EP1520933A1 - Baukonstruktion, einzelnes Bauelement und Verfahren zur Verstärkung dieser Baukonstruktion - Google Patents

Baukonstruktion, einzelnes Bauelement und Verfahren zur Verstärkung dieser Baukonstruktion Download PDFInfo

- Publication number

- EP1520933A1 EP1520933A1 EP04300644A EP04300644A EP1520933A1 EP 1520933 A1 EP1520933 A1 EP 1520933A1 EP 04300644 A EP04300644 A EP 04300644A EP 04300644 A EP04300644 A EP 04300644A EP 1520933 A1 EP1520933 A1 EP 1520933A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- volume

- impacts

- individual

- deformed

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000010276 construction Methods 0.000 title claims description 29

- 238000000034 method Methods 0.000 title claims description 9

- 230000003014 reinforcing effect Effects 0.000 title claims description 9

- 239000000463 material Substances 0.000 claims abstract description 60

- 239000004567 concrete Substances 0.000 claims abstract description 9

- 239000004746 geotextile Substances 0.000 claims description 16

- 238000000926 separation method Methods 0.000 claims description 9

- 239000000203 mixture Substances 0.000 claims description 8

- 239000011435 rock Substances 0.000 claims description 8

- 239000008188 pellet Substances 0.000 claims description 7

- 230000002787 reinforcement Effects 0.000 claims description 6

- 239000002184 metal Substances 0.000 claims description 5

- 239000004793 Polystyrene Substances 0.000 claims description 4

- 229920002223 polystyrene Polymers 0.000 claims description 4

- 229910000831 Steel Inorganic materials 0.000 claims description 2

- 239000010959 steel Substances 0.000 claims description 2

- 230000001747 exhibiting effect Effects 0.000 claims 1

- 239000004575 stone Substances 0.000 abstract description 6

- 239000004576 sand Substances 0.000 abstract description 4

- 230000004888 barrier function Effects 0.000 abstract 1

- 230000005489 elastic deformation Effects 0.000 abstract 1

- 230000001681 protective effect Effects 0.000 description 15

- 238000010521 absorption reaction Methods 0.000 description 3

- 238000005253 cladding Methods 0.000 description 3

- 239000007779 soft material Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 238000009418 renovation Methods 0.000 description 2

- 238000005336 cracking Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 238000002513 implantation Methods 0.000 description 1

- 239000010410 layer Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000009993 protective function Effects 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

- 239000011150 reinforced concrete Substances 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000009528 severe injury Effects 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D29/00—Independent underground or underwater structures; Retaining walls

- E02D29/02—Retaining or protecting walls

- E02D29/0208—Gabions

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01F—ADDITIONAL WORK, SUCH AS EQUIPPING ROADS OR THE CONSTRUCTION OF PLATFORMS, HELICOPTER LANDING STAGES, SIGNS, SNOW FENCES, OR THE LIKE

- E01F7/00—Devices affording protection against snow, sand drifts, side-wind effects, snowslides, avalanches or falling rocks; Anti-dazzle arrangements ; Sight-screens for roads, e.g. to mask accident site

- E01F7/04—Devices affording protection against snowslides, avalanches or falling rocks, e.g. avalanche preventing structures, galleries

- E01F7/045—Devices specially adapted for protecting against falling rocks, e.g. galleries, nets, rock traps

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D2300/00—Materials

- E02D2300/0001—Rubbers

- E02D2300/0003—Car tires

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D2300/00—Materials

- E02D2300/0051—Including fibers

- E02D2300/0054—Including fibers made from plastic

- E02D2300/006—Including fibers made from plastic being recycled

- E02D2300/0062—Shredded car tires

Definitions

- the present invention relates to a civil engineering structure providing protection against impacts of moving masses, projectiles, especially stones. It also relates to an individual element of construction intended for the realization protective works in the field of civil engineering and public works. Another aspect of the invention relates to a method of reinforcing a structure ensuring a protection against impacts.

- a main problem that the invention proposes to solve is to provide a civil engineering work that can easily be repaired.

- a second problem is to design a work with mechanical properties such as does not require oversizing to ensure its protective functions.

- a third problem is that of improving the aesthetic and ecological aspect of while maintaining their functional aspect.

- a fourth problem is to put point an individual element of construction capable of limiting the deterioration of the entire civil engineering work with which it is associated.

- a fifth problem is to realize an element that can be prefabricated outside dangerous zones, that is to say subject to falling rocks.

