EP1568441B1 - Vorrichtung zur Herstellung von Zahnriemenformen - Google Patents

Vorrichtung zur Herstellung von Zahnriemenformen Download PDFInfo

- Publication number

- EP1568441B1 EP1568441B1 EP05007364A EP05007364A EP1568441B1 EP 1568441 B1 EP1568441 B1 EP 1568441B1 EP 05007364 A EP05007364 A EP 05007364A EP 05007364 A EP05007364 A EP 05007364A EP 1568441 B1 EP1568441 B1 EP 1568441B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- profile

- trimming

- workpiece

- grinding wheel

- grinding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title description 5

- 238000000227 grinding Methods 0.000 claims abstract description 86

- 238000000034 method Methods 0.000 claims abstract description 16

- 239000010432 diamond Substances 0.000 claims description 16

- 229910003460 diamond Inorganic materials 0.000 claims description 16

- 230000002093 peripheral effect Effects 0.000 claims description 5

- 238000009966 trimming Methods 0.000 claims 13

- 238000000465 moulding Methods 0.000 abstract 1

- 238000005520 cutting process Methods 0.000 description 3

- 238000003801 milling Methods 0.000 description 3

- 239000007921 spray Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 2

- 229920013648 Perbunan Polymers 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B5/00—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor

- B24B5/02—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor involving centres or chucks for holding work

- B24B5/04—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor involving centres or chucks for holding work for grinding cylindrical surfaces externally

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B19/00—Single-purpose machines or devices for particular grinding operations not covered by any other main group

- B24B19/02—Single-purpose machines or devices for particular grinding operations not covered by any other main group for grinding grooves, e.g. on shafts, in casings, in tubes, homokinetic joint elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B5/00—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor

- B24B5/02—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor involving centres or chucks for holding work

- B24B5/04—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor involving centres or chucks for holding work for grinding cylindrical surfaces externally

- B24B5/045—Machines or devices designed for grinding surfaces of revolution on work, including those which also grind adjacent plane surfaces; Accessories therefor involving centres or chucks for holding work for grinding cylindrical surfaces externally with the grinding wheel axis perpendicular to the workpiece axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B53/00—Devices or means for dressing or conditioning abrasive surfaces

- B24B53/04—Devices or means for dressing or conditioning abrasive surfaces of cylindrical or conical surfaces on abrasive tools or wheels

- B24B53/047—Devices or means for dressing or conditioning abrasive surfaces of cylindrical or conical surfaces on abrasive tools or wheels equipped with one or more diamonds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B53/00—Devices or means for dressing or conditioning abrasive surfaces

- B24B53/06—Devices or means for dressing or conditioning abrasive surfaces of profiled abrasive wheels

- B24B53/07—Devices or means for dressing or conditioning abrasive surfaces of profiled abrasive wheels by means of forming tools having a shape complementary to that to be produced, e.g. blocks, profile rolls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B53/00—Devices or means for dressing or conditioning abrasive surfaces

- B24B53/06—Devices or means for dressing or conditioning abrasive surfaces of profiled abrasive wheels

- B24B53/08—Devices or means for dressing or conditioning abrasive surfaces of profiled abrasive wheels controlled by information means, e.g. patterns, templets, punched tapes or the like

- B24B53/085—Devices or means for dressing or conditioning abrasive surfaces of profiled abrasive wheels controlled by information means, e.g. patterns, templets, punched tapes or the like for workpieces having a grooved profile, e.g. gears, splined shafts, threads, worms

Definitions

- a device with the features a) - e) is, for example, from the GB-A-1 253 685 known.

- Timing belt forms are usually steel tube rolls which are straight-toothed on their shell circumference and used as an inner core in the manufacture of toothed belts, e.g. from Perbunan gum or plastic, needed.

- the heated toothed belt material is pressed into the toothing of the toothed belt shape.

- the toothing of the toothed belt forms thus forms the die of the toothed belt toothing.

- timing belt shapes It is known to produce timing belt shapes by milling from cylindrical blanks.

- the requirements for the accuracy of the tooth geometries of timing belts has increased enormously.

- the tooth surface should be as smooth as possible, i. if possible, have no illustrations of existing in the timing belt shapes Fräsriefen.

