EP1366785A1 - Ski, Verfahren zur Montage einer Skibindung an dem Ski und Verfahren zur Herstellung des Skis - Google Patents

Ski, Verfahren zur Montage einer Skibindung an dem Ski und Verfahren zur Herstellung des Skis Download PDFInfo

- Publication number

- EP1366785A1 EP1366785A1 EP03011124A EP03011124A EP1366785A1 EP 1366785 A1 EP1366785 A1 EP 1366785A1 EP 03011124 A EP03011124 A EP 03011124A EP 03011124 A EP03011124 A EP 03011124A EP 1366785 A1 EP1366785 A1 EP 1366785A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ski

- binding

- mounting device

- mounting

- ski body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C5/00—Skis or snowboards

- A63C5/12—Making thereof; Selection of particular materials

- A63C5/128—A part for the binding being integrated within the board structure, e.g. plate, rail, insert

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/003—Non-swivel sole plate fixed on the ski

Definitions

- the present invention relates to a ski, a method for assembling additional elements, e.g. Ski binding and ski brake, on the ski and a method of making the ski.

- ski bindings and ski brakes either directly or by means of a binding plate attached to the ski by screwing. This is the bond either screwed directly to the ski or bolted the binding plate to the ski and the binding is mounted on the binding plate.

- a binding plate for mounting the ski binding found wide application. It has shown that it is advantageous if at least one binding element with respect to the ski body is movably mounted, for example, the bending line of the ski through the binding plate and to disrupt the bond formation as little as possible.

- a known binding mounting device is described for example in DE-U-200 12 437.

- the device comprises a front base plate with a mounting zone suitable for a front retaining element is provided, and a rear base plate having a mounting zone, which is provided for a rear retaining element.

- the rear base plate has in its lower part a transverse pivot for connection to the ski, around which the base plate can swing freely relative to the ski when installed on the ski.

- the other base plate has a circuit board, the mounting zone and facilities for a Mounted on the ski, which are intended to firmly attach the board to the ski or in a guide long the longitudinal direction of the ski over a limited Amplitude can slide.

- the base plates are characterized by a non-expandable or non-stretchable connection connected to each other, wherein the compound is formed is that they themselves recover a relative distance of the base plates from each other and is neutral to a relative approximation of the base plates.

- DE-U-200 12 438 describes a similar device, where there the front base plate in its lower part a transverse pivot for connection to the ski that allows the base plate to jump freely relative to the ski when on the ski is installed.

- the rear base plate has means which are provided to the Base plate firmly mounted on the ski.

- the base plates are not here by a extensible connection interconnected.

- the device described in DE-U-200 13 978 has two transverse pivots each one of the front binding element and the rear binding element assigned.

- the distance between the two pivots is in the range of 156 to 376 mm.

- EP-A-1 175 925 describes an alpine ski with an elongate ski body which is a front ski End, has a rear end and a central area.

- the ski body consists of a Main core, which covers a running surface of the ski, a stack of sliding and reinforcing layers with two lateral ski edges, with the core itself through a stack of Reinforcement and possibly decorative layers are covered.

- a main core which covers a running surface of the ski, a stack of sliding and reinforcing layers with two lateral ski edges, with the core itself through a stack of Reinforcement and possibly decorative layers are covered.

- auxiliary core which in this central area one of the Surface of the ski protruding rib with reduced width forms.

- Rib is a binding plate by means of two transverse pins, extending through the rib and the Binding plate extend, fastened.

- EP-A-1 161 972 describes a ski with a profiled rail system which is at least is provided in the binding area on the ski upper side.

- the profile rail system exists at least one extending in the longitudinal direction of the rail, which is to attach functional elements, for example a bond or its elements or a binding plate, by pushing on the rail.

- the rail is molded over several Dowels or dowel sections by a dowel joint or anchoring with connected to the ski body.

- ski and mounting devices for binding assembly have the Disadvantage that the binding plates or binding elements attached by means of aids on the ski which, in particular, negatively influences the bending line of the ski, additional Requires assembly steps, the ski body weakens and is less flexible. This is especially true when using screws, dowels and bolts too.

