EP1580331B1 - Undercarriage for mobile working machines - Google Patents

Undercarriage for mobile working machines Download PDFInfo

- Publication number

- EP1580331B1 EP1580331B1 EP20050006586 EP05006586A EP1580331B1 EP 1580331 B1 EP1580331 B1 EP 1580331B1 EP 20050006586 EP20050006586 EP 20050006586 EP 05006586 A EP05006586 A EP 05006586A EP 1580331 B1 EP1580331 B1 EP 1580331B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- support

- continuous

- mobile

- mobile unit

- devices

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C23/00—Cranes comprising essentially a beam, boom, or triangular structure acting as a cantilever and mounted for translatory of swinging movements in vertical or horizontal planes or a combination of such movements, e.g. jib-cranes, derricks, tower cranes

- B66C23/62—Constructional features or details

- B66C23/72—Counterweights or supports for balancing lifting couples

- B66C23/78—Supports, e.g. outriggers, for mobile cranes

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02F—DREDGING; SOIL-SHIFTING

- E02F9/00—Component parts of dredgers or soil-shifting machines, not restricted to one of the kinds covered by groups E02F3/00 - E02F7/00

- E02F9/08—Superstructures; Supports for superstructures

- E02F9/085—Ground-engaging fitting for supporting the machines while working, e.g. outriggers, legs

Definitions

- the invention relates to an undercarriage for mobile machines with extendable support devices according to the preamble of claim 1.

- Mobile work machines such as hydraulic excavators, rope excavators and other earthmoving machines or handling equipment usually have an undercarriage, on which the driving devices, for example, the wheels or for example chain drives are arranged. Furthermore, the undercarriage usually has a receiving plate for a slewing ring bearing, on which the superstructure belonging to the revolving stage with slewing gear can be placed.

- This known construction has a large manufacturing effort, in particular due to the extensive components and bearings.

- the track width of the working machine is usually determined by the undercarriage and the chassis hinged thereto.

- a mobile crane with an undercarriage according to the preamble of claim 1 known.

- a mobile on rubber tires wheels crane described with a main frame, the same time the undercarriage forms.

- On the main frame are lowered to a lower support feet provided.

- four support arms are hinged to the main frame, which can be transferred from a folded into an unfolded position.

- the support arms also carry appropriate outriggers.

- the publication FR-A-1 494 349 shows an undercarriage for a crane that can be towed or moved by means of a towing vehicle.

- the chassis in the front and rear area driver devices, wherein in the central region pivotable arms are arranged on the chassis.

- the publication DE 1 209 259 refers to a gantry crane, whose framework consists of two parts interconnected by a hinge joint with field jockey axis, which can be pivoted against each other to change the portal width scissor-like.

- the publication GB 2 135 273 A relates to a mobile crane with a chassis on which a supporting device is rotatably arranged in the region of the front drive wheel.

- the publication DE 34 08 172 A1 relates to a crane having a main frame and ground engaging wheels disposed along the length of the frame on each side thereof for supporting the frame for travel along the ground.

- the publication EP 1 382 560 A1 refers to a vehicle crane whose undercarriage has a central box as a support structure, are formed on the three swing-out support beams.

- Object of the present invention is to develop a generic undercarriage such that bearings and components can be saved and thus a low manufacturing cost, which leads to a minimization of manufacturing costs, is possible.

- an undercarriage for mobile machines is provided with executable support means with a first continuous rigid support on which a part of the support devices is arranged and on which a further continuous support is pivoted articulated carrying the rest of the support means.

- a main drive means is arranged centrally on the first continuous carrier, the first continuous rigid carrier being oriented obliquely to the longitudinal axis of the undercarriage fixed by the main drive means and the further continuous carrier being point symmetrical to a real or imaginary pivot point aligned with the continuous rigid carrier, which also Carrying facilities.

- This new design dissolves from the usual construction concept of the undercarriage, which usually consisted of a complex welded construction with rigidly arranged side members and these interconnecting cross members on which the slewing ring bearings, existed. Characterized in that the support means are arranged directly on the continuous rigid support and on the continuous support connected to it, a direct power flow from the superstructure is made possible in the support means, which is a technical implementation of the tree root principle. This design saves bearing points and components, which on the one hand leads to a lower manufacturing cost and thus to lower production costs.

