EP1585397B1 - Socquette - Google Patents

Socquette Download PDFInfo

- Publication number

- EP1585397B1 EP1585397B1 EP04701581A EP04701581A EP1585397B1 EP 1585397 B1 EP1585397 B1 EP 1585397B1 EP 04701581 A EP04701581 A EP 04701581A EP 04701581 A EP04701581 A EP 04701581A EP 1585397 B1 EP1585397 B1 EP 1585397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sock

- air

- area

- channels

- accordance

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B1/00—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes

- D04B1/22—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes specially adapted for knitting goods of particular configuration

- D04B1/24—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes specially adapted for knitting goods of particular configuration wearing apparel

- D04B1/26—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes specially adapted for knitting goods of particular configuration wearing apparel stockings

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41B—SHIRTS; UNDERWEAR; BABY LINEN; HANDKERCHIEFS

- A41B11/00—Hosiery; Panti-hose

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41B—SHIRTS; UNDERWEAR; BABY LINEN; HANDKERCHIEFS

- A41B11/00—Hosiery; Panti-hose

- A41B11/02—Reinforcements

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D31/00—Materials specially adapted for outerwear

- A41D31/04—Materials specially adapted for outerwear characterised by special function or use

- A41D31/12—Hygroscopic; Water retaining

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41B—SHIRTS; UNDERWEAR; BABY LINEN; HANDKERCHIEFS

- A41B2400/00—Functions or special features of shirts, underwear, baby linen or handkerchiefs not provided for in other groups of this subclass

- A41B2400/60—Moisture handling or wicking function

Definitions

- the invention relates to a sock, in particular for use in sports activities, according to the preamble of patent claim 1.

- the human feet are often housed in sturdy shoes. This especially if the person moves a lot and fast, for example during sports activities. Already through the sturdy footwear creates an increased sweat on the feet. In sports activity of humans, this sweat attack is above average. Since the accumulation of sweat in the shoe or sock increases the risk of blistering on the foot, efforts are made to allow the sweat to be removed from the shoe or sock.

- From the DE 297 15 762 U1 is a climate-regulating stocking known, especially for use in recreational sports such as jogging, inline skating, skiing or the like, the at least one of the sole of the foot reaching to the waistband integrated Air channel of climate-regulating net knitted fabric has.

- the air-conditioning duct allows evaporation of most of the resulting moisture, in which the sweat moisture is conveyed from the sole region of the shoe to a region of the stocking where free evaporation is possible.

- a sock in which functional or reinforcing regions are formed; the reinforcement area is arranged in the footfall area.

- the functional area extends in the foot part over the instep as well as over the lengths.

- the functional area is separated laterally by a dividing line from the reinforcement area.

- air channels are incorporated.

- the air channels are arranged in the vicinity of the dividing line to the reinforcing area in a strip-shaped zone.

- the object of the present invention is to further improve the removal of moisture from the shoe. According to the invention, this object is solved by the features of claim 1.

- a sock especially for sporting activities, created that further improves the removal of sweat from the shoe or the sock.

- an air-conditioning duct in the entrance area, it is possible to convey moisture occurring in the region of the sole of the foot directly from the region of the sole of the foot via the air-conditioning duct. The moisture can then escape through ventilation holes in the footwear.

- By connecting the air conditioning duct with the side air ducts there is an additional way to remove the sweat from the area of the sole of the foot. In the case of air channels on the inside and outside of the leg, the connection of the air ducts causes additional air circulation in the boot.

- the area of occurrence of the sock has a central air-conditioning duct, from which further air-conditioning channels branch off to the outside of the sock. This achieves a uniform climate in the entrance area.

- a pressure equalization between the channels is effected, resulting in a uniform dehumidification under load.

- a pleasant appearance is created.

- the air conditioning duct is bent or wavy.

- an increase in the effective channel length is achieved, which on the one hand causes an increase in the transport capacity, on the other hand, the cooling surface is increased in the appearance area.