- DE-C-195 27 063 describes a ski in which the ski binding by means of a base / support plate attachable to the ski.

- the base / carrier plate has in width to each other variable jaws, which by means of clamping edges in a longitudinal groove and on the ski side surfaces engages and thus can be brought into locking position.

- the Jaws and guide blocks arranged thereon slide in a guide slot and a guide rail of the base plate according to the ski width.

- a centering of the Base plate and a horizontal clamping action of both jaws is done by a single screw or nut.

- the disadvantage of this construction is in particular the use a separate binding plate, through which the bending line of the ski body essential being affected. Furthermore, the binding plate projects transversely across the width of the ski body on both sides, so that this construction e.g. when cornering, in particular in connection with carving skis, is disadvantageous because the binding plate is in contact with gets the underground.

- DE-C-27 11 199 describes a fastener for a ski binding without use of fixing screws with mounting jaws, which are in the area of the ski side surfaces protrude, in the distance mutually changeable and can be brought into clamping position are and at their free ends to ski directed projections, which in in the Ski 43 vom intervene longitudinal grooves. Even with this construction stands out Fastening element beyond the width of the ski body, which is in terms of use The ski also disadvantages.

- EP-A-0 383 104 relates to a ski with a ski binding consisting of toe pieces and consists of a coupled with this via a link heel holder.

- front jaw and heel hold are each mounted on a cross-sectionally U-shaped carriage, At the free leg ends inwardly projecting Flunche are attached, which in a ski fest Guide rail are mounted. Also in this case a binding plate is provided, which protrudes beyond the width of the ski body.

- DE-A-197 53 451 discloses a fastening system for ski bindings, one with a Has ski-connected retaining element releasably connected to a connected with a ski binding Bonding plate is connected.

- the holding element is screwed to the ski body and is For example, by means of a dovetail guide with the binding plate connectable.

- the present invention has for its object to provide an improved ski, with which the binding assembly is facilitated and at the same time the properties of the Skis are not significantly adversely affected.

- Another task of the present The invention is to provide an improved method of bond assembly.

- the invention is based on the idea of a mounting device in the ski body of the ski to integrate, with the ski binding can be attached directly to the ski.

- the mounting device is formed in principle in the manner of a binding plate and in incorporated the ski body.

- the ski according to the invention has all Benefits associated with the use of a binding plate on and has the additional considerable advantage that the binding are mounted directly on the mounting device can. These are typically no further aids, such as screws, bolts or dowels required.

- the width of the mounting device is typically in the range of about 50% to 95%, preferably in the range of about 75% to 90% of the smallest width of the ski body. As a result, especially at Carvingski ensures that no part of Mounting device extends beyond the width of the ski body out and so to an impairment the driving behavior of the ski performs, for example, a part of the mounting device comes into contact with the underground.

- the bond to the mounting device becomes jammed attached.

- the mounting device at least one in the longitudinal direction of Skis extending undercut groove, but preferably two mutually parallel Grooves that are open on sides facing away from each other.

- the integration of the Mounting element in the ski body is preferably carried out by a suitable receiving rail is already pressed in the gluing of the ski body or that the core complex of the ski is designed by installing a suitable material so that a suitable guide groove by subsequent milling (for example in the passage) during production of the ski is created.

- a suitable thermoplastic, a fiber-reinforced plastic, in particular glass fiber reinforcing Plastic, or have a plastic-coated metallic material preferably a suitable thermoplastic, a fiber-reinforced plastic, in particular glass fiber reinforcing Plastic, or have a plastic-coated metallic material.

- the longitudinal fixing of the binding parts is preferably carried out analogously to the binding assembly on conventional binding plates, by their integrated leadership allow free bending or flexing. This is particularly advantageous for when Bending the ski through the formation of tie and shoe on the ski this not to be tense, ie not to negatively influence its bending line.

- inventive Ski are all variations of "Free-Flex" as possible from the corresponding Binding plate are known. For example, the fixation of the jaw part the binding and a free flexing of the heel part via the connecting tongue with which the Back part is connected to the heel part, possible. Conversely, also the heel part attached and the jaw part to be free to move.

