EP1585201A1 - Connecteur - Google Patents

Connecteur Download PDFInfo

- Publication number

- EP1585201A1 EP1585201A1 EP05012056A EP05012056A EP1585201A1 EP 1585201 A1 EP1585201 A1 EP 1585201A1 EP 05012056 A EP05012056 A EP 05012056A EP 05012056 A EP05012056 A EP 05012056A EP 1585201 A1 EP1585201 A1 EP 1585201A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- connector

- shield

- complementary

- locking

- securing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/648—Protective earth or shield arrangements on coupling devices, e.g. anti-static shielding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/72—Coupling devices for rigid printing circuits or like structures coupling with the edge of the rigid printed circuits or like structures

- H01R12/722—Coupling devices for rigid printing circuits or like structures coupling with the edge of the rigid printed circuits or like structures coupling devices mounted on the edge of the printed circuits

- H01R12/724—Coupling devices for rigid printing circuits or like structures coupling with the edge of the rigid printed circuits or like structures coupling devices mounted on the edge of the printed circuits containing contact members forming a right angle

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/648—Protective earth or shield arrangements on coupling devices, e.g. anti-static shielding

- H01R13/658—High frequency shielding arrangements, e.g. against EMI [Electro-Magnetic Interference] or EMP [Electro-Magnetic Pulse]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/7005—Guiding, mounting, polarizing or locking means; Extractors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/516—Means for holding or embracing insulating body, e.g. casing, hoods

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R2201/00—Connectors or connections adapted for particular applications

- H01R2201/26—Connectors or connections adapted for particular applications for vehicles

Definitions

- the present invention relates to a connector for mating with a complementary connector, in particular for Use in a motor vehicle.

- Connectors are used to easily lines with another line or a circuit carrier with an electrical Circuit electrically and mechanically connect. Connectors therefore find particular application in motor vehicle construction. In This area of use must such connectors on the one hand be very inexpensive to produce and on the other under unfavorable Operating conditions, in particular with vibrations and / or shocks, allow a stable connection.

- a connector having the features of the preamble of the claim 1 is known from US-A-4 900 262.

- the present invention is therefore based on the object, a simple To provide connectors by means of which simply low-interference Connections to a circuit carrier or shielded cables can be produced.

- the connector according to the invention for mating with a complementary connector in a plugging direction in particular for Use in a motor vehicle, has a contact element receptacle for receiving a contact element, preferably at least two Contact elements, a contact element receiving at least partially surrounding shield and a contact element receptacle and the Shielding at least partially accommodating housing.

- a contact element receptacle for receiving contact elements is intended.

- the contact element receiving preferably as a plastic injection molded part is formed, can corresponding recording channels exhibit.

- the contact elements can be in the contact element receptacle pushed in, pressed or injected.

- the contact element receptacle for receiving at least two, more preferably formed more than two contact elements.

- Such a connector is then particularly suitable for connection of lines of a bus system in a motor vehicle, often have multiple wires.

- any contact elements such as pins, tongues or blades or contact sockets.

- the Contact elements are connectable to conductors, among which under the Invention not only wires of cables are understood, but also Tracks on circuit boards.

- an electrically conductive material preferably a metal manufactured shield serves to shield contact elements in the contact element recording against electrical and electromagnetic Fields.

- a metal manufactured shield serves to shield contact elements in the contact element recording against electrical and electromagnetic Fields.

- it can have a contacting device, to which a conductor with a reference potential, for example ground, is connectable.

- the shield preferably takes the contact element receptacle on.

- the shields of the connector and the complementary Connector be suitably designed so that when Plug the connectors into electrical contact between the shields is made.

- the contact element receiving and at least partially surrounding this Shield are at least partially surrounded by the housing, this protects against external influences and in particular for mechanical connection with a complementary connector or whose housing may be formed.

- the housing can the connector and / or the complementary connector Have guides by means of which the connector when mating on or in one another are feasible.

- the risk of having a manufactured connector due to vibrations and / or shocks accidentally triggers reduce, rejects Shielding at least one securing element, preferably one Snap or locking element, on, when plugging the connector with a corresponding complementary connector relative to a complementary securing element of the complementary Connector, preferably a complementary snap or Locking element, in a securing position relative to the complementary Fuse element is movable and by means of which in the backup position by cooperation with the complementary securing element a relative movement of the connector from the mated Location is limited.

- the complementary connector can in particular as a suitably designed connector according to the invention, in particular according to one of claims 1 to 8, with a corresponding be formed complementary security element.

- One of the Securing elements is at least partially, preferably in one of the Plug direction deviating direction, movable.

- the connector and the complementary connector are therefore at least in a predetermined Range of layers in a mated state, in the contact elements and the complementary contact elements still are in contact with each other, securable, that is, only by overcoming apart from certain forces determined by the securing elements.

- the securing elements can in particular be designed in this way be that a relative movement of the connector from the mated Location is blocked.

- the fuse elements can continue in the backup position a contact between the shields of the assembled Provide connector if the complementary Securing element also on a shield of the complementary Connector is formed.

- the use of snap or Locking elements has the advantage that these when reaching the backup position automatically to form a snap or locking connection with each other Snap or snap, allowing the backup automatically can be done.

- Another object of the invention is a connector system with a first connector according to the invention and an inventive, connectable to the first connector, to this complementary second connector.

- the complementary second Connector can this purpose, in particular in a trained accordingly Contact element receiving arranged, corresponding to the Contact elements of the first connector complementary second Contact elements as well as a housing that mates with the Housing of the first connector allowed to have.