- a sixth problem is that of putting a process for reinforcing a pre-existing protective structure.

- the invention therefore relates to a civil engineering work intended to ensure a protection against moving mass impacts and having a face exposed to mobile mass impacts.

- the work is characterized in that it comprises, at the level of the face exposed to mass impacts mobiles, a set of individual building elements joined together, filled wholly or partly with at least one material having a capacity to be deformed elastoplastically, the individual elements of construction likely to be degraded by mobile mass impacts being suitable for individually replaced by individual elements of similar construction.

- elastoplastic deformation of a material is meant a deformation of the material associated with its ability to regain its original shape, up to threshold beyond which the deformation will be final.

- the structure may comprise gabions filled with pebbles or fine materials isolated by a geotextile and a set of individual elements of construction arranged on the face exposed to the impacts of moving masses of the structure.

- the structure may comprise an embankment reinforced with geotextile webs, or geosynthetic webs, or webs of double twist wire mesh, or welded wire mesh or steel reinforcing bars and a set of individual building elements arranged on the face exposed to impacts of moving masses of the structure, and which are connected or not to the reinforcements.

- the material having an ability to be deformed can be chosen, alone or in mixture, in the group which may comprise pieces of shredded tires, carved pellets of tires, pieces of polystyrene, earthy materials, sand, gravel, pebbles, crushed recycled concrete, etc.

- the elements individual builders may present a first volume of a first material having an ability to be deformed elastoplastically and a second volume of a second loose material.

- the second movable material is intended for example to aesthetically dress the outside and also absorb some of the energy.

- the separation between two volumes may be oriented in a plane substantially perpendicular to the mean direction of arrival of moving masses, to optimize energy absorption during impacts.

- soft materials we mean materials that deform and that take a given configuration by splitting or rearranging.

- each element individual construction which forms a container delimited by an envelope exterior, may have a first volume of a first material having a ability to be deformed elastoplastically and a second volume of a second movable material, the separation between the two volumes being oriented according to a plane substantially perpendicular to the mean direction of arrival of the moving masses.

- the individual element of construction and protection is in two parts or two volumes, each with distinct mechanical properties.

- the first volume shows elastoplasticity properties with respect to impacts and the second volume has absorption properties of a portion of the energy of impacts.

- Moving masses arrive on the structure with preferential direction arrival and impact. We take into account the average statistical direction of arrival of these moving masses, while knowing that bounces and random trajectories of moving masses can occur. In many cases, the separation plan between the two volumes is substantially vertical.

- the first material having an ability to be deformed can be chosen, alone or in a mixture, in the group which may comprise pieces of shredded tires, cut pellets of tires, pieces of polystyrene, earthy materials, sand, gravel, pebbles, crushed recycled concrete, etc.

- the second material, furniture can be chosen, alone or in mixture, in the group that can include topsoil, sands, gravels, pebbles, blocks of rocks, crushed concrete, etc.

- the outer casing may be constituted by a cage of a metal gabion, the cage may be, if necessary, covered internally with a geotextile material.

- the separation between the volume of the material having an ability to be deformed and the volume of loose material can be achieved by a wall of a geotextile material, or mesh, or wire mesh, etc.

- the individual building element may also include a multiplicity volumes, successively a volume of a loose material and a volume of one first material having an ability to be deformed elastoplastically.

- the separation between the volumes can be respectively oriented according to a plan substantially perpendicular to the mean direction of arrival of the moving masses.

- a civil engineering work intended to provide protection against moving mass impacts, and having a face exposed to the impacts of moving masses is characterized in that it comprises at least an element as described above.

- any impact against the face will only affect one or more individual building elements, without compromising the structural integrity of the structure.

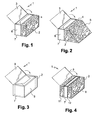

- an individual building element (1) can be present in the form of a substantially parallelepiped gabion.

- the gabion comprises an outer metal cage (2) made for example, in double mesh twist or welded mesh.

- the cage (2) can be closed by a lid (3).

- the gabions are used to construct protective structures or to reinforce existing works.

- the cage (2) has two distinct volumes (4 and 6).

- a first volume (4) is located at the front of the cage (2) relative to the hinge of closing the lid (3).

- a second volume (6) is located at the back of the cage (2) relative to the closing hinge of the lid (3).

- the first volume at the front (4) contains movable materials, as an example pebbles, sands, gravels or topsoil.

- the second volume located at the rear (6) contains materials with elastoplastic properties, for example pellets or pellets based on shredded tires.

