EP1553291A2 - Machine a piston elevateur - Google Patents

Machine a piston elevateur Download PDFInfo

- Publication number

- EP1553291A2 EP1553291A2 EP04405737A EP04405737A EP1553291A2 EP 1553291 A2 EP1553291 A2 EP 1553291A2 EP 04405737 A EP04405737 A EP 04405737A EP 04405737 A EP04405737 A EP 04405737A EP 1553291 A2 EP1553291 A2 EP 1553291A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- control ring

- recess

- engine according

- pistons

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B1/00—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders

- F04B1/04—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders having cylinders in star- or fan-arrangement

- F04B1/053—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders having cylinders in star- or fan-arrangement with actuating or actuated elements at the inner ends of the cylinders

Definitions

- the invention relates to a reciprocating engine with annular juxtaposed, radially directed piston-cylinder units and with an eccentric shaft extending through a the cylinder enclosing housing body of a machine housing extends and whose eccentric the Ausforcehub the Piston controls, with the inward stroke of the piston by a controlled common, engaging in the piston control ring becomes.

- a reciprocating piston engine whose pistons radially through an eccentric be moved outward, is known from EP 0088677.

- the outward stroke of the piston is through an eccentric and a rolling bearing enclosing this mechanically controlled during the inward stroke by the force a spring deformed by the lifting movement takes place, so that They the piston in contact with the outer ring of the bearing holds.

- Such a spring has u.a. the disadvantage that their arrangement the size of the machine adversely affected.

- For Their arrangement in the cylinder room also requires a room which acts as a dead space by an almost on the away stroke complete ejection of the medium is prevented.

- the Machine size mitbe carriedde size of the coupling ring results it thereby by its admission in a itself over the entire Scope of the cylinder block extending, even for his Assembly required large annular channel.

- This ring channel is used Also, the inclusion of a stop, a lateral ejection prevent the coupling ring from the annular groove of the piston should. Also by the relatively considerable size the dome ring, for which also a design made of wire provided is such a machine for high working speeds not suitable.

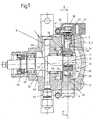

- the radial piston machine 1 has a preferably odd number For example, five piston-cylinder units 2,3, the ring-shaped next to each other, in a common, relatively flat Housing body 4 of a machine housing 5 is arranged are by in the massive material five radially directed, the piston 2 leading cylinder bores 3 incorporated are.

- the housing body 4 is corresponding The representation in Figure 2 preferably star-shaped and has on the outside five flange 6 for the tight assembly of Exhaust valves 7 and of a discharge line 8 enclosing Cylinder heads 9.

- the cylinder bores end 3 arranged in a centric to the eccentric shaft 12, smallest possible, circular gear chamber 10, in which the Eccentric 11 of the eccentric shaft 12 with a surrounding him Rolling 13 performs a circulation movement.

- the outer ring 14 of e.g. Rolling bearing designed as a needle bearing 13 is in constant contact with him, inner end face 15 of the piston 2, so that the circulation movement of the eccentric 11 the pistons 2 consecutive, pushes radially outwards to perform its outward stroke.

- This coupling causes the control ring 16 by the outward stroke of each piston 2 in order the orbital movement of the eccentric 11 is pulled outwards is and therefore arranged diametrically opposite one another Pulling the piston 2, pulls it inwards, so that it is hers Make an inward stroke.

- the recess 17 of the piston has the shape of a toward a secant-guided and the cross-sectional shape of the control ring 16 adapted incision, thus parallel to each other Surfaces.

- the recess 17 from the inner End face 15 of the piston 2 a minimum distance, the thickness of a bottom wall 18 of the preferably as a hollow body executed piston 2 corresponds and she is on one limited peripheral region of the piston (2) as a lateral interruption its in cylinder 3 sliding, cylindrical sliding surface executed.

- five inner control surfaces 20 of the control ring 16 are at least approximately and go over a small, for better distribution of am Control ring 16 forces provided rounding 22 in the circumferentially following inner control surface 20 via, such that the control ring 16 has a polygonal inner contour Has.