- the device according to the invention allows a method for the production of toothed belt forms in which by means of at least one rotating grinding wheel with a profiled circumference in the pre-machining substantially cylindrical circumference of a workpiece, a die of the desired toothed belt toothing is incorporated, wherein the circumferential profile of the profile of a complete tooth groove of desired timing belt shape corresponds.

- the die for the timing belt is not milled but by grinding with specially profiled grinding wheels with a grinding motion parallel to Longitudinal axis of the workpiece generated.

- Tooth groove is understood to mean the full area from the head of a tooth to the head of the adjacent tooth. The grinding of two adjacent tooth grooves thus leads to a complete tooth of the toothed belt shape being produced, ie also the outer diameter of the toothed belt shape is ground.

- the shrinkage of the toothed belt material during cooling in the manufacturing process must be considered.

- profiled grinding wheels also allows to easily create the finest substructures in the tooth profile, z. B. a wavy sub-profile in the tooth flanks. For this purpose, for. B. running parallel to the toothed belt axis forming channels in the profile. Timing belts with such sub-profiles are in the DE 199 08 672 C1 disclosed.

- the dressing is required due to the gradual wear of the grinding wheel.

- the use of a profile dressing with profiled dressing area has the advantage that a complex CNC control for the movement of other dressing means, such as a dressing pin, is not required because the profiled dressing area predetermines a solid profile.

- a profile dressing element is therefore particularly useful if variations of the profile shape are not needed and high quantities are to be produced with identical gearing geometries.

- the device according to the invention can also be designed such that the at least one profile dressing element is positioned and adjustable relative to the workpiece holder such that viewed in the direction of the longitudinal center axis of the at least one clamped workpiece, the projection of the profile of the dressing area on a workpiece face the profile of the cross section of corresponds to a grinding process aspired cut.

- the profile of the profile of the dressing area of the dressing element specifies the cutting path exactly for each grinding operation, i.

- the dressing area must be exactly in alignment with the desired cutting process. Thus, it is completely irrelevant how much was removed during the dressing process from the diameter of the grinding wheel.

- the workpiece is rotated about an angle corresponding to the pitch circle pitch of the toothing geometry.

- the grinding wheel is fed to the workpiece for re-dressing over the dressing area of the dressing element and in continuation of a straight-line translational movement for the next grinding operation. Assuming that the dressing area has not been significantly worn, the dressing wheel is always at the correct relative height after dressing, relative to the workpiece. Any signs of wear on the dressing area can be compensated by a manual or automated adjustment.

- the relative movement between the grinding wheel and the workpiece can be achieved by a movement of the grinding wheel with respect to a machine frame or a movement of a tool holder.

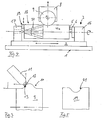

- Fig. 1 shows a grinding device with a machine frame 1, on which a horizontally movable grinding table 2 is mounted.

- the grinding table 2 carries a workpiece holder 3, in which the roller-shaped blank 4 is clamped for a toothed belt shape between a dividing head 16 and an abutment 17.

- the blank 4 can be controlled by a turntable 6 about a horizontal axis of rotation 7 is rotated.

- the axis of rotation 7 simultaneously forms the longitudinal center axis of the blank 4 in the blank 4.

- the workpiece holder 3 comprises a high-precision direct measuring system, not separately shown here, which permits an exact rotational angle adjustment.

- Above the workpiece holder 3, a grinding wheel 9 is rotatably fixed to a grinding wheel holder 8.

- the grinding wheel holder 8 is highly precisely controlled in the vertical direction movable.

- the counter profile of the toothed belt toothing must be incorporated in the circumference of the blank 4, the toothing being rectilinear and constant in the direction of the longitudinal central axis of the blank 4.

- the circumference now forms, seen in cross-section, the die for the toothed belt toothing.

- the grinding wheel 9 has on its circumference a profile 10, which is visible in an enlarged view in Fig. 2.

- the circumferential profile 10 of the grinding wheel 9 corresponds the desired profile of a Zahnnut the timing belt shape.

- the circumferential profile 10 of the grinding wheel 9 can be re-dressed with a dressing pin 11 before each grinding operation. This is done with the help of a CNC-controlled process.