- the channels are designed waisted in the tread area. Due to the partial rejuvenation of the channel path an accelerated air flow is achieved, which in turn accelerates the removal of moisture from the area of occurrence and causes an increase in the cooling capacity in this area.

- the sock has upholstery.

- the upholstery can be arranged at different points of the sock. On the one hand, they reduce the abrasion of the skin and, on the other hand, the danger of pressure points forming on the foot.

- the sock is equipped with an X-cross bandage.

- the X-Cross Bandage supports the ankle in the transition area between leg and foot.

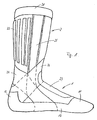

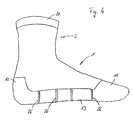

- the sock chosen as an embodiment ( Fig. 1 ) consists of a foot part 1 and a shaft 2.

- the foot part 1 has a toe area 11, a heel area 12 and an access area 13 located between the toe and heel area.

- the regions 11, 12 and 13 can, as shown in the exemplary embodiment, be made of reinforced material.

- the use of material combinations such as virgin wool with Elastomaschinetechnikstoffen, such as elastane, is possible.

- the arrangement of additional pads or Paddings in the above areas is possible.

- the shaft 2 is provided at its end facing away from the foot part 1 with a collar 21.

- the shaft 2 is provided with pads 22, in the example shown bar padding being provided; other forms of upholstery are possible.

- pads 22 in the example shown bar padding being provided; other forms of upholstery are possible.

- the pads are generally made of plastic yarns or compound fabrics or yarn or similar materials.

- the upholstery of the sock made of hollow-core fibers, which are wound with wool or cotton.

- the hollow-chamber plastic yarns are particularly strong shock and pressure damping.

- the appearance area 13 may be made of microfiber knit which helps to reduce the abrasion.

- the footbed is also made of microfibre in the toe and heel area.

- the sock is also equipped with an X-Cross bandage 24, which is formed of an elastic climate-regulating fabric.

- the X-Cross Bandage 24 supports the ankle in the transition area between leg and foot.

- an air duct 25 which extends into the appearance area 13 and is formed from climate-regulating net knitted fabric.

- the air channel 25 helps to drain moisture up from the tread area.

- Such an air channel 25 may also be provided on the inside of the leg or on both sides of the sock.

- At least one air conditioning duct 26 is provided in the access area 13 of the sock.

- three air conditioning channels 26 are provided.

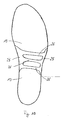

- the air conditioning channels 26 begin and end at the outer edge of the tread area and are arcuate, thereby increasing the effective channel length. This effect is reflected by the wave-shaped design of the air conditioning duct in the embodiment FIG. 3 still increased.

- Increasing the effective channel length increases the transport capacity and increases the cooling area in the entrance area.

- the air conditioning ducts 26 can pull through the entire - reinforced - appearance area 13 of the sock, so extend to the side areas that embed the foot.

- the air conditioning channels 26 are formed of climate-regulating net knitted fabric. They may be designed such that the thickness of the net knit fabric corresponds to the thickness of the appearance area, so that a continuous surface results. As a result, the wearing comfort is positively influenced.

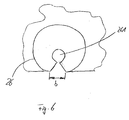

- the air conditioning ducts 26 are designed waisted in the appearance area 13 of the sock. Due to the partial taper 261 of the air conditioning duct 26, an acceleration of the air duct is achieved (so-called Venturi principle). As a result, on the one hand the removal of moisture from the area of occurrence 13 is accelerated, on the other hand an increase of the cooling capacity in this area is achieved.

- This advantage can be further enhanced by the fact that the air conditioning ducts 26 have a substantially circular cross section ( FIG. 6 ).

- the taper 261 has an approximately circular cross-section.

- the air duct 26 then has the shape of a Laval nozzle, whereby the positive properties are further improved.