- the first volume at the front (4) is oriented on the protective structure on the side of the face exposed to impacts.

- the pellets used may have dimensions of the order of one centimeter.

- Shredded tires are maintained using an envelope (7) made, for example, of a geotextile material.

- a geonatte may also make the separation between loose materials and elastoplastic materials.

- the arrangement of the two volumes (4 and 6) may be reversed with respect to the first embodiment of Figure 1.

- the first volume containing soft materials (4) may be placed at the rear and the second volume containing materials with elastoplastic properties (6) may be disposed at the front of the side of the face exposed to the impacts of the protective structure.

- the cage (2) presents also the same two separate volumes (4 and 6).

- the front (5) exposed to the impacts has an inclination for example substantially equal to 45 ° by report horizontally.

- Such inclined front face (5) will allow implantation much easier plants, giving the cage (2) and all of the work obtained with this type of cage (2) an aesthetic and ecological aspect much more attractive.

- the cage (2) has a single volume (8).

- This single volume (8) contains materials with properties elastoplastics, such as shredded tires, which are preserved by a envelope (7) made for example of a geotextile material.

- the cage (2) has three separate volumes (9, 11 and 12).

- a first volume (9) is located at the front of the cage (2), in this case with respect to the closing hinge of the lid (3).

- a second volume (11) is located at the rear of the cage (2), in this case with respect to the hinge of closing the lid (3).

- a third volume (12) is interposed in a central position between the first volume at the front (9) and the second volume at the rear (11).

- the first volume at the front (9) and the second volume at the back (11) contain materials furniture, such as pebbles, sand, gravel or topsoil.

- the third central volume (12) contains materials with elastoplastic properties, as for example shredded tires, which are preserved by an envelope (7) made for example of a geotextile material.

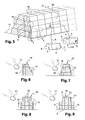

- Figure 5 illustrates a protective structure (13) which is formed of a first stack of metal gabions (14) secured to one another. These gabions (14) are filled with stone-like materials, rocks.

- the structure (13) is oriented so as to have a vertical or inclined face that is particularly exposed to falls stones and other landslides. This structure (13) protects a road (17) and / or dwellings at the base of the other side of the structure (13), on the opposite side from exposed side.

- the structure (13) comprises a cladding (16) made from individual removable building elements.

- gabions inclined front face (1) in accordance with the second form embodiment of Figure 2, are used. These gabions (1) are arranged by compared to others and compared to the traditional gabions of stacking (14), in order to present their first soft material volume (4) on the exposed front face and so as to present their second elastoplastic material volume (6) at the back and against the gabions of the stack (14).

- a structure (18) with a stack of gabions (14) comprises a protective cladding (19) which is made with gabions according to the first embodiment of Figure 1.

- the structure (18) has a face exposed to falling rocks (21) substantially vertical.

- This structure (18) can also be made with a stack of gabions classics filled with materials usually chosen for a work according to the state of technique and gabions only filled with compliant elastoplastic materials in the third embodiment of Figure 3.

- the work (22) includes a massive structure formed of a stack of gabions (14). It includes in in addition to a protective covering (19) which is made with gabions according to the second embodiment of Figure 2.

- the work (22) has an inclined face (16) which is exposed to falling rocks (21) and which can be planted.

- the work (23) includes a stack of gabions (14) and comprises a central protection core (24) which is made with gabions according to the third embodiment of Figure 3.

- the work (25) includes a stack of gabions according to the first embodiment of FIG. according to the fourth embodiment of Figure 4.

- This embodiment can also be built from alternating gabions filled with materials usually chosen for a work according to the state of the art and gabions according to the third embodiment of Figure 3.

- the book (26) presents a massive structure formed by an embankment (27), for example earthen, reinforced with regular way over its entire height by geotextile reinforcement plies (28) or geosynthetic or lattice or wire mesh.

- the reinforcement plies (28) extend only on a part of the thickness of the embankment (27).

- a protective siding inclined (29), secured or not to the main structure of the structure, is realized by several longitudinal elements in one piece, which conform to the first embodiment of Figure 1 or the third embodiment of Figure 3.

- the outer portion (30) of the cladding (29) may be pebbles or topsoil or a mixture earth-pebbles then vegetated.

- the structure (31) comprises also an embankment (27), for example earthen, reinforced regularly on any its height by reinforcing layers of geotextile (28) or geosynthetic or lattice or wire mesh.

- the reinforcing plies (28) extend in this case over the whole of the thickness of the embankment (27). The stability of both faces is ensured.

