EP1522234B1 - Procédé pour fabriquer des brosses, en particulier des brosses à dents - Google Patents

Procédé pour fabriquer des brosses, en particulier des brosses à dents Download PDFInfo

- Publication number

- EP1522234B1 EP1522234B1 EP04024201.8A EP04024201A EP1522234B1 EP 1522234 B1 EP1522234 B1 EP 1522234B1 EP 04024201 A EP04024201 A EP 04024201A EP 1522234 B1 EP1522234 B1 EP 1522234B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bristle

- bristle bundles

- motion

- hole

- bundles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title description 6

- 238000000034 method Methods 0.000 claims description 33

- 238000003780 insertion Methods 0.000 claims description 3

- 230000037431 insertion Effects 0.000 claims description 3

- 230000014759 maintenance of location Effects 0.000 claims 2

- 238000000926 separation method Methods 0.000 claims 2

- 238000003860 storage Methods 0.000 description 5

- 239000000969 carrier Substances 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D3/00—Preparing, i.e. Manufacturing brush bodies

- A46D3/08—Parts of brush-making machines

- A46D3/082—Magazines for bristles; Feeding bristles to magazines; Knot picking

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/10—For human or animal care

- A46B2200/1066—Toothbrush for cleaning the teeth or dentures

Definitions

- the present invention relates to a method for producing brushes, in particular toothbrushes, in which the bristle bundles are divided from at least one bristle supply in a first direction of movement by a single compartment element which bears sealingly against an opening of the bristle supply and is fastened to at least one bristle carrier by the latter Abforcelement be removed in a second direction of movement, wherein, after in the first direction of movement a plurality of bristle bundles have been divided with the one Abwellement, the Abforcelement is stopped and these bristle bundles are removed simultaneously in the second direction of movement from the Abforcelement.

- the present invention is based on the problem to improve the generic method in terms of its speed and performance.

- a plurality of bristle bundles with a first circular segment-shaped movement can be divided off from a bristle supply and provided at the same time for attachment to at least one bristle carrier.

- the performance of the method can be improved.

- inventive Methods for providing bundles of bristles for attachment to the bristle carrier are initially separated from a bristle supply by a compartment element in a first circular segment-shaped movement direction. After the bundles of bristles have been divided by means of the dividing element, the dividing element is stopped and the bundles of bristles held on the dividing element are grasped in a second direction of movement, preferably orthogonal to the first direction of movement, and removed at the same time.

- the bristle bundles are removed substantially simultaneously, namely that the bundles of bristles initially provided in a first direction of movement are removed from the dividing element before it is set in motion again for dividing further bristle bundles.

- the bundles of bristles removed in the second direction of movement are finished bundles of bristles, which can be seen as individual bundles on the finished brush or form the subset of an enlarged bundle of bristles in which a plurality of bristle bundles are combined with identical or substantially identical number of bristle filaments.

- the bristle bundles thus produced are removed from the compartment element for attachment to the bristle carrier. This means that the bristle bundles are removed from the compartment element.

- the bristle bundles can either be gripped with a stuffing tool in a manner known per se and fastened directly to the bristle carrier.

- the bristle bundles can also be transferred to a holder for further preparation of the bristle bundles for later attachment to a bristle carrier.

- the bristle bundles are simultaneously introduced into at least one perforated field pattern in the second direction of movement, which corresponds to a bristle arrangement of a single bristle carrier.

- the perforated field pattern according to the invention is a pattern of holes which are provided in an arrangement corresponding to the size, number and relative orientation of the bristles of the finished brush. Since the bundles of bristles are introduced at the same time in the or the hole field pattern in the second movement, such a perforated field pattern can be stuffed faster with bristle bundles.

- the bristle bundles are held in the second direction of movement via a common stuffing tool and at the same time introduced into different holes of the at least one hole field pattern.

- the stuffing tool required to carry out this preferred method of operation can be designed, despite increased output, with only slightly higher mass than a stuffing tool for stuffing only one bristle bundle.

- the bristle bundles are held in the second direction of movement over a plurality of stuffing tools and at the same time introduced into different holes of the at least one hole field pattern.

- the different stuffing tools are preferably coordinated so that even in the event of failure of one or more Stopftechnikmaschineen the still working stuffing tools can ensure production.