- the Abrichtit 11 is axially movable relative to the axis of rotation of the grinding wheel as well as in the radial direction.

- the dressing pin 11 also has a dressing pivot axis 12, which extends substantially perpendicular to the axial and radial directions and through the center of a round diamond 13 at the tip of the dressing pin 11. Equipped with such degrees of freedom, almost any profile can be entered into the circumference of the grinding wheel 9 with the dressing pin 11.

- Accuracies of up to +/- 0.01 mm can be achieved.

- a virtual diamond radius can be specified for the CNC control. In this way, e.g. a constant deviation from the ideal line in the course of the profile can be easily corrected without having to change the entire CNC programming.

- the grinding wheel is constantly cleaned by means of a spray nozzle pair 14 (Fig.1), which reaches both edges of the peripheral profile 10 sufficiently uniform.

- a further spray nozzle pair 15 is used, which cleans the grinding wheel 9 at high pressure and thus prevents their clogging.

- the nozzle pair 15 is arranged in the immediate vicinity of the grinding papers 9.

- Fig. 4 shows an alternative construction of a grinding device. Corresponding parts in different figures are provided with the same reference numerals.

- the blank 4a is shorter in FIG. 4 than in FIG. 1.

- the tool holder 3 has the same spacing in its dividing devices 16 and 17 as in FIG. 1.

- a length adapter 18 provided with struts 20 is provided. With the help of one or more length adapters 18, it is also possible to avoid adjusting the divisors 16 and 17 of the workpiece holder 3, even with different lengths of blanks 4a, in order to obtain a high degree of exactness once achieved in a costly manner.

- a profile diamond 19 is arranged, which serves for dressing the grinding wheel 9 and is shown enlarged in Figure 5.

- the profile diamond 19 has a dressing edge 21 whose profile corresponds to the profile of the desired Zahnnut the timing belt shape.

- the profile diamond 19 is oriented such that by a further process of the grinding table 2, the grinding wheel 9 without vertical position change in the correct working position reaches the workpiece 4a and produces in a single grinding process, the die for a complete tooth of the belt including tooth root.

- the grinding wheel holder 8 is raised and the grinding table 2 moved back to the starting position.

- the grinding wheel holder 8 is lowered again, but because of the given during grinding wear by a small distance further than before the previous passage. In this way, the circumference of the grinding wheel 9 is re-dressed before each grinding.

- the profile diamond 19 is mounted in the vertical direction in its position changeable, so that any wear can be compensated or adaptation to different workpiece diameter is possible.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

- Grinding-Machine Dressing And Accessory Apparatuses (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Devices For Conveying Motion By Means Of Endless Flexible Members (AREA)

- Preliminary Treatment Of Fibers (AREA)

- Seal Device For Vehicle (AREA)

- Preparation Of Compounds By Using Micro-Organisms (AREA)

- Heating, Cooling, Or Curing Plastics Or The Like In General (AREA)

- Fish Paste Products (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10059067 | 2000-11-28 | ||

| DE10059067A DE10059067A1 (de) | 2000-11-28 | 2000-11-28 | Verfahren und Vorrichtung zur Herstellung von Zahnriemenformen und Zahnrädern |

| EP01995545A EP1339527B2 (de) | 2000-11-28 | 2001-11-28 | Verfahren zur herstellung von zahnriemenformen |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01995545A Division EP1339527B2 (de) | 2000-11-28 | 2001-11-28 | Verfahren zur herstellung von zahnriemenformen |

| EP01995545.9 Division | 2001-11-28 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1568441A1 EP1568441A1 (de) | 2005-08-31 |

| EP1568441B1 true EP1568441B1 (de) | 2007-08-15 |

Family

ID=7664981

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01995545A Expired - Lifetime EP1339527B2 (de) | 2000-11-28 | 2001-11-28 | Verfahren zur herstellung von zahnriemenformen |

| EP05007364A Expired - Lifetime EP1568441B1 (de) | 2000-11-28 | 2001-11-28 | Vorrichtung zur Herstellung von Zahnriemenformen |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01995545A Expired - Lifetime EP1339527B2 (de) | 2000-11-28 | 2001-11-28 | Verfahren zur herstellung von zahnriemenformen |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US7125316B2 (pl) |

