EP1570987A2 - Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze - Google Patents

Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze Download PDFInfo

- Publication number

- EP1570987A2 EP1570987A2 EP05103008A EP05103008A EP1570987A2 EP 1570987 A2 EP1570987 A2 EP 1570987A2 EP 05103008 A EP05103008 A EP 05103008A EP 05103008 A EP05103008 A EP 05103008A EP 1570987 A2 EP1570987 A2 EP 1570987A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- pressure

- rollers

- adjusting

- adjustable

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims abstract description 10

- 238000007639 printing Methods 0.000 claims abstract description 16

- 230000001105 regulatory effect Effects 0.000 abstract description 2

- 239000012528 membrane Substances 0.000 description 3

- 230000001276 controlling effect Effects 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 239000013013 elastic material Substances 0.000 description 1

- 238000007646 gravure printing Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F31/00—Inking arrangements or devices

- B41F31/30—Arrangements for tripping, lifting, adjusting, or removing inking rollers; Supports, bearings, or forks therefor

- B41F31/32—Lifting or adjusting devices

- B41F31/36—Lifting or adjusting devices fluid-pressure operated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/08—Cylinders

- B41F13/24—Cylinder-tripping devices; Cylinder-impression adjustments

- B41F13/34—Cylinder lifting or adjusting devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/08—Cylinders

- B41F13/24—Cylinder-tripping devices; Cylinder-impression adjustments

- B41F13/34—Cylinder lifting or adjusting devices

- B41F13/40—Cylinder lifting or adjusting devices fluid-pressure operated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F31/00—Inking arrangements or devices

- B41F31/30—Arrangements for tripping, lifting, adjusting, or removing inking rollers; Supports, bearings, or forks therefor

- B41F31/301—Devices for tripping and adjusting form rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F7/00—Rotary lithographic machines

- B41F7/20—Details

- B41F7/24—Damping devices

- B41F7/40—Devices for tripping or lifting damping rollers; Supporting, adjusting, or removing arrangements therefor

Definitions

- the invention relates to a method for adjusting the contact pressure of an adjustable mounted roller according to the preamble of claim 1.

- rollers In conventional printing machines, such as web-fed rotary printing presses, there are a variety of rollers available.

- ink rollers are provided, the serve the transfer of color from a color memory on the plate cylinder.

- the inking rollers can be dosed the color transferred to the plate cylinders, so that the color is transmitted as a uniform film of a certain thickness. Faults, like for example, speed variations and torsional vibrations can thereby be compensated.

- dampening rollers can be provided in the printing press, the a dampening solution, such as water, transferred to the printing unit.

- pairs of rollers are formed by mutually engaging rollers at where at least one of the rollers has a cylindrical surface of elastic material, so that this cylindrical surface depends on the contact pressure of the opposite roller at least slightly deformed.

- the result is given by the elastic Deformation of the roll surface extending straight between the rolls Contact area, referred to as a contact strip.

- the width of the contact strip can be varied by creating the contact pressure between the rollers, the width of the contract strip has a significant influence on the print result Has. For example, if the contact strip is too narrow in an inking unit, it will not enough color transfer, whereas in cases where the contact strip too wide is, the elastic roller can be damaged by the occurring flexing work.

- the strip width depending on the operating conditions, for example, the temperature of the printing machines or their Wear level, to always be able to adjust correctly, it is necessary to use the one roller to be stored in an adjustable position so that they are provided with an actuator with an adjustable force in the direction the opposite roller can be pressed. Is then the right contact pressure found between the two rollers, a fixing device for fixing the pressed first roller relative to the second roller to sustain the contact pressure permanently to obtain.

- DE 38 08 142 A1 describes a device for supporting two cylinders. Here is the contact pressure between two on and off rolls by changing the Pressure of the print medium changeable. Also, a switching device is arranged with which the pressure medium can be guided optionally to different actuators.

- DE-OS 16 11 303 discloses a device for turning on and off a Printing cylinder of a gravure printing machine, wherein a pressure reducing valve is provided.

- ink rollers are known by means of pressure-actuable actuators are adjustable.

- the invention has for its object to provide a method for adjusting the To create contact pressure of an adjustably mounted roller.

- the actuator for adjusting the contact pressure in the manner of with a pressurized medium, a biased gas, in particular compressed air acted upon Pressure body formed.