- the bristle bundles are simultaneously introduced into corresponding holes of different perforated field patterns in the second direction of movement.

- This preferred process facilitates mass production of a plurality of identical hole pattern brushes.

- the relative movement between the hole field pattern and the stuffing tool in a direction substantially transverse to the extension of the holes required to stuff a hole field pattern to provide empty holes for the stuffing device in this embodiment detects a plurality of hole field patterns whose corresponding holes are stuffed with bristle bundles at the same time ,

- This preferred development of the method according to the invention initially simplifies the structural design of the device required for carrying out the method.

- the preferred method is particularly suitable for the preparation of bundles of bristles which are stuffed into a perforated field pattern whose holes have identical lateral spacing from each other. The lateral spacing of the recesses provided on the dividing element and accommodating the bristle bundles corresponds exactly to this lateral spacing of individual holes of the perforated field pattern.

- the prepared bundles of bristles taken from the dividing element at the removal position are directly introduced into adjacent holes of the perforated field pattern in this preferred embodiment without changing their lateral spacing.

- the movement in the second direction of movement may be an exclusively linear movement, resulting in a fast and simple procedure.

- the bristle bundles are held in the second direction of movement via a common stuffing tool and at the same time introduced into a single hole of the perforated field pattern.

- the bundles of bristles are thereby conveyed while maintaining their lateral distance to an opening of a hole and moved toward each other when introduced into the hole.

- the bristle bundles slide on insertion into the hole on the surface of a funnel-shaped opening of the hole. This ensures a safe introduction of the bristle bundles into the hole with a simple configuration of the device for carrying out the method.

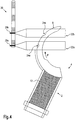

- FIG. 1 and 2 each schematically show essential parts of a device for carrying out the method, which has a bristle storage container 2, a circular-arc-shaped dividing element 4 and a stuffing tool 6.

- the compartment element 4 lies with its outer peripheral surface 8 sealingly against an opening of the bristle reservoir 2. Furthermore, the compartment element 4 has two recesses 10a, 10b positioned next to one another.

- bristle filaments 12 are removed from the storage container 2 by means of the compartment element 4.

- a certain number of bristle filaments 12 are removed from the bristle storage container 2 only when the recesses 10a, 10b of the compartment element 4 at the opening the bristle reservoir 2 are passed.

- the bristle filaments 12 are thereby divided into two different bristle bundles 14 in a controlled manner.

- the bristle bundles 14 are guided in a continuous movement in the direction of the arrow P to a stuffing tool 6.

- the circular compartment element 4 terminates the first direction of movement only when the bristle bundles 14 have reached a position in which the bristle bundles 14 can be introduced in a linear movement in holes 16 provided for them of a bristle carrier 18 at the same time.

- this second movement which is substantially orthogonal to the first movement, ie substantially perpendicular to the instantaneous movement of the bristle bundles 14 immediately prior to stopping of the dividing element 4 for removal of the bristle bundles 14, the bristle bundles 14a, 14b are spaced apart so that the distance between the bristle bundles 14a, 14b, the distance between the holes 16a, 16b and the distance between the recesses 10a, 10b (at right angles to the direction of movement of the stuffing tool 6) corresponds.

- FIG. 2 is different from the one in FIG. 1 shown embodiment in that the bristle bundles are introduced into a single hole field plate 20. Thereafter, the perforated field plate 20 can either be attached directly to a bristle carrier or serves as a support while the bundles of bristles are attached to a bristle carrier.

- FIG. 2 - as well as in the FIGS. 4 . 5 -

- the introduction of the bristle bundles in the hole field plate 20 is shown schematically simplified. In fact, the bundles 14a, 14b are removed from the tamping tool and introduced into the perforated field plate 20 in the axial direction, ie perpendicular to the plane of the drawing.

- the dividing element 4 abuts on its outer circumferential surface 8 on a counter surface, are closed by the recesses 10a, 10b.

- the bristle bundles 14a, 14b can be removed from the compartment element 4, for example, by a punch engaging in the recesses 10a, 10b.

- FIGS. 3 to 5 show further embodiments of the method according to the invention.

- FIGS. 1 and 2 like parts, marked with the same reference numerals.