| EP (2) | EP1339527B2 (pl) |

| JP (1) | JP2004524169A (pl) |

| KR (1) | KR100783206B1 (pl) |

| CN (1) | CN1216721C (pl) |

| AT (2) | ATE369939T1 (pl) |

| AU (1) | AU2002226281A1 (pl) |

| BR (1) | BR0115685A (pl) |

| DE (3) | DE10059067A1 (pl) |

| ES (2) | ES2291996T3 (pl) |

| MX (1) | MXPA03004648A (pl) |

| PL (1) | PL201008B1 (pl) |

| PT (2) | PT1568441E (pl) |

| SI (2) | SI1339527T2 (pl) |

| WO (1) | WO2002043919A1 (pl) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012037584A1 (de) * | 2010-09-23 | 2012-03-29 | Inova Lisec Technologiezentrum Gmbh | Verfahren und anordnung zum nachschärfen von schleifscheiben |

| JP5748582B2 (ja) * | 2011-07-12 | 2015-07-15 | 三菱重工業株式会社 | ねじ状工具の製作方法 |

| CN103465134B (zh) * | 2013-09-03 | 2016-09-14 | 宁波菲仕运动控制技术有限公司 | 一种定子割槽设备 |

| CN103692353A (zh) * | 2013-12-13 | 2014-04-02 | 江苏飞船股份有限公司 | 外圆磨床砂轮修整器 |

| US10384326B2 (en) * | 2015-12-21 | 2019-08-20 | General Electric Company | Surface treatment of turbomachinery |

| DE102016204273B4 (de) * | 2016-03-15 | 2023-11-30 | Erwin Junker Maschinenfabrik Gmbh | Verfahren zur schleif-komplettbearbeitung von wellenförmigen werkstücken mit zylindrischen und profilierten abschnitten |

| US10096460B2 (en) | 2016-08-02 | 2018-10-09 | Semiconductor Components Industries, Llc | Semiconductor wafer and method of wafer thinning using grinding phase and separation phase |

| CN111941284B (zh) * | 2020-07-27 | 2022-01-07 | 西安理工大学 | 一种辊环复合平面研磨修整装置 |

| CN113263401A (zh) * | 2021-06-16 | 2021-08-17 | 无锡微研股份有限公司 | 一种冲头备件的加工方法 |

| CN114290133A (zh) * | 2022-01-13 | 2022-04-08 | 无锡微研股份有限公司 | 一种空调模波纹刀批量加工方法 |

| CN114871867A (zh) * | 2022-05-23 | 2022-08-09 | 扬州市职业大学(扬州开放大学) | 具有砂轮自修整功能的数控磨床 |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1753707A (en) * | 1923-03-07 | 1930-04-08 | Chrysler Corp | Process of grinding toothed articles |

| US1780747A (en) * | 1926-06-16 | 1930-11-04 | Gen Motors Corp | Finishing spline shafts |

| US3299577A (en) * | 1964-04-14 | 1967-01-24 | Nat Broach & Mach | Method and apparatus for trimming grinding wheels |

| GB1082418A (en) | 1966-07-22 | 1967-09-06 | Toolmasters Ltd | Improvements relating to grinding wheels |

| DE1577534A1 (de) * | 1966-09-03 | 1970-03-19 | Zahnradfabrik Friedrichshafen | Abrichteinrichtung |

| GB1253685A (en) | 1968-03-04 | 1971-11-17 | Heald Machine Co | Grinding machine |

| US3819405A (en) * | 1970-12-09 | 1974-06-25 | Porosan Interests Inc | A method of producing a volatilizing article of manufacture |

| US3877179A (en) * | 1973-02-13 | 1975-04-15 | Cincinnati Milacron Inc | Work locating device for grinding machines |

| JPS5431992A (en) | 1977-08-16 | 1979-03-09 | Tokyo Optical | Slit lamp having binocular real microscope |

| US4322916A (en) * | 1978-03-13 | 1982-04-06 | Dayco Corporation | Apparatus for making multiple rib belts |