- the engagement means of the binding preferably has projections, which are inserted during the merging in a groove of the mounting device.

- the fixing of the bond is preferably carried out exclusively by clamping.

- the binding has two binding elements and optionally a ski brake, which by a Connecting web are connected together.

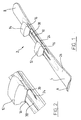

- the ski 2 of the invention shown in Figure 1 has a substantially elongated Ski body 4 with a front ski end 6 and a rear ski end 8, and a mounting device 10 on, with the help of a substantially of a front binding element 12 and a rear binding element 14 existing ski binding directly on the ski. 2 can be mounted.

- the mounting device 10 is integrated in the ski body 4, that it is sufficiently firmly connected to the ski body 4 to the binding elements 12th and 14 and to withstand the loads occurring during use of the ski 2.

- the mounting device 10 is formed such that the bond 12, 14 pushed from the front end 4 and / or from the rear end 8 of the ski 2 and preferably can be attached by clamping.

- the binding elements 12, 14 on their underside in each case a substantially C-shaped engagement means in cross-section 16, the free ends 18 and 20 in respective on the sides of the mounting device 10th provided longitudinal grooves 22 and 24 engage.

- the mounting device 10 preferably protrudes beyond the otherwise substantially flat Surface 26 of the ski 2 and is typically in the conventional binding mounting area of the ski.

- the Mounting device 10 along the length of the ski 2 different cross-sectional shapes and / or dimensions, in order to ensure the most harmonious transition possible from the flat ski surface 26 to form the mounting device and the optimal bending line of the ski at least largely to maintain.

- the length of the mounting device 10 is from the mounting point from about 250 to 400 mm in each direction, so it has a total length from about 500 to 800 mm.

- the height of the ski 2 in the region of the mounting device 10 is preferably in the range between about 12 to 25 mm and can along the length of Skis 2 vary.

- the width of the mounting device 10 is in the range of about 50 to 95%, preferably in the range of about 75 to 90% of the smallest width of the ski body 4.

- the groove 22nd or 24 preferably has a depth of about 2.0 to 5.0 mm, more preferably about 2.5 to 3.5 mm, and a height or width of about 1.5 to 4, 0 mm, more preferably from about 2, 0 to 3.0 mm.

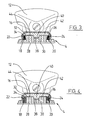

- FIGS. 3 and 4 show two exemplary embodiments of the invention Ski shown in cross-section.

- the ski body 4 in Essentially a tread 28, a Skikern 30 and a cover layer 32, extending from the tread 28 extends around the ski core 30 from one side of the ski 2 to the other.

- Skikern 30 is essentially made of individual layers glued together and pressed together, typically constructed of organic materials (e.g., wood) with additional deposits 34 and 36 are provided, in which the grooves 22 and 24 are formed.

- the ski body 4 further comprises over and / or under reinforcement layers (not shown) the ski core 30, e.g. metal, plastic (e.g., epoxy prepregs).

- the inserts 34, 36 may extend over part of the height of the ski core, such as this is shown in FIG. 3, or over the entire height of the core 30, as shown in FIG.

- the inserts 34 and 36 - also referred to as guide parts - are preferably made of a thermosetting plastic, thermoplastic, made of a fiber-reinforced plastic, in particular glass-fiber reinforced plastic, or of a plastic-coated Metallic material is formed to match the free ends 18 and 20 of the commonly used To provide good sliding properties to metal engaging means (e.g., steel) 16; so that the binding elements 12 and 14 can be moved well along the ski 2.

- deposits 34 and 36 into the ski body may require pretreatment (e.g., bonding pretreatment).

- the parts to be connected may be required to have the necessary affinity to the Skibau typically used epoxy resins, or produce Epoxidprepregs.

- the deposits or guide parts 34 and 36 may be, for example, prefabricated profile or Be receiving rails that have the grooves 22 and 24 already. When gluing the ski body 4, the rails are co-pressed, so integrated into the ski body. Should be doing the Cover layer 32, the grooves 22 and 24 completely or partially cover, it may optionally be removed after pressing.

- the ski body 4 in its core 30, the inserts 34 and 36 initially without grooves, glued and pressed, and then the guide grooves 22 and 24, for example, in the flow subsequently milled.