- the in the FIG. 3 shown bristle arrangement has two stuffing tools 22a, 22b.

- the sealing element abutting against the bristle storage container 2 is moved in a first circular arc-shaped movement in the direction of the arrow P.

- bristle filaments are removed from the first recess 24b from the bristle storage container 2 and divided into a bristle bundle 26b.

- further bristle filaments 12 are divided into a bristle bundle 26a by means of the second recess 24a.

- the bristle bundles 26 are guided in the direction of the arrow P until they are in a position in which the bundles of bristles 26a, 26b are each moved simultaneously by a tamping tool 24a, 24b into a respective hole 28a, 28b of one of the bristle carriers 30a, 30b can be introduced.

- FIG. 4 is different from the one in FIG. 3 shown embodiment in that the bristle bundles are simultaneously introduced into corresponding holes of a plurality of hole field pattern formed in a perforated field plate.

- FIG. 5 shows a further embodiment in which the bristle bundles 16a, 16b are introduced into a single hole of a perforated field pattern.

- FIG. 5 shows a perforated field plate 19 having a hole 17 with a funnel-shaped opening.

- the bristle bundles 16a, 16b become, as in the in FIG. 1 shown embodiment, separated from the bristle supply 2 and conveyed by the Abteielement 4 to the stuffing tool 6.

- the bristle bundles are then removed at the same time by means of the stuffing tool 6 of the compartment element 4 and are conveyed in a linear movement to the mouth of the hole 17.

- the bristle bundles 16a, 16b are then introduced into the hole 17 at the same time, with the bristle bundles 16a, 16b sliding off the funnel-shaped surface of the opening.

- the distance between the recesses of the compartment element and the distance between the holes to be stuffed is preferably matched to one another such that the divided bristle bundles can be introduced into the holes while maintaining their lateral spacing.

- the divided bristle bundles the bundles of bristles which can be seen as individual bristle bundles on the finished brush, can be, on the other hand, the divided bristle bundles can form the subset of an enlarged bristle bundle.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Brushes (AREA)

Claims (8)

- Procédé de fabrication de brosses, en particulier des brosses à dents, dans lequel des faisceaux de poils (14, 26) sont répartis dans une première direction de mouvement à partir d'au moins un stock de poils (2) à partir d'un seul élément de séparation (4) reposant par sa face périphérique externe (8) très près d'une ouverture du stock de poils (2) et pour fixation au niveau d'au moins un support de poils (18) à partir de l'élément de séparation (4) dans une seconde direction de mouvement, dans lequel, après séparation de plusieurs faisceaux de poils (14, 26) dans la première direction de mouvement à l'aide dudit élément de séparation (4), ledit élément de séparation s'interrompt et lesdits faisceaux de poils (14, 26) sont retirés dans la seconde direction de mouvement dans le même temps à partir de l'élément de séparation (4), caractérisé en ce

que la première direction de mouvement est une direction de mouvement en forme de segments circulaires et que les faisceaux de poils ((26) sont introduits dans la seconde direction de mouvement dans le même temps dans plusieurs schémas de champs de perforation ou un seul schéma de champ de perforations, qui correspond à une configuration de poils d'un seul support de poils. - Procédé selon la revendication 1, caractérisé en ce que les faisceaux de poils (14) sont maintenus dans la seconde direction de mouvement par l'intermédiaire d'un outil de capitonnage commun (6) et introduits dans le même temps dans différents trous (16) des schémas de champs de perforation.

- Procédé selon la revendication 1, caractérisé en ce que les faisceaux de poils (26) sont maintenus dans la seconde direction de mouvement par l'intermédiaire de plusieurs outils de capitonnage 22) et introduits dans le même temps dans différents trous (28) des schémas de champs de perforation.

- Procédé selon la revendications 1, caractérisé en ce que les faisceaux de poils (14) sont maintenus dans la seconde direction de mouvement par l'intermédiaire d'un outil de capitonnage commun (6) et introduits dans le même temps dans différents trous (16) des schémas de champs de perforation.

- Procédé selon l'une des revendications précédentes, caractérisé en ce que les faisceaux de poils (14, 26) sont introduits dans le même temps dans les trous (16, 28) des schémas de champs de perforation dans la seconde direction de mouvement en conservant leur distance latérale.