| JPS5537201A (en) | 1978-08-29 | 1980-03-15 | Isao Tomizawa | Grinder wheel shaping method at orifice of small-diameter tube |

| US4343666A (en) * | 1978-11-02 | 1982-08-10 | Dayco Corporation | Method of making toothed belt |

| US4359841A (en) * | 1979-11-08 | 1982-11-23 | Trw Inc. | Grinding wheel wear detection and dressing method |

| US4329192A (en) * | 1981-01-19 | 1982-05-11 | Dayco Corporation | Apparatus and method for making a belt construction |

| DE3200063C2 (de) * | 1982-01-04 | 1984-06-28 | Breco Kunststoffverarbeitungs-Gesellschaft mbH & Co KG, 4952 Porta Westfalica | Verfahren zur Herstellung eines armierten Zahnriemens mit Gewebeauflage |

| DE3239914A1 (de) | 1982-10-28 | 1984-05-03 | Montanwerke Walter GmbH, 7400 Tübingen | Schleifmaschine zum schleifen der spanflaeche von spiralgenuteten werkzeugen |

| DE3438917A1 (de) * | 1984-10-24 | 1986-04-24 | Wilhelm Herm. Müller GmbH & Co KG, 3000 Hannover | Vorrichtung zur herstellung von endlosen zahnriemen |

| JPS61197161A (ja) | 1985-02-25 | 1986-09-01 | Amada Co Ltd | ドレツシング装置 |

| CH671912A5 (pl) * | 1987-01-25 | 1989-10-13 | Tschudin Werkzeugmasch | |

| DE3825465A1 (de) | 1987-08-04 | 1989-02-16 | Hauni Werke Koerber & Co Kg | Verfahren und vorrichtung zum bahngesteuerten abrichten eines schleifscheibenprofils |

| JP2510649B2 (ja) | 1988-01-22 | 1996-06-26 | 株式会社梅谷製作所 | 段ロ−ルの製法 |

| US4971602A (en) * | 1989-09-26 | 1990-11-20 | Crawford Robert B | Method for grinding gear teeth |

| JP2532954B2 (ja) | 1989-12-13 | 1996-09-11 | ユニッタ株式会社 | 両歯歯付無端ベルトおよびその製造方法 |

| JPH0463619A (ja) * | 1990-07-02 | 1992-02-28 | Mitsubishi Materials Corp | 総形研削砥石 |

| JPH07102500B2 (ja) * | 1991-09-20 | 1995-11-08 | 三ツ星ベルト株式会社 | Vリブドベルトの研磨方法 |

| DE4302353A1 (en) * | 1993-01-28 | 1993-08-19 | Kapp Werkzeugmasch | Grinding machine for shaping and profiling workpiece e.g. toothed wheel - uses computer to redress grinding wheel controlled by differences between stored profile and measured workpiece profile |

| DE4446275A1 (de) | 1994-01-10 | 1995-07-13 | White Hydraulics Inc | Verfahren zum Herstellen von Gerotor-Rotoren |

| US5486133A (en) * | 1994-05-31 | 1996-01-23 | Russell; Jerry | Timing belt grinding apparatus and method |

| US5595528A (en) * | 1994-10-19 | 1997-01-21 | Vermont Rebuild, Inc. | Grinding wheel dresser |

| DE69709924D1 (de) * | 1996-06-15 | 2002-02-28 | Unova Uk Ltd | Flexible verbindung einer schleifmaschinenspindel zu einer plattform |

| US6113474A (en) * | 1997-10-01 | 2000-09-05 | Cummins Engine Company, Inc. | Constant force truing and dressing apparatus and method |

| US6425807B2 (en) | 1999-04-29 | 2002-07-30 | White Hydraulics, Inc. | Method and apparatus for grinding rotors for hydraulic motors and apparatus therefor |

-

2000

- 2000-11-28 DE DE10059067A patent/DE10059067A1/de not_active Withdrawn

-

2001

- 2001-11-28 EP EP01995545A patent/EP1339527B2/de not_active Expired - Lifetime

- 2001-11-28 JP JP2002545882A patent/JP2004524169A/ja active Pending

- 2001-11-28 AU AU2002226281A patent/AU2002226281A1/en not_active Abandoned

- 2001-11-28 DE DE50112885T patent/DE50112885D1/de not_active Expired - Fee Related

