EP1574641B1 - Dispositif de fermeture pour conteneurs, portes, armoires, meubles ou similaires - Google Patents

Dispositif de fermeture pour conteneurs, portes, armoires, meubles ou similaires Download PDFInfo

- Publication number

- EP1574641B1 EP1574641B1 EP04029499A EP04029499A EP1574641B1 EP 1574641 B1 EP1574641 B1 EP 1574641B1 EP 04029499 A EP04029499 A EP 04029499A EP 04029499 A EP04029499 A EP 04029499A EP 1574641 B1 EP1574641 B1 EP 1574641B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- lock

- locking

- locking device

- specified

- combination

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 230000008878 coupling Effects 0.000 claims abstract description 9

- 238000010168 coupling process Methods 0.000 claims abstract description 9

- 238000005859 coupling reaction Methods 0.000 claims abstract description 9

- 230000000903 blocking effect Effects 0.000 claims description 15

- 238000006073 displacement reaction Methods 0.000 claims description 5

- 230000000284 resting effect Effects 0.000 claims 2

- 230000000994 depressogenic effect Effects 0.000 claims 1

- 230000002093 peripheral effect Effects 0.000 description 8

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000011161 development Methods 0.000 description 3

- 230000018109 developmental process Effects 0.000 description 3

- 230000007774 longterm Effects 0.000 description 2

- 241000196324 Embryophyta Species 0.000 description 1

- 244000023431 Proboscidea parviflora Species 0.000 description 1

- 235000019096 Proboscidea parviflora Nutrition 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B37/00—Permutation or combination locks; Puzzle locks

- E05B37/02—Permutation or combination locks; Puzzle locks with tumbler discs or rings arranged on a single axis, each disc being adjustable independently of the others

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B13/00—Devices preventing the key or the handle or both from being used

- E05B13/10—Devices preventing the key or the handle or both from being used formed by a lock arranged in the handle

- E05B13/103—Combination lock

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B13/00—Devices preventing the key or the handle or both from being used

- E05B13/10—Devices preventing the key or the handle or both from being used formed by a lock arranged in the handle

- E05B13/101—Devices preventing the key or the handle or both from being used formed by a lock arranged in the handle for disconnecting the handle

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B37/00—Permutation or combination locks; Puzzle locks

- E05B37/0031—Locks with both permutation and key actuation

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B37/00—Permutation or combination locks; Puzzle locks

- E05B37/0048—Permutation or combination locks; Puzzle locks with changeable combination

- E05B37/0058—Permutation or combination locks; Puzzle locks with changeable combination by axial disengagement between hub and rim of tumbler discs or rings

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B37/00—Permutation or combination locks; Puzzle locks

- E05B37/0075—Automatic scrambling

- E05B37/0079—Automatic scrambling when unlocking

Definitions

- the invention relates to a locking device for containers, doors, cabinets, furniture or the like., With a lock carrier on which a combination lock is arranged, and a fixed part, in relation to which the lock carrier is rotatably arranged with the combination lock.

- Known such locking devices usually have a closed and an open position, between which a rotary handle or lock carrier of the closing device can be moved or rotated.

- the rotation of the lock carrier is usually limited by stop or limiting elements, these stop and limiting elements are often part of the locking or blocking serving components of the locking device or yet in direct technical and constructive connection to such the locking or blocking serving components stand.

- stop or limiting elements are often part of the locking or blocking serving components of the locking device or yet in direct technical and constructive connection to such the locking or blocking serving components stand.

- a locking device to which a button belongs, which is freely rotatable with respect to a fixed part, here a housing.

- the button has an adjustment ring for a key secret and is rotatably connected by means of a drive element with a combination lock, which includes shims, via a correspondingly shaped annular projection of the button-side shim of the combination lock.

- a nose of a pawl which is pivotally hinged to a plate connected to the lock plate and biased by a spring in the direction of the axes of the shims, engage in the mutually aligned recesses of the shims of the combination lock.

- a drive connection between the button on the one hand and the plate or the associated lock bolt is created on the other hand, so that the lock bolt is adjustable.

- the shims of the combination lock are either not or only against the system pressure, which is exerted by the spring-loaded pawl on the outer peripheral surface of the shims, rotatable.

- the DE 197 19 392 A1 shows a locking device in which the provided with a combination lock lock carrier or the lock housing with not set key secret of the combination lock in the direction of rotation with respect to a fixed part acting base knob is fixed, as provided at one end to a coupling slide of the combination lock double jaw is in locking engagement with recesses of a support plate of the base knob.