- Procédé selon l'une des revendications précédentes, caractérisé en ce que les faisceaux de poils (14) sont maintenus dans la seconde direction de mouvement par l'intermédiaire d'un outil de capitonnage commun (6) et introduits dans le même temps dans un seul trou (17) de l'un des schémas de champs de perforation.

- Procédé selon la revendication 6, caractérisé en ce que les faisceaux de poils (14) sont acheminés à une embouchure d'un trou en conservant leur distance latérale puis empilés les uns au-dessus des autres en pénétrant dans le trou.

- Procédé selon la revendication 7, caractérisé en ce que les faisceaux de poils (14), lors de l'introduction dans le trou (17) glissent à la surface d'une ouverture en forme de trémie au niveau du trou (17).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10346867 | 2003-10-09 | ||

| DE10346867A DE10346867A1 (de) | 2003-10-09 | 2003-10-09 | Verfahren zur Herstellung von Bürsten, insbesondere Zahnbürsten |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1522234A2 EP1522234A2 (fr) | 2005-04-13 |

| EP1522234A3 EP1522234A3 (fr) | 2010-06-30 |

| EP1522234B1 true EP1522234B1 (fr) | 2017-12-06 |

| EP1522234B2 EP1522234B2 (fr) | 2020-11-18 |

Family

ID=34306335

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04024201.8A Expired - Lifetime EP1522234B2 (fr) | 2003-10-09 | 2004-10-11 | Procédé pour fabriquer des brosses, en particulier des brosses à dents |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1522234B2 (fr) |

| DE (1) | DE10346867A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3138438B1 (fr) * | 2015-09-03 | 2018-09-05 | The Procter and Gamble Company | Cueilleur de touffe pour un dispositif de prélèvement de touffe d'une machine de fabrication de brosse |

| EP3138436A1 (fr) * | 2015-09-03 | 2017-03-08 | The Procter and Gamble Company | Dispositif de ramassage de touffes destiné à une machine de fabrication de brosse |

| KR102104378B1 (ko) | 2016-04-08 | 2020-04-27 | 엠 + 씨 쉬퍼 게엠베하 | 강모 필라멘트 카세트에 강모 배치를 공급하기 위한 공급장치 |

| EP3351142B1 (fr) | 2017-01-24 | 2019-10-16 | The Procter and Gamble Company | Dispositif de ramassage de touffes destiné à une machine de fabrication de brosse |

| EP3351143B1 (fr) | 2017-01-24 | 2019-11-06 | The Procter and Gamble Company | Cueilleur de touffes destiné à une machine de fabrication de brosse |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0405204A2 (fr) * | 1989-06-24 | 1991-01-02 | Frisetta GmbH | Dispositif et procédé pour façonner une répartition de soies ou une touffe de soies |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7016156U (de) * | 1969-05-08 | 1973-06-07 | Robert Lardenois | Haarbuerste. |

| DE1938937A1 (de) | 1969-07-31 | 1971-02-11 | Zahoransky Anton Fa | Verfahren und Vorrichtung zum Herstellen von Buersten mit mindestens zwei Borstensorten |

| DE2849510A1 (de) * | 1978-11-15 | 1980-06-04 | Zahoransky Anton Fa | Buerstenherstellungsmaschine sowie verfahren zum herstellen von buersten |

| GB2289236B (en) * | 1994-05-09 | 1997-08-06 | Boucherie Nv G B | A brush making machine |

| BE1009051A3 (nl) * | 1995-01-24 | 1996-11-05 | Boucherie Nv G B | Borstelvervaardigingsmachine en werkwijze voor het vervaardigen van borstels. |

| DE69906425T2 (de) * | 1998-07-14 | 2004-01-08 | G.B. Boucherie N.V. | Verfahren zum Herstellen von Bürsten sowie Bürstenherstellungsmaschine zur Durchführung dieses Verfahrens |