- valves are provided. Because of a wet or Inking a variety of adjustable rollers are provided, would be one of the number the actuators corresponding number of valves normally necessary, giving a meant high equipment expense. This high effort is thereby avoided that a switching device is provided with the control valves optionally connectable to different actuators. This means with others Words that the adjustable rollers are then not all set at the same time can, but only the actuators are actuated, via the switching device connected to the adjusting valves. Depending on the design of the color or However, dampening units are only enough to set the entire inking or dampening system Valves with which successively the contact pressure of the various adjustable Rolling is adjusted.

- only two valves are provided with which then simultaneously the pressure of two actuators on an adjustable roller is adjustable.

- an adjustable roller by actuation of the two valves is adjusted and after the adjustment by pressing the fixing the Setting is fixed. After fixation can then with the setting of the next adjustable roller to be continued.

- the angular position of the second roller on which the first roller with adjustable contact pressure is pressed recorded.

- this angular position is it is possible that the pressing or adjusting the adjustable roller then only in certain angular positions of the second roller is performed.

- This type of control of the pressure is particularly important in the form of cylinders, at the periphery of fastening means for fixing the printing plates are provided. Namely, the setting or employment of adjustable rollers in a straight Angular position made at which the adjustable roller on the fastening device of the forme cylinder comes to rest, the set values by the changed diameter in the field of fastening device falsified. These Falsification can be excluded by controlling the angular position of the second roller become.

- the setting of the Contact pressure and / or the employment of the first roller to the second roller at simultaneous rotation of the rolls is a preferred embodiment.

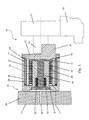

- Fig. 1 is a device 20 for adjusting the contact pressure between a first Roller 21 and a second roller 22 are shown.

- the roller 21 can with the ends of their Axis 23 or pin releasably provided on a device 20 on the Quick release fastened 24.

- Such quick fasteners are out of the art known in the art and have a semicircular bearing shell, in which the ends the axis 23 can be inserted. By attaching a in Fig. 1 not shown upper bearing shell can then the axis 23 on the quick release 24th be determined.

- the device 20 is essentially composed of a frame holder 26 and a Roll holder 27 constructed, the relative to each other in a plane that is perpendicular extends to the drawing plane, can be moved against each other.

- the Frame holder 26 is made of a base plate 28, for example by means of a Swivel arm can be pivotally attached to the frame of a printing press, and a sleeve body 29 constructed.

- On the side facing the roller 21 has the Sleeve body 29 a recess 31 into which a cylindrical portion 32 of the Roller holder 27 engages.

- the inner diameter of the recess 31 and the outer diameter of the section 32 is chosen so that a in the Basic position circular cylindrical gap 33 with a gap width of about 1 mm to 10 mm, in particular of about 2 mm. Through the gap 33, the maximum adjustment range for Adjustment of the roller holder 27 relative to the frame holder 26 defined.

- actuating movements can or the desired contact pressure between the roller 21 and to apply the roller 22 are distributed in the gap 33 over the circumference total four actuators 34 in the form of pressure hoses 34, of which in FIG. 1 only two are shown in section, arranged.

- Feed lines 48 can be formed by the walls of the actuators 34

- Pressure chambers 36 are pressurized.

- the roller 21 is pressed against the roller 22 with the desired contact pressure can be. Because the air cushion pressurized in the actuators 34 is compressible is, mechanical disturbances can be caused by the resulting spring action be intercepted.

- Lammellen implant 37 attached to the attached to the sleeve body 29 Lammellen implantn 38 arranged to form a Lammellenps combing are.

- Lammellen implantn 37 and 38th formed Lammellenps 37 and 38 is a cross-sectionally T-shaped punch 39th provided, the circular punch head 40 with an annular flange 41 at the outermost Lammellenelement 37 and 38 of the Lammellenpers to the plant comes.

- a pressure plate 42 is attached, on which the spring force of a trained in the manner of a plate spring package 43

- Spring element 43 acts.

- the spring element 43 is biased between the pressure plate 42 and the sleeve body 29 mounted so that of the Lammellenmaschinen 37 and 38 formed Lammellenb by the spring force from the punch 39 on the Lammellenmaschine 37 and 38 is transmitted, is clamped.

- a Pressure port 44 is provided through which a pressure chamber 46 between the Pressure plate 42 and the base plate 28 with a pressure medium, such as compressed air can be applied.

- the adjustment of the contact pressure between the rollers 21 and 22 takes place, for example in the following way.

- the pressure chamber 46 with a sufficient pressure acted upon, so that the Lammellenimplantation 37 and 38 no longer frictionally be pinched.