- a siding of inclined protection (32) is formed by a plurality of longitudinal elements in one piece, which are in accordance with the third embodiment of Figure 3. exterior of the siding (32) may be pebbles or topsoil or a mixture earth-pebbles (33) then vegetated.

- the work (34) is a embankment (27), for example earthen, reinforced in a regular manner over its entire height by reinforcing plies made of geotextile (28) or geosynthetic or lattice or mesh metal, which extend only over part of the thickness of the embankment (27), to ensure the stability of the slope.

- the local stability of one of the faces is ensured at using gabions (14) filled with materials usually chosen for a structure according to the state of the art.

- a protective layer (37) is made with gabions (1) according to the first embodiment of Figure 1.

- the work (38) is consisting of a vertical stack of gabions (14), filled with usually chosen for a work according to the state of the art, attached to an embankment (27) reinforced by reinforcement plies of geotextile (28) or geosynthetic or trellis or wire mesh, extending over the entire thickness of the backfill (27), so to assure, on both sides, the stability of the slope.

- Protective siding (39) substantially vertical is realized with gabions conforming to the first form of embodiment of Figure 1, but inverted with their front volume filled with materials elastoplastic.

- the work (40) is formed with a vertical stack of gabions (14) attached to a reinforced embankment (27) by plies of geotextile (28) or geosynthetic or lattice or wire mesh, extending over the entire thickness of the embankment (27), so as to ensure on the other, the stability of the slope.

- An inclined protection facing (41) substantially similar to the facings of the fifth and sixth embodiments of structures (see Figures 10 and 11), is made by several longitudinal elements in one piece, which are in accordance with the first embodiment of Figure 1.

- the dimensions of the protection gabions can be very variable, depending on the desired protection structure.

- Other applications can be envisaged, such as protective works in the military field or reinforcements of canal banks, rivers, rivers and seasides, where the masses are the objects transported by the watercourse, or even traffic lanes, for protect vehicle impacts.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Civil Engineering (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Architecture (AREA)

- Revetment (AREA)

- Devices Affording Protection Of Roads Or Walls For Sound Insulation (AREA)

- Pit Excavations, Shoring, Fill Or Stabilisation Of Slopes (AREA)

- Refuge Islands, Traffic Blockers, Or Guard Fence (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0350644 | 2003-10-03 | ||

| FR0350644A FR2860529B1 (fr) | 2003-10-03 | 2003-10-03 | Ouvrage de genie civil, element individuel de construction et procede de renforcement d'un tel ouvrage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1520933A1 true EP1520933A1 (de) | 2005-04-06 |

| EP1520933B1 EP1520933B1 (de) | 2011-11-09 |

Family

ID=34307565

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04300644A Expired - Lifetime EP1520933B1 (de) | 2003-10-03 | 2004-09-30 | Baukonstruktion |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7425107B2 (de) |

| EP (1) | EP1520933B1 (de) |

| AT (1) | ATE532905T1 (de) |

| CA (1) | CA2481161C (de) |

| ES (1) | ES2372490T3 (de) |

| FR (1) | FR2860529B1 (de) |

| PT (1) | PT1520933E (de) |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1777350A1 (de) * | 2005-10-20 | 2007-04-25 | Franken-Schotter GmbH & Co. KG | Steinkorb zur Erstellung eines Deichs |

| FR2902808A1 (fr) * | 2006-06-26 | 2007-12-28 | Entpr Travaux Publics Setp Sar | Mur antibruit et procede de construction d'un tel mur |

| FR2903712A1 (fr) * | 2006-07-17 | 2008-01-18 | France Maccaferri Soc Par Acti | Element de construction pour ouvrage de genie civil |

| FR2904337A1 (fr) * | 2006-07-28 | 2008-02-01 | France Maccaferri Soc Par Acti | Procede de fabrication d'un element individuel de construction rempli destine a un ouvrage de genie civil |

| EP1775388A3 (de) * | 2005-10-17 | 2008-07-02 | Bauunternehmen Deutschle GmbH & Co. KG | Verfahren zum Errichten von Mauern aus Ortbeton unter Verwendung von Gabionen |

| FR2910914A1 (fr) * | 2006-12-29 | 2008-07-04 | Joseph Golcheh | Merlon acoustique avec un noyau anti bruit |

| EP1881114A3 (de) * | 2006-07-17 | 2010-01-13 | France Maccaferri | Verfahren zur Herstellung von einzelnen Vollbausteinen zur Erstellung eines Bauwerks |