- the mounting device 10 is in the binding mounting area provided and preferably protrudes above the surface 26 of the ski 2 upwards.

- the bending line of the ski 2 is impaired as little as possible, so that the inventive Ski 2 has a largely optimal bending line.

- a longitudinal recess 38 is provided in which a connecting tongue 40, which preferably connects the two binding elements 12 and 14, at least partially included.

- a connecting tongue 40 in the region of the binding elements 12 and 14 additionally one Section 42, which is located outside the recess and on a surface 44 of the ski, around the binding elements 12 and 14 on a relative to the tread 28 of the ski 2 higher lying To bring the level.

- the Connecting tongue 40 preferably substantially completely within the recess 38th

- the inventive Ski 2 Due to the inventive design of the ski, in particular the mounting device with the grooves 22 and 24, and the recess 38 and the connecting tongue 40 is a free Bending or flexing of the ski 2 possible. This can cause a distortion of the binding shoe system be avoided when bending the ski.

- the inventive Ski 2 different variations of binding mounting possible, allowing a free bending ("Free-Flex").

- the front binding element or jaw part 12 be fixed and the rear binding element or heel part 14 by the engagement means 16 and the grooves 22 and 24 are movably guided, wherein the two binding elements 12 and 14 are interconnected by the connecting tongue 40 to the distance the two binding elements to each other to keep substantially constant.

- the fixation of the rear binding member or heel member 14 and movable Guiding the front binding member or jaw member 12 using the connecting tongue 40 possible.

- the connecting tongue 40 at to fix the mounting device 10, so that both binding elements 12 and 14 in the longitudinal direction slidably mounted in the grooves 22 and 24. This is a free mobility ensures both the baking and the heel part at a deflection of the ski.

- the ski 2 according to the invention with integrated mounting device 10 has in particular the Advantage that a ski binding and possibly a ski brake are mounted directly on the ski can, without the intermediate elements, such as a dowelled or bolted Rail system, screws, bolts, binding plates and the like required are.

- the properties of the ski according to the invention remain, in particular Bending behavior or its bending line largely preserved, so that at considerably simplified Binding assembly and all the benefits of using a binding plate simultaneously a ski with optimal characteristics is provided.

Landscapes

- Fittings On The Vehicle Exterior For Carrying Loads, And Devices For Holding Or Mounting Articles (AREA)

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

- Electrochromic Elements, Electrophoresis, Or Variable Reflection Or Absorption Elements (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Carbon And Carbon Compounds (AREA)

Abstract

Description

- Figur 1

- eine perspektivische Ansicht des erfindungsgemäßen Skis mit einer schematisch dargestellten, montierten Bindung;

- Figur 2

- einen vergrößerten Ausschnitt aus der perspektivischen Darstellung gemäß Figur 1;

- Figur 3

- einen Querschnitt durch den erfindungsgemäßen Ski gemäß einer ersten Ausführungsform;

- Figur 4

- einen Querschnitt durch den erfindungsgemäßen Ski gemäß einer zweiten Ausführungsform; und

- Figur 5

- eine schematische Seitenansicht des erfindungsgemäßen Skis.

Claims (19)

- Ski mit einem Skikörper (4) und einer in den Skikörper (4) integrierten Montageeinrichtung (10) zur direkten Montage einer Bindung (12, 14) am Ski (2), wobei die Breite der Montageeinrichtung (10) im Bereich zwischen 50 % und 95 % der kleinsten Breite des Skikörpers (4) liegt.

- Ski nach Anspruch 1, wobei die Montageeinrichtung (10) derart ausgebildet ist, daß die Bindung (12, 14) klemmend am Ski (2) befestigbar sind.

- Ski nach Anspruch 1 oder 2, wobei die Montageeinrichtung (10) mindestens, eine in Längsrichtung des Skis (2) verlaufende hinterschnittene Nut (22, 24) aufweist.

- Ski nach Anspruch 3, wobei die Montageeinrichtung (10) zwei parallel zueinander verlaufende Nuten (22, 24) aufweist, die auf voneinander wegweisenden Seiten offen sind.