- the actuators 34 each with just as much pressure urges that the desired contact pressure between the rollers 21 and 22 or between the roller 21 and others, not shown in Fig. 1 Rolling forms and leads to a contact strip of the desired width.

- the pressure chamber 46 is depressurized, whereby the punch 39 the Lammellenmaschine 37 and 38 clamped together, so that the roller holder 27 relative is fixed to the frame holder 26 in the desired position.

- Last will be the actors 34 depressurises.

- FIG. 2 shows the frame holder 26 with the Recess 31 and the engaging portion 32 of the roller holder 27.

- a gap 33 is formed, in which the in Figs. 2 and 3 only schematically indicated by force arrows actuators 34 are arranged.

- the possible Adjusting movements between the frame holder 26 and the roll holder 27 are by an actuating plane, which is in the representation of Fig. 2 and 3 in the plane of the drawing extends, defined, wherein the adjustment range of the adjusting movements by the width of Slits 33 is limited.

- the roll holder 27 and, as a result, the attached thereto roller 21 are laterally offset relative to the frame holder 26, which by a corresponding control of the actuators 34 and the consequent Force effect on the section 32 is effected.

- the desired position of Roller holder 27 is found relative to the frame holder 26, which can be from the Lammellenimplantationn 37 and 38 or the punch 39 and the pressure plate 42 formed fixing device are actuated, so that the position is permanently fixed and the actuators 34 need not be driven further.

- FIG. 4 the device 20 with base plate 28 in a perspective view of shown in front.

- the sleeve body 29 is by means of four fastening screws 47 on the Base plate 28 attached (see Fig. 1, shown schematically).

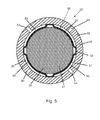

- FIG. 5 shows a second exemplary embodiment of an actuator 50 for a device 20 in FIG Cross-section.

- the basic structure of the device 20 with frame holder 26, Roller holder 27 and a fixing device for fixing the roller holder 27 relative to the roll holder 26 corresponds to the structure described with Fig. 1 and therefore must will not be explained further.

- To form the actuator 50 is in the gap 33 a cylindrical membrane 51, whose upper and lower edges with the inner diameter the sleeve body 29 is connected (not shown in Fig. 5) arranged.

- the Membrane 51 is also in four strip-shaped areas 52 with the Inner diameter of the sleeve body 29 connected, for example glued, so As a result, through the sleeve body 29 and the diaphragm 51 four pressure chambers 53rd are formed, which are distributed uniformly over the circumference of the gap 33.

- the Pressure chambers 53 can each have pressure inlet openings 54 with compressed air be acted upon, so depending on the pressure in the four pressure chambers 53, a resultant force acts on the portion 32 of the roll holder 27.

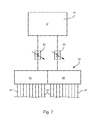

- FIG. 6 an inking unit 56 is shown, with which of a roller 57 printing ink on a can be transferred in the manner of a forme cylinder 22a formed roller 22a.

- to Transfer of ink are in the inking unit 56 five adjustable rollers 21a; 21b; 21c; 21d; 21e provided.

- the ends of the adjustable rollers 21a to 21e are respectively in FIG Devices 20 mounted, which indicated in Fig. 6 by the corresponding actuators 34 is.

- rollers 21a; 21b; 21c; 21d; 21e For example, set up a dampening roller and three or four inking rollers become.

- rollers 21a; 21c; 21e are employed on the roller 22a.

- the rollers 21a; 21c; 21e can by pressurizing the various actuators 34 on the rollers 21a to 21e, the contact pressure between the various rollers 57; 21a to 21e; 22a be set.

- roller 22a On the roller 22a is one or more fasteners 58 or Interruptions 58 are provided, which are designed in particular in the manner of a gap 58 is.

- the front and rear edge of a Pressure plate are fixed to attach the pressure plate to the roller 22a.

- the Rotation angle of the roller 22a is detected by a sensor, not shown, and to the Control forwarded.

- adjusting the rollers 21a; 21c; 21e or at the Adjustment of the contact pressure of these rollers 21a; 21c; 21e will be the respective Angle of rotation of the roller 22a taken into account, thereby preventing the rollers 21a; 21c; 21e when hiring or when adjusting the contact pressure at the Interrupt 58 are present.

- the setting of the rollers 21a to 21e or their Adjustment to the roller 22a can also be used with a rotating printing unit with a rotating roller 22a done.

- the adjustment of the contact pressure and / or the employment of the first Rolls 21a to 21e to the second roller 22a takes place at low speeds, especially at 3,000 to 5,000 U / h ..