- a central channel 262 is arranged on the longitudinal central axis of the area of occurrence 13, from which arc-shaped air conditioning ducts 26 branch off on both sides, which end at the outer edge of the access area 13. Due to the central connection of the air conditioning ducts 26 through the central channel 262, a uniform climate is achieved via the access area 13. The connection also causes equal pressure in all the air conditioning ducts 26, thereby achieving uniform dehumidification under load. Furthermore, the even pressure creates a pleasant sensation. In a modification of the embodiment, it is possible to continue the central channel 262 beyond the access area 13 into the toe area 11 and / or heel area 12.

- An air channel 25 is provided on the inside of the leg.

- the air channel 25 extends into the foot cavity.

- the air conditioning ducts 26 go out, which are arranged radially.

- wide areas of the access area are achieved by the air conditioning ducts 26, so that it is possible to remove moisture from the entire area of occurrence.

- the width and the length of the air conditioning channels 26 are usually freely selectable.

- the number of air conditioning channels 26 is variable. By increasing the lengths or widths of the air conditioning ducts 26 or increasing the number of air conditioning ducts 26, an increase in the conveyable moisture is possible.

- an air channel 25 is arranged in each case on the inside of the leg and the outside of the leg of the sock.

- the air conditioning ducts 26 extend between the air ducts on the inside of the leg and the outside of the leg.

- the number and dimensions of the air conditioning ducts are essentially freely selectable here as well.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Socks And Pantyhose (AREA)

- Knitting Of Fabric (AREA)

Claims (10)

- Socquette, en particulier destinée à l'emploi dans des activités sportives, au moins un canal climatique (26) étant prévu dans la zone de déroulement (13) et des canaux d'aération (25) étant prévus sur le côté intérieur et/ou sur le côté extérieur de la jambe, caractérisée en ce que les canaux d'aération (25) sont reliés à au moins un canal climatique (26).

- Socquette selon la revendication 1, caractérisée en ce que les canaux climatiques (26) présentent un tracé en arc dans la zone de déroulement (13).

- Socquette selon les revendications 1 ou 2, caractérisée en ce que les canaux climatiques (26) présentent des rétrécissements partiels (261).

- Socquette selon l'une des revendications 1 à 3, caractérisée en ce que les canaux climatiques (26) présentent une section essentiellement circulaire.

- Socquette selon l'une des revendications 1 à 4, caractérisée en ce que les canaux climatiques (26) sont reliés entre eux par un canal central (262).

- Socquette selon l'une des revendications 1 à 5, caractérisée en ce que des canaux d'aération (25) et les canaux climatiques (26) se composent du même matériau.

- Socquette selon l'une des revendications 2 à 6, caractérisée en ce que le canal d'aération (25) se compose d'un textile tricoté réticulé régulateur du climat.

- Socquette selon l'une des revendications 2 à 7, caractérisée en ce que le canal climatique (26) se compose d'un textile tricoté réticulé régulateur du climat.

- Socquette selon l'une des revendications 1 à 8, caractérisée en ce qu'elle est équipée d'un bandage (24) en croix X.

- Socquette selon l'une des revendications 1 à 9, caractérisée en ce qu'elle présente des rembourrages (22, 23).

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI200431130T SI1585397T1 (sl) | 2003-01-21 | 2004-01-13 | Kratka nogavica |

| CY20091100613T CY1109133T1 (el) | 2003-01-21 | 2009-06-10 | Καλτσα |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20300973U DE20300973U1 (de) | 2003-01-21 | 2003-01-21 | Socke |

| DE20300973U | 2003-01-21 | ||

| PCT/DE2004/000023 WO2004064551A1 (fr) | 2003-01-21 | 2004-01-13 | Socquette |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1585397A1 EP1585397A1 (fr) | 2005-10-19 |

| EP1585397B1 true EP1585397B1 (fr) | 2009-03-11 |

Family

ID=7979321

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04701581A Expired - Lifetime EP1585397B1 (fr) | 2003-01-21 | 2004-01-13 | Socquette |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US20060143801A1 (fr) |