- a rotation or pivoting of the lock carrier or housing is only and only possible if spent at the combination lock key secret of the coupling slide in its engagement between its coupling insert and the handle mandrel side coupling square producing operating position, since then turn the double claw out of engagement with the basisknaufnessen recesses is.

- the invention is based on the object, a locking device for containers, doors, cabinets, furniture or the like. the type described above such that mechanical stresses on the components of the locking device are significantly reduced and that in particular the locking or blocking serving components of the locking device to a much lesser extent than in the prior art or no longer mechanically stressed.

- this is provided with a secondary lock, which is arranged with the combination lock on the lock carrier.

- the secondary lock can be used, for example, to find a lost key secret of the combination lock again, or the secondary lock can be a so-called.

- Lock with master key function by means of which the locking device can also be spent in its open position, if the key secret is not set on the combination lock.

- the combination lock has a locking piece, which comes in at the combination lockberichtgeheimnis in engagement with a locking bolt on which a closing member of the locking device is mounted and which is rotatable with him in engagement locking piece with the lock carrier.

- the key lock is not set on the combination lock, there is no intervention between the number lock-side locking piece and the locking bolt of the locking device in this embodiment. Any mechanical stresses on the locking bolt or of components connected to it are thus reliably excluded when the lock carrier is rotated when the key secret is not set on the combination lock. Only when the engagement between the number lock side locking piece and the locking bolt is made, the locking bolt can be actuated by rotation of the lock carrier, with the result that the locking device can be brought into its open position.

- the locking piece has a nose which is pressed in the key lock set on the combination lock in the direction of the locking bolt and engages with a recess thereof when the Nose and the recess of the locking bolt are aligned.

- any mechanical stress on the locking piece or the nose thereof can be excluded if a positioning device is arranged between the lock carrier and the fixed part, by means of which the lock carrier can be positioned with respect to the fixed part or the locking bolt in a rotational position in which the locking piece and the lock bolt are engageable.

- the positioning device can be formed in a structurally technically less complicated manner as a ball catch with a recess formed in the lock carrier or fixed part and a salary on the fixed part or the lock carrier ball, wherein the ball is biased by a biasing spring in the direction of the lock carrier or the fixed part.

- the secondary lock can be advantageously designed as a cylinder lock, in which case the key of the cylinder lock can virtually serve as a master key.

- the solid part of the locking device according to the invention can be conveniently as a simple way on the container, the door, the cabinet, the furniture or the like.

- form attachable sub-plate said sub-plate can be accommodated in a cylindrical housing which is rotatable with the lock carrier with respect to the lower plate.

- the locking device is advantageously provided with a sliding latch, which presses by means of the secondary lock from its rest position to its operating position in which it presses the locking piece of the combination lock out of engagement with clutch discs of number wheels of the combination lock, and by means of a spring in its rest position is biased.

- the locking device is equipped with a slotted guide, which is formed on the inside of a cylindrical wall of the lower plate and by means of the locking piece of Combination lock with rotation of the lock carrier with respect to the lower plate is out of contact with clutch discs of number wheels of the combination lock can be pressed.

- the number wheels are adjusted when lifting the system between the locking piece on the one hand and the outer peripheral surfaces of the clutch discs on the other hand provided by a multi-function spring spring arms, the spring arms of the multifunction spring cooperate with connected to the clutch discs and thus the number wheels actuators, the are shaped so that by means of the spring arms, a rotation of the clutch discs and thus the number wheels takes place on an axis of the combination lock.

- a right or a left turn of the locking bolt of the locking device may be appropriate.

- a clockwise or a left turn of the locking bolt of the locking device can be adjusted according to a further advantageous embodiment of the locking device according to the invention by means of a slide-back slider with a control cam, which can be brought into engagement with different arcuate Kulissenaus fundamentalesque in the locking bolt.

- This backdrop recesses may be arranged, for example, with different radius with respect to a center of the locking bolt.

- a second positioning device is arranged between the locking bolt and the lower plate, by means of which the locking bolt is in its closed position and in its right or left position Left open position with respect to the lower plate is positionable.

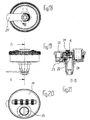

- the locking device is provided according to a further advantageous development of the invention with a Codierblech, to cancel the rotationally fixed engagement between the number wheels of Combination lock on the one hand and the clutch discs of the same on the other hand axially displaceable and in particular has a projection which is operable with the lock open and set to the combination lock key secret to the axial displacement of the Codierblechs.

- the authorized user of Locking device knows the key secret of the combination lock, so that he, if he wants a change of the key secret, can open the locking device, the key lock must be set on the combination lock.

- the projection provided on the coding plate can be actuated by means of a suitable tool.