- the switching device 59 shown in Fig. 7 is suitable for driving the a total of 20 actuators on the adjustable rollers 21a to 21e on one side.

- the Switching device 59 is shown only schematically and is below briefly explained.

- a pressure medium such as compressed air with be taken sufficiently high pressure level.

- the pressure medium flows into two separate Pressure chambers 64; 66, in which, depending on the position of the pressure control valves 62 and 63 there is a corresponding pressure level.

- Pressure lines 67 Associated with each actuator 34 Pressure lines 67, the set in the pressure chambers 64 and 66, the pressure to the Actuators 34 are transmitted.

- the changeover of the changeover device 59 is clocked.

- the duration of a time clock for Adjustment of an adjustable roller 21a to 21e of the inking unit 56 or dampening unit is 0.1 to 2 seconds, especially 0.5 seconds.

- shut-off devices For example, provided shut-off valves, so that optionally different to the Pressure chambers 64 and 66 connected pressure lines 67 are shut off can. If now the contact pressure to be set on an adjustable roller 21, so All pressure lines 67 are shut off, which lead to actuators 34, for the Setting are not required. In the result it follows that the by the Pressure control valves 62; 63 regulated air pressure transmitted only to the actuators 34 be involved in the setting of each desired roller 21. After Setting this roller 21, the corresponding contact pressure by pressing the Fixed fixing, so that by switching the switching device 59th then the next adjustable roller 21 can be adjusted.

- both pressure control valves 62; 63 set air pressures are applied simultaneously the actuators 34; 50 of several adjusters. Only with the Adjustments in which the fixing is opened is done a setting.

- Adjusting the contact pressure means that the contact pressure in the salaried state (in contact) of the roller to another roller before hiring or hired Condition is changeable, d. H. the surface pressure of the roller is in addition to parked condition changeable.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Spinning Or Twisting Of Yarns (AREA)

- Treatments Of Macromolecular Shaped Articles (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

- Treatment Of Fiber Materials (AREA)

- Fixing For Electrophotography (AREA)

- Rolls And Other Rotary Bodies (AREA)

Abstract

Description

- Fig. 1

- eine schematisch dargestellte Vorrichtung zum Einstellen des Anpressdrucks zwischen zwei Walzen im Längsschnitt;

- Fig. 2

- die schematisch im Querschnitt dargestellte Vorrichtung gemäß Fig. 1 in einer Grundstellung;

- Fig. 3

- die schematisch im Querschnitt dargestellte Vorrichtung gemäß Fig. 1 in einer ausgelenkten Stellung;

- Fig. 4

- die Vorrichtung gemäß Fig. 1 in einer perspektivischen Ansicht von vorne;

- Fig. 5

- ein zweites Ausführungsbeispiel eines Aktors für eine Vorrichtung im Querschnitt;

- Fig. 6

- ein Farbwerk mit mehreren einstellbaren Walzen zur Anstellung an einem Formzylinder;

- Fig. 7

- eine Umschalteinrichtung zur wahlweisen Umschaltung zweier Ventile zwischen verschiedenen Aktoren.

- 01 bis 19

- -

- 20

- Vorrichtung

- 21

- Walze

- 22

- Walze

- 23

- Achse

- 24

- Schnellverschluss

- 25

- -

- 26

- Rahmenhalter

- 27

- Walzenhalter

- 28

- Grundplatte (26)

- 29

- Hülsenkörper (26)

- 30

- -

- 31

- Ausnehmung (26)

- 32

- Abschnitt (27)

- 33

- Spalt

- 34

- Aktor, Druckschlauch

- 35

- -

- 36

- Druckkammer

- 37

- Lammellenelement (27)

- 38

- Lammellenelement (26)

- 39

- Stempel

- 40

- Stempelkopf

- 41

- Flansch (40)

- 42

- Druckplatte

- 43

- Federelement, Tellerfederpaket

- 44

- Druckanschluss

- 45

- -

- 46

- Druckkammer

- 47

- Befestigungsschraube

- 48

- Zuleitung

- 49

- -

- 50

- Aktor

- 51

- Membran

- 52

- Befestigungsabschnitt

- 53

- Druckkammer

- 54

- Druckeinlassöffnung

- 55

- -

- 56

- Farbwerk

- 57

- Walze

- 58

- Befestigungseinrichtung, Unterbrechung, Spalt

- 59

- Umschalteinrichtung

- 60

- -

- 61

- Druckspeicher

- 62

- Ventil, Druckregelventil

- 63

- Ventil, Druckregelventil

- 64

- Druckkammer

- 65

- -

- 66

- Druckkammer

- 67

- Druckleitung

- 21a

- Walze

- 21b

- Walze

- 21c

- Walze

- 21d

- Walze

- 21e

- Walze

- 22a

- Walze, Formzylinder

Claims (5)