| EP2136002A3 (de) * | 2008-06-20 | 2011-08-17 | Betafence Holding NV | Gabion |

| WO2011154714A1 (en) * | 2010-06-11 | 2011-12-15 | Hesco Bastion Limited | Barrier assembly for shoreline |

| ITRN20110011A1 (it) * | 2011-02-24 | 2012-08-25 | Lega Rocciatori S R L | Elemento costruttivo composito prefabbricato per la realizzazione mimetica di barriere di contenimento terreni, rilevati paramassi e simili |

| EP2459809B1 (de) * | 2009-07-28 | 2019-06-26 | Hesco Bastion Limited | Drahtkorbsystem |

| FR3097574A1 (fr) * | 2020-06-25 | 2020-12-25 | Soletanche Freyssinet | Structure d’absorption d’une énergie d’impact |

| EP4293161A1 (de) * | 2022-06-15 | 2023-12-20 | Oichtner, Franz | Fahrzeugsicherheitsbarriere |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009042860A1 (en) | 2007-09-27 | 2009-04-02 | Prs Mediterranean Ltd. | Earthquake resistant earth retention system using geocells |

| GB0804487D0 (en) | 2008-03-11 | 2008-04-16 | Terram Ltd | Cellular structures |

| US20090235813A1 (en) * | 2008-03-24 | 2009-09-24 | Arthur Henry Cashin | Ballistics Barrier |

| US20090235507A1 (en) * | 2008-03-24 | 2009-09-24 | Arthur Henry Cashin | Method Of Repairing A Ballistics Barrier |

| US20090235814A1 (en) * | 2008-03-24 | 2009-09-24 | Cashin Arthur H | Mobile Reconfigurable Barricade |

| US20090250675A1 (en) * | 2008-03-24 | 2009-10-08 | Arthur Henry Cashin | Vehicle Barrier |

| FR2969673B1 (fr) * | 2010-12-23 | 2013-02-08 | Terre Armee Int | Procede de modification d'un ouvrage en sol renforce |

| GB2493007B (en) | 2011-07-21 | 2017-08-30 | Fiberweb Holdings Ltd | Confinement structures for particulate fill materials |

| RU2524223C1 (ru) * | 2013-04-30 | 2014-07-27 | Федеральное государственное бюджетное образовательное учреждение высшего профессионального образования "Уральский государственный университет путей сообщения" (УрГУПС) | Устройство для отвода воды от балластного слоя железнодорожной насыпи |

| CA2862199C (en) | 2013-09-04 | 2021-05-11 | William Khamis | Geotextile sheeting stabilized fiberglass swimming pool body |

| KR20160051775A (ko) * | 2013-09-06 | 2016-05-11 | 가부시키가이샤 프로텍 엔지니어링 | 충격 흡수용 제방 |

| GB2526786A (en) * | 2014-05-28 | 2015-12-09 | Alan Lofthouse | Improvements to tyre bale use as infill for gabion baskets |

| JP6397684B2 (ja) * | 2014-08-01 | 2018-09-26 | 東京インキ株式会社 | 落下物の防護構造の構築工法、及び落下物の防護構造 |

| JP6348426B2 (ja) * | 2015-01-30 | 2018-06-27 | 公益財団法人鉄道総合技術研究所 | 衝撃検知・表示装置 |

| WO2017024286A1 (en) * | 2015-08-06 | 2017-02-09 | University Of Utah Research Foundation | Light-weight bridge support systems and methods of use |

| US10619345B2 (en) * | 2015-12-10 | 2020-04-14 | Smart Vent Products, Inc. | Flood vent having a panel |

| TR201810470T4 (tr) * | 2016-03-04 | 2018-08-27 | Omya Int Ag | Gabyon, böyle bir gabyonu ihtiva eden gürültü azaltma duvarı ve böyle bir gabyonun uygulanmasına yönelik bir işlem. |

| US20200230483A1 (en) * | 2016-07-29 | 2020-07-23 | Ecobunker Limited | Golf course bunker |

| US11306454B2 (en) | 2016-08-31 | 2022-04-19 | Wilkinson Ecological Design | Erosion control apparatus |

| US10125462B2 (en) | 2016-08-31 | 2018-11-13 | Wilkinson Ecological Design | Erosion control apparatus |

| US11492771B2 (en) | 2016-08-31 | 2022-11-08 | Wilkinson Ecological Design | Erosion control apparatus |

| US11306455B2 (en) | 2016-08-31 | 2022-04-19 | Wilkinson Ecological Design | Erosion control apparatus |