- the connectors according to the invention allow a simple connection a shielded cable with another, in particular also shielded, line or a circuit carrier, wherein the contacting region at least partially shielded and thus trouble-free is.

- the housing can be constructed basically arbitrary, but is a Embodiment preferred, wherein the housing of at least two Assembled housing parts, in particular put together and / or pushed.

- The, preferably as plastic injection molded parts trained housing parts can have fastening elements for this purpose, by which they are optionally connected movably.

- the connector is then assembled by joining the Contact element reception, shielding and housing easy produced.

- a molding of the housing to a Line be avoided if this by plugging the Housing parts can be enclosed.

- the housing parts can do this preferably have corresponding indentations in edge regions, the only after joining the housing parts an opening for receiving form the line.

- the indentations may preferably Have portions of a cuff after joining of the housing surrounds a conduit.

- the line can then join the housing parts are installed in the housing. This can be particularly advantageous if the contact elements with the line are connected before assembling the connector to allow easy handling during assembly. The production of such a connector as well as Connection with a line is then particularly cost-effective.

- the housing is formed in one piece, and a sleeve-shaped portion, in which the shield with the contact element receptacle is inserted.

- the shield with the Contact element reception is characterized by a relative movement between the housing and the shield with the contact element receiving in pushed the sleeve-shaped portion, so that the housing can be pushed over the shield.

- Such a housing is very simple and stable. Furthermore it is easy through Plastic injection molding produced.

- the housing then a flap for at least partially closing an opening on, through which the shield with the contact element receiving in the Housing is inserted.

- the flap can optionally be in one Edge region have a recess through which a conduit feasible is.

- this is formed from one or more stamped and bent parts.

- the Shielding is so very easy and also full or large area produced.

- the shield as completely as possible, in particular substantially to the end faces of the contact element receptacle, on or in which parts of contact elements are arranged, encloses same. In essence, this means in particular that at seams or corners small manufacturing gaps or holes may occur, but preferably not in areas. Especially preferred surrounds the shield also on the mating side of the contact element receptacle from this protruding ends of in the contact element receptacle arranged contact elements.

- the shield be at least two sliding transversely to the direction of insertion shielding parts has, which are preferably formed as stamped and bent parts. Especially Preferably, the shield has only two shielding parts on. Preferably, the shielding parts are via the contact element receptacle pushed.

- the shielding parts can still Have complementary fasteners by means of which they together are connectable. In this way, a shield can be very simply be provided for contact element receptacles that a simply pushing a shield in the direction of insertion not or only allow with additional steps.

- the contact element receiving and the shield extending transversely to the direction of insertion, cooperating Have blocking elements which have a relative movement between the Contact element receptacle and the shield in and / or against the Block plug-in direction.

- cooperating Have blocking elements which have a relative movement between the Contact element receptacle and the shield in and / or against the Block plug-in direction.

- these locking elements can around a groove and a corresponding bar or against each other acting protrusions. In this way, with ease of manufacture the shield sure a relative movement between the Shielding and the contact element recording even when occurring larger insertion forces on the contact elements and thus the contact element recording be prevented.

- the shield in one piece as a stamped and bent part is trained.

- Such shields are not only stand out by a particularly simple and inexpensive production, but also allow easy production of the connector, as only a part is to handle.

- the shield has a relation to the Plug-in direction angled, bent wing having, at least partially closes an insertion opening in the shield, by the contact element recording in the shield inserted is.

- a good shielding of such a Insertion opening reached.

- a relative movement between Contact element receptacle and shielding against the plugging direction prevented, as this blocked by the bent wing becomes.

- the contact element receptacle can not be so by plug forces Mating with another connector back out of the Shielding be pushed.

- Such shields are preferably used with contact element receptacles for receiving Contact elements are formed, the conductor-side ends opposite the plug-in direction are angled.

- the contact element receiving substantially L-shaped be can then in particular at an angle be angled from about 90 ° relative to the direction of insertion.

- Such Shielding may occur before a turn of the wing from a preferably aligned parallel to the direction of insertion simply on the contact element receiving deferred or the contact element receiving in the shield are pushed in, whereupon the wing is on the Contact element holder is bent over.

- a wing is accordingly also for contact element recordings usable, which receive linear contact elements and may in particular an opening or preferably a recess in the edge, through the cable to contact elements in the Contact element holder are feasible. Basically, too several wings are used to close the insertion opening.

- the wing holding elements preferably in the bent state in the insertion direction, and formed in the housing corresponding complementary holding elements are, by means of which the bent wing in one to the direction of insertion inclined direction relative to the housing is fastened.

- expedient the retaining elements and the complementary retaining elements are designed that the shield with the bent wing in the housing one or the housing on the shield with the bent Wings are pushed on.

- holding elements can in particular parallel to slot direction extending grooves or slots in conjunction with corresponding projections, strips or springs are used. On this way, the wing can simply be inserted into the housing, while blocking a later bending of the wing. Of the bent wing can then in particular via the contact element receptacle Take on the wing forces applied to the wing and on the Housing transferred.

- the connector as a device receptacle is formed, preferably on opposite Sides of the shield contacts for connection to a circuit carrier are formed.

- the contacts of the shield are used preferably for mechanical connection to the circuit carrier and at the same time for electrical connection to tracks on the Circuit carriers.