| EP (1) | EP1585397B1 (fr) |

| JP (1) | JP2006515651A (fr) |

| CN (1) | CN100393255C (fr) |

| AT (1) | ATE424735T1 (fr) |

| AU (1) | AU2004206701B2 (fr) |

| CA (1) | CA2513786C (fr) |

| CY (1) | CY1109133T1 (fr) |

| DE (2) | DE20300973U1 (fr) |

| DK (1) | DK1585397T3 (fr) |

| ES (1) | ES2324038T3 (fr) |

| PT (1) | PT1585397E (fr) |

| SI (1) | SI1585397T1 (fr) |

| WO (1) | WO2004064551A1 (fr) |

Families Citing this family (42)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20301812U1 (de) * | 2003-02-05 | 2003-04-10 | Brand Factory Swiss Gmbh, Rotkreuz | Socke |

| DE20310652U1 (de) * | 2003-07-11 | 2003-11-13 | Brand Factory Swiss Gmbh, Rotkreuz | Socke |

| DE202004013816U1 (de) * | 2004-09-02 | 2004-12-09 | X-Technology Swiss Gmbh | Socke |

| DE102005043821A1 (de) * | 2005-06-10 | 2007-03-22 | X-Technology Swiss Gmbh | Socke |

| JP4755686B2 (ja) * | 2005-07-09 | 2011-08-24 | エクス−テクノロジー スイス ゲゼルシャフト ミット ベシュレンクテル ハフツング | ソックス |

| DE102005043541A1 (de) * | 2005-09-12 | 2007-03-15 | X Technology Swiss Gmbh | Socke |

| US20090158504A1 (en) * | 2005-12-08 | 2009-06-25 | The New Zealand Sock Company | Sock |

| DE202006001381U1 (de) * | 2006-01-27 | 2006-06-22 | X-Technology Swiss Gmbh | Socke |

| FR2901100B1 (fr) * | 2006-05-16 | 2012-11-23 | Promiles | Vetement notamment pour la pratique d'un sport |

| US7934267B2 (en) | 2007-05-31 | 2011-05-03 | Nike, Inc. | Articles of apparel providing enhanced body position feedback |

| US7996924B2 (en) | 2007-05-31 | 2011-08-16 | Nike, Inc. | Articles of apparel providing enhanced body position feedback |

| US8336118B2 (en) | 2007-05-31 | 2012-12-25 | Nike, Inc. | Articles of apparel providing enhanced body position feedback |

| USD627147S1 (en) * | 2009-04-08 | 2010-11-16 | X-Technology Swiss Gmbh | Sock |

| WO2011143369A2 (fr) * | 2010-05-11 | 2011-11-17 | Columbia Sportswear North America, Inc. | Chaussette performante |

| EP2575524A4 (fr) * | 2010-05-26 | 2017-12-13 | Ellen Spicuzza | Procédé et dispositif pour protéger le corps humain du choc de coup de pied |

| US20120102613A1 (en) * | 2010-10-27 | 2012-05-03 | Damian Loth | Compression sock |

| USD641969S1 (en) * | 2010-10-27 | 2011-07-26 | Lifestyle Medical Group, LLC | Sock |

| USD650574S1 (en) * | 2010-10-27 | 2011-12-20 | Lifestyle Medical Group, LLC | Sock |

| EP2632847A1 (fr) * | 2010-10-31 | 2013-09-04 | Jeannette Swearingen | Bandage-chaussette pour sabot |

| DE102011106737B4 (de) | 2011-06-28 | 2023-03-09 | Ofa Bamberg Gmbh | Kompressionsstrumpf mit Lüftungskanälen und Anti-Rutschprofil |

| DE202011051102U1 (de) * | 2011-08-25 | 2011-10-27 | X-Technology Swiss Gmbh | Socke mit Leitpolstern |