- a slight convex curvature of these control surfaces 20 in the circumferential direction may be advantageous to a load the transversely to the piston axis end boundary edges 61.62 of the contact surfaces 18 counteract.

- the control ring 16 may extend across the pistons 2 and in this direction unhindered relative to the piston Transverse motion, which is characterized by the in-phase the orbital movement of the eccentric 11 taking place control movement results. In this case, slide his inner control surfaces 20 on the respective inner bottom wall 18 of the five pistons 2. In addition allow the laterally open recesses 17 of the piston. 2 when assembling the machine a simple assembly of the moving components.

- control ring 16 has five circular arc-shaped parts 21st a cylindrical surface, each through a recess 23 of the Control ring 16 are limited. These five recesses 23 form in each case an inflow opening to the through the recess 17th laterally open, cylindrical interior 24 of the piston. 2

- the recesses 23 are arranged such that they as shown in Fig.3 on a lateral Part of the respective engagement region of the control ring 16 extend, and the inflow into the piston recess 17th accordingly laterally and thereby tangentially in the cylindrical Interior 24 of the piston 2 takes place.

- the diaphragm 33 of a check valve 31 by means of its edge 35 e.g. by welding attached.

- the membrane 33 has a central locking part 32 and three extending from this arcuate to the membrane edge 35 Web portions 34, so that the web portions 34 spring elements form for the lifting movement of the closing part 32.

- connection blocks 39 From the cylindrical work chambers 3, the working medium flows in connection blocks 39, the connection via connecting channels 40 to a the machine housing 5 enclosing manifold 41 produce. Through this outside the housing body. 4 Attached terminal blocks are the plate-shaped parts of the Cylinder heads 9 under prestress close to the housing body. 4 held.

- the eccentric shaft 12 is in the machine housing 5 and its bell-shaped housing body 50 by two bearings 42,43 stored.

- a drive-side sealing arrangement 44 seals the Housing interior 45 axially outward, while the free, the eccentric 11 and a balance weight 46 supporting shaft end 47 in a housing space 48 ends, by a flanged Housing cover 49 is closed.

- a compensation channel through the eccentric shaft extend through.

- the inflow of the working medium in the reciprocating engine. 1 takes place via at least one bell-shaped second housing block 50 radially connected connection piece 51. Subsequently flows through it according to the illustration in 5 in the housing inner wall 52 provided axial channels 53,54 and encounters a rotating with the eccentric shaft 11 Baffle 55, at which a lubricant in the gaseous Operating medium is deposited. The flow continues by flow around the baffle plate 55 and a gap 56th between the baffle plate and the housing body 50 to the centric arranged to the housing and shaft axis 57 and circular Gear chamber 10 of the housing body 4, in which the eccentric 11 rotates so that the operating medium from the end Housing chamber 48 in the manner previously described in the piston 2 can flow.

- the reciprocating piston engine 1 is particularly suitable as a compressor of a CO 2 air conditioning system for installation in the engine compartment of a motor vehicle. Furthermore, the essential components of the invention of the machine are designed so that they can be produced in a simple manner and mounted to each other.

- the pistons 2 are made two telescopically nested parts and before her Association is at one of these parts, i. the piston bottom 29 having part, the valve diaphragm 33 attached and on the other part the recess 17 by a lateral milling produced.

- the piston bottom 29 having part, the valve diaphragm 33 attached and on the other part the recess 17 by a lateral milling produced.