- the housing may expediently additional Attachment elements, for example, have pins by means of of which it is connectable to the circuit carrier, so that it for example when mating with a complementary connector occurring forces can be transferred well to the circuit carrier.

- the Contact element recording as well as the contact elements can thereby preferably be L-shaped, so that the plugging direction parallel can run to a circuit board on which the device receptacle then held.

- the shielding be two, preferably formed on opposite sides of the shield, Has safety elements. These can each be the same or different be educated. In particular, when arranged on opposite Sides of the shield can better distribute occurring forces become. In addition, there is additional security through the achieved redundancy.

- the securing element is a resilient snap or Has latching hook, preferably in a through the shield formed collar is formed.

- the resilient snap or catch hook can in particular by a spring arm with a free at the Be formed end arranged snap or locking projection.

- the shield is then preferably made of a corresponding elastic Sheet metal made. Is the snap or catch hook in one by the Shield formed formed collar, the collar preferably surrounds From the contact element receiving outstanding contact elements, so that these are mechanically protected before and during mating and are well electromagnetically shielded after mating.

- the securing element has a securing projection has behind the in the backup position a snap or Latch hook of a mated with the connector complementary Connector engages.

- the complementary connector can according to the invention and in particular according to the preceding one Paragraph-described embodiment and / or claim 10 is formed be.

- Such a securing element or snap or locking element is therefore a fuse element designed as a snap-in or snap-in hook complementary.

- the securing projection can in particular through a shoulder of a recess or depression in the Shielding of the connector to be formed.

- a relative to the contact element receiving between an unlocking position and a locking position movable locking element is provided, wherein in the unlocking position of the locking element the fuse elements of the connector and the complementary connector in the backup position and / or off this are movable out and the locking element in the locking position the fuse elements one of their backup position against a Motion locked from the backup position.

- the complementary connector can according to the invention and in particular accordingly one or more of the previously described embodiments and / or be formed of one of claims 1 to 11.

- the locking element parallel to the direction of insertion is displaceable relative to the shield and preferably the shield surrounds at least partially sleeve-like.

- An education as Sleeve is particularly advantageous when two at opposite Side of the shield trained fuse elements provided are, then with only one locking element both security elements at the same time can be locked or unlocked.

- the locking element manually in the Locking position is movable.

- a resilient Element is provided by movement of the locking element is clamped relative to the connector in the unlocking position and by means of its restoring force, the locking element in the Locking position is movable. This way can be an automatic Lock achieved and in particular largely prevented can, that due to a mounting error locking does not take place.

- the production of the connector is simplified.

- the resilient element by a formed in the insertion direction spring is formed. This can in particular between a projection or stop of the locking element and a support element on the housing, the contact element receptacle or preferably the shield can be arranged.

- the connector according to the invention particularly Easy to produce when the housing is mounted last.

- the shield of the connector can be a Have recess or recess into which the snap or latch hook of the complementary connector by mating the Plug-in connector can be snapped or latched so that the locking element at least partially over the snap or latch hook is movable. It is then preferred that when mating with a complementary connector through the locking element the housing, the shield or preferably the snap or Latch hook of the complementary connector in the unlocking position is movable. In this way, not just an automatic results Locking, but it is also when mating one automatic unlocking possible, so that the security elements without additional mounting handles can reach their backup position.

- the Connector system according to the invention can in particular a corresponding formed first connector and an inventive Complementary second connector, whose housing, Shielding or preferably snap or latching hooks accordingly is trained.

- the actuating part can be rigid with the locking element be coupled.

- the locking element has a driving stop, at least during a Part of the opening movement of the actuating part to a complementary Stop of the operating part is applied.

- this limits Stop also the movement of the locking element in the insertion direction and thus determines the locking position of the locking element.

- the locking element during mating simply without an opening movement of the actuating element, for example with the help of the snap or latch hook of a complementary Connector to be moved from its locking position.

- the actuator can be used for mating become.

- simply the connector can be solved.

- the locking element by a spring in Its locking position is maintained by appropriate design the spring the necessary force to move the locking element from the locking position to the unlocking position easy, but be determined effectively.

- the movable securing element is designed as a snap hook, the movement by relative to the complementary snap element, that is a safety projection, against the plug-in direction, from the backup position is movable, if corresponding forces act.

- this can be an oblique to the Have plugging direction extending hook surface, the move apart the plugged connector parallel to the insertion direction on the safety projection derived by appropriate Forcing forces are moved transversely to the direction of insertion.

- the first connector formed by the shield Collar in which at least partially a plurality of male contact elements are arranged, and that in the contact element receiving the second connector arranged a plurality of female contact elements are, wherein the contact element receiving the second connector with the shield is insertable into the collar of the first connector. In this way, a large-area contact between the two Shielding achieved.

- the connector system according to the invention are preferably the first connector as inventive device recording or as inventive plug coupling formed and the complementary second connector as a plug with locking element.

- contact element recording on cable can be hit or struck Contact elements are arranged.

- the striking of contact elements Cable is also commonly used to make a so-called crimp connection designated.

- the second connector 14 is connected to a line 16 connected. It is as complementary to the first connector 10 Connector designed and so with this plugged together to the cable 16 to the circuit substrate 12 and in particular on it to connect arranged conductor tracks.

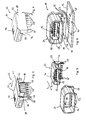

- the first connector or the device holder 10 are shown in FIGS. 2 to 6 shown in more detail.