| US20140359913A1 (en) * | 2011-12-27 | 2014-12-11 | Robert Magri | Protective Ice Hockey Sock |

| US20130160176A1 (en) * | 2011-12-27 | 2013-06-27 | Robert Magri | Protective Ice Hockey Sock |

| CN102783716B (zh) * | 2012-08-30 | 2014-07-09 | 浙江东方百富袜业制造有限公司 | 多功能袜 |

| USD691789S1 (en) * | 2013-05-29 | 2013-10-22 | Nike, Inc. | Sock |

| USD696509S1 (en) * | 2013-05-29 | 2013-12-31 | Nike, Inc. | Sock |

| US9226527B2 (en) | 2013-08-13 | 2016-01-05 | Peter D. Dahlgren | Sock |

| DE202013008246U1 (de) | 2013-09-18 | 2013-10-02 | Wilox Strumpfwaren Gmbh | Socke mit verengtem Luftkanal |

| USD700430S1 (en) * | 2013-11-27 | 2014-03-04 | Nike, Inc. | Sock |

| US10362811B2 (en) * | 2014-01-22 | 2019-07-30 | Soksystem, Llc | Sock with support assemblage |

| USD752819S1 (en) | 2014-08-22 | 2016-03-29 | Robert Magri | Protective barrier element |

| CN106889656A (zh) * | 2015-12-21 | 2017-06-27 | 海宁市越立袜业有限公司 | 一种滑雪袜 |

| USD862063S1 (en) | 2016-06-09 | 2019-10-08 | Skinners Technologies S.R.O. | Barefoot footwear |

| IT201700107834A1 (it) | 2017-09-27 | 2019-03-27 | Geox Spa | Fodera perfezionata per capi d'abbigliamento, calzature o accessori |

| HUE062692T2 (hu) * | 2017-12-12 | 2023-11-28 | Trere Innovation S R L | Dinamikus szellõztetõrendszer zoknikhoz |

| USD910305S1 (en) | 2018-03-29 | 2021-02-16 | Simms Fishing Products Llc | Bootie portion of a stockingfoot wader |

| US10897932B2 (en) | 2018-06-24 | 2021-01-26 | Simms Fishing Products Llc | Stockingfoot wader |

| ES2928196T3 (es) * | 2018-08-22 | 2022-11-16 | X Tech Swiss Gmbh | Calcetines deportivos o venda deportiva |

| USD878740S1 (en) * | 2019-10-25 | 2020-03-24 | Shenzhen Eigday Heating Limited | Sock |

| USD896498S1 (en) * | 2020-04-07 | 2020-09-22 | Binbin LIN | Sock |

| USD975990S1 (en) * | 2021-08-12 | 2023-01-24 | Bifang Mao | Ski sock |

| US20230329358A1 (en) * | 2022-04-19 | 2023-10-19 | Corey W. Hutchinson | Foot and Ankle Compression and Support Apparatus |

Family Cites Families (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4925611Y1 (fr) * | 1970-12-19 | 1974-07-11 | ||

| US4104892A (en) * | 1976-11-15 | 1978-08-08 | Thorneburg Hosiery Mill, Inc. | Cushioned sole tube sock and method |

| US4206515A (en) * | 1978-09-18 | 1980-06-10 | Robinson James D | Athletic sock |

| US4295647A (en) * | 1980-03-17 | 1981-10-20 | Daly James E | Game and article for use therewith |

| JPS56138810U (fr) * | 1980-03-18 | 1981-10-20 | ||

| US4341096A (en) * | 1980-08-06 | 1982-07-27 | Kayser-Roth Hosiery, Inc. | Sock with triple layer fabric in foot and method |

| US4373361A (en) * | 1981-04-13 | 1983-02-15 | Thorneburg James L | Ski sock with integrally knit thickened fabric areas |

| US4651354A (en) * | 1985-04-18 | 1987-03-24 | Petrey John O | Foot cover |

| US4898007A (en) * | 1987-11-16 | 1990-02-06 | Dahlgren Ray E | Moisture management sock |