- the Codierblech By displacement of the projection and thus the Codierblechs the rotationally fixed engagement between the number wheels and the clutch discs of the combination lock is released, so that the rotational position of each number wheel can be changed with respect to the associated clutch disc.

- the Codierblech can get back into his assumed release of the projection axial position, so that then the engagement between the number wheels and the clutch discs is restored and changed the key secret of the combination lock according to the adjustment of the number wheels with respect to the clutch discs is.

- the locking device according to the invention for furniture with unrestricted or overlapping doors, flaps, gates or the like. it is advantageous if the locking bolt is adjustable between a state locked on the fixed part and a movable state to the fixed part. If the locking bolt is then in its blocked state on the fixed part, it is not possible by means of a check card or the like., Or the like through the door, flap, Torschlitz. projects to the inside of the piece of furniture to move the locking bolt for the purpose of transferring the locking device in its open position. Opening the locking device in the manner indicated above is then not possible.

- the locking bolt is adjustable in his fixed to the fixed part state at the key lock set on the combination lock from its state locked on the fixed part. So if the currently valid key secret is set on the combination lock, the locking bolt is moved into its movable state to the fixed part.

- the locking bolt is adjustable by means of the secondary lock from its state locked to the fixed part in its movable state to the fixed part.

- a blocking element is provided according to an advantageous embodiment, which is arranged between the locking bolt and the fixed part.

- the blocking element is expediently designed as a pressure bolt, which is guided in the locking bolt and projects with a pin in a link device in a locking bolt facing side of the fixed part.

- the link device advantageously has a holding position in which the pin of the pressure bar can be fixed.

- the fixed part-side link device has a release groove into which the pin of the pressure bar is adjustable at key lock set on the combination lock.

- the fixed part-side link device has a further release groove into which the pin of the pressure bar is adjustable by means of the secondary lock.

- the closing device advantageously has a slide spring, by means of the pressure bolt from the first and / or the second release groove in the direction is biased to the holding position.

- a compression spring is advantageously provided by means of which the locking piece in a pin or the pressure bolt against the force the slider spring is biased out of the holding position in the first release groove-adjusting direction.

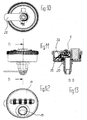

- FIG. 1 shown in exploded view embodiment of a locking device 1 according to the invention is used, for example, to close a not shown in the figures Office or other piece of furniture, such as a cabinet or the like., To close.

- the locking device 1 in the illustrated embodiment a combination lock 2, the four number wheels 3 are arranged rotatably about an axis 4 of the combination lock 2 around.

- These number wheels 3 are not seated directly on the axle 4, but between the number wheels 3 and the axle 4 are provided coaxially with the axle 4 and the number wheels 3 clutch plates 5, of which in each case one associated with a number wheel 3.

- the clutch discs 5 have a larger diameter portion, in the outer periphery of a recess 6 is formed.

- engaging members 7 are arranged on the outer peripheral surface. With the small diameter portion having the engaging elements 7, each clutch disc 5 protrudes in the axial direction in the assigned number wheel 3, wherein on the inner peripheral surface of each number wheel 3 receiving elements 8 are provided for the engagement elements 7 of the clutch disc 5.

- the clutch plate side engagement elements 7 can be placed in and out of engagement with the wheel side receiving elements 8. If the number wheels 3 are freely rotatable with respect to the clutch plates 5 and thus with respect to the axis 4, the key secret of the combination lock 2 can be set or changed. As soon as the engagement between the wheel-side receiving elements 8 and the coupling disk-side engagement elements 7 is then restored by a corresponding relative movement of the clutch disks 5, the new key secret is set on the combination lock 2.

- the Codierblech 9 For axial displacement of the clutch plates 5 is a Codierblech 9, which is accommodated in the axial direction of the axis 4 displaceable within a closing support 10.

- the Codierblech 9 has, as from FIG. 1 shows a down box-shaped cross-section, 9 recesses 11 are formed in the upper wall of the Codierblechs, through which the number wheels 3 protrude.

- Each recess 11 has at its in FIG. 1 Right boundary wall on a web 12 which is in the assembled state of the combination lock 2 each with a recess 6 of a clutch disc 5 in engagement.

- the Codierblech 9 is penetrated in its longitudinal direction through the axis 4, by means of the manner known in the prior art, the engagement between the clutch plates 5 and the number wheels 3 can be canceled.

- the above-described combination lock 2 with the components to be described below is supported by a designed as a cylindrical key lock secondary lock 13 on a provided with a cover plate 14 lock carrier 15.