- a reciprocating piston engine 1 according to the invention is for high rotational speeds of more than 10 000 rpm, so that the Balancing the eccentric shaft 12 and the rotating with it Components, i.a. by the balance weight 46 and e.g. a recess 60 on the co-rotating baffle plate 55 of is of particular importance.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

- Reciprocating Pumps (AREA)

- Details Of Reciprocating Pumps (AREA)

- Valve Device For Special Equipments (AREA)

- Lubrication Of Internal Combustion Engines (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10356373 | 2003-12-03 | ||

| DE10356373A DE10356373A1 (de) | 2003-12-03 | 2003-12-03 | Hubkolbenmaschine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1553291A2 true EP1553291A2 (fr) | 2005-07-13 |

| EP1553291A3 EP1553291A3 (fr) | 2008-03-12 |

| EP1553291B1 EP1553291B1 (fr) | 2009-03-11 |

Family

ID=34585294

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04405737A Not-in-force EP1553291B1 (fr) | 2003-12-03 | 2004-11-29 | Machine a piston elevateur |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7273004B2 (fr) |

| EP (1) | EP1553291B1 (fr) |

| JP (1) | JP4523394B2 (fr) |

| CN (1) | CN1651720B (fr) |

| AT (1) | ATE425358T1 (fr) |

| DE (2) | DE10356373A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102020211680A1 (de) | 2020-09-17 | 2022-03-17 | Thyssenkrupp Ag | Kolben-Zylinder-Baugruppe für einen Radialkolbenverdichter sowie Radialkolbenverdichter |

| WO2024170360A1 (fr) * | 2023-02-13 | 2024-08-22 | Thyssenkrupp Dynamic Components Gmbh | Compresseur à pistons radiaux |

Families Citing this family (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8011897B2 (en) * | 2005-08-05 | 2011-09-06 | Carleton Life Support Systems Inc. | Cam driven piston compressor |

| DE102005061456B4 (de) * | 2005-12-22 | 2015-09-24 | Magna Powertrain Bad Homburg GmbH | Zylinderblock einer Hubkolbenmaschine mit durch Spannring gehaltenen Zylinderköpfen |

| KR100934297B1 (ko) * | 2007-09-27 | 2009-12-29 | 김배영 | 유체펌프 |

| WO2009086051A2 (fr) * | 2007-12-21 | 2009-07-09 | Carleton Life Support Systems Inc. | Compresseur radial à came et ensembles compresseurs à cames |

| US20100101534A1 (en) * | 2008-10-27 | 2010-04-29 | Tzu-Wei Yu | Multiple-fuel rotary engine |

| DE102009006040A1 (de) | 2009-01-24 | 2010-07-29 | Bock Kältemaschinen GmbH | Verdichter |

| CN101876302B (zh) * | 2010-06-23 | 2012-05-23 | 宁波运星机械制造有限公司 | 一种多缸往复泵 |

| WO2012017820A1 (fr) * | 2010-08-02 | 2012-02-09 | 日邦産業株式会社 | Machine à fluide tournante |

| CN102220902B (zh) * | 2011-03-13 | 2016-05-04 | 李培基 | 直轴偏心多缸双循环内燃发动机 |

| CN102900470A (zh) * | 2011-07-25 | 2013-01-30 | 祁喜林 | 星形发动机 |

| DE102012005297A1 (de) | 2012-03-19 | 2013-09-19 | Gea Bock Gmbh | Verdichtereinheit, sowie Verdichter |

| CN103967743A (zh) * | 2013-01-29 | 2014-08-06 | 王彦彬 | 磁力式同平面多缸多级组合压缩机 |

| CN103967745A (zh) * | 2013-01-30 | 2014-08-06 | 王彦彬 | 同平面多缸多级凸轮组合压缩机 |

| CN104776005A (zh) * | 2015-03-25 | 2015-07-15 | 安徽工程大学 | 一种活塞式压缩机 |

| US11002268B2 (en) | 2015-07-27 | 2021-05-11 | Cobham Mission Systems Davenport Lss Inc. | Sealed cavity compressor to reduce contaminant induction |

| CN107313911A (zh) * | 2017-06-19 | 2017-11-03 | 肖福俊 | 新型高性能四缸柱塞泵 |

| CN108869231B (zh) * | 2018-08-03 | 2024-02-13 | 东莞力嘉塑料制品有限公司 | 一种旋转式导轨驱动活塞泵 |

| CN109404250B (zh) * | 2018-10-17 | 2019-10-11 | 安徽工业大学 | 一种燃气喷射发动机 |

| LU103051B1 (de) | 2022-12-16 | 2024-06-17 | Thyssenkrupp Ag | Radialkolbenverdichter, sowie Verfahren zur Montage eines Radialkolbenverdichters |