| JPH072790Y2 (ja) * | 1989-09-29 | 1995-01-25 | 株式会社クボタ | セグメント取付金具 |

| US5307522A (en) * | 1992-02-07 | 1994-05-03 | James L. Throneburg | Snowboarding sock |

| US5329640A (en) * | 1993-04-14 | 1994-07-19 | Hourigan James T | Cushioned sock |

| US5319807A (en) * | 1993-05-25 | 1994-06-14 | Brier Daniel L | Moisture-management sock and shoe for creating a moisture managing environment for the feet |

| US5335517A (en) * | 1993-07-23 | 1994-08-09 | James L. Throneburg | Anatomical isotonic sock and method of knitting the same |

| US5560226A (en) * | 1995-01-12 | 1996-10-01 | Throneburg; James L. | Foot protector in combination with hosiery and method of knitting same |

| US5596770A (en) * | 1995-11-01 | 1997-01-28 | Kunesh; J. Denise | Two-ply inflatable sock |

| US5603232A (en) * | 1995-11-22 | 1997-02-18 | Throneburg; James L. | Foot protector for use in combination with hosiery and method of making and using same |

| US5617745A (en) * | 1996-01-04 | 1997-04-08 | Della Corte; Michael P. | Support sock |

| US5771495A (en) * | 1996-01-08 | 1998-06-30 | The Burton Corporation | Snowboarding sock |

| US5774898A (en) * | 1996-05-02 | 1998-07-07 | Malpee; Mitchell G. | Athletic footwear for soft terrain |

| US5724836A (en) * | 1996-07-16 | 1998-03-10 | Sara Lee Corporation | Sock with breathable panel |

| US5784721A (en) * | 1996-08-15 | 1998-07-28 | Wyoming Woolens | Padded fleece sock and method of making same |

| US5708985A (en) * | 1996-11-12 | 1998-01-20 | Ogden & Company, Inc. | Enhanced frictional engagement sock |

| US5768713A (en) * | 1997-02-21 | 1998-06-23 | Crick; Elsa | Hosiery article with moisture absorbing pads |

| DE29715762U1 (de) * | 1997-09-03 | 1998-01-08 | HIGHTEACH Institut für Marketing & Personalentwicklung GmbH, 58313 Herdecke | Klimaregulierender Strumpf |

| IT244098Y1 (it) * | 1998-06-26 | 2002-03-07 | Vegas Spa | Struttura di calza ad elevato conforto |

| US6021527A (en) * | 1998-08-31 | 2000-02-08 | Fox River Mills, Inc. | Anatomically designed sock |

| JP2000345405A (ja) * | 1999-06-07 | 2000-12-12 | Shigeo Miyawaki | 先端部分に通気孔を設け通気性を良くしたソックス |

| US6082146A (en) * | 1999-07-01 | 2000-07-04 | Dahlgren; Ray E. | Moisture management sock |

| US6247182B1 (en) * | 1999-12-29 | 2001-06-19 | Hedy T. Tasbas | Stocking device |

| US6275997B1 (en) * | 2000-04-20 | 2001-08-21 | Vikki Richardson | Gel-cushion socks |

| JP2002088512A (ja) * | 2000-09-07 | 2002-03-27 | Kiyoshi Ono | 靴 下 |

| JP2002146602A (ja) * | 2000-11-07 | 2002-05-22 | Noriko Higuchi | 足包囲部材 |

| CN2472519Y (zh) * | 2001-04-09 | 2002-01-23 | 薛贤明 | 袜子 |

| US6708348B1 (en) * | 2001-06-29 | 2004-03-23 | Injinji Footwear, Inc. | Anatomic dry athletic toe sock |

| US7069600B1 (en) * | 2001-06-29 | 2006-07-04 | Injinji Footwear, Inc. | Toe sock |