- variable track width can also be adjusted under load. In desired positions can then be supported by appropriate extension of the support of the entire undercarriage.

- the continuous rigid support may be connected via a rotary joint in the real pivot point with the second continuous rigid support. It can be arranged in the region of the connecting axis between the two carriers, a main driving device, in which case can be arranged on the respective carriers additional Hilfsfahr wornen in the form of support rollers.

- the continuous rigid support is connected to two laterally swingable carriers.

- the carriers can accommodate actively steered wheel sets as driving devices.

- the further continuous carrier can be swung out via drive means, such as piston-cylinder arrangements, threaded spindles or gear.

- the additional continuous carrier can be fixed in its respective position by means of locking means, such as multi-disc brakes or bolts.

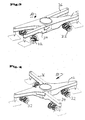

- an undercarriage 10 which is a rigidly continuous support 12 which is pivotally connected via a rotary connection not shown here in detail with a second continuous rigid support 14.

- support devices 20 At or after the respective ends of the continuous rigid support 12 and 14 support devices 20 are arranged, which consist essentially of support plates 22, which are on adjusting or 24 retractable.

- the continuous rigid support 12 and 14 which are connected to each other via ball slewing rings, centered on each pivot bearing 26.

- On the turntable bearing 26 of the rigid continuous support 14 can put on the turntable of the upper carriage of the working machine in the usual way. Since these are known constructions, this is not shown in more detail in the drawing.

- a single-wheel drive with individual wheels 18 is arranged.

- the driving stability results from four support rollers 30, which are each arranged on the arms of the rigid support 12 and 14 respectively.

- the undercarriage is shown in a driving position while in Fig. 4 the undercarriage is shown in the working position, in which the rigid support 12 and 14 are pivoted against each other and in a support position. In this case, the rigid support 12 and 14 are pivoted so far that they occupy a nearly right angle to each other.

- the first continuous rigid support 12 is not aligned in the imaginary longitudinal axis of the undercarriage, but obliquely to this, so that here results in an asymmetrical arrangement with respect to a possible axis symmetry imaginary longitudinal axis of the undercarriage.

- the second continuous carrier 14 is arranged point-symmetrical to the first carrier arm 12.

- FIG. 3 A similar symmetry results from the construction of the undercarriage not according to the invention Fig. 3 , This has a likewise asymmetric continuous rigid support 12 on which divided support arms 34 and 36 are each pivotally articulated. A pivoting of the support arms takes place here in manner not shown on adjusting means, which may include drive means such as piston-cylinder assemblies, threaded spindles or gear.

- the split support arms shown here can be fixable in their respective position via locking means, such as multi-disc brakes or in the simplest case bolts (not shown here in detail).

- active wheel sets 32 are arranged on the respective support arms.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Vehicle Cleaning, Maintenance, Repair, Refitting, And Outriggers (AREA)

- Jib Cranes (AREA)

- Forklifts And Lifting Vehicles (AREA)

- Non-Deflectable Wheels, Steering Of Trailers, Or Other Steering (AREA)

Description

Die Erfindung betrifft einen Unterwagen für mobile Arbeitsmaschinen mit ausfahrbaren Abstützeinrichtungen nach dem Oberbegriff des Anspruchs 1.The invention relates to an undercarriage for mobile machines with extendable support devices according to the preamble of claim 1.

Mobile Arbeitsmaschinen, wie beispielsweise Hydraulikbagger, Seilbagger und andere Erdbewegungsmaschinen bzw. Umschlaggeräte haben üblicherweise einen Unterwagen, an welchem die Fahreinrichtungen, beispielsweise also die Räder oder beispielsweise Kettenlaufwerke angeordnet sind. Weiterhin weist der Unterwagen in der Regel eine Aufnahmeplatte für ein Drehkranzlager auf, auf welchem die zum Oberwagen gehörige Drehbühne mit Schwenkwerk aufsetzbar ist. Diese bekannte Konstruktion weist insbesondere aufgrund der umfangreichen Bauteile und Lagerstellen einen großen Fertigungsaufwand auf.Mobile work machines, such as hydraulic excavators, rope excavators and other earthmoving machines or handling equipment usually have an undercarriage, on which the driving devices, for example, the wheels or for example chain drives are arranged. Furthermore, the undercarriage usually has a receiving plate for a slewing ring bearing, on which the superstructure belonging to the revolving stage with slewing gear can be placed. This known construction has a large manufacturing effort, in particular due to the extensive components and bearings.