- the combination lock 2 is connected to the lock carrier 15, the secondary lock 13 and connected to the lock carrier 15 cylindrical housing 16 with respect to a disposed within this cylindrical housing 16 lower plate 17 rotatably, wherein the lower plate 17 is arranged rotationally fixed with respect to the other components described above.

- the combination lock 2 with the components forming it is a total of the lower plate 17 rotatable, which in turn or the like in a suitable manner on the piece of furniture. is fixed.

- the coding plate 9 is provided with a projection 18 which is operable in itself in its open position befindaji locking device 1.

- a multi-function spring 19 is arranged, by means of which a above the multi-function spring 19 disposed within the lock carrier 10 locking piece 20 of the combination lock 2 is biased in the direction of its release position.

- the locking piece 20 is seated between the multi-function spring 19 and the Codierblech 9 and is located with its surface against the outer peripheral surfaces of the clutch plates 5 at. It can only assume its release position if, when set to the number wheels 3 key secret of the combination lock 2 according to the clutch plates 5 with their flattened outer peripheral portions 21 facing the locking piece 20. Then the latter by the multi-function spring 19 in FIG. 1 pushed upwards.

- the key secret of the combination lock 2 and the locking piece 20 is offset by means of the multifunction spring 19 upwards, engages in FIG. 1 obliquely downwardly extending nose 22 of the locking piece 20th in a recess 23 of a locking bolt 24, with the result that the locking bolt 24 is rotatable together with the combination lock 2 and the lock carrier 15 with respect to the lower plate 17.

- the locking bolt 24 extends through the lower plate 17 in the axial direction and is connected at its end projecting through the lower plate 17 with a closing member 25 which is adjustable by rotation of the locking bar 24 into and out of engagement with a lock latch, not shown in the figures.

- a positioning device is provided by means of the lock carrier 15 is positioned in a rotational position with respect to the lower plate 17, in which the nose 22 of the locking piece 20 of the combination lock 2 with the recess 23 of the locking bar 24th flees.

- This positioning device is designed in the form of a ball catch and has in the illustrated embodiment a biased by a biasing spring 26 in the direction of the lower plate 17 ball 27, wherein the biasing spring 26 and the ball 27 are arranged in a receiving groove 28 of the lock carrier 15.

- Associated with the ball 27 is a recess 29 on the end face of a cylindrical wall 30 of the lower plate 17.

- a sliding latch 31 is provided between the lock carrier 10 and the locking latch 24.

- the sliding bolt 31 has an approximately central recess 32 which is penetrated by a cylindrical projection 33 of the locking bolt 24.

- the shape of the recess 32 of the sliding latch 31 is selected so that the sliding latch 31 is reciprocable with respect to the cylindrical recess 33 of the locking bar.

- the sliding bolt 31 has an actuating portion 34 and - this diametrically opposite - a parking lug 35.

- the adjusting lug 35 of the sliding latch 31 In its rest position is the adjusting lug 35 of the sliding latch 31, as can be seen in particular FIG. 2 and the section B - B off FIG. 17 yields, out of engagement with the nose 22 of the locking piece 20, which abuts against the clutch plates 5 of the out of the key secret outlocked combination lock 2.

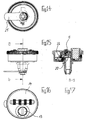

- the sliding latch 31 is in his in FIG. 6 and in FIG. 13 illustrated operating position adjustable by the secondary or cylinder lock 13 from his in FIG. 5 shown position in his in FIG. 9 shown position is rotated.

- the sliding latch 31 is acted upon by actuators 36 acting on its actuation section 34 and provided on the underside of the secondary or cylinder lock 13 in the actuators FIG. 6 shown position, against the force of a spring 37, by means of which the sliding latch 31 is biased in its rest position.

- the adjusting lug 35 comes into abutment against the nose 22 of the locking piece 20 and presses this nose 22 in the Drawing plane in FIG. 6 or to the right in FIG. 13 , with the result that the locking piece 20 gets out of engagement with the peripheral surfaces of the clutch discs 5 of the combination lock.

- spring arms can now interact with preferably designed as heart discs, connected to the clutch discs actuators to rotate the number wheels 3 of the combination lock 2 in their key secret of the combination lock 2 corresponding positions.

- the cylindrical wall 30 of the lower plate 17 is provided on its inner side with a slotted guide 38, as best of FIG. 25 evident.

- the latter has a slide 41 which can be actuated from the rear side of the locking device 1 and is restrained.

- the slider 41 has a control cam 42 and is guided in a guide groove 43 provided in the lower plate.

- the control cam 42 of the slider 41 can be moved into a position corresponding to a left-hand rotation or a clockwise rotation of the locking device 1, wherein each rotation of the locking device 1 is assigned a sliding recess 44 or 45 in the locking bolt 24.