- the first connector 10 consists of three prefabricated, nested components, namely a first Contact element receptacle 18 with formed as a contact pins 20 Contact elements, one as a one-piece stamped and bent part of a metal sheet fabricated first shield 22 and a first housing 24th

- the trained as a plastic injection molded part first contact element receptacle 18 has an L-shape with a running in a direction of insertion S 1 first leg 26 with an asymmetrical cross section and a relative to this at an angle of 90 ° angled second leg 26 '.

- a first end face 28 of the first leg 26 is oriented orthogonal to the plug-in direction S 1 and a second end face 28 'of the second leg 26' orthogonal to the first end face 28.

- the contact element receptacle 18 includes in corresponding channels and grooves pressed several, in the example six, also L-shaped parallel contact pins 20, the conductor-side contacting ends 30 with respect to the insertion direction S 1 angled at an angle of about 90 ° from the second end face 28 'of second leg 26 'and the plug ends 32 extending parallel to the insertion direction S 1 extending from the first end face 28 of the first leg 26 protrude.

- a resilient metal sheet first shield 22 is shown in Fig. 2 in an already partially bent state, and has a sleeve portion 34 which corresponds in shape to the corresponding portion of the first contact element receptacle 18.

- a substantially U-shaped foot member 36 with arranged on opposite sides forked feet 38, which together with the sleeve portion 34 an orthogonal to the insertion direction S 1 oriented insertion opening 40 encloses U-shaped.

- the contact element receptacle 18 in the first shield 22 can be inserted (see Fig .. 3).

- the sleeve portion 34 and in particular its interior have transversely to the direction of insertion on a cross section corresponding to the cross section of the contact element receiving transversely to the insertion direction S 1 , so that the contact element receptacle 18 closely fitting to the inner wall of the sleeve portion 34 is inserted into this.

- two resilient snap hooks 46 are formed as securing elements, which are formed by a spring arm with a hook-shaped portion formed thereon by bending.

- the hook-shaped portions are bent in a V-shape with obliquely inclined to the plug-in direction S 1 legs.

- These securing elements are arranged symmetrically to each other on opposite sides of the sleeve portion 34, wherein the hook-shaped protruding portions each point into the interior of the sleeve portion 34.

- the securing elements 46 simultaneously serve for contacting a second shield of the second connector 14.

- the foot part 36 also corresponds in shape to the shape of the corresponding one Section of the first contact element receptacle 18, i. of second leg 26 ', wherein the forked feet 38 for mounting on the circuit carrier 12 are formed in corresponding holes 48.

- the wing 42 is dimensioned such that by bending the wing 42 along a bending line orthogonal to the plug-in direction S 1, the insertion opening 40 is essentially coverable or closable by the wing 42 (see Fig .. 4).

- the wing 42 and the side parts 44 thereto are formed so that in the bent state, the lower edge is approximately aligned with the lower edge of the foot part 36 and the leg 26 '.

- On the side parts 44 further bent guide rails 50 are formed, which extend in the bent state in Fig. 4 parallel to the insertion direction S 1 .

- the first housing 24 is integrally formed as an injection molded part of a dimensionally stable plastic sleeve-like with an asymmetric, the cross section of the first shield 18 corresponding cross-section transverse to the insertion direction S 1 . It has for attachment to the circuit substrate 12 has two retaining pin 52 and a substantially U-shaped wall portion 54 which is formed so that it receives the foot portion 36 of the shield substantially form-fitting manner, and when mounted on the circuit substrate 12 on this with his lower edge is seated.

- a circumferential receiving groove 56 to Recording a housing collar of the second connector 14 is formed. Furthermore, parallel to the plug-in direction Si, which are parallel to the Walls of the sleeve-like portion of the housing 24 extends, retaining grooves 58 for receiving the guide rails 50 on the side parts 44 of the Wing 42 of the first shield 22 is formed.

- the first contact element receptacle 18 in the first shield 22 is inserted.

- the wing 42 is oriented parallel to the plug-in direction S 1 in the assembled state.

- the part of the sleeve portion 34, which projects beyond the end face 28, now forms a collar 59 surrounding the plug-in ends 32, the edge of which protrudes beyond the plug-in ends 32 in the insertion direction S 1 .

- the wing 42 is bent over to the first contact element receptacle 18 until it is angled at an angle of about 90 ° relative to the plug-in direction S 1 at the edge of the foot portion 36 abuts (see Fig .. 4).

- the first contact element receptacle 18 is now secured against movements parallel to the plug-in direction S 1 by the bent wing 42 on the one hand and the wing section 42 opposite the wall portion of the foot part 36 on the other.

- the first contact element receptacle 18 including the plug-in ends 32 to the end faces of the legs 26 and 26 ' is substantially completely enclosed by the first shield 22.

- the unit thus formed is inserted into the first housing 24, wherein the guide rails 50 are inserted at the side parts 44 in the retaining grooves 58 in the first housing 24.

- These are designed such that, at least for assembly purposes, the unit of first contact element receptacle 18 and first shield 22 is connected to the housing 24 by means of a clamping fit.

- a bending of the wing 42 in a position parallel to the insertion direction S 1 is now blocked by the guide rails 50 held in the retaining grooves 58, so that the first contact element receptacle 18 is securely held in the first shield 22.

- the first housing 24 surrounds the sleeve portion 34 of the first shield 18 so that it is mechanically well protected.

- the unit thus formed can now be mounted on the circuit carrier 12 be, with the feet 38 in the holes 48, the retaining pin 52 in corresponding Fixing holes 60 and the contacting ends 30 in Contact holes 62 are introduced.