| WO2024126399A1 (fr) | 2022-12-16 | 2024-06-20 | Thyssenkrupp Dynamic Components Gmbh | Compresseur à pistons radiaux et procédé d'assemblage d'un compresseur à pistons radiaux |

| DE102022133721A1 (de) | 2022-12-16 | 2024-06-27 | Thyssenkrupp Ag | Radialkolbenverdichter, sowie Verfahren zur Montage eines Radialkolbenverdichters |

| DE102023103387A1 (de) | 2023-02-13 | 2024-08-14 | Thyssenkrupp Ag | Kolben-Zylinderbohrung-Baugruppe für einen Radialkolbenverdichter sowie Radialkolbenverdichter |

| DE102023106706A1 (de) * | 2023-03-17 | 2024-09-19 | Thyssenkrupp Ag | Radialkolbenverdichter |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1453663A1 (de) * | 1963-02-16 | 1969-03-13 | Teves Gmbh Alfred | Radialkolbenpumpe |

| GB1216763A (en) * | 1967-06-24 | 1970-12-23 | Teves Gmbh Alfred | Improvements in or relating to piston pumps |

| GB2225614A (en) * | 1988-12-02 | 1990-06-06 | Teves Gmbh Alfred | Radial piston pump |

| DE19948445A1 (de) * | 1999-10-08 | 2001-04-12 | Continental Teves Ag & Co Ohg | 6-Kolben-Pumpe, insbesondere für geregelte Bremssysteme |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4128084A (en) * | 1975-07-25 | 1978-12-05 | Iris Jean Carrington Sutherland | Rotary engine |

| FR2523222A1 (fr) | 1982-03-09 | 1983-09-16 | Citroen Sa | Pompe modulaire |

| AT394892B (de) * | 1989-09-18 | 1992-07-10 | Tech Hydraulikgeraete Ges M B | Radialkolbenpumpe |

| US5338160A (en) * | 1989-09-18 | 1994-08-16 | Gesellschaft fur okologische Okomobil Technologie fur Fahrzeuge GmbH | Individual controllable cylinder-plunger assemblies of a radial piston pump |

| US9083674B2 (en) * | 2013-03-11 | 2015-07-14 | Aol Inc. | Systems and methods for sharing audio feeds |

-

2003

- 2003-12-03 DE DE10356373A patent/DE10356373A1/de not_active Withdrawn

-

2004

- 2004-11-29 AT AT04405737T patent/ATE425358T1/de not_active IP Right Cessation

- 2004-11-29 DE DE502004009129T patent/DE502004009129D1/de active Active

- 2004-11-29 EP EP04405737A patent/EP1553291B1/fr not_active Not-in-force

- 2004-12-03 US US11/004,655 patent/US7273004B2/en not_active Expired - Fee Related

- 2004-12-03 CN CN2004100822394A patent/CN1651720B/zh not_active Expired - Fee Related

- 2004-12-03 JP JP2004351322A patent/JP4523394B2/ja not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1453663A1 (de) * | 1963-02-16 | 1969-03-13 | Teves Gmbh Alfred | Radialkolbenpumpe |

| GB1216763A (en) * | 1967-06-24 | 1970-12-23 | Teves Gmbh Alfred | Improvements in or relating to piston pumps |

| GB2225614A (en) * | 1988-12-02 | 1990-06-06 | Teves Gmbh Alfred | Radial piston pump |

| DE19948445A1 (de) * | 1999-10-08 | 2001-04-12 | Continental Teves Ag & Co Ohg | 6-Kolben-Pumpe, insbesondere für geregelte Bremssysteme |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102020211680A1 (de) | 2020-09-17 | 2022-03-17 | Thyssenkrupp Ag | Kolben-Zylinder-Baugruppe für einen Radialkolbenverdichter sowie Radialkolbenverdichter |