- a further positioning device is provided, by means of which the locking bolt 24 can be positioned in defined positions with respect to the lower plate 17.

- This further positioning device also has a spring 46 and a ball 47, which is pressed by means of the spring 46 in the direction of the lower plate 17.

- recesses 48 are provided in the delivery and in the open position of the locking bar into which the ball 47 engages by means of the spring 46 when the locking latch 24 is in the relevant position.

- the lock carrier 15 holding the combination lock 2 and the secondary lock 13 is freely rotatable with respect to the lower plate 17 and the locking bolt 24 positioned on the lower plate 17 by means of the further positioning device 46, 47.

- the locking piece 20 When setting the key secret of the combination lock 2, the locking piece 20 is biased so that its nose 22 in a rotation of the lock carrier 15 in the recess 23rd the locking bolt 24 engages, so that after this latching the locking bolt 24 is rotatable with the lock carrier 15 to bring the closing member 25 out of engagement with the lock latch, not shown in the figures.

- first position the lock carrier 15 by means of the first positioning device 26, 27, 28, 29, so that the nose 22 of the locking piece 20 of the recess 23 of the locking bolt 24 is opposed even before the setting of the key secret of the combination lock 2.

- any stresses of components of the locking device 1, the locking or the like. serve, be excluded.

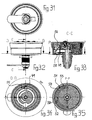

- FIGS. 30 to 46 differs from the above-described by a lock between the latch 24 on the one hand and the fixed part or the lower plate 17 on the other acting blocking element in the form of a pressure bar 49.

- the pressure bar 49 has at its in FIG. 30 Bottom of a pin 50 which projects into a link 51, which is formed on the pressure bar 49 facing side of the lower plate 17.

- To the backdrop 51 include, as best of the Figures 30 . 35 . 40 and 45 shows a holding position 52, a first release groove 53 and a second release groove 54, wherein the first release groove 53 is radially inwardly of the second release groove 54 and wherein in the radial direction between the two Freijuten 53, 54, the holding position 52 of the link 51 is formed.

- the pressure bar 49 is slidably mounted in the radial direction in a guide 57 which is formed in the locking latch 24.

- a slide spring 55 which is also held in a corresponding recess of the locking bolt 24 and which is arranged and designed so that in the unloaded state of the slider spring 55 of the pressure bar 49 with its pin 50 in the holding position 52 of the link 51st located.

- In this position of the pressure bar 49 is a rotation between the locking bar 24 and the fixed part or the lower plate 17, or the like with respect to a piece of furniture. is fixed, not possible.

- the lock carrier 15, however, is still freely rotatable with respect to the fixed part or the lower plate 17.

- the locking piece 20 presses, as best from a synopsis of Figures 38 and 40 emerges supported by a compression spring 56 which is disposed between the locking piece 20 and the lock carrier 10 and the lock carrier 15, the pressure bolt 49 and its pin 50 from the holding position 52 of the link device 51 out in the radially inner first release groove 53rd Nunrang the locking bolt 24 is rotatable with respect to the fixed part or the lower plate 17, since the blocking engagement between the pressure bolt side pin 50 and the holding position 52 of the link device 51 is repealed.

- the locking latch 24 with respect to the fixed part or the lower plate 17, or the like on the piece of furniture. is fixed, not turned.

- the closing member 25 of the locking device 1 the rotationally fixed to the locking bolt 24 to bring from its blocking in its release position, even in the event that od because of the unrestricted or non-overlapping design of the doors, gates .dgl. by means of a check card or the like. behind the door, the gate or the like can be penetrated.

Landscapes

- Lock And Its Accessories (AREA)

- Closures For Containers (AREA)

- Support Devices For Sliding Doors (AREA)

Claims (23)

- Dispositif de fermeture pour conteneurs, portes, armoires, meubles ou similaires comprenant un porte-serrure (15) sur lequel est disposé une serrure à combinaison (2), et une partie fixe (17) par rapport à laquelle le porte-serrure (15) est agencé de manière à pouvoir tourner avec la serrure à combinaison (2), caractérisé en ce que dans l'état fermé du dispositif de fermeture, le porte-serrure (15) avec la serrure à combinaison (2) qui lui est attribuée présente une roue libre de 360 degrés par rapport à la partie fixe (17).

- Dispositif de fermeture selon la revendication 1, comprenant une serrure secondaire (13) qui est agencée sur le porte-serrure (15) avec la serrure à combinaison (2).

