04-17 | 2001-11-13 | Igor K. Kotliar | Hypoxic fire prevention and fire suppression systems for computer rooms and other human occupied facilities |

| JPH09276428A (en) | 1996-04-08 | 1997-10-28 | Sekiko Ryo | Method and system for preventing and distinguishing fire |

| US5799495A (en) | 1996-10-30 | 1998-09-01 | Nitec, Inc. | Container oxygen control system for transporting and ripening perishable goods |

| JP3832612B2 (en) | 1997-07-16 | 2006-10-11 | 忠弘 大見 | Fire extinguishing method and apparatus in clean room |

| US20020040940A1 (en) * | 1998-03-18 | 2002-04-11 | Wagner Ernst Werner | Inerting method and apparatus for preventing and extinguishing fires in enclosed spaces |

| EP1157186B1 (en) * | 1999-03-03 | 2003-08-27 | FMC Technologies, Inc. | Explosion prevention system for internal turret mooring system |

| JP2001046536A (en) | 1999-08-12 | 2001-02-20 | Purosasu:Kk | Suppression method and apparatus for machine fire |

| ATE335526T1 (en) * | 2000-04-17 | 2006-09-15 | Igor K Kotliar | HYPOXIC FIRE FIGHTING SYSTEMS AND BREATHABLE FIRE EXTINGUISHING MEDIA |

| DE10033650A1 (en) | 2000-07-11 | 2002-01-31 | Messer Griesheim Gmbh | Plant and method for storing and / or processing objects under inert conditions |

| RU2200044C2 (en) | 2000-12-09 | 2003-03-10 | Русаков Валерий Федорович | Method for providing fire-suppressing concentration of inert diluent (versions) |

| GB2374007A (en) | 2001-04-04 | 2002-10-09 | Kidde Plc | Fire / explosion protection system and method, using inert gas produced in low temperature catalytic oxidation of organic fuel |

| JP4039017B2 (en) | 2001-08-28 | 2008-01-30 | 松下電工株式会社 | Fire extinguishing system for precision processing equipment |

| WO2003024505A2 (en) * | 2001-09-14 | 2003-03-27 | The United States Of America, As Represented By The Secretary Of The Navy Thomas Mcdonnell, Patent Counsel For The Navy | Reduced-oxygen breathing device |

| JP2003102858A (en) * | 2001-09-28 | 2003-04-08 | Nohmi Bosai Ltd | Fire prevention system for closed space |

| DE10164293A1 (en) * | 2001-12-28 | 2003-07-10 | Wagner Alarm Sicherung | Method and device for measuring the oxygen content |

| GB2397821B (en) * | 2003-01-30 | 2006-04-05 | Smartmembrane Corp | Oxygen and nitrogen enriched atmospheres in aircraft |

| EP1683548B1 (en) | 2005-01-21 | 2012-12-12 | Amrona AG | Inerting method for avoiding fire |

-

2005

- 2005-01-21 EP EP05001224A patent/EP1683548B1/en active Active

- 2005-01-21 DK DK05001224.4T patent/DK1683548T3/en active

- 2005-01-21 ES ES05001224T patent/ES2398958T3/en active Active

- 2005-01-21 PL PL05001224T patent/PL1683548T3/en unknown

- 2005-11-03 CA CA2594663A patent/CA2594663C/en not_active Expired - Fee Related

- 2005-11-03 WO PCT/EP2005/011773 patent/WO2006076936A1/en active Application Filing

- 2005-11-03 RU RU2007131661/12A patent/RU2372954C2/en not_active IP Right Cessation

- 2005-11-03 UA UAA200708372A patent/UA91041C2/en unknown

- 2005-11-03 CN CNA2005800467253A patent/CN101102820A/en active Pending

- 2005-11-03 US US11/795,798 patent/US8517116B2/en active Active

- 2005-11-03 BR BRPI0519823A patent/BRPI0519823B1/en not_active IP Right Cessation