- Verfahren zum Einstellen des Anpressdrucks zwischen einer verstellbar gelagerten ersten Walze (21; 21a; 21b; 21c; 21d; 21e) und zumindest einer zweiten Walze (22; 22a) und/oder zum An- oder Abstellen der erste Walze (21; 21a; 21b; 21c; 21d; 21e) an die zweite Walze (22; 22a) in einer Druckmaschine, mit zumindest einem Aktor (34; 50), mit dem die erste Walze (21; 21a; 21b; 21c; 21 d; 21e) mit einer einstellbaren Kraft in Richtung der zweiten Walze (22; 22a) gedrückt wird, wobei die zweite Walze (22; 22a) an ihrer Mantelfläche eine Unterbrechung (58) aufweist, dadurch gekennzeichnet, dass mindestens zwei an den Formzylinder (22a) anstellbare Walzen (21a; 21c; 21e) zeitversetzt angestellt werden.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass mindestens zwei an den Formzylinder (22a) anstellbare Walzen (21a; 21c; 21e) zeitversetzt angestellt werden.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass mindestens drei an den Formzylinder (22a) anstellbare Walzen (21a; 21c; 21e) zeitversetzt angestellt werden.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass mindestens vier an den Formzylinder (22a) anstellbare Walzen (21a; 21c; 21e) zeitversetzt angestellt werden.

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass mindestens fünf an den Formzylinder (22a) anstellbare Walzen (21a; 21c; 21e) zeitversetzt angestellt werden.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2002144046 DE10244046B4 (de) | 2002-09-21 | 2002-09-21 | Vorrichtung zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| DE10244046 | 2002-09-21 | ||

| EP03798064A EP1539495B1 (de) | 2002-09-21 | 2003-09-05 | Vorrichtungen und verfahren zum einstellen des anpressdrucks einer verstellbar gelagerten walze |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03798064A Division EP1539495B1 (de) | 2002-09-21 | 2003-09-05 | Vorrichtungen und verfahren zum einstellen des anpressdrucks einer verstellbar gelagerten walze |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1570987A2 true EP1570987A2 (de) | 2005-09-07 |

| EP1570987A3 EP1570987A3 (de) | 2006-07-12 |

Family

ID=31983981

Family Applications (5)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05103008A Withdrawn EP1570987A3 (de) | 2002-09-21 | 2003-09-05 | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| EP05103011A Withdrawn EP1570988A3 (de) | 2002-09-21 | 2003-09-05 | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| EP03798064A Expired - Lifetime EP1539495B1 (de) | 2002-09-21 | 2003-09-05 | Vorrichtungen und verfahren zum einstellen des anpressdrucks einer verstellbar gelagerten walze |

| EP05103004A Expired - Lifetime EP1570986B1 (de) | 2002-09-21 | 2003-09-05 | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| EP05103000A Withdrawn EP1570985A3 (de) | 2002-09-21 | 2003-09-05 | Vorrichtung zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

Family Applications After (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05103011A Withdrawn EP1570988A3 (de) | 2002-09-21 | 2003-09-05 | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| EP03798064A Expired - Lifetime EP1539495B1 (de) | 2002-09-21 | 2003-09-05 | Vorrichtungen und verfahren zum einstellen des anpressdrucks einer verstellbar gelagerten walze |

| EP05103004A Expired - Lifetime EP1570986B1 (de) | 2002-09-21 | 2003-09-05 | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| EP05103000A Withdrawn EP1570985A3 (de) | 2002-09-21 | 2003-09-05 | Vorrichtung zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