| US12043973B2 (en) | 2017-08-31 | 2024-07-23 | Wilkinson Ecological Design | Erosion control apparatus |

| US12234619B2 (en) | 2016-08-31 | 2025-02-25 | Wilkinson Ecological Design | Erosion control apparatus |

| EP3456885B1 (de) * | 2017-09-13 | 2024-06-05 | Propex Operating Company, LLC | Geotextilbasierte struktur zur verbesserung von vegetativem wachstum und erosionswiderstand |

| US11095017B2 (en) * | 2018-07-13 | 2021-08-17 | Apple Inc. | Electronic device having angle of arrival detection capabilities |

| CN109826126A (zh) * | 2019-04-09 | 2019-05-31 | 北方工业大学 | 一种居民小区用圆柱形路障 |

| CN114134910A (zh) * | 2021-12-15 | 2022-03-04 | 重庆地质矿产研究院 | 一种岩溶塌陷柔性治理方法 |

| CN115852992A (zh) * | 2022-11-22 | 2023-03-28 | 武汉理工大学 | 一种废轮胎-透水混凝土复合结构及其制备方法和应用 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5320455A (en) * | 1992-04-22 | 1994-06-14 | The Tensar Corporation | Geocell with facing panel |

| US5636938A (en) * | 1994-06-15 | 1997-06-10 | Ragazzo; George | Gabion system |

| US5677016A (en) * | 1994-09-19 | 1997-10-14 | Officine Maccaferri S.P.A. | Foldable multicellular structure for rapid intervention works |

| US20030125425A1 (en) * | 2000-08-18 | 2003-07-03 | Earth-Link Technology Enterprises Ltd. | Lightweight and porous construction materials containing rubber |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NO152611C (no) * | 1978-10-16 | 1985-10-23 | Plg Res | Plastnettkonstruksjon, fremgangsmaate til dens fremstilling og anvendelse av konstruksjonen |

| US5156495B1 (en) * | 1978-10-16 | 1994-08-30 | Plg Res | Plastic material mesh structure |

| US4643271A (en) * | 1984-12-18 | 1987-02-17 | Thomas J. Kelley | Sound barrier |

| GB2221941A (en) * | 1988-08-16 | 1990-02-21 | David Deacon | Crash barrier |

| US4960349A (en) * | 1988-12-05 | 1990-10-02 | Nicolon Corporation | Woven geotextile grid |

| US4992003A (en) * | 1989-01-16 | 1991-02-12 | Yehuda Welded Mesh Ltd. | Unit comprising mesh combined with geotextile |

| US4904124A (en) * | 1989-06-14 | 1990-02-27 | The Reinforced Earth Company | Constructional work and method of construction of vertical retaining wall |

| IT1238432B (it) * | 1990-01-19 | 1993-07-26 | Procedimento atto alla realizzazione di strutture di contenimento di terreni mediante elementi con reti a doppia torsione. | |

| US5076735A (en) * | 1990-08-31 | 1991-12-31 | Hilfiker William K | Welded wire component gabions and method of making the same and construction soil reinforced retaining walls therefrom |

| US5549418A (en) * | 1994-05-09 | 1996-08-27 | Benchmark Foam, Inc. | Expanded polystyrene lightweight fill |

| JPH0868016A (ja) * | 1994-08-31 | 1996-03-12 | Nippon Samikon Kk | 落石防護体におけるサンドクッション材保持構造 |

| US5575121A (en) * | 1995-03-07 | 1996-11-19 | Lajaunie; Philippe | Sound barrier wall construction using tire sections |

| ZA963715B (en) * | 1995-05-12 | 1996-11-20 | Tensar Corp | Bonded composite open mesh structural textiles |

| US5582492A (en) * | 1995-10-18 | 1996-12-10 | Doyle, Jr.; Henry G. | Method and apparatus for an anchored earth restraining wall |

| US5795106A (en) * | 1996-04-01 | 1998-08-18 | Herd; Ian M. | Retaining wall system and method of construction thereof |

| DE19652636B4 (de) * | 1996-12-18 | 2005-02-24 | Thomas Rothfuss | Lärmschutzwand aus Drahtkörben |

| GB0103581D0 (en) * | 2001-02-14 | 2001-03-28 | Total Tyre Recovery Ltd | Marine structures and flood defence systems |

| FR2835266A1 (fr) | 2002-01-29 | 2003-08-01 | Pneuresil Applic | Procede de construction d'un ouvrage protecteur et ouvrage protecteur obtenu |