Im Übrigen ist durch den Unterwagen und die daran angelenkten Fahrwerke die Spurbreite der Arbeitsmaschine in der Regel festgelegt.Incidentally, the track width of the working machine is usually determined by the undercarriage and the chassis hinged thereto.

Aus der

Die Druckschrift

Die Druckschrift

Die Druckschrift

Die Druckschrift

Die Druckschrift

Aufgabe der vorliegenden Erfindung ist es, einen gattungsgemäßen Unterwagen derart weiterzubilden, dass Lagerstellen und Bauteile eingespart werden können und somit ein geringer Fertigungsaufwand, der zu einer Minimierung der Herstellkosten führt, ermöglicht wird.Object of the present invention is to develop a generic undercarriage such that bearings and components can be saved and thus a low manufacturing cost, which leads to a minimization of manufacturing costs, is possible.

Erfindungsgemäß wird diese Aufgabe durch die Kombination der Merkmale des Anspruchs 1 gelöst. Demnach wird ein Unterwagen für mobile Arbeitsmaschinen mit ausführbaren Abstützeinrichtungen mit einem ersten durchgehenden starren Träger ausgestattet, an dem ein Teil der Abstützvorrichtungen angeordnet ist und an dem ein weiterer durchgehender Träger ausschwenkbar angelenkt ist, die die restlichen Abstützeinrichtungen tragen. Erfindungsgemäß ist mittig am ersten durchgehenden Träger eine Hauptfahreinrichtung angeordnet, wobei der erste durchgehende starre Träger schräg zur durch die Hauptfahreinrichtung festgelegte Längsachse des Unterwagens ausgerichtet und der weitere durchgehende Träger ist punktsymmetrisch zu einem realen oder gedachten Schwenkpunkt auf den durchgehenden starren Träger ausgerichtet, wobei dieser ebenfalls Fahreinrichtungen trägt. Diese neue Konstruktion löst sich von dem üblichen Baukonzept des Unterwagens, der in der Regel aus einer komplexen Schweißkonstruktion mit starr zueinander angeordneten Längsträgern und diese miteinander verbindenden Querträgern, auf dem das Drehkranzlager lagert, bestand. Dadurch, dass an dem durchgehenden starren Träger und an dem mit ihm verbundenen durchgehenden Träger unmittelbar die Abstützeinrichtungen angeordnet sind, wird ein direkter Kraftfluss vom Oberwagen in die Abstützeinrichtungen ermöglicht, was eine technische Umsetzung des Baumwurzelprinzips darstellt. Diese Konstruktionsweise spart Lagerstellen und Bauteile ein, was einerseits zu einem geringeren Fertigungsaufwand und damit auch zu geringeren Herstellungskosten führt. Aufgrund der schrägen und damit asymmetrischen Ausrichtungen des ersten Trägers und der entsprechenden punktsymmetrischen Zuordnung des entweder zweiten starren Trägers wobei dieser jeweils ebenfalls Fahreinrichtungen trägt, ist durch Verschwenken der Träger zueinander eine variable Spurbreite möglich. Diese variable Spurbreite kann auch unter Last eingestellt werden. In gewünschten Stellungen kann dann durch entsprechendes Ausfahren der Abstützvorrichtung der gesamte Unterwagen abgestützt werden.According to the invention this object is achieved by the combination of the features of claim 1. Accordingly, an undercarriage for mobile machines is provided with executable support means with a first continuous rigid support on which a part of the support devices is arranged and on which a further continuous support is pivoted articulated carrying the rest of the support means. According to the invention, a main drive means is arranged centrally on the first continuous carrier, the first continuous rigid carrier being oriented obliquely to the longitudinal axis of the undercarriage fixed by the main drive means and the further continuous carrier being point symmetrical to a real or imaginary pivot point aligned with the continuous rigid carrier, which also Carrying facilities. This new design dissolves from the usual construction concept of the undercarriage, which usually consisted of a complex welded construction with rigidly arranged side members and these interconnecting cross members on which the slewing ring bearings, existed. Characterized in that the support means are arranged directly on the continuous rigid support and on the continuous support connected to it, a direct power flow from the superstructure is made possible in the support means, which is a technical implementation of the tree root principle. This design saves bearing points and components, which on the one hand leads to a lower manufacturing cost and thus to lower production costs. Due to the oblique and thus asymmetrical orientations of the first carrier and the corresponding point-symmetrical assignment of either the second rigid carrier which also carries each driving means is by pivoting the carrier to each other a variable track width possible. This variable track width can also be adjusted under load. In desired positions can then be supported by appropriate extension of the support of the entire undercarriage.