- Ski nach Anspruch 3 oder 4, wobei die Nut (22, 24) in den Skikörper (4) eingefräst ist

- Ski nach einem der Ansprüche 1 bis 4, wobei die Montageeinrichtung (10) in Form mindestens einer Schiene (34, 36) in den Ski (2) integriert ist.

- Ski nach einem der Ansprüche 1 bis 6, wobei die Montageeinrichtung (10) auf der Oberseite (26) des Skikörpers (4) angeordnet ist und davon absteht.

- Ski nach einem der Ansprüche 3 bis 7, wobei die Montageeinrichtung (10) zumindest im Bereich der Nut (22, 24) eine Einlage (34, 36) aus duroplastischem Kunststoff, thermoplastischem Kunststoff, faserverstärktem Kunststoff, insbesondere glasfaserverstärktem Kunststoff, und/oder kunststoffbeschichtetem Metall aufweist.

- Ski nach einem der Ansprüche 1 bis 8, wobei die Montageeinrichtung (10) mit dem Skikörper (4) verklebt ist.

- Ski nach einem der Ansprüche 1 bis 9, wobei der Skikörper (4) eine sich in Längsrichtung erstreckende Aussparung (38) auf der Oberseite (26) aufweist.

- Ski nach einem der Ansprüche 1 bis 10 und einer mittels der Montageeinrichtung (10) montierten Bindung (12, 14) und optional mit einer mittels der Montageeinrichtung (10) montierten Skibremse.

- Ski nach einem der Ansprüche 1 bis 11, wobei die Breite der Montageeinrichtung im Bereich zwischen 75 % und 90 % der kleinsten Breite des Skikörpers (4) liegt.

- Verfahren zum Herstellen eines Skis, insbesondere eines Skis (2) nach einem der Ansprüche 1 bis 10, wobei in einen Skikörper (4) eine Montageeinrichtung (10) zum direkten Montieren einer Bindung (12, 14) integriert wird.

- Verfahren nach Anspruch 12, wobei die Montageeinrichtung (10) mit mindestens einer in Längsrichtung des Skis (2) verlaufenden, hinterschnittenen Nut (22, 24) versehen wird, in der die Bindung (12, 14) befestigbar ist.

- Verfahren nach Anspruch 14, wobei die Nut (22, 24) nachträglich in den Skikörper (4), vorzugsweise in eine im Skikörper (4) vorgesehene Einlage (34, 36), eingefräst wird.

- Verfahren nach Anspruch 14, wobei die Nut (22, 24) in einer Schiene (34, 36) vorgesehen ist, die in den Skikörper (4) eingelegt und mit dem Skikörper (4) verklebt und verpreßt wird.

- Verfahren nach einem der Ansprüche 14 bis 16, wobei zwei parallel zueinander verlaufende Nuten (22, 24), die auf voneinander wegweisenden Seiten offen sind, im Skikörper (4) ausgebildet werden.

- Verfahren nach einem der Ansprüche 12 bis 17, wobei der Skikörper (4) entlang eines Längsabschnitts zumindest über einen Teil seines Querschnitts höher ausgebildet und die Montageeinrichtung (10) in diesem Abschnitt auf der Oberseite (26) des Skikörpers (4) angeformt wird.

- Verfahren zum Montieren einer Bindung (12, 14) an einem Ski (2) nach einem der Ansprüche 1 bis 12 mit den Schritten:a) Bereitstellen mindestens einer zu montierenden Bindung (12, 14), die mindestens eine Eingriffseinrichtung (16) zum Ineingriffbringen mit der Montageeinrichtung (10) aufweist;b) Zusammenführen der Eingriffseinrichtung (16) der Bindung (12, 14) und der Montageeinrichtung (10) des Skis (2); undc) Fixieren der Bindung (12, 14) am Ski (2) mittels der Montageeinrichtung (10).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10223547A DE10223547B4 (de) | 2002-05-27 | 2002-05-27 | Ski, Verfahren zur Montage einer Skibindung an dem Ski und Verfahren zur Herstellung des Skis |