| US20030156908A1 (en) * | 2002-02-19 | 2003-08-21 | Chung-Yi Liaw | Soil-retaining wall of recycled tires by ecological constructing method |

| FR2845702B1 (fr) * | 2002-10-10 | 2005-05-13 | Michel Poteur | Dispositif allege et souple pour la retention de solides instables, notamment de blocs rocheux susceptibles de se detacher |

| JP2005083068A (ja) * | 2003-09-09 | 2005-03-31 | Nippon Steel Metal Prod Co Ltd | 土木構造物用緩衝材と落石防止柵およびその構築方法 |

-

2003

- 2003-10-03 FR FR0350644A patent/FR2860529B1/fr not_active Expired - Fee Related

-

2004

- 2004-09-30 AT AT04300644T patent/ATE532905T1/de active

- 2004-09-30 ES ES04300644T patent/ES2372490T3/es not_active Expired - Lifetime

- 2004-09-30 CA CA2481161A patent/CA2481161C/fr not_active Expired - Fee Related

- 2004-09-30 PT PT04300644T patent/PT1520933E/pt unknown

- 2004-09-30 US US10/954,715 patent/US7425107B2/en not_active Expired - Fee Related

- 2004-09-30 EP EP04300644A patent/EP1520933B1/de not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5320455A (en) * | 1992-04-22 | 1994-06-14 | The Tensar Corporation | Geocell with facing panel |

| US5636938A (en) * | 1994-06-15 | 1997-06-10 | Ragazzo; George | Gabion system |

| US5677016A (en) * | 1994-09-19 | 1997-10-14 | Officine Maccaferri S.P.A. | Foldable multicellular structure for rapid intervention works |

| US20030125425A1 (en) * | 2000-08-18 | 2003-07-03 | Earth-Link Technology Enterprises Ltd. | Lightweight and porous construction materials containing rubber |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1775388A3 (de) * | 2005-10-17 | 2008-07-02 | Bauunternehmen Deutschle GmbH & Co. KG | Verfahren zum Errichten von Mauern aus Ortbeton unter Verwendung von Gabionen |

| EP1777350A1 (de) * | 2005-10-20 | 2007-04-25 | Franken-Schotter GmbH & Co. KG | Steinkorb zur Erstellung eines Deichs |

| FR2902808A1 (fr) * | 2006-06-26 | 2007-12-28 | Entpr Travaux Publics Setp Sar | Mur antibruit et procede de construction d'un tel mur |

| EP1881114A3 (de) * | 2006-07-17 | 2010-01-13 | France Maccaferri | Verfahren zur Herstellung von einzelnen Vollbausteinen zur Erstellung eines Bauwerks |

| FR2903712A1 (fr) * | 2006-07-17 | 2008-01-18 | France Maccaferri Soc Par Acti | Element de construction pour ouvrage de genie civil |

| FR2904337A1 (fr) * | 2006-07-28 | 2008-02-01 | France Maccaferri Soc Par Acti | Procede de fabrication d'un element individuel de construction rempli destine a un ouvrage de genie civil |

| FR2910914A1 (fr) * | 2006-12-29 | 2008-07-04 | Joseph Golcheh | Merlon acoustique avec un noyau anti bruit |

| EP2136002A3 (de) * | 2008-06-20 | 2011-08-17 | Betafence Holding NV | Gabion |

| EP2459809B1 (de) * | 2009-07-28 | 2019-06-26 | Hesco Bastion Limited | Drahtkorbsystem |

| WO2011154714A1 (en) * | 2010-06-11 | 2011-12-15 | Hesco Bastion Limited | Barrier assembly for shoreline |

| ITRN20110011A1 (it) * | 2011-02-24 | 2012-08-25 | Lega Rocciatori S R L | Elemento costruttivo composito prefabbricato per la realizzazione mimetica di barriere di contenimento terreni, rilevati paramassi e simili |

| FR3097574A1 (fr) * | 2020-06-25 | 2020-12-25 | Soletanche Freyssinet | Structure d’absorption d’une énergie d’impact |

| WO2021260336A1 (fr) | 2020-06-25 | 2021-12-30 | Soletanche Freyssinet | Structure d'absorption d'une énergie d'impact |

| EP4293161A1 (de) * | 2022-06-15 | 2023-12-20 | Oichtner, Franz | Fahrzeugsicherheitsbarriere |