Bevorzugte Ausgestaltungen der Erfindung ergeben sich aus den sich an den Hauptanspruch anschließenden Unteransprüchen.Preferred embodiments of the invention will become apparent from the subsequent claims to the main claim.

So kann der durchgehende starre Träger über eine Drehverbindung im realen Schwenkpunkt mit dem zweiten durchgehenden starren Träger verbunden sein. Es kann eine Hauptfahreinrichtung im Bereich der Verbindungsachse zwischen den beiden Trägern angeordnet sein, wobei dann an den jeweiligen Trägern zusätzliche Hilfsfahreinrichtungen in Form von Stützrollen angeordnet sein können.Thus, the continuous rigid support may be connected via a rotary joint in the real pivot point with the second continuous rigid support. It can be arranged in the region of the connecting axis between the two carriers, a main driving device, in which case can be arranged on the respective carriers additional Hilfsfahreinrichtungen in the form of support rollers.

Gemäß einer alternativen Ausführungsform ist der durchgehende starre Träger mit zwei seitlich ausschwenkbaren Trägern verbunden.According to an alternative embodiment, the continuous rigid support is connected to two laterally swingable carriers.

Vorteilhaft können die Träger als Fahreinrichtungen aktiv gelenkte Radsätze aufnehmen.Advantageously, the carriers can accommodate actively steered wheel sets as driving devices.

Gemäß einer weiteren vorteilhaften Ausbildung der Erfindung können der weitere durchgehende Träger über Antriebsmittel, wie Kolben-Zylinderanordnungen, Gewindespindeln oder Getriebe ausschwenkbar sein. Der weitere durchgehende Träger Kann über Feststellmittel, wie Lamellenbremsen oder Bolzen, in ihrer jeweiligen Position festlegbar sein.According to a further advantageous embodiment of the invention, the further continuous carrier can be swung out via drive means, such as piston-cylinder arrangements, threaded spindles or gear. The additional continuous carrier can be fixed in its respective position by means of locking means, such as multi-disc brakes or bolts.

Weitere Merkmale, Einzelheiten und Vorteile der Erfindung werden anhand der in der Zeichnung dargestellten Ausführungsbeispiele näher erläutert.Further features, details and advantages of the invention will be explained in more detail with reference to the embodiments illustrated in the drawings.

Es zeigen:

- Fig. 1:

- eine Ausführungsform des erfindungsgemäßen Unterwagens in Fahrstellung,

- Fig. 2:

- Ausführungsform gemäß

Fig. 1 in Arbeitsstellung, - Fig. 3:

- eine nicht erfindungsgemäße Ausführungsvariante eines Unterwagens in Fahrstellung und

- Fig. 4:

- die Ausführungsvariante gemäß

Fig. 3 in Arbeitsstellung.

- Fig. 1:

- an embodiment of the undercarriage according to the invention in driving position,

- Fig. 2:

- Embodiment according to

Fig. 1 in working position, - 3:

- a non-inventive embodiment of a undercarriage in driving position and

- 4:

- the embodiment according to

Fig. 3 in working position.