- Dispositif de fermeture selon la revendication 1 ou 2, dont la serrure à combinaison (2) présente une pièce d'arrêt (20) qui, lorsqu'un code secret est réglé sur la serrure à combinaison (2), se met en prise avec un pêne de fermeture (24) sur lequel un élément de fermeture (25) du dispositif de fermeture (1) est placé et qui peut être tourné avec le porte-serrure (15) lorsque la pièce d'arrêt (20) se trouve en prise avec lui.

- Dispositif de fermeture selon la revendication 3, dans lequel la pièce d'arrêt (20) présente un taquet (22) qui est appuyé en direction du pêne de fermeture (24) lorsqu'un code secret est réglé sur la serrure à combinaison (2) et se met en prise avec un évidement (23) de celui-ci lorsque le taquet (22) et l'évidement (23) du pêne de fermeture (24) affleurent l'un avec l'autre.

- Dispositif de fermeture selon la revendication 3 ou 4, dans lequel un dispositif de positionnement (26, 27, 28, 29) est placé entre le porte-serrure (15) et la partie fixe (17), au moyen duquel le porte-serrure (15) peut être positionné dans une position de rotation par rapport à la partie fixe (17) respectivement au pêne de fermeture (24), position dans laquelle la pièce d'arrêt (20) et le pêne de fermeture (24) peuvent être mis en prise.

- Dispositif de fermeture selon la revendication 5, dont le dispositif de positionnement (26, 27, 28, 29) est formé comme encliquetage à bille avec un évidement (29) formé dans le porte-serrure (15) ou la partie fixe (17) et une bille (27) maintenue sur la partie fixe (17) respectivement le porte-serrure (15), laquelle est précontrainte dans le sens du porte-serrure (15) respectivement de la partie fixe (17) au moyen d'un ressort de précontrainte (26).

- Dispositif de fermeture selon l'une des revendications 2 à 6 dont la serrure secondaire est formée comme une serrure à barillet (13).

- Dispositif de fermeture selon l'une des revendications 1 à 7 dont la partie fixe est formée comme un plateau inférieur (17) reçu dans un boitier cylindrique (16) qui peut être tourné avec le porte-serrure (15) par rapport au plateau inférieur (17).

- Dispositif de fermeture selon l'une des revendications 3 à 8, comprenant un pêne coulissant (31) qui peut être déplacé au moyen de la serrure secondaire (13) de sa position de repos à sa position de fonctionnement dans laquelle il appuie la pièce d'arrêt (20) de la serrure à combinaison (2) en la faisant sortir avec des disques d'accouplement (5) de rouleaux chiffrés (3) de celle-ci et qui est précontraint au moyen d'un ressort (37) dans sa position de repos.

- Dispositif de fermeture selon la revendication 8, comprenant un guide à coulisse (38) formé sur le côté intérieur d'une paroi cylindrique (30) du plateau inférieur (17) et au moyen duquel la pièce d'arrêt (20) de la serrure à combinaison (2), lorsque le porte-serrure (15) est tourné par rapport au plateau inférieur (17), peut être appuyée en étant sortie avec les disques d'accouplement (5) des rouleaux chiffrés (3) de la serrure à combinaison (2).

- Dispositif de fermeture selon l'une des revendications 3 à 10, dans lequel une rotation à droite respectivement à gauche du pêne de fermeture (24) du dispositif de fermeture (1) peut être réglée au moyen d'un poussoir (41) encliquetable par l'arrière avec une came de commande (42) qui peut être mise en prise avec différents évidements à coulisse arqués (44, 45) dans le pêne de fermeture (24).

- Dispositif de fermeture selon l'une des revendications 8 à 11, dans lequel un deuxième dispositif de positionnement (46, 47, 48) est placé entre le pêne de fermeture (24) et le plateau inférieur (17), au moyen duquel le pêne de fermeture (24) peut être positionné dans sa position de fermeture et dans sa position d'ouverture à droite respectivement à gauche par rapport au plateau inférieur (17).

- Dispositif de fermeture selon l'une des revendications 1 à 12, comprenant une tôle de codage (9) mobile axialement pour arrêter la mise en prise résistante à la rotation entre les rouleaux chiffrés (3) de la serrure à combinaison (2) d'une part et les disques d'accouplement (5) de celle-ci d'autre part et présente une saillie (18) qui peut être actionnée pour déplacer axialement la tôle de codage (9) lorsque le dispositif de fermeture (1) est ouvert et qu'un code secret est réglé sur la serrure à combinaison (2).

- Dispositif de fermeture selon l'une des revendications 3 à 13 dont le pêne de fermeture (24) peut être déplacé entre un état bloqué sur la partie fixe (17) et un état mobile par rapport à la partie fixe (17).