| WO2022058321A1 (fr) | 2020-09-17 | 2022-03-24 | thyssenkrupp Presta Ilsenburg GmbH | Ensemble piston-cylindre pour un compresseur à pistons radiaux et compresseur à pistons radiaux |

| WO2024170360A1 (fr) * | 2023-02-13 | 2024-08-22 | Thyssenkrupp Dynamic Components Gmbh | Compresseur à pistons radiaux |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE425358T1 (de) | 2009-03-15 |

| DE10356373A1 (de) | 2005-07-07 |

| US20050120984A1 (en) | 2005-06-09 |

| US7273004B2 (en) | 2007-09-25 |

| JP2005163792A (ja) | 2005-06-23 |

| EP1553291B1 (fr) | 2009-03-11 |

| DE502004009129D1 (de) | 2009-04-23 |

| JP4523394B2 (ja) | 2010-08-11 |

| EP1553291A3 (fr) | 2008-03-12 |

| CN1651720B (zh) | 2010-10-13 |

| CN1651720A (zh) | 2005-08-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1553291B1 (fr) | Machine a piston elevateur | |

| EP2137378B1 (fr) | Pompe ou moteur | |

| DE69104093T2 (de) | Klimaanlagekompressor. | |

| WO2005085635A1 (fr) | Machine a piston axial | |

| DE19850158A1 (de) | Seitenkanal-Kraftstoffpumpe | |

| DE2216579A1 (de) | Achsialkolbenverdichter | |

| WO2012034619A1 (fr) | Machine à pistons axiaux | |

| EP1019637B1 (fr) | Moteur oscillant radial | |

| DE3213855A1 (de) | Hubkolbenmotor mit taumelscheibenmechanismus | |

| DE4326323A1 (de) | Taumelscheibenverdichter | |

| WO1999057423A1 (fr) | Dispositif de deplacement hydraulique de l'angle de rotation d'un arbre par rapport a une roue d'entrainement | |

| EP0320963A2 (fr) | Pompe volumétrique pour fluides fonctionnant comme une pompe à pistons tournants | |

| WO2011161178A1 (fr) | Machine à pistons axiaux | |

| DE112010001701B4 (de) | Flügelzellenpumpe mit verbessertem Rotor und Drehschiebererweiterungsring | |

| DE4326408A1 (de) | Vielfach-Axialkolbenverdichter | |

| DE102016203587A1 (de) | Taumelscheibenverdichter mit veränderlicher Verdrängung | |

| WO2012010262A1 (fr) | Ensemble piston | |

| DE3030285A1 (de) | Axialkolbenpumpe | |

| DE19881099B3 (de) | Drehschwingungsdämpfer für eine verriegelbare Kupplung, die zu einem hydrodynamischen Momentwandler gehört, insbesondere für Kraftfahrzeuge | |

| WO2016058736A1 (fr) | Pompe à carburant | |

| DE3804842C2 (fr) | ||

| DE102010036199A1 (de) | Axialkolbenmaschine mit verringerter Verlustleistung | |

| DE2555595C2 (de) | Flügelzellenpumpe | |

| AT505061A1 (de) | Drehschieberpumpe | |

| DE1903256C3 (de) | Ventilanordnung für Kolbenpumpen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VISTEON GLOBAL TECHNOLOGIES, INC. Owner name: OBRIST ENGINEERING GMBH Owner name: IXETIC BAD HOMBURG GMBH |

|

| 17P | Request for examination filed |

Effective date: 20080912 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004009129 Country of ref document: DE Date of ref document: 20090423 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090611 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090622 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090824 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090711 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090611 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 |

|

| 26N | No opposition filed |

Effective date: 20091214 |

|

| BERE | Be: lapsed |

Owner name: IXETIC BAD HOMBURG G.M.B.H. Effective date: 20091130 Owner name: OBRIST ENGINEERING GMBH Effective date: 20091130 Owner name: VISTEON GLOBAL TECHNOLOGIES, INC. Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091130 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090311 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20161129 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20161213 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20161223 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004009129 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180602 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171130 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171129 |