Country Status (8)

| Country | Link |

|---|---|

| US (3) | US7387069B2 (de) |

| EP (5) | EP1570987A3 (de) |

| JP (1) | JP4307382B2 (de) |

| CN (2) | CN1331669C (de) |

| AT (2) | ATE461042T1 (de) |

| AU (1) | AU2003266200A1 (de) |

| DE (5) | DE10261984A1 (de) |

| WO (1) | WO2004028810A1 (de) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10261984A1 (de) * | 2002-09-21 | 2004-04-08 | Koenig & Bauer Ag | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| DE102004004665B4 (de) | 2004-01-30 | 2005-12-29 | Koenig & Bauer Ag | Vorrichtung zum Einstellen einer von einer Walze in einem Walzenstreifen auf einen benachbarten Rotationskörper ausgeübten Anpresskraft und zum Anstellen der Walze an den Rotationskörper oder zum Abstellen der Walze von dem Rotationskörper |

| EP1867478B1 (de) * | 2005-04-21 | 2009-01-28 | Koenig & Bauer Aktiengesellschaft | Druckwerk mit mindestens zwei zusammenwirkenden Zylindern |

| DE102006028434B4 (de) * | 2005-06-23 | 2014-01-30 | Koenig & Bauer Aktiengesellschaft | Druckeinheit einer Druckmaschine mit mindestens zwei Druckwerken |

| JP2007229954A (ja) * | 2006-02-27 | 2007-09-13 | Mitsubishi Heavy Ind Ltd | 印刷機械のニップ確認システム、およびプログラム |

| DE102006030290B3 (de) * | 2006-03-03 | 2007-10-18 | Koenig & Bauer Aktiengesellschaft | Druckwerk |

| WO2007099148A2 (de) | 2006-03-03 | 2007-09-07 | Koenig & Bauer Aktiengesellschaft | Druckwerke einer druckmaschine |

| US8919250B2 (en) * | 2010-08-02 | 2014-12-30 | Goss International Americas, Inc. | Printing press and method for positioning cylinders therein |

| US8854634B2 (en) * | 2012-06-14 | 2014-10-07 | Xerox Corporation | Transfix roller with adjustable crown for use in an indirect printer |

| US8888480B2 (en) | 2012-09-05 | 2014-11-18 | Aprecia Pharmaceuticals Company | Three-dimensional printing system and equipment assembly |

| RU2620807C2 (ru) | 2012-09-05 | 2017-05-29 | Апреция Фармасьютикалз Компани | Система и комплект оборудования для трехмерной печати |

| CN109908355B (zh) | 2013-03-15 | 2022-11-15 | 阿普雷奇亚制药有限责任公司 | 包含左乙拉西坦的快速分散剂型 |

| FR3004671B1 (fr) * | 2013-04-22 | 2015-05-22 | Pakea | Machine pour la fabrication en continu de corps tubulaires de boites notamment a base de carton ou similaire |

| CN104908409A (zh) * | 2015-06-01 | 2015-09-16 | 铜陵方正塑业科技有限公司 | 印刷装置 |

| CN116423825A (zh) | 2015-08-21 | 2023-07-14 | 阿普雷奇亚制药有限责任公司 | 三维打印系统和设备组件 |

| US10765658B2 (en) | 2016-06-22 | 2020-09-08 | Mastix LLC | Oral compositions delivering therapeutically effective amounts of cannabinoids |

| CN112297605A (zh) * | 2020-10-10 | 2021-02-02 | 山东华冠智能卡有限公司 | 一种基于石墨烯导电浆料的rfid天线印刷设备 |

| CN112895683A (zh) * | 2020-12-28 | 2021-06-04 | 安徽庆丰余防伪科技有限公司 | 一种用于防伪标签的压合装置 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2774301A (en) | 1953-05-13 | 1956-12-18 | Hoe & Co R | Ink roller mounting for printing machines |

| GB1213935A (en) | 1968-02-07 | 1970-11-25 | Albert Schnellpressen | Improvements in or relating to inking apparatus for rotary printing presses |

| DE1611303A1 (de) | 1968-01-29 | 1970-12-10 | Albert Schnellpressen | Vorrichtung zum An- und Abstellen des Druckzylinders mit der Zwischenwalze gegenueber dem Formzylinder an Tiefdruckrotationsmaschinen |

| DE3808142A1 (de) | 1988-03-11 | 1989-09-21 | Goebel Gmbh Maschf | Lagereinrichtung |

| DE19719305A1 (de) | 1997-05-07 | 1998-11-12 | Roland Man Druckmasch | Lageranordnung für eine Walze eines Farb- oder Feuchtwerkes |

| DE19919733A1 (de) | 1998-05-22 | 1999-11-25 | Heidelberger Druckmasch Ag | Vorrichtung und Verfahren zum halbautomatischen Einstellen von Walzen |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE64064C (de) | l. D. craig in San Francisco, Staat Californien, V. St. A | Zweiseitig mit Klebstoff versehener Streifen zur Verbindung von Papierblättern u. dergl | ||

| US2306044A (en) * | 1939-05-05 | 1942-12-22 | Davidson William Ward | Printing press |