- Dispositif de fermeture selon la revendication 14, dont le pêne de fermeture (24) peut être déplacé de son état bloqué sur la partie fixe (17) à son état mobile par rapport à la partie fixe (17) lorsqu'un code secret est réglé sur la serrure à combinaison (2).

- Dispositif de fermeture selon la revendication 14 ou 15, dont le pêne de fermeture (24) peut être déplacé de son état bloqué sur la partie fixe (17) à son état mobile par rapport à la partie fixe (17) au moyen de la serrure secondaire (13).

- Dispositif de fermeture selon l'une des revendications 14 à 16, comprenant un élément de blocage (49) placé entre le pêne de fermeture (24) et la partie fixe (17) et au moyen duquel le pêne de fermeture (24) peut être bloqué sur la partie fixe (17).

- Dispositif de fermeture selon la revendication 17, dont l'élément de blocage est un pêne de compression (49) dirigé dans le pêne de fermeture (24) et qui fait saillie avec un tenon (50) dans un dispositif à coulisse (51) dans un côté de la partie fixe (17) tourné vers le pêne de fermeture (24).

- Dispositif de fermeture selon la revendication 18, dont le dispositif à coulisse (51) côté partie fixe présente une position de retenue (52) dans laquelle le tenon (50) du pêne de compression (49) peut être fixé.

- Dispositif de fermeture selon la revendication 18 ou 19, dont le dispositif à coulisse (51) côté partie fixe présente une rainure de déclenchement (53) dans laquelle le tenon (50) du pêne de compression (49) peut être déplacé lorsqu'un code secret est réglé sur la serrure à combinaison (2).

- Dispositif de fermeture selon l'une des revendications 18 à 20 dont le dispositif à coulisse (51) côté partie fixe présente une autre rainure de déclenchement (54) dans laquelle le tenon (50) du pêne de compression (49) peut être déplacé au moyen de la serrure secondaire (13).

- Dispositif de fermeture selon la revendication 20 ou 21, comprenant un ressort de palette (55) au moyen duquel le pêne de compression (49) est précontraint depuis la première (53) et/ou la deuxième rainure de déclenchement (54) dans le sens de la position de retenue (52).

- Dispositif de fermeture selon la revendication 22, comprenant un ressort de compression (56) au moyen duquel la pièce d'arrêt (20) est précontrainte dans un sens déplaçant le tenon (50) respectivement le pêne de compression (49) contre la force du ressort de palette (55) hors de la position de retenue (52) dans la première rainure de déclenchement (53).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004012000A DE102004012000A1 (de) | 2004-03-10 | 2004-03-10 | Schließvorrichtung für Behältnisse, Türen, Schränke, Möbel od. dgl. |

| DE102004012000 | 2004-03-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1574641A2 EP1574641A2 (fr) | 2005-09-14 |

| EP1574641A3 EP1574641A3 (fr) | 2006-05-03 |

| EP1574641B1 true EP1574641B1 (fr) | 2010-07-28 |

Family

ID=34813662

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04029499A Not-in-force EP1574641B1 (fr) | 2004-03-10 | 2004-12-14 | Dispositif de fermeture pour conteneurs, portes, armoires, meubles ou similaires |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1574641B1 (fr) |

| AT (1) | ATE475765T1 (fr) |

| DE (2) | DE102004012000A1 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009016954B4 (de) | 2009-04-14 | 2024-02-01 | Sudhaus Gmbh & Co. Kg | Schlossvorrichtung |

| DE102014006673A1 (de) * | 2014-05-08 | 2015-11-12 | W&F Locks Ohg | Schlossvorrichtung |

| DE102014109224A1 (de) * | 2014-07-01 | 2016-01-07 | S. Franzen Söhne GmbH | Verschluss mit beim Öffnen des Verschlusses selbsttätig löschender Codierung eines Zahlenschlosses |

| CN105178718A (zh) * | 2015-08-18 | 2015-12-23 | 谢龙明 | 一种旋钮式密码锁 |

| DE102017002014A1 (de) * | 2017-03-03 | 2018-09-06 | Sudhaus Gmbh & Co. Kg | Schließvorrichtung für Behältnisse, Türen, Schränke, Möbel od. dgl. |

| CN115110842A (zh) * | 2022-07-08 | 2022-09-27 | 厦门美科安防科技股份有限公司 | 一种字轮密码锁复位辅助结构 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2251145A (en) * | 1940-02-28 | 1941-07-29 | Dudley Lock Corp | Key and combination operated lock |

| US3521471A (en) * | 1967-04-05 | 1970-07-21 | Donato Aretola | Combination locks |

| DE9106293U1 (de) * | 1991-05-22 | 1991-09-12 | Solidor AG, O-5630 Heiligenstadt | Codierschloß |

| DE19719392A1 (de) * | 1997-05-07 | 1998-11-12 | Siegfried Merklein | Türhandhabe mit Zahlenschloß |

| DE19906371A1 (de) * | 1999-02-16 | 2000-08-24 | Siegfried Merklein | Türhandhabe mit Zahlenschloß |

| DE10206991B4 (de) * | 2002-02-19 | 2007-04-12 | Sudhaus Gmbh & Co. | Zahlenschloss für Schränke, Möbel od. dgl. |