- the retaining pins 52 sit while in the press fit in the mounting holes 60.

- the feet 38 are used both as a mechanical support for the first shield 22 as well for contacting printed conductors on the circuit carrier 12.

- the so very easy to manufacture first connector 10 in the form of a device holder is then very firm even with very large insertion forces on the Circuit carrier 12 is held.

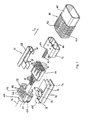

- the second connector 14 is shown in more detail in FIG. He has one second contact element receptacle 64, a second shield 66 with two Shielding parts 68 and 70, a locking element 72 with two resilient elements 74 and a housing 76 with a housing cap 78 and an actuating part 80.

- the second contact element receptacle 64 is likewise designed as a plastic injection-molded part and has a flat cuboidal basic shape.

- a plurality of, in the example, six channels arranged in a row parallel to one another, for receiving contact elements 82, are formed parallel to a plug-in direction S 2 of the second plug connector.

- the contact elements 82 have on the plug side contact sockets and on a conductor side means for abutting cables 84 of the line 16 and for establishing a crimp connection with the cables 84.

- the second shield 66 consists of the two designed as stamped and bent parts shielding parts 68 and 70, which can be put together in a direction transverse to the insertion direction S 2 .

- the two shield parts 68 and 70 are substantially U-shaped so that they enclose the second contact element receptacle 64 after mating and abut against this.

- the first shielding member 68 is for connection to the second Shielding part 70 has two pairs of first tongues 88 and second tongues 90, which are each lowered relative to the outer surfaces.

- the second shielding member 70 has, in an L-shaped outer portion 92, opposed flat recessed portions 94 protruding parallel to its surface beyond the L-shaped portion 92. Breakthroughs 96 are furthermore punched out in the recessed regions 94, which roughly correspond in shape to the shape of the first tongues 88. At the opposite side of the insertion direction S 2 side of the openings 96 each support elements 98 are bent approximately orthogonal to the level of the recessed areas 94. Furthermore, a sixteenbiegbare clamp 100 is formed for contacting a not shown in the figures shielding of the line 16 at the opposite end of the insertion direction S 2 end face.

- the second shielding member is also 70 except for the clamp 100 symmetrical to a parallel to the recessed Formed area 94 extending plane.

- the recessed portions 94 are opposite to the L-shaped portion 92 so far lowered that the locking projections 86 of the second contact element receptacle 64 in the frontal portion of the L-shaped portion 92nd are durable.

- the housing cap 78 is in two parts and consists of a top 102 and a Lower part 104 plugged together and has a corresponding from Cuff sections of the upper and lower part formed cuff 106 for receiving the line 16.

- the housing cap 78 is essentially pot-shaped, wherein the pot walls are shaped so that they are put together Shield 66 can receive partially and positively (see FIG. 9).

- each two fasteners 108 formed by means of which the actuating member 80 slidably on the Housing cap 78 is durable.

- the breadth of the shift is here through the length of slots 110 in the fasteners 108 certainly.

- support elements 112 formed in the form of the support elements 98th correspond to the second shielding part 70 and these in the assembled Support the condition of the second connector.

- the locking element 72 is also sleeve-shaped as a plastic injection molded part executed and corresponds in shape substantially the shape of the sleeve-shaped portion of the housing cap 78.

- On opposite Flat sides of the locking element 72 are stop elements 114 formed, which serve on the one hand, the resilient, in Shape of coil springs formed to hold elements 74 and the other than driving stroke to act.

- two optional sliding plates 116 are fastened in metal in the edge portion in the insertion direction S 2 .

- the actuating member 80 is also formed as an injection molded part made of plastic. It has the form of a sleeve which receives the locking element 72 and the housing cap 78 at least partially tight fitting.

- a front housing collar 118 in the direction of insertion S 2 has smooth walls and a cross-section such that it can be inserted in a form-fitting manner into the first housing 24 and in particular its receiving groove 56.

- a rear handle portion 120 seen in the direction of insertion S 2 symmetrical parallel to the insertion direction S 2 extending, opposite ends of the insertion direction S 2 open guide channels 122 are formed on opposite flat sides, in which the support members 98, the housing support members 112 and the stop members 114 are feasible.

- actuating part 80 to on the fasteners 108 complementary fasteners on so that the actuating member 80 slidably on the housing cap 78th held and managed.

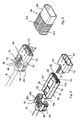

- first Cable 84 struck against the contact elements 82 by crimping.

- the Contact elements 82 are then injection molded second contact element receptacle 64 is inserted and there in a known Way latched.

- the two shielding parts 68 and 70 transversely to the plug-in direction S2 via the second contact element receptacle 64, with the second tongues 90 under the L-shaped section 92 and edge portions of recessed areas 94 in the first Shielding 68 engage.

- the first tongues snap 88 in the apertures 96 and close them.

- the contact element holder 64 is now completely up to its front sides of the shield 66 enclosed because the apertures 96 through the first tongues 88 are covered.

- the contact element receptacle 64 is opposite the shield 66 is no longer displaceable, since the locking projections 86 engage in the acting as a blocking element L-shaped portion 92.

- the clamp 100 becomes the exposed shield of the conduit 16 bent and contacted with this (see Fig. 8).

- the exposed recessed areas 94 now form recesses 124 on opposite sides. At their end faces in the insertion direction S 2 , the recesses 124 define shoulders each having a securing projection 126 as securing elements complementary to the securing elements or snap hooks 46.