- 2005-11-03 JP JP2007551550A patent/JP2008528073A/en active Pending

- 2005-11-03 MX MX2007008702A patent/MX2007008702A/en active IP Right Grant

- 2005-11-03 AU AU2005325609A patent/AU2005325609B2/en not_active Ceased

-

2006

- 2006-10-25 HK HK06111778.9A patent/HK1091152A1/en not_active IP Right Cessation

-

2007

- 2007-07-11 KR KR1020077015831A patent/KR101179786B1/en not_active IP Right Cessation

- 2007-08-21 NO NO20074265A patent/NO20074265L/en not_active Application Discontinuation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19811851A1 (en) * | 1998-03-18 | 1999-09-23 | Wagner Alarm Sicherung | Fire fighting nitrogen generator for closed room oxygen concentration reduction, to halt combustion |

| US20030226669A1 (en) * | 2001-01-11 | 2003-12-11 | Wagner Ernst Werner | Inert rendering method with a nitrogen buffer |

| EP1312392A1 (en) * | 2001-11-15 | 2003-05-21 | Wagner Alarm- und Sicherungssysteme GmbH | Method and device for extinguishing fires in tunnels |

| WO2004080540A1 (en) * | 2003-03-11 | 2004-09-23 | Basf Coatings Ag | Fire and explosion protection method in a high-bay warehouse in which chemical hazardous materials are stored, and fire/explosion-protected high-bay warehouse |

| EP1475128A1 (en) * | 2003-05-08 | 2004-11-10 | Vesta Srl | Inert gas fire-fighting apparatus and relative method for extinguishing fires |

Cited By (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101359846B1 (en) * | 2006-10-19 | 2014-02-06 | 암로나 아게 | Inerting arrangement with safety device |

| WO2008046673A1 (en) * | 2006-10-19 | 2008-04-24 | Amrona Ag | Inerting arrangement with safety device |

| CN101394901B (en) * | 2006-10-19 | 2012-05-16 | 艾摩罗那股份公司 | Method and system for determining catalyst activity |

| WO2008046674A1 (en) * | 2006-10-19 | 2008-04-24 | Amrona Ag | Inertisation device comprising a nitrogen generator |

| AU2007312475B2 (en) * | 2006-10-19 | 2012-05-17 | Amrona Ag | Inertisation device comprising a nitrogen generator |

| NO343788B1 (en) * | 2006-10-19 | 2019-06-11 | Amrona Ag | Inerting device comprising a nitrogen generator |

| NO338900B1 (en) * | 2006-10-19 | 2016-10-31 | Amrona Ag | Initiation event with security device |

| CN101528311B (en) * | 2006-10-19 | 2012-06-27 | 艾摩罗那股份公司 | Inerting arrangement with safety device |

| US7673694B2 (en) | 2006-10-19 | 2010-03-09 | Amrona Ag | Inertization device with nitrogen generator |

| KR101359857B1 (en) * | 2006-10-19 | 2014-02-06 | 암로나 아게 | Inertisation device comprising a nitrogen generator |

| US7857068B2 (en) | 2006-10-19 | 2010-12-28 | Amrona Ag | Inertization device with safety device |

| AU2007312474B2 (en) * | 2006-10-19 | 2011-11-24 | Amrona Ag | Inerting arrangement with safety device |

| EP1913978A1 (en) | 2006-10-19 | 2008-04-23 | Amrona AG | Inerting device with nitrogen generator |

| EP1913979A1 (en) * | 2006-10-19 | 2008-04-23 | Amrona AG | Inerting device with nitrogen generator |

| EP1913980A1 (en) * | 2006-10-19 | 2008-04-23 | Amrona AG | Inerting device with safety device |

| AU2007312475C1 (en) * | 2006-10-19 | 2013-07-04 | Amrona Ag | Inertisation device comprising a nitrogen generator |

| CN101479011B (en) * | 2006-12-08 | 2012-09-05 | 艾摩罗那股份公司 | Method and device for the regulated supply of gas |

| US7717776B2 (en) | 2006-12-08 | 2010-05-18 | Amrona Ag | Method and apparatus for supplying additional air in a controlled manner |

| KR101373639B1 (en) * | 2006-12-08 | 2014-03-12 | 암로나 아게 | Method and device for the regulated feed of supply air |