In den

Die durchgehenden starren Träger 12 und 14, die über Kugeldrehkränze miteinander verbunden sind, weisen mittig jeweils Drehkranzlager 26 auf. Auf dem Drehkranzlager 26 des starren durchgehenden Trägers 14 kann in üblicher Weise die Drehbühne des Oberwagens der Arbeitsmaschine aufsetzen. Da es sich hier um bekannte Konstruktionen handelt, wird dies nicht näher in der Zeichnung dargestellt.The continuous

Mittels einer weiteren hier nicht näher dargestellten Drehverbindung, die in einer Achse mit der zuvor genannten Drehverbindung angeordnet ist, ist ein Einzelradantrieb mit Einzelrädern 18 angeordnet. Im hier vorliegenden Fall sind nur zwei Einzelräder vorhanden. Die Fahrstabilität ergibt sich durch jeweils vier Stützrollen 30, die jeweils an den Armen der starren Träger 12 bzw. 14 angeordnet sind. In

Wie in der

Eine ähnliche Symmetrie ergibt sich aus der nicht erfindungsgemäßen Konstruktion des Unterwagens entsprechend der

Im hier dargestellten Ausführungsbeispiel sind an den jeweiligen Trägerarmen aktive gelenkte Radsätze 32 angeordnet.In the embodiment shown here active wheel sets 32 are arranged on the respective support arms.

Claims (7)

- A mobile unit (10) for mobile machines having extensible support devices (20) comprising a first, continuous rigid support (12) on which travel devices (30) and some of the support devices (20) are arranged and on which a further continuous support (14), which supports the remaining support devices (20), is outwardly pivotably linked,

characterized in that

a main travel device (18) is disposed centrally at the first, continuous rigid support (12), with the first, continuous rigid support (12) being aligned at an angle to the longitudinal axis of the mobile unit defined by the main travel device (18) in travel position; and in that the further continuous support (14) is aligned with point symmetry to a real pivot point on the first continuous rigid support (12), with it likewise supporting travel devices (30, 32). - A mobile unit (10) for mobile machines in accordance with claim 1, wherein the first, continuous rigid support (12) is connected to the second, continuous rigid support (14) via a rotary joint at the real pivot point.

- A mobile unit (10) for mobile machines in accordance with claim 2, wherein the main travel device (18) is arranged in the region of the connection axis between both continuous supports (12, 14).

- A mobile unit (10) for mobile machines in accordance with claim 3, wherein support rollers (30) are arranged as travel devices on the respective continuous supports (12, 14).

- A mobile unit (10) for mobile machines in accordance with any of claims 1 - 4, wherein the supports (12, 14, 34, 36) have actively steered wheel sets (30, 32) as travel devices.

- A mobile unit (10) for mobile machines in accordance with any of claims 1 - 5, wherein the further continuous support (14) is outwardly pivotable via drive means such as piston-in-cylinder arrangements, threaded spindles or transmissions.

- A mobile unit (10) for mobile machines in accordance with any of claims 1 - 6, wherein the further continuous support (14) is fixable in its respective position via fixing means such as multi-plate brakes or bolts.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202004004714U DE202004004714U1 (en) | 2004-03-25 | 2004-03-25 | Undercarriage for mobile machines |

| DE202004004714U | 2004-03-25 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1580331A2 EP1580331A2 (en) | 2005-09-28 |

| EP1580331A3 EP1580331A3 (en) | 2006-09-27 |

| EP1580331B1 true EP1580331B1 (en) | 2015-05-20 |

Family

ID=34854228

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20050006586 Expired - Lifetime EP1580331B1 (en) | 2004-03-25 | 2005-03-24 | Undercarriage for mobile working machines |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US7478835B2 (en) |

| EP (1) | EP1580331B1 (en) |

| DE (1) | DE202004004714U1 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9284168B2 (en) * | 2009-10-01 | 2016-03-15 | Mw Industries, Inc. | Guyless service rig with side-mounted, pivotally deployable rear outriggers |

| US8176665B2 (en) * | 2009-12-28 | 2012-05-15 | Peter Petrovic | Portable target stand for signage |

| EP2466016A1 (en) | 2010-12-14 | 2012-06-20 | Caterpillar, Inc. | Frame assembly and a method of manufacturing thereof |