- the operating part 80 is on the resulting Unit pushed and locked with the housing cap 78, so that the second connector 14 shown in Fig. 1 is formed.

- the second connector with the actuating member 80 is inserted into the first housing 24, wherein the non-symmetrical shape of the inner cross section of the housing 24 and the corresponding outer cross section of the actuating part 80th or the housing collar 118 excluded accidental rotation is.

- the housing collar 118 is designed so that it is in the receiving groove 56 in the housing 24 substantially form-fitting manner is.

- the mating ends 32 of the contact pins 20 are inserted into the contact elements 82 in the second contact element receptacle 64, wherein at the same time, favored by mutually bent edges on the front side of the second shield 66, in Figs. 10 to 15 only incomplete and schematically shown snap hook 46 of the second shield 66 are resiliently bent apart and thus stretched. They abut against the end face of the locking element 72 and push the locking element 72, which surrounds the shield 66 and is guided in the guide channel 118 with the stop element 114, from a locking position in which it covers the recesses 124 and the securing projections 126 against the plug-in direction S 1 to the housing cap 78 to.

- the resilient elements 84 are supported on the support elements 98 of the second shield 66.

- the locking element 72 is the Securing projections 126 and the recess 124 at least partially free, so that the snap hooks 46 behind the securing projections 126 can snap into the recesses 124 in a backup position (see Fig. 11). The locking element 72 then has the unlocking position reached.

- the snap hooks 46 after snapping into the recesses 124, no longer block the locking member 72 so that it is urged by the resilient members 74 that are urged by the movement of the locking member 72 relative to the second shield 66

- Snap hook 46 is moved away in its locking position, in which now the wells 124 with the securing projections 126 and the snap hooks 46 are covered.

- a movement of the snap hook 46 in a direction orthogonal to the plug-in direction S 1 or S 2 that is, beyond the securing projections 126 away, no longer possible.

- the first and second connectors 10 and 14 are now secured in the mated position, since the snap hooks 46 engage behind the securing projections 126 and thus prevent a disengagement of the two connectors parallel to the direction of insertion.

- the actuating member 80 is moved by an opening movement opposite to the insertion direction S 2 on the housing cap 78 to an open position, wherein the run in the guide channels 122 stop elements 114 acting as driving stops 128 acting in the direction of insertion S 2 end walls 130 of the guide channels 122nd be taken as complementary attacks.

- the locking element 72 is moved from the locking position into the unlocking position.

- a predetermined by the resilient elements 74 and their spring constant force is necessary so that accidental movement of the actuating member 80 by specifying appropriate forces or spring constants of the resilient elements 74 can be largely excluded.

- the length or locking position of the locking element 72 is selected so that the actuating member 80 only over a predetermined Distance, in the example about 6 mm, must be moved until the Unlocking is achieved. This excludes, on the one hand, that in a short, random movement of the operating part 80 already a release can take place.

- the minimum unlocking force can be easily adjusted, which is necessary to effect unlocking.

- the snap hooks 46 of the first Shield 22 by applying a corresponding force over the Retaining projections 126 pulled and spread apart, including the corresponding hook-shaped portions substantially V-shaped are bent so that the securing projections 126 on the corresponding Legs of the hook-shaped sections are guided.

- the Snap hooks 46 do not hinder the further pulling apart more, so that the connectors can be completely separated.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Connector Housings Or Holding Contact Members (AREA)

- Earth Drilling (AREA)

- Piezo-Electric Or Mechanical Vibrators, Or Delay Or Filter Circuits (AREA)

- Quick-Acting Or Multi-Walled Pipe Joints (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT05012056T ATE346404T1 (de) | 2003-06-03 | 2003-06-03 | Steckverbinder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03012603A EP1484822B1 (fr) | 2003-06-03 | 2003-06-03 | Connecteur |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03012603A Division EP1484822B1 (fr) | 2003-06-03 | 2003-06-03 | Connecteur |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1585201A1 true EP1585201A1 (fr) | 2005-10-12 |

| EP1585201B1 EP1585201B1 (fr) | 2006-11-22 |

Family

ID=33155144

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03012603A Expired - Lifetime EP1484822B1 (fr) | 2003-06-03 | 2003-06-03 | Connecteur |

| EP05012056A Expired - Lifetime EP1585201B1 (fr) | 2003-06-03 | 2003-06-03 | Connecteur |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03012603A Expired - Lifetime EP1484822B1 (fr) | 2003-06-03 | 2003-06-03 | Connecteur |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7077703B2 (fr) |

| EP (2) | EP1484822B1 (fr) |

| AT (1) | ATE346403T1 (fr) |

| DE (2) | DE50305800D1 (fr) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1183345B (it) * | 1985-02-13 | 1987-10-22 | Montefluos Spa | Poliuretani fluorurati contenenti blocchi poliosiperfluoroalchilenici di migliorate caratteristiche meccaniche |

| US6719581B2 (en) * | 2002-07-25 | 2004-04-13 | Nippon Dics Co., Ltd. | Plug for speaker cables, and speaker terminal and speaker terminal system provided with them |

| FR2875037B1 (fr) * | 2004-09-07 | 2006-10-20 | Itt Mfg Enterprises Inc | Ensemble de connexion pour carte a puce comportant des moyens de protection contre la fraude |

| US7285004B1 (en) * | 2005-04-21 | 2007-10-23 | Yazaki North America, Inc. | USB locking connector system |