| DE10223547 | 2002-05-27 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1366785A1 true EP1366785A1 (de) | 2003-12-03 |

| EP1366785B1 EP1366785B1 (de) | 2010-03-03 |

Family

ID=29414216

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03011124A Expired - Lifetime EP1366785B1 (de) | 2002-05-27 | 2003-05-22 | Ski und Verfahren zur Montage einer Skibindung an dem Ski |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1366785B1 (de) |

| AT (1) | ATE459400T1 (de) |

| DE (2) | DE10223547B4 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2851926A1 (fr) * | 2003-03-07 | 2004-09-10 | Tyrolia Technology Gmbh | Planche de glisse, en particulier ski, et procede de fabrication associe |

| EP1559453A1 (de) | 2004-01-29 | 2005-08-03 | Blizzard Sport GmbH | Ski, insbesondere Alpinsky |

| EP1674138A1 (de) | 2004-12-21 | 2006-06-28 | Blizzard Sport GmbH | Gleitbrett, insbesondere Alpinski oder Snowboard |

| EP1815894A1 (de) * | 2006-01-27 | 2007-08-08 | NORDICA S.p.A. | Verfahren zur Herstellung eines Sportartikels und mit einem solchen Verfahren hergestellter Sportartikel |

| EP2204223A1 (de) * | 2009-01-05 | 2010-07-07 | Rottefella AS | Ski und Skibindungsgehäuse |

| EP2272573A1 (de) * | 2009-07-06 | 2011-01-12 | ATOMIC Austria GmbH | Brettartiges Gleitgerät in der Gestalt eines Schis oder Snowboards |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005054009A1 (de) | 2005-11-10 | 2007-05-16 | Marker Voelkl Int Gmbh | Schneegleitbrett bzw. Ski |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2911199C2 (de) | 1978-05-04 | 1986-11-20 | Ettore Thiene Vicenza Bortoli | Befestigungselement für ein Skibindungsteil |

| WO1988004563A1 (en) | 1986-12-19 | 1988-06-30 | Witco A/S | Longitudinally adjustable ski binding |

| EP0383104A2 (de) | 1989-02-15 | 1990-08-22 | HTM Sport- und Freizeitgeräte Aktiengesellschaft | Ski |

| US5397150A (en) * | 1992-07-09 | 1995-03-14 | Salomon S.A. | Ribbed ski provided with a support |

| DE19753451A1 (de) | 1997-12-02 | 1999-06-17 | Anton Neumayer | Befestigungssystem für Skibindungen |

| DE19527063C2 (de) | 1995-07-25 | 2000-02-03 | Dietrich Wertz | Grund-/Trägerplatte für Skibindungen |

| DE20012438U1 (de) | 1999-07-27 | 2000-10-26 | Salomon S.A., Metz-Tessy | Übergangsvorrichtung zwischen einem Schuh und einem Ski |

| DE20012437U1 (de) | 1999-07-27 | 2000-10-26 | Salomon S.A., Metz-Tessy | Übergangsvorrichtung zwischen einem Schuh und einem Ski |

| DE20013978U1 (de) | 1999-09-02 | 2000-12-21 | Salomon S.A., Metz-Tessy | Alpinski, der vorgesehen ist, um mit einer Übertragungsvorrichtung und einer Skifahreinheit ausgerüstet zu werden |

| EP1161972A2 (de) | 2000-06-09 | 2001-12-12 | Völkl Sports GmbH & Co. KG | Gleitbrett, insbesondere Ski sowie Profilschienen-System für ein solches Gleitbrett |

| EP1175925A1 (de) | 2000-07-28 | 2002-01-30 | Salomon S.A. | Gleitbrett |

| EP1240925A1 (de) * | 2001-03-12 | 2002-09-18 | Andreas Allmann | Führungsschiene und Vorrichtung zum Verbinden einer Bindung für einen Sportschuh mit einem Ski oder Snowboard |

| DE20212023U1 (de) * | 2002-08-05 | 2003-01-16 | Blessing, Holger, Dipl.-Betriebsw. (FH), 80999 München | Skibindung |

| EP1279421A1 (de) * | 2001-07-25 | 2003-01-29 | Skis Rossignol S.A. | Bindungsplatte und Gleitbrett mit einer solchen Einrichtung |