| WO2008068076A1 (en) * | 2006-12-08 | 2008-06-12 | Amrona Ag | Method and device for the regulated supply of incoming air |

| EP1930048A1 (en) * | 2006-12-08 | 2008-06-11 | Amrona AG | Method and device for regulated feeding of supply air |

| WO2009016168A1 (en) | 2007-08-01 | 2009-02-05 | Amrona Ag | Device and method for fire-prevention and for extinguishing a fire that has broken out in an enclosed area |

| EP2173440B1 (en) * | 2007-08-01 | 2015-07-22 | Amrona AG | Device and method for fire-prevention and for extinguishing a fire that has broken out in an enclosed area |

| NL2006405C2 (en) * | 2011-03-16 | 2012-09-18 | Storex B V | OXYGEN REDUCTION SYSTEM IN A SPACE IN A BUILDING. |

| RU2712378C2 (en) * | 2015-12-22 | 2020-01-28 | Амрона Аг | Oxygen reduction system and method of oxygen reduction system operation |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008528073A (en) | 2008-07-31 |

| DK1683548T3 (en) | 2013-02-11 |

| ES2398958T3 (en) | 2013-03-22 |

| WO2006076936A1 (en) | 2006-07-27 |

| HK1091152A1 (en) | 2007-01-12 |

| BRPI0519823A2 (en) | 2009-03-24 |

| CA2594663A1 (en) | 2006-07-27 |

| BRPI0519823B1 (en) | 2016-06-14 |

| EP1683548B1 (en) | 2012-12-12 |

| CA2594663C (en) | 2014-01-07 |

| KR101179786B1 (en) | 2012-09-04 |

| MX2007008702A (en) | 2007-10-23 |

| AU2005325609A1 (en) | 2006-07-27 |

| RU2007131661A (en) | 2009-02-27 |

| US20080196907A1 (en) | 2008-08-21 |

| PL1683548T3 (en) | 2013-04-30 |

| AU2005325609B2 (en) | 2011-02-10 |

| KR20070102511A (en) | 2007-10-18 |

| CN101102820A (en) | 2008-01-09 |

| US8517116B2 (en) | 2013-08-27 |

| RU2372954C2 (en) | 2009-11-20 |

| NO20074265L (en) | 2007-08-21 |

| UA91041C2 (en) | 2010-06-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1683548B1 (en) | Inerting method for avoiding fire | |

| EP2186546B1 (en) | Inert gas fire extinguisher for reducing the risk of and extinguishing fires in a protected area | |

| EP1062005B1 (en) | Inerting method for preventing and extinguishing fires in enclosed spaces | |

| EP1913980B1 (en) | Inerting device with safety device | |

| EP3141287B1 (en) | Method and device for determining and/or monitoring the air permeability of an enclosed space | |

| EP1913978A1 (en) | Inerting device with nitrogen generator | |

| EP2173440B1 (en) | Device and method for fire-prevention and for extinguishing a fire that has broken out in an enclosed area | |

| DE10205373B4 (en) | Fire protection | |

| EP1550482B1 (en) | Inerting method for extinguishing fires | |

| EP1261396B1 (en) | Inert rendering method with a nitrogen buffer | |

| EP2462994B1 (en) | Inertisation method to prevent and/or extinguish fires and inertisation system to implement the method | |

| EP2204219A1 (en) | Inertisation method to prevent and/or extinguish fires and inertisation system to implement the method | |

| EP2881149B1 (en) | Oxygen reduction system and method for operating an oxygen reduction system | |

| EP1838396B1 (en) | Inerting method for preventing fires | |

| EP1913979B1 (en) | Inerting device with nitrogen generator | |

| WO2016110340A1 (en) | Method and system for preventing and/or extinguishing a fire | |

| EP1550481B1 (en) | Inerting method for decreasing the risk of a fire | |

| DE102005023101B4 (en) | Method for introducing an inert gas and plant for inerting | |

| EP2998002B1 (en) | Inert gas extinguishing system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050201 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1091152 Country of ref document: HK |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20071024 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502005013322 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: A62C0039000000 Ipc: A62C0099000000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A62C 99/00 20100101AFI20120730BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|