| US20080076289A1 (en) * | 2006-09-11 | 2008-03-27 | Yueh-Hua Hsu Huang | Structure of Connnectors |

| US7413446B1 (en) * | 2007-05-14 | 2008-08-19 | Fci Americas Technology, Inc. | Electrical connector module |

| TW201039498A (en) * | 2009-04-20 | 2010-11-01 | Innodisk Corp | SATA data connection device with raised reliability |

| CN201515098U (zh) | 2009-09-11 | 2010-06-23 | 上海莫仕连接器有限公司 | 电连接装置 |

| KR101666868B1 (ko) * | 2009-12-29 | 2016-10-19 | 한국단자공업 주식회사 | 유에스비이 소켓 |

| WO2011160971A1 (fr) * | 2010-06-23 | 2011-12-29 | Tyco Electronics France Sas | Connecteur électrique coudé doté d'une seconde ouverture de face de fiche et module de connecteur électrique doté de deux éléments de boîtier pourvus chacun d'au moins une extension d'isolation |

| US8804354B2 (en) | 2012-09-11 | 2014-08-12 | Apple Inc. | Load sharing device and I/O architecture against imparted abuse loads |

| US8804355B2 (en) * | 2012-09-11 | 2014-08-12 | Apple Inc. | Connector bracket |

| CN203225432U (zh) * | 2013-04-02 | 2013-10-02 | 富士康(昆山)电脑接插件有限公司 | 电连接器组件 |

| TWM482180U (zh) * | 2014-02-07 | 2014-07-11 | Wieson Technologies Co Ltd | 插頭連接器結構 |

| DE102019202444A1 (de) * | 2019-02-22 | 2020-08-27 | Zf Friedrichshafen Ag | Bestückungselement für einen Aktor |

| CN112366481A (zh) * | 2019-07-25 | 2021-02-12 | 富士康(昆山)电脑接插件有限公司 | 电连接器组合、插头连接器及插座连接器 |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0224200A2 (fr) * | 1985-11-22 | 1987-06-03 | STEWART STAMPING CORPORATION (a Connecticut Corporation) | Connecteur fiche et douille blindé |

| US4810210A (en) * | 1987-02-12 | 1989-03-07 | Hosiden Electronics Co., Ltd. | Multipin connector |

| US4900262A (en) * | 1988-03-07 | 1990-02-13 | Hirose Electric Co., Ltd. | Lock mechanism for electrical connector |

| US5035652A (en) * | 1989-05-22 | 1991-07-30 | Hosiden Electronics Co., Ltd. | Multipin connector socket |

| US5171161A (en) * | 1991-05-09 | 1992-12-15 | Molex Incorporated | Electrical connector assemblies |

| EP0562311A2 (fr) * | 1992-03-25 | 1993-09-29 | Hosiden Corporation | Connecteur électrique multipolaire à fiches |

| EP0601265A2 (fr) * | 1992-12-11 | 1994-06-15 | Hosiden Corporation | Connecteur électrique multipolaire à douille |

| US5545052A (en) * | 1992-08-19 | 1996-08-13 | Honda Tsushin Kogyo Kabushiki Kaisha | Electrical connector |

| EP0738029A1 (fr) * | 1995-03-31 | 1996-10-16 | Molex Incorporated | Connecteur électrique avec verrouillage |

| US5634809A (en) * | 1995-08-21 | 1997-06-03 | Honda Tsushin Kogyo Kabushiki Kaisha Tsushin Kogyo Co. Ltd. | Connector with lock mechanism |

| US6007381A (en) * | 1997-08-08 | 1999-12-28 | Molex Incorporated | Circuit board connector with improved mounting characteristics |

| EP1028496A2 (fr) * | 1999-01-26 | 2000-08-16 | Molex Incorporated | Connecteur électrique avec dispositif de verrouillage et ressort métalique |

| US6431887B1 (en) * | 2000-05-31 | 2002-08-13 | Tyco Electronics Corporation | Electrical connector assembly with an EMI shielded plug and grounding latch member |

| US20020151205A1 (en) * | 2001-04-13 | 2002-10-17 | Huetter John P. | Apparatus and metod for cable connection retention |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4797116A (en) * | 1987-01-26 | 1989-01-10 | Amp Incorporated | Electrical connector having a movable contact guide and lance-maintaining member |

| US5167516A (en) * | 1991-08-21 | 1992-12-01 | Foxconn International, Inc. | Connection with floating shield |

| US5244415A (en) * | 1992-02-07 | 1993-09-14 | Harbor Electronics, Inc. | Shielded electrical connector and cable |

| JP3355567B2 (ja) * | 1998-02-04 | 2002-12-09 | 住友電装株式会社 | 基板用コネクタ |

| TW540867U (en) * | 1998-12-31 | 2003-07-01 | Hon Hai Prec Ind Co Ltd | Cable connector |

| TW420418U (en) * | 1999-05-15 | 2001-01-21 | Hon Hai Prec Ind Co Ltd | Electrical cable connector |

-

2003

- 2003-06-03 DE DE50305800T patent/DE50305800D1/de not_active Expired - Fee Related

- 2003-06-03 EP EP03012603A patent/EP1484822B1/fr not_active Expired - Lifetime

- 2003-06-03 EP EP05012056A patent/EP1585201B1/fr not_active Expired - Lifetime

- 2003-06-03 AT AT03012603T patent/ATE346403T1/de not_active IP Right Cessation

- 2003-06-03 DE DE50305747T patent/DE50305747D1/de not_active Expired - Fee Related