| DE20111503U1 (de) * | 2001-07-14 | 2001-10-04 | Kunert Werke Gmbh | Socke, insbesondere Sport- oder Wandersocke |

| JP3090737U (ja) * | 2002-06-14 | 2002-12-26 | 株式会社ユニバル | テーピングソックス |

| DE20217332U1 (de) * | 2002-11-11 | 2003-02-27 | Brand Factory Swiss Gmbh, Rotkreuz | Socke |

| DE20315356U1 (de) * | 2003-10-07 | 2004-02-26 | Brand Factory Swiss Gmbh | Socke |

| WO2005048749A2 (fr) * | 2003-11-14 | 2005-06-02 | Joseph Cacioppo | Chaussette hygienique jetable |

-

2003

- 2003-01-21 DE DE20300973U patent/DE20300973U1/de not_active Expired - Lifetime

-

2004

- 2004-01-13 SI SI200431130T patent/SI1585397T1/sl unknown

- 2004-01-13 CA CA2513786A patent/CA2513786C/fr not_active Expired - Fee Related

- 2004-01-13 CN CNB2004800025501A patent/CN100393255C/zh not_active Expired - Fee Related

- 2004-01-13 AT AT04701581T patent/ATE424735T1/de active

- 2004-01-13 PT PT04701581T patent/PT1585397E/pt unknown

- 2004-01-13 DK DK04701581T patent/DK1585397T3/da active

- 2004-01-13 WO PCT/DE2004/000023 patent/WO2004064551A1/fr not_active Ceased

- 2004-01-13 DE DE502004009134T patent/DE502004009134D1/de not_active Expired - Lifetime

- 2004-01-13 JP JP2006500470A patent/JP2006515651A/ja active Pending

- 2004-01-13 EP EP04701581A patent/EP1585397B1/fr not_active Expired - Lifetime

- 2004-01-13 US US10/542,557 patent/US20060143801A1/en not_active Abandoned

- 2004-01-13 ES ES04701581T patent/ES2324038T3/es not_active Expired - Lifetime

- 2004-01-13 AU AU2004206701A patent/AU2004206701B2/en not_active Ceased

-

2009

- 2009-06-10 CY CY20091100613T patent/CY1109133T1/el unknown

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006515651A (ja) | 2006-06-01 |

| US20060143801A1 (en) | 2006-07-06 |

| SI1585397T1 (sl) | 2009-08-31 |

| CA2513786C (fr) | 2011-09-20 |

| CN1741754A (zh) | 2006-03-01 |

| DE502004009134D1 (de) | 2009-04-23 |

| CN100393255C (zh) | 2008-06-11 |

| DK1585397T3 (da) | 2009-06-29 |

| EP1585397A1 (fr) | 2005-10-19 |

| ATE424735T1 (de) | 2009-03-15 |

| WO2004064551A1 (fr) | 2004-08-05 |

| AU2004206701A1 (en) | 2004-08-05 |

| DE20300973U1 (de) | 2003-03-27 |

| CY1109133T1 (el) | 2014-07-02 |

| AU2004206701B2 (en) | 2007-12-20 |

| CA2513786A1 (fr) | 2004-08-05 |

| PT1585397E (pt) | 2009-06-03 |

| ES2324038T3 (es) | 2009-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1585397B1 (fr) | Socquette | |

| EP1589837B1 (fr) | Chaussette | |

| EP1701626B1 (fr) | Chaussette | |

| EP1562681B1 (fr) | Chaussette | |

| EP1959767B1 (fr) | Chaussette | |

| EP1476033A1 (fr) | Vetement thermoregulant et procede pour eliminer l'humidite presente dans des zones de la peau | |

| EP1796490B1 (fr) | Chaussette | |

| EP2747589B1 (fr) | Chaussette | |

| EP1893044B1 (fr) | Chaussette | |

| DE20016825U1 (de) | Schuh-Socken-Kombination | |

| EP1929894A1 (fr) | Coiffe pour semelles de chaussures | |

| DE102011106737A1 (de) | Kompressionsstrumpf mit Lüftungskanälen und Anti-Rutschprofil | |