- 2001-11-28 AT AT05007364T patent/ATE369939T1/de not_active IP Right Cessation

- 2001-11-28 SI SI200130403T patent/SI1339527T2/sl unknown

- 2001-11-28 CN CN018196292A patent/CN1216721C/zh not_active Expired - Fee Related

- 2001-11-28 PL PL366126A patent/PL201008B1/pl unknown

- 2001-11-28 ES ES05007364T patent/ES2291996T3/es not_active Expired - Lifetime

- 2001-11-28 ES ES01995545T patent/ES2243593T5/es not_active Expired - Lifetime

- 2001-11-28 MX MXPA03004648A patent/MXPA03004648A/es active IP Right Grant

- 2001-11-28 EP EP05007364A patent/EP1568441B1/de not_active Expired - Lifetime

- 2001-11-28 US US10/432,476 patent/US7125316B2/en not_active Expired - Fee Related

- 2001-11-28 WO PCT/DE2001/004471 patent/WO2002043919A1/de not_active Ceased

- 2001-11-28 AT AT01995545T patent/ATE296711T1/de not_active IP Right Cessation

- 2001-11-28 PT PT05007364T patent/PT1568441E/pt unknown

- 2001-11-28 KR KR1020037007092A patent/KR100783206B1/ko not_active Expired - Fee Related

- 2001-11-28 BR BR0115685-3A patent/BR0115685A/pt active Search and Examination

- 2001-11-28 PT PT01995545T patent/PT1339527E/pt unknown

- 2001-11-28 DE DE50106409T patent/DE50106409D1/de not_active Expired - Lifetime

- 2001-11-28 SI SI200130785T patent/SI1568441T1/sl unknown

Also Published As

| Publication number | Publication date |

|---|---|

| KR20040028687A (ko) | 2004-04-03 |

| ES2243593T3 (es) | 2005-12-01 |

| EP1568441A1 (de) | 2005-08-31 |

| MXPA03004648A (es) | 2004-10-14 |

| SI1568441T1 (sl) | 2008-02-29 |

| DE10059067A1 (de) | 2002-06-06 |

| SI1339527T1 (sl) | 2005-12-31 |

| AU2002226281A1 (en) | 2002-06-11 |

| CN1216721C (zh) | 2005-08-31 |

| ES2243593T5 (es) | 2011-08-30 |

| PL366126A1 (pl) | 2005-01-24 |

| PT1568441E (pt) | 2007-11-13 |

| CN1501851A (zh) | 2004-06-02 |

| PT1339527E (pt) | 2005-11-30 |

| SI1339527T2 (sl) | 2011-06-30 |

| EP1339527B1 (de) | 2005-06-01 |

| US20040029497A1 (en) | 2004-02-12 |

| DE50112885D1 (de) | 2007-09-27 |

| US7125316B2 (en) | 2006-10-24 |

| ES2291996T3 (es) | 2008-03-01 |

| ATE369939T1 (de) | 2007-09-15 |

| BR0115685A (pt) | 2003-09-09 |

| ATE296711T1 (de) | 2005-06-15 |

| PL201008B1 (pl) | 2009-02-27 |

| EP1339527B2 (de) | 2011-04-27 |

| EP1339527A1 (de) | 2003-09-03 |

| JP2004524169A (ja) | 2004-08-12 |

| WO2002043919A1 (de) | 2002-06-06 |

| DE50106409D1 (de) | 2005-07-07 |

| KR100783206B1 (ko) | 2007-12-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2823924B2 (de) | Doppelabrichter | |

| DE69526851T2 (de) | Schneckenförmige schleifscheibe, verfahren zum abrichten und schleifen eines werkstückes | |

| EP2895290B1 (de) | Verfahren zum modifizieren der flanken eines zahns eines zahnrads mit hilfe eines werkzeugs | |

| DE19619401C1 (de) | Verfahren, Werkzeug und Vorrichtung zum Profilieren von Schleifschnecken für das kontinuierliche Wälzschleifen | |

| DE10330474B4 (de) | Vorrichtung zur Herstellung eines Zahnrads aus einem Zahnradrohling | |