-

2004

- 2004-03-10 DE DE102004012000A patent/DE102004012000A1/de not_active Withdrawn

- 2004-12-14 DE DE502004011442T patent/DE502004011442D1/de active Active

- 2004-12-14 AT AT04029499T patent/ATE475765T1/de active

- 2004-12-14 EP EP04029499A patent/EP1574641B1/fr not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| ATE475765T1 (de) | 2010-08-15 |

| EP1574641A3 (fr) | 2006-05-03 |

| DE102004012000A1 (de) | 2005-09-22 |

| EP1574641A2 (fr) | 2005-09-14 |

| DE502004011442D1 (de) | 2010-09-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3615749B1 (fr) | Ferrure pour fênetre ou porte | |

| EP3589807B1 (fr) | Dispositif de fermeture pour contenants, portes, armoires, meubles ou similaires | |

| WO2000023677A1 (fr) | Ferrure de fenetre et/ou de porte | |

| DE102009016954B4 (de) | Schlossvorrichtung | |

| EP0682167A1 (fr) | Serrure mortaisée avec pêne demi-tour et pêne dormant | |

| EP0819810B1 (fr) | Ferrure pour une serrure | |

| DE3126760C2 (de) | Vorrichtung zum Neueinstellen des Schlüsselgeheimnisses in einem Permutationsschloß für Koffer oder dergleichen | |

| EP3336284B1 (fr) | Corps de butée pour poignée d'actionnement, poignée d'actionnement et porte | |

| WO2016128267A1 (fr) | Mâchoire de serrage destinée à être montée sur une glissière d'une table d'opération | |

| EP1574641B1 (fr) | Dispositif de fermeture pour conteneurs, portes, armoires, meubles ou similaires | |

| EP2873787A2 (fr) | Maniement d'actionnement | |

| EP1528194B1 (fr) | Ferrure, notamment ferrure de fenêtre | |

| EP2107189A1 (fr) | Armature pour fenêtres ou portes | |

| EP1267020B1 (fr) | Dispositif de verrouillage | |

| WO2019238172A1 (fr) | Dispositif de verrouillage pour un véhicule automobile | |

| EP2034109A2 (fr) | Dispositif de sécurité | |

| EP0001283A1 (fr) | Roulette orientable immobilisable pour appareils mobiles, notamment pour récipients à ordures ou appareils analogues | |

| DE3040586C2 (de) | Aufsetzschloß mit einer Schubfalle | |

| EP2034110B1 (fr) | Rosette avec dispositif de fixation | |

| AT394241B (de) | Schloss | |

| DE10200153A1 (de) | Elektromotorische Verriegelungsvorrichtung für Möbel | |

| DE10140209A1 (de) | Schloßvorrichtung für Möbel, Schränke ud.dgl. | |

| EP1256670B1 (fr) | Serrure de poignée de fenêtre | |

| EP0880632B1 (fr) | Armature de serrure pour portes ou similaires, notamment pour portes de garages | |

| EP3486417A1 (fr) | Positionneur de couvercle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1085778 Country of ref document: HK |

|

| 17P | Request for examination filed |

Effective date: 20060929 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070524 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004011442 Country of ref document: DE Date of ref document: 20100909 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20100728 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20100728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101129 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101028 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101128 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101029 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101108 |

|

| 26N | No opposition filed |

Effective date: 20110429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101231 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004011442 Country of ref document: DE Effective date: 20110429 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: WD Ref document number: 1085778 Country of ref document: HK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101214 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100728 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20191220 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20211221 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20211222 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20221222 Year of fee payment: 19 Ref country code: FR Payment date: 20221220 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230224 Year of fee payment: 19 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230413 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 475765 Country of ref document: AT Kind code of ref document: T Effective date: 20221214 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20221231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221231 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004011442 Country of ref document: DE Representative=s name: MOSER GOETZE & PARTNER PATENTANWAELTE MBB, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004011442 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20231214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231231 |