-

2004

- 2004-05-27 US US10/855,152 patent/US7077703B2/en not_active Expired - Fee Related

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0224200A2 (fr) * | 1985-11-22 | 1987-06-03 | STEWART STAMPING CORPORATION (a Connecticut Corporation) | Connecteur fiche et douille blindé |

| US4810210A (en) * | 1987-02-12 | 1989-03-07 | Hosiden Electronics Co., Ltd. | Multipin connector |

| US4900262A (en) * | 1988-03-07 | 1990-02-13 | Hirose Electric Co., Ltd. | Lock mechanism for electrical connector |

| US5035652A (en) * | 1989-05-22 | 1991-07-30 | Hosiden Electronics Co., Ltd. | Multipin connector socket |

| US5171161A (en) * | 1991-05-09 | 1992-12-15 | Molex Incorporated | Electrical connector assemblies |

| EP0562311A2 (fr) * | 1992-03-25 | 1993-09-29 | Hosiden Corporation | Connecteur électrique multipolaire à fiches |

| US5545052A (en) * | 1992-08-19 | 1996-08-13 | Honda Tsushin Kogyo Kabushiki Kaisha | Electrical connector |

| EP0601265A2 (fr) * | 1992-12-11 | 1994-06-15 | Hosiden Corporation | Connecteur électrique multipolaire à douille |

| EP0738029A1 (fr) * | 1995-03-31 | 1996-10-16 | Molex Incorporated | Connecteur électrique avec verrouillage |

| US5634809A (en) * | 1995-08-21 | 1997-06-03 | Honda Tsushin Kogyo Kabushiki Kaisha Tsushin Kogyo Co. Ltd. | Connector with lock mechanism |

| US6007381A (en) * | 1997-08-08 | 1999-12-28 | Molex Incorporated | Circuit board connector with improved mounting characteristics |

| EP1028496A2 (fr) * | 1999-01-26 | 2000-08-16 | Molex Incorporated | Connecteur électrique avec dispositif de verrouillage et ressort métalique |

| US6431887B1 (en) * | 2000-05-31 | 2002-08-13 | Tyco Electronics Corporation | Electrical connector assembly with an EMI shielded plug and grounding latch member |

| US20020151205A1 (en) * | 2001-04-13 | 2002-10-17 | Huetter John P. | Apparatus and metod for cable connection retention |

Also Published As

| Publication number | Publication date |

|---|---|

| DE50305747D1 (de) | 2007-01-04 |

| DE50305800D1 (de) | 2007-01-04 |

| EP1585201B1 (fr) | 2006-11-22 |

| EP1484822B1 (fr) | 2006-11-22 |

| ATE346403T1 (de) | 2006-12-15 |

| US7077703B2 (en) | 2006-07-18 |

| US20040248467A1 (en) | 2004-12-09 |

| EP1484822A1 (fr) | 2004-12-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60027611T2 (de) | Kabelverbinder mit gesteuerter Impedanz | |

| DE69405493T2 (de) | Elektrischer Verbinder für gedruckte Schaltungen mit Befestigungselementen | |

| DE3650367T2 (de) | Abgeschirmter elektrischer Verbinder. | |

| EP1484822B1 (fr) | Connecteur | |

| DE3686879T2 (de) | Elektrischer verbinder und rastvorrichtung dafuer. | |

| DE19500959C2 (de) | Elektrischer Steckverbinder | |

| DE4112030C2 (fr) | ||

| DE3686859T2 (de) | Elektrischer verbinder und kabelendverschlussvorrichtung dafuer. | |

| DE69600063T2 (de) | Verbinder mit Sekundärverriegelung und Kupplungsvorrichtung | |

| DE102008038563B4 (de) | Verbinder | |

| DE4013189C2 (de) | Elektrische Steckverbindungsvorrichtung | |

| DE102009056517B4 (de) | Steckverbinderanordnung mit erstem und zweitem Stecker und Gegenstecker | |

| DE10221227A1 (de) | Steckverbinder mit Haltern | |

| DE10119695B4 (de) | Steckverbinder für elektronische Bauelemente | |

| DE4119685C2 (de) | Elektrische Steckverbindungsvorrichtung | |

| WO2008110190A2 (fr) | Connecteur électrique comprenant un couvercle antipoussière | |

| WO1996031920A1 (fr) | Connecteur a fiches pour cable plat | |

| DE69013734T2 (de) | Elektrischer Verbinder. | |

| EP1139493B1 (fr) | Connecteur électrique pour le raccordement de câbles à un appareil | |

| DE102012104857B4 (de) | Elektrische Steckverbindung | |

| EP0831559A2 (fr) | Connecteur à fiche | |

| DE102021129010A1 (de) | Kontaktträgereinrichtung, Anschlussvorrichtung, Betätiger, Steckverbindereinsatz und Montageverfahren sowie Kabelanschlusssystem | |

| EP1445840B1 (fr) | Connecteur Electrique | |

| EP1269579B1 (fr) | Connecteur a fiches pour conducteurs a bande plate | |

| WO2021004893A1 (fr) | Connecteur direct |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1484822 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20051118 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1484822 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50305800 Country of ref document: DE Date of ref document: 20070104 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070222 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070222 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070423 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20061122 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070823 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 |

|

| BERE | Be: lapsed |

Owner name: DELPHI TECHNOLOGIES, INC. Effective date: 20070630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070603 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080624 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080612 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080617 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070523 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061122 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090603 |