| WO2003013290A2 (fr) | Chaussette | |

| DE102005027100A1 (de) | Socke | |

| DE20118058U1 (de) | Socke | |

| DE20300208U1 (de) | Socke | |

| DE20314607U1 (de) | Socke, insbesondere Trekking-Socke | |

| AT412610B (de) | Socken bzw. strumpf | |

| DE202005019393U1 (de) | Strumpf aus gestricktem Garn zur Fußbekleidung | |

| WO2007065730A1 (fr) | Chaussette en maille utilisee comme article chaussant | |

| DE10328607A1 (de) | Socke oder Strumpf mit Reliefstruktur im Auftrittsbereich | |

| WO2019158595A1 (fr) | Bas thermorégulant |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050720 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: X-TECHNOLOGY SWISS GMBH |

|

| 17Q | First examination report despatched |

Effective date: 20061206 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004009134 Country of ref document: DE Date of ref document: 20090423 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20090527 |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR Ref country code: CH Ref legal event code: NV Representative=s name: RIEDERER HASLER & PARTNER PATENTANWAELTE AG |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20090401493 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2324038 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: EE Ref legal event code: FG4A Ref document number: E003212 Country of ref document: EE Effective date: 20090609 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E006247 Country of ref document: HU |

|

| 26N | No opposition filed |

Effective date: 20091214 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20100107 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20101227 Year of fee payment: 8 Ref country code: RO Payment date: 20101227 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20110112 Year of fee payment: 8 Ref country code: HU Payment date: 20110204 Year of fee payment: 8 Ref country code: MC Payment date: 20110113 Year of fee payment: 8 Ref country code: IE Payment date: 20110120 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110124 Year of fee payment: 8 Ref country code: CZ Payment date: 20110111 Year of fee payment: 8 Ref country code: BG Payment date: 20110113 Year of fee payment: 8 Ref country code: DE Payment date: 20110121 Year of fee payment: 8 Ref country code: AT Payment date: 20110113 Year of fee payment: 8 Ref country code: PT Payment date: 20110107 Year of fee payment: 8 Ref country code: SK Payment date: 20110105 Year of fee payment: 8 Ref country code: SE Payment date: 20110113 Year of fee payment: 8 Ref country code: SI Payment date: 20101228 Year of fee payment: 8 Ref country code: FR Payment date: 20110202 Year of fee payment: 8 Ref country code: FI Payment date: 20110113 Year of fee payment: 8 Ref country code: EE Payment date: 20110112 Year of fee payment: 8 Ref country code: NL Payment date: 20110117 Year of fee payment: 8 Ref country code: IT Payment date: 20110124 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20110104 Year of fee payment: 8 Ref country code: GR Payment date: 20110117 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110120 Year of fee payment: 8 Ref country code: ES Payment date: 20110125 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CY Payment date: 20110110 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20120713 |

|

| BERE | Be: lapsed |

Owner name: X-TECHNOLOGY SWISS GMBH Effective date: 20120131 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20120801 |

|

| LTLA | Lt: lapse of european patent or patent extension |

Effective date: 20120113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: ML Ref document number: 20090401493 Country of ref document: GR Effective date: 20120802 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120113 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 5581 Country of ref document: SK Effective date: 20120113 |

|

| REG | Reference to a national code |

Ref country code: EE Ref legal event code: MM4A Ref document number: E003212 Country of ref document: EE Effective date: 20120131 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120928 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20120928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: EE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120114 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120801 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004009134 Country of ref document: DE Effective date: 20120801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120713 Ref country code: SI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120114 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120802 Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120114 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 424735 Country of ref document: AT Kind code of ref document: T Effective date: 20120113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120801 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20130705 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121231 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120113 |