| US8684372B2 (en) * | 2012-06-26 | 2014-04-01 | Luca Buttazzoni | Modular dolly kit |

| US8850656B2 (en) | 2012-06-26 | 2014-10-07 | Luca Buttazzoni | Castor assembly for a modular dolly |

| US9010798B2 (en) | 2012-07-23 | 2015-04-21 | Luca Buttazzoni | Self-contained dolly assembly |

| US9409585B2 (en) | 2013-07-15 | 2016-08-09 | Luca Buttazzoni | Castor supported dolly assembly capable of being made from lightweight materials and of being used as a pallet assembly |

| US8876145B1 (en) | 2013-07-15 | 2014-11-04 | Luca Buttazzoni | Castor supported dolly assembly capable of being made from lightweight materials and so as to be disposable or severable |

| US8910955B1 (en) | 2013-12-03 | 2014-12-16 | Luca Buttazzoni | Lightweight dolly assembly |

| DE102015226314A1 (en) * | 2015-12-21 | 2017-06-22 | Terex Global Gmbh | Modular crane, transport unit for a modular crane and method of operating such a crane |

| US9868620B1 (en) * | 2016-06-22 | 2018-01-16 | James Alford Flippin | Expandable car jack |

| CN108980546B (en) * | 2018-08-13 | 2021-03-23 | 李丽莎 | Electronic whiteboard bracket capable of automatically adjusting height and width |

| DE102019116809B4 (en) * | 2019-06-21 | 2024-11-28 | Hubtex Maschinenbau Gmbh & Co. Kg | Transport vehicle, method for picking up a load by a transport vehicle and system with a transport vehicle and a load |

| US11535500B1 (en) * | 2021-08-31 | 2022-12-27 | Crossjack Llc | Expandable car jack |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1209259A (en) | 1958-07-16 | 1960-03-01 | Method of manufacturing a tubular filter with a pleated wall and filter thus obtained | |

| DE1209259B (en) * | 1962-07-24 | 1966-01-20 | Beteiligungs & Patentverw Gmbh | Gantry crane |

| FR1494349A (en) * | 1966-07-19 | 1967-09-08 | Potain & Cie Ets F | Improvements to towable tower crane frames |

| FR1582095A (en) * | 1968-06-07 | 1969-09-26 | ||

| DE2142750A1 (en) * | 1971-08-26 | 1973-04-12 | Krupp Gmbh | TRUCK CRANE |

| DE2807518C3 (en) * | 1978-02-22 | 1981-09-24 | Habegger, Willy, Hünibach | Wheel suspension for a traveling and walking gear |

| DE2807519C2 (en) * | 1978-02-22 | 1983-10-20 | Habegger, Willy, Hünibach | Driving and walking gear |

| US4394913A (en) * | 1980-11-07 | 1983-07-26 | Harnischfeger Corporation | Crane having power operated outriggers and lock means therefor |

| DE3336638C2 (en) * | 1982-10-12 | 1987-04-16 | Fried. Krupp Gmbh, 4300 Essen | High-capacity mobile crane with extendable boom, especially telescopic boom |

| FR2534237B1 (en) * | 1982-10-12 | 1987-10-23 | Krupp Gmbh | HIGH-STRENGTH ROLLING CRANE WITH EXTENDABLE BOOM, ESPECIALLY WITH TELESCOPIC BOOM |

| FR2541259B1 (en) * | 1983-02-23 | 1986-11-14 | Ppm Sa | MOBILE MACHINE, SUCH AS A MOBILE CRANE, COMPRISING A TURRET AND A SET OF STABILIZERS |

| US4496062A (en) * | 1983-03-07 | 1985-01-29 | Harnischfeger Corporation | Crane having stabilizing outriggers |

| US5029895A (en) * | 1989-07-11 | 1991-07-09 | Schwing America, Inc. | Outrigger-mounted axle assembly |

| EP1008549A3 (en) * | 1998-12-09 | 2000-08-02 | Compact Truck AG | Vehicle mounted crane |

| DE10233813A1 (en) * | 2002-07-19 | 2004-02-19 | Terex-Demag Gmbh & Co. Kg | Mobile crane with swivel beams |