-

2002

- 2002-05-27 DE DE10223547A patent/DE10223547B4/de not_active Expired - Lifetime

-

2003

- 2003-05-22 EP EP03011124A patent/EP1366785B1/de not_active Expired - Lifetime

- 2003-05-22 DE DE50312467T patent/DE50312467D1/de not_active Expired - Fee Related

- 2003-05-22 AT AT03011124T patent/ATE459400T1/de active

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2911199C2 (de) | 1978-05-04 | 1986-11-20 | Ettore Thiene Vicenza Bortoli | Befestigungselement für ein Skibindungsteil |

| WO1988004563A1 (en) | 1986-12-19 | 1988-06-30 | Witco A/S | Longitudinally adjustable ski binding |

| EP0383104A2 (de) | 1989-02-15 | 1990-08-22 | HTM Sport- und Freizeitgeräte Aktiengesellschaft | Ski |

| US5397150A (en) * | 1992-07-09 | 1995-03-14 | Salomon S.A. | Ribbed ski provided with a support |

| DE19527063C2 (de) | 1995-07-25 | 2000-02-03 | Dietrich Wertz | Grund-/Trägerplatte für Skibindungen |

| DE19753451A1 (de) | 1997-12-02 | 1999-06-17 | Anton Neumayer | Befestigungssystem für Skibindungen |

| DE20012438U1 (de) | 1999-07-27 | 2000-10-26 | Salomon S.A., Metz-Tessy | Übergangsvorrichtung zwischen einem Schuh und einem Ski |

| DE20012437U1 (de) | 1999-07-27 | 2000-10-26 | Salomon S.A., Metz-Tessy | Übergangsvorrichtung zwischen einem Schuh und einem Ski |

| DE20013978U1 (de) | 1999-09-02 | 2000-12-21 | Salomon S.A., Metz-Tessy | Alpinski, der vorgesehen ist, um mit einer Übertragungsvorrichtung und einer Skifahreinheit ausgerüstet zu werden |

| EP1161972A2 (de) | 2000-06-09 | 2001-12-12 | Völkl Sports GmbH & Co. KG | Gleitbrett, insbesondere Ski sowie Profilschienen-System für ein solches Gleitbrett |

| EP1175925A1 (de) | 2000-07-28 | 2002-01-30 | Salomon S.A. | Gleitbrett |

| EP1240925A1 (de) * | 2001-03-12 | 2002-09-18 | Andreas Allmann | Führungsschiene und Vorrichtung zum Verbinden einer Bindung für einen Sportschuh mit einem Ski oder Snowboard |

| EP1279421A1 (de) * | 2001-07-25 | 2003-01-29 | Skis Rossignol S.A. | Bindungsplatte und Gleitbrett mit einer solchen Einrichtung |

| DE20212023U1 (de) * | 2002-08-05 | 2003-01-16 | Blessing, Holger, Dipl.-Betriebsw. (FH), 80999 München | Skibindung |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2851926A1 (fr) * | 2003-03-07 | 2004-09-10 | Tyrolia Technology Gmbh | Planche de glisse, en particulier ski, et procede de fabrication associe |

| WO2004078287A1 (de) * | 2003-03-07 | 2004-09-16 | Tyrolia Technology Gmbh | Gleitbrett, insbesondere ski, und verfahren zur herstellung |

| EP1559453A1 (de) | 2004-01-29 | 2005-08-03 | Blizzard Sport GmbH | Ski, insbesondere Alpinsky |

| US7344149B2 (en) | 2004-01-29 | 2008-03-18 | Blizzard Sport Gmbh | Ski, in particular an alpine ski |

| EP1674138A1 (de) | 2004-12-21 | 2006-06-28 | Blizzard Sport GmbH | Gleitbrett, insbesondere Alpinski oder Snowboard |

| US7357405B2 (en) | 2004-12-21 | 2008-04-15 | Blizzard Sport Gmbh | Sliding board, in particular alpine ski or snowboard |