| US3157118A (en) | 1962-07-02 | 1964-11-17 | Miller Printing Machinery Co | Printing press |

| US3389450A (en) * | 1966-05-20 | 1968-06-25 | Mount Hope Machine Company Inc | Non-deflecting roll |

| DE1561014B1 (de) * | 1967-03-02 | 1970-02-12 | Maschf Augsburg Nuernberg Ag | Verstellbare Walzenlagerung, insbesondere für Reib- und Auftragwalzen von Farbwerken an Druckmaschinen |

| DE3820026A1 (de) * | 1988-06-13 | 1989-12-14 | Heidelberger Druckmasch Ag | Vorrichtung zur kraftschluessigen kupplung eines festzahnrades und eines verstellzahnrades an einem zylinder einer wendeeinrichtung in einer bogenrotationsdruckmaschine und elektrische absicherung einer solchen vorrichtung |

| DE4216781C2 (de) * | 1992-05-21 | 1995-08-03 | Heidelberger Druckmasch Ag | Vorrichtung zur Aufnahme von Rotationskörperzapfen |

| DE4231673C2 (de) | 1992-09-22 | 1994-11-10 | Roland Man Druckmasch | Vorrichtung zur Walzeneinstellung in Druckmaschinen |

| US5448949A (en) * | 1993-08-24 | 1995-09-12 | Heidelberger Druckmaschinen Ag | Method and device for adjusting a contact pressure between ink-carrying cylinders of a printing machine |

| DE4436629C2 (de) | 1994-10-13 | 1998-08-13 | Koenig & Bauer Albert Ag | Lagerbuchse |

| CN2210784Y (zh) * | 1995-01-17 | 1995-10-25 | 邵一康 | 标签印刷机供、输、匀、刷墨机构 |

| US5678485A (en) * | 1995-12-22 | 1997-10-21 | Heidelberger Druckmaschinen Ag | Counterpoise and lift mechanism |

| DE19717305A1 (de) | 1997-04-24 | 1998-11-05 | Hans Hager | Kurbeltrieb |

| DE19822662C2 (de) * | 1998-05-20 | 2003-12-24 | Roland Man Druckmasch | Verfahren zur Farbreproduktion auf einer Bilddaten orientierten Druckmaschine |

| US6098542A (en) | 1999-02-17 | 2000-08-08 | Heidelberger Druckmaschinen Ag | Method and device for force loading a rubber blanket roller in a printing press |

| DE10113314C2 (de) | 2001-03-20 | 2003-10-30 | Koenig & Bauer Ag | Fixiereinrichtung |

| DE10152020C2 (de) | 2001-03-20 | 2003-05-08 | Koenig & Bauer Ag | Vorrichtung zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

| CN2493402Y (zh) * | 2001-06-07 | 2002-05-29 | 万谙机械企业股份有限公司 | 印刷机的印刷装置 |

| CN1330481C (zh) * | 2001-12-06 | 2007-08-08 | 柯尼格及包尔公开股份有限公司 | 印刷机中用于对辊进行调整的装置 |

| DE10261984A1 (de) * | 2002-09-21 | 2004-04-08 | Koenig & Bauer Ag | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze |

-

2002

- 2002-09-21 DE DE10261984A patent/DE10261984A1/de not_active Withdrawn

- 2002-09-21 DE DE10261985A patent/DE10261985A1/de not_active Withdrawn

- 2002-09-21 DE DE10261983A patent/DE10261983A1/de not_active Withdrawn

-

2003

- 2003-09-05 EP EP05103008A patent/EP1570987A3/de not_active Withdrawn

- 2003-09-05 CN CNB038238152A patent/CN1331669C/zh not_active Expired - Fee Related

- 2003-09-05 CN CN2007100917947A patent/CN101041286B/zh not_active Expired - Fee Related

- 2003-09-05 DE DE50313271T patent/DE50313271D1/de not_active Expired - Lifetime

- 2003-09-05 AT AT03798064T patent/ATE461042T1/de not_active IP Right Cessation

- 2003-09-05 JP JP2004538700A patent/JP4307382B2/ja not_active Expired - Fee Related