-

2003

- 2003-10-09 DE DE10346867A patent/DE10346867A1/de not_active Withdrawn

-

2004

- 2004-10-11 EP EP04024201.8A patent/EP1522234B2/fr not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0405204A2 (fr) * | 1989-06-24 | 1991-01-02 | Frisetta GmbH | Dispositif et procédé pour façonner une répartition de soies ou une touffe de soies |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10346867A1 (de) | 2005-05-04 |

| EP1522234A3 (fr) | 2010-06-30 |

| EP1522234A2 (fr) | 2005-04-13 |

| EP1522234B2 (fr) | 2020-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2408334B1 (fr) | Procédé et dispositif de fabrication des ensembles de poils pour des brosses | |

| EP3223650A1 (fr) | Procédé et dispositif de fabrication d'un nettoyeur inter-dentaire | |

| EP3037016B1 (fr) | Machine de fabrication de brosse et procede d'insertion de faisceaux de soies dans des ouvertures d'un support de faisceau | |

| EP1864588A2 (fr) | Brosse à dents et procédé destiné à sa fabrication | |

| DE102005061193B4 (de) | Handhabungsverfahren und -vorrichtung, insbesondere an einer Spritzgussmaschine | |

| EP0135238A2 (fr) | Dispositif pour la fermeture d'enveloppes d'emballage tubulaires avec des agrafes de fermeture en U | |

| DE3832520A1 (de) | Verfahren und vorrichtung zum herstellen von buersten, insbesondere von buersten fuer hygienische beduerfnisse, wie zahnbuersten | |

| EP1522234B1 (fr) | Procédé pour fabriquer des brosses, en particulier des brosses à dents | |

| EP0993262A1 (fr) | Dispositif de moulage par injection | |

| DE1919859A1 (de) | Verfahren fuer die gruppenweise Zufuhr von Werkstuecken einer Arbeitsmaschine sowie Vorrichtung zur Ausfuehrung des Verfahrens | |

| DE60114214T2 (de) | Verfahren zur herstellung einer zahnbürste | |

| EP0710534B1 (fr) | Procédé et dispositif pour fabriquer des corps de brosse à partir d'au moins deux composants de matière plastique | |

| EP3612054B1 (fr) | Procédé et dispositif destinés à fabriquer des brosses | |

| DE10062398C5 (de) | Verfahren zur Bildung eines Borstenbündels sowie eine zur Durchführung des Verfahrens geeignete Vorrichtung | |

| EP2110325A1 (fr) | Unité de vanne d'arrêt d'un dispositif d'alimentation et de tri pour machines d'emballage | |

| DE10030811C2 (de) | Verfahren und Vorrichtung zur Herstellung von Bürsten | |

| EP0371108B1 (fr) | Procede pour fabriquer des arceaux de fil metallique pour maintenir des bouchons de bouteille | |

| WO2023138931A1 (fr) | Dispositif et procédé pour diviser des faisceaux de poils à partir d'une alimentation en filaments de poils en vrac | |

| DE102022111906B3 (de) | Vorrichtung zur Verdichtung von Borstenbündeln, Borstenwarenherstellungsmaschine und Verfahren zur Verdichtung von Borstenbündeln | |

| EP3496568B1 (fr) | Procédé et dispositif pour fabriquer des ensembles de soies pour des brosses et machine à fabriquer des soies | |

| DE69416395T2 (de) | Methode und Einrichtung zur Bürstenherstellung | |

| DE202006017919U1 (de) | Vorrichtung zum Herstellen von Bürsten | |

| EP1476043B1 (fr) | Dispositif de blocage et procede de fixation de faisceaux de filaments | |

| WO1989011359A1 (fr) | Dispositif pour fabriquer des muselets de fil metallique servant a maintenir les bouchons de bouteilles | |

| EP1290961A1 (fr) | Dispositif pour fabriquer des articles de brosserie, en particulier de brosses à dents |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20100729 |

|

| AKX | Designation fees paid |

Designated state(s): BE CH DE FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20120412 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170519 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR GB IT LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENT- UND MARKENANWAELTE, CH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502004015615 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502004015615 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: ZAHORANSKY AG Effective date: 20180905 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20181011 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181011 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181031 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AELC |

|

| 27A | Patent maintained in amended form |

Effective date: 20201118 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE CH DE FR GB IT LI |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502004015615 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20201030 Year of fee payment: 17 Ref country code: CH Payment date: 20201023 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211011 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20221021 Year of fee payment: 19 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230523 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231026 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20231031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231031 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502004015615 Country of ref document: DE |