| EP1987920B1 (de) | Schleifmaschine zum Schleifen eines Zahnrades | |

| DE3320042C2 (pl) | ||

| EP0485339B1 (de) | Verfahren und Vorrichtung zum Profilieren von Schleifscheiben | |

| DE69127833T2 (de) | Verfahren und vorrichtung zur herstellung gerad- und schrägzahnstirnräder | |

| DE102006061759A1 (de) | Verzahnungsschleifmaschine, Verfahren zum Abrichten eines Profilschleifrads und Verfahren zum Schleifen eines Werkstücks | |

| EP3388179A1 (de) | Verfahren zur verzahnbearbeitung eines werkstücks | |

| EP1568441B1 (de) | Vorrichtung zur Herstellung von Zahnriemenformen | |

| EP3299105A1 (de) | Kegelrad-verzahnmaschine zum anfasen von kegelradzahnkanten und verfahren zum anfasen der zahnkanten von kegelrädern | |

| EP2036673B1 (de) | Verfahren zum Abrichten eines für die Feinbearbeitung der Zähne eines Zahnrades bestimmten Werkzeugs | |

| DE69426111T2 (de) | Verfahren und Maschine zum Herstellen von Kronenrädern | |

| DE20320294U1 (de) | Vorrichtung zur Herstellung eines Zahnrads | |

| DE102007043404A1 (de) | Verfahren zum Abrichten eines für die Feinbearbeitung der Zähne eines Zahnrades bestimmten Werkzeugs | |

| DE102007043384B4 (de) | Verfahren zum Abrichten eines für die Feinbearbeitung der Zähne eines Zahnrades bestimmten Werkzeugs | |

| EP2570221B1 (de) | Verfahren zum Schleifbearbeiten von einer als Außen- oder Innenverzahnung ausgebildeten Verzahnung eines Werkstücks | |

| DE102007043402B4 (de) | Verfahren zum Abrichten eines für die Feinbearbeitung der Zähne eines Zahnrades bestimmten Werkzeugs | |

| DE4340608A1 (de) | Schneidmesser | |

| DE10113301B4 (de) | Verfahren und Vorrichtung zum Hinterschleifen der Schneidzähne von zylindrisch oder kegelig geformten Abwalzfräsern sowie Abwalzfräser | |

| DE10131060A1 (de) | Vorrichtung zum Herstellen und Bearbeiten der Gerad- bzw. Schrägverzahnung von Werkstücken | |

| EP4066974A1 (de) | Verfahren zum erzeugen von verschränkungen an den zahnflanken eines innenverzahnten werkstücks | |

| DE2644331B2 (de) | Vorrichtung zum Herstellen oder Bearbeiten von Stirnrädern |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1339527 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17P | Request for examination filed |

Effective date: 20060225 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AXX | Extension fees paid |

Extension state: SI Payment date: 20060225 |

|

| 17Q | First examination report despatched |

Effective date: 20060711 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1339527 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: SI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50112885 Country of ref document: DE Date of ref document: 20070927 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20071026 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20071122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070815 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070815 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2291996 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071116 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070815 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: ZAHNRADFABRICK FRIEDRICH HOELTJE Effective date: 20080515 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071115 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| R26 | Opposition filed (corrected) |

Opponent name: ZAHNRADFABRICK FRIEDRICH HOELTJE Effective date: 20080515 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20081118 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071128 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20081121 Year of fee payment: 8 Ref country code: PT Payment date: 20081120 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20081203 Year of fee payment: 8 Ref country code: IT Payment date: 20081124 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081118 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081130 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081121 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071128 |

|

| BERE | Be: lapsed |

Owner name: BAUMLER, PETER Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20100528 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100528 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100730 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20100713 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091128 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20081120 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20111116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091128 |

|

| PLBD | Termination of opposition procedure: decision despatched |

Free format text: ORIGINAL CODE: EPIDOSNOPC1 |

|

| PLBM | Termination of opposition procedure: date of legal effect published |

Free format text: ORIGINAL CODE: 0009276 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION PROCEDURE CLOSED |

|

| 27C | Opposition proceedings terminated |

Effective date: 20130424 |