- 2003-09-05 WO PCT/DE2003/002946 patent/WO2004028810A1/de not_active Ceased

- 2003-09-05 EP EP05103011A patent/EP1570988A3/de not_active Withdrawn

- 2003-09-05 AT AT05103004T patent/ATE488365T1/de active

- 2003-09-05 AU AU2003266200A patent/AU2003266200A1/en not_active Abandoned

- 2003-09-05 DE DE50312535T patent/DE50312535D1/de not_active Expired - Lifetime

- 2003-09-05 EP EP03798064A patent/EP1539495B1/de not_active Expired - Lifetime

- 2003-09-05 US US10/528,468 patent/US7387069B2/en not_active Expired - Fee Related

- 2003-09-05 EP EP05103004A patent/EP1570986B1/de not_active Expired - Lifetime

- 2003-09-05 EP EP05103000A patent/EP1570985A3/de not_active Withdrawn

-

2008

- 2008-05-28 US US12/153,937 patent/US7765930B2/en not_active Expired - Fee Related

- 2008-05-28 US US12/153,938 patent/US20080229961A1/en not_active Abandoned

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2774301A (en) | 1953-05-13 | 1956-12-18 | Hoe & Co R | Ink roller mounting for printing machines |

| DE1611303A1 (de) | 1968-01-29 | 1970-12-10 | Albert Schnellpressen | Vorrichtung zum An- und Abstellen des Druckzylinders mit der Zwischenwalze gegenueber dem Formzylinder an Tiefdruckrotationsmaschinen |

| GB1213935A (en) | 1968-02-07 | 1970-11-25 | Albert Schnellpressen | Improvements in or relating to inking apparatus for rotary printing presses |

| DE3808142A1 (de) | 1988-03-11 | 1989-09-21 | Goebel Gmbh Maschf | Lagereinrichtung |

| DE19719305A1 (de) | 1997-05-07 | 1998-11-12 | Roland Man Druckmasch | Lageranordnung für eine Walze eines Farb- oder Feuchtwerkes |

| DE19919733A1 (de) | 1998-05-22 | 1999-11-25 | Heidelberger Druckmasch Ag | Vorrichtung und Verfahren zum halbautomatischen Einstellen von Walzen |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1331669C (zh) | 2007-08-15 |

| EP1570988A3 (de) | 2006-07-12 |

| US20080229960A1 (en) | 2008-09-25 |

| ATE461042T1 (de) | 2010-04-15 |

| CN101041286B (zh) | 2011-12-14 |

| CN1688443A (zh) | 2005-10-26 |

| EP1570985A3 (de) | 2006-07-12 |

| EP1539495A1 (de) | 2005-06-15 |

| EP1570987A3 (de) | 2006-07-12 |

| WO2004028810A1 (de) | 2004-04-08 |

| JP4307382B2 (ja) | 2009-08-05 |

| EP1539495B1 (de) | 2010-03-17 |

| DE10261985A1 (de) | 2004-04-08 |

| DE50312535D1 (de) | 2010-04-29 |

| EP1570986A2 (de) | 2005-09-07 |

| US7387069B2 (en) | 2008-06-17 |

| JP2005538876A (ja) | 2005-12-22 |

| EP1570986A3 (de) | 2006-07-12 |

| US20060042485A1 (en) | 2006-03-02 |

| US20080229961A1 (en) | 2008-09-25 |

| CN101041286A (zh) | 2007-09-26 |

| DE10261983A1 (de) | 2004-04-08 |

| DE50313271D1 (de) | 2010-12-30 |

| EP1570988A2 (de) | 2005-09-07 |

| ATE488365T1 (de) | 2010-12-15 |

| EP1570985A2 (de) | 2005-09-07 |

| EP1570986B1 (de) | 2010-11-17 |

| US7765930B2 (en) | 2010-08-03 |

| DE10261984A1 (de) | 2004-04-08 |

| AU2003266200A1 (en) | 2004-04-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1570986B1 (de) | Verfahren zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze | |

| EP1461207B1 (de) | Verfahren zum betrieb eines farbwerkes oder feuchtwerkes in einer druckmaschine | |

| EP1437221B1 (de) | Vorrichtung zum Einstellen eines Anpressdrucks einer verstellbar gelagerten Walze | |

| DE10113314C2 (de) | Fixiereinrichtung | |

| DE10244046B4 (de) | Vorrichtung zum Einstellen des Anpressdrucks einer verstellbar gelagerten Walze | |

| DE10262042B4 (de) | Farbwerk mit zumindest drei Walzen bzw. Zylinder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1539495 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: JENTZSCH, PETER Inventor name: FAIST, BERND Inventor name: SCHNEIDER, GEORG |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20060621 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 17Q | First examination report despatched |

Effective date: 20100519 |

|

| 18W | Application withdrawn |

Effective date: 20100602 |