| CN1792402B (zh) * | 2004-12-21 | 2010-12-08 | 布里扎德运动有限责任公司 | 滑板 |

| EP1815894A1 (de) * | 2006-01-27 | 2007-08-08 | NORDICA S.p.A. | Verfahren zur Herstellung eines Sportartikels und mit einem solchen Verfahren hergestellter Sportartikel |

| EP2204223A1 (de) * | 2009-01-05 | 2010-07-07 | Rottefella AS | Ski und Skibindungsgehäuse |

| EP2272573A1 (de) * | 2009-07-06 | 2011-01-12 | ATOMIC Austria GmbH | Brettartiges Gleitgerät in der Gestalt eines Schis oder Snowboards |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1366785B1 (de) | 2010-03-03 |

| ATE459400T1 (de) | 2010-03-15 |

| DE10223547A1 (de) | 2003-12-18 |

| DE50312467D1 (de) | 2010-04-15 |

| DE10223547B4 (de) | 2006-09-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0922629B1 (de) | Raupensteg für Laufketten von Raupenfahrzeugen insbesondere für Pisten- oder Loipenspurgeräte | |

| EP1562683B1 (de) | Ski mit bindungs-montagehilfe, verfahren zur herstellung eines solchen skis sowie entsprechende montagehilfe | |

| EP1679098B1 (de) | Gleitbrett, insbesondere Ski | |

| EP1245254B1 (de) | Schi, insbesondere Alpinschi | |

| EP1611927B1 (de) | Schneegleitbrett | |

| DE10223547B4 (de) | Ski, Verfahren zur Montage einer Skibindung an dem Ski und Verfahren zur Herstellung des Skis | |

| AT500252B1 (de) | Gleitbrett, insbesondere ski | |

| EP1424107B1 (de) | Gleitbrett, insbesondere Ski | |

| EP1563879B1 (de) | Gleitbrett, insbesondere Ski | |

| EP1576989A1 (de) | Gleitbrett, insbesondere Ski | |

| EP1542776B1 (de) | Gleitbrett, insbesondere ski, und verfahren zur herstellung | |

| EP1550487B1 (de) | Ski und Verfahren zur Herstellung des Skis | |

| DE20321008U1 (de) | Ski mit integrierter Montageeinrichtung | |

| EP1601428A1 (de) | Gleitbrett, insbesondere ski, und verfahren zur herstellung | |

| EP2210650B1 (de) | Mehrteilige Bindungsplatte zum Anordnen einer Skibindung auf einem Ski | |

| DE202004000806U1 (de) | Gleitbrett, insbesondere Ski | |

| AT410758B (de) | Schi, insbesondere alpinschi | |

| DE10237765B4 (de) | Bindungsplatte für ein Schneegleitbrett, insbesondere Ski sowie Schneegleitbrett mit einer solchen Bindungsplatte | |

| AT502885A2 (de) | Gleitbrett, insbesondere ski und verfahren zur herstellung | |

| EP1687073A1 (de) | Gleitbrett, insbesondere ski, und verfahren zur herstellung | |

| AT7292U1 (de) | Gleitbrett, insbesondere ski, und verfahren zur herstellung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20040602 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20051118 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: SKI AND METHOD FOR MOUNTING A SKIBINDING ON A SKI |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: VOSSIUS & PARTNER |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 50312467 Country of ref document: DE Date of ref document: 20100415 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20100303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100614 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100604 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 |

|

| BERE | Be: lapsed |

Owner name: HEAD TECHNOLOGY GMBH Effective date: 20100531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100603 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100531 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100705 |

|

| 26N | No opposition filed |

Effective date: 20101206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100522 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100904 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100303 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: HEAD TECHNOLOGY GMBH, AT Free format text: FORMER OWNER: HEAD TECHNOLOGY GMBH, AT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20220427 Year of fee payment: 20 Ref country code: GB Payment date: 20220519 Year of fee payment: 20 Ref country code: FR Payment date: 20220524 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20220519 Year of fee payment: 20 Ref country code: AT Payment date: 20220520 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20230521 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 459400 Country of ref document: AT Kind code of ref document: T Effective date: 20230522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20230521 |