-

2004

- 2004-03-25 DE DE202004004714U patent/DE202004004714U1/en not_active Expired - Lifetime

-

2005

- 2005-03-24 EP EP20050006586 patent/EP1580331B1/en not_active Expired - Lifetime

- 2005-03-25 US US11/089,638 patent/US7478835B2/en not_active Expired - Lifetime

-

2008

- 2008-12-09 US US12/316,103 patent/US20090167008A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| US20050211862A1 (en) | 2005-09-29 |

| US20090167008A1 (en) | 2009-07-02 |

| US7478835B2 (en) | 2009-01-20 |

| EP1580331A3 (en) | 2006-09-27 |

| DE202004004714U1 (en) | 2005-09-08 |

| EP1580331A2 (en) | 2005-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1580331B1 (en) | Undercarriage for mobile working machines | |

| DE3912194C2 (en) | vehicle | |

| DE102016008822B4 (en) | Mobile crane with adjustable ballast take-up device | |

| DE102008032739B4 (en) | Mobile crane and method of assembly | |

| EP1008549A2 (en) | Vehicle mounted crane | |

| EP1925754B1 (en) | Rail-road excavator | |

| DE29713081U1 (en) | Header with support wheels | |

| EP1466856A2 (en) | Mobile crane with outrigger structure | |

| EP4232300B1 (en) | Chassis and its use | |

| DE29613415U1 (en) | Crane vehicle | |

| EP3718823B1 (en) | Device for holding an end of an elongated object, in particular a self-supporting load, and vehicle using this device | |

| DE2140233B2 (en) | MULTI-AXLE MOBILE CRANE | |

| EP2886505B1 (en) | Crane | |

| DE102008006119B3 (en) | Mobile crane has upper structure, on which boom is hinged to teeter around horizontal axis, and cabin that is provided for crane operator, which is arranged on upper structure pivoting over sluing mechanism | |

| EP2944166A1 (en) | Trolley of an agricultural machine | |

| DE2837398A1 (en) | Self-propelled crane for heavy loads - has steerable multi-axle trailer to carry rear outrigger support legs | |

| EP3174779B1 (en) | Heavy load transport vehicle of variable width | |

| DE4446047A1 (en) | Aircraft towing vehicle | |

| DE4215599C2 (en) | Compost turning machine | |

| DE102012001377B4 (en) | Ballast truck for a derrick crane | |

| DE2513297B2 (en) | ROTARY TREATMENT MACHINE WITH A THREE-POINT FRAME FOR OPTIONAL AT THE FRONT OR REAR MOUNTING TO A TRACTOR | |

| DE9417893U1 (en) | mower | |

| DE202008015729U1 (en) | Support for wheeled excavators | |

| DE3814690C2 (en) | Haymaking machine with work tools that can be folded up for transport | |

| DE102011122582B4 (en) | Crane with spacer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: AUTENRIETH, OLIVER |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E02F 9/08 20060101ALI20060823BHEP Ipc: E02F 9/02 20060101AFI20050706BHEP Ipc: B66C 23/78 20060101ALI20060823BHEP |

|

| 17P | Request for examination filed |

Effective date: 20061025 |

|

| 17Q | First examination report despatched |

Effective date: 20070327 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150219 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: AUTENRIETH, OLIVER |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: AUTENRIETH, OLIVER |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 727832 Country of ref document: AT Kind code of ref document: T Effective date: 20150615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502005014794 Country of ref document: DE Effective date: 20150625 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150921 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150821 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150820 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150920 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502005014794 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150520 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| 26N | No opposition filed |

Effective date: 20160223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160324 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160324 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 727832 Country of ref document: AT Kind code of ref document: T Effective date: 20160324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160324 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20050324 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150520 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20180330 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190324 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230607 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240320 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20240326 Year of fee payment: 20 Ref country code: GB Payment date: 20240320 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20240326 Year of fee payment: 20 Ref country code: FR Payment date: 20240321 Year of fee payment: 20 Ref country code: BE Payment date: 20240320 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240403 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502005014794 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20250323 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20250323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20250323 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20250324 |