Also Published As

| Publication number | Publication date |

|---|---|

| PT1520933E (pt) | 2011-12-15 |

| CA2481161A1 (fr) | 2005-04-03 |

| EP1520933B1 (de) | 2011-11-09 |

| CA2481161C (fr) | 2012-03-13 |

| ES2372490T3 (es) | 2012-01-20 |

| FR2860529A1 (fr) | 2005-04-08 |

| US7425107B2 (en) | 2008-09-16 |

| ATE532905T1 (de) | 2011-11-15 |

| FR2860529B1 (fr) | 2006-12-15 |

| US20050262794A1 (en) | 2005-12-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1520933B1 (de) | Baukonstruktion | |

| EP2352884B1 (de) | Verstärkte bodenstruktur und verkleidungselemente zu ihrer konstruktion | |

| JP5067307B2 (ja) | 道路の変状防止構造及び道路の変状防止方法 | |

| CA3119193A1 (fr) | Dispositif pour la contention d'elements granulaires | |

| WO2006114547A1 (fr) | Dispositif allonge pour les amenagements maritimes et fluviaux et son procede de fabrication | |

| EP2655750B1 (de) | Verfahren zur modifizierung einer stützwand mit bewehrter erde | |

| EP1706540A1 (de) | Vorgefertigtes schalldämmungsmodul für eine lärmmindernde wand und herstellungsverfahren dafür | |

| FR2682700A1 (fr) | Dispositif pour la realisation d'un remblai renforce. | |

| EP0220996B1 (de) | Verfahren zum Herstellen eines leichten geschmeidigen und isolierenden Dämmkörpers und so hergestellter Dämmkörper | |

| JP2013159902A (ja) | ケーソン式防波堤の補強構造 | |

| EP0371898A1 (de) | Bauverfahren für ein leichtes und elastisches Baumassiv aus Elementarblöcken aus Bruchstücken von komprimierten Materialien | |

| CA3188111A1 (fr) | Structure d'absorption d'une energie d'impact | |

| FR2902808A1 (fr) | Mur antibruit et procede de construction d'un tel mur | |

| FR2835266A1 (fr) | Procede de construction d'un ouvrage protecteur et ouvrage protecteur obtenu | |

| JP2023103653A (ja) | 法面形成用ブロック及び法面構造及び治水構造 | |

| FR2845702A1 (fr) | Dispositif allege et souple pour la retention de solides instables, notamment de blocs rocheux susceptibles de se detacher | |

| FR2741643A1 (fr) | Procede de renforcement d'ouvrages, constitues au moins d'un materiau non coherent, au moyen d'elements allonges de renfort et element de renfort pour la mise en oeuvre du procede | |

| BE1009217A6 (fr) | Element de construction d'un ecran. | |

| FR2894267A1 (fr) | Procede et dispositif de fabrication d'une structure de separation exterieure comportant une paroi prefabriquee maintenue par des organes d'ancrage au sol et structure obtenue | |

| BE412902A (de) | ||

| FR3078084A1 (fr) | Systeme de bassin de retention d'eau de pluie enterre, constitue de petites pieces creuses en matiere plastique disposees en vrac | |

| FR2892434A1 (fr) | Ouvrage d'art et procede de construction de l'ouvrage. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050914 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: HR Payment date: 20050914 Extension state: MK Payment date: 20050914 |

|

| 17Q | First examination report despatched |

Effective date: 20080303 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: CIVIL ENGINEERING STRUCTURE |

|

| GRAC | Information related to communication of intention to grant a patent modified |

Free format text: ORIGINAL CODE: EPIDOSCIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FRANCE MACCAFERRI |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: HR MK |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20111122 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602004035210 Country of ref document: DE Effective date: 20120105 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2372490 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120120 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20111109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120210 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120209 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120810 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602004035210 Country of ref document: DE Effective date: 20120810 |

|

| BERE | Be: lapsed |

Owner name: FRANCE MACCAFERRI Effective date: 20120930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040930 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160914 Year of fee payment: 13 Ref country code: CH Payment date: 20160919 Year of fee payment: 13 Ref country code: IT Payment date: 20160912 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20160818 Year of fee payment: 13 Ref country code: AT Payment date: 20160823 Year of fee payment: 13 Ref country code: FR Payment date: 20160928 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20160929 Year of fee payment: 13 Ref country code: TR Payment date: 20160921 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602004035210 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 532905 Country of ref document: AT Kind code of ref document: T Effective date: 20170930 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180402 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180404 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171002 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181017 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |