EP1325685A2 - Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial für die tabakverarbeitende Industrie - Google Patents

Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial für die tabakverarbeitende Industrie Download PDFInfo

- Publication number

- EP1325685A2 EP1325685A2 EP02027381A EP02027381A EP1325685A2 EP 1325685 A2 EP1325685 A2 EP 1325685A2 EP 02027381 A EP02027381 A EP 02027381A EP 02027381 A EP02027381 A EP 02027381A EP 1325685 A2 EP1325685 A2 EP 1325685A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- section

- air

- suction

- strip

- filter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 14

- 239000000463 material Substances 0.000 title claims abstract description 10

- 241000208125 Nicotiana Species 0.000 title claims description 7

- 235000002637 Nicotiana tabacum Nutrition 0.000 title claims description 7

- 230000001105 regulatory effect Effects 0.000 claims description 11

- 238000004140 cleaning Methods 0.000 claims description 3

- 235000019504 cigarettes Nutrition 0.000 abstract 1

- 239000003570 air Substances 0.000 description 70

- 210000000056 organ Anatomy 0.000 description 9

- 239000000835 fiber Substances 0.000 description 7

- 239000002245 particle Substances 0.000 description 4

- 238000003892 spreading Methods 0.000 description 4

- 239000000428 dust Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 239000012080 ambient air Substances 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 229920002301 cellulose acetate Polymers 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- URAYPUMNDPQOKB-UHFFFAOYSA-N triacetin Chemical compound CC(=O)OCC(OC(C)=O)COC(C)=O URAYPUMNDPQOKB-UHFFFAOYSA-N 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- ITQJMPLOCOOZQS-UHFFFAOYSA-N 1,4-dihydrotriazete Chemical compound C1NN=N1 ITQJMPLOCOOZQS-UHFFFAOYSA-N 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000009530 blood pressure measurement Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 210000004907 gland Anatomy 0.000 description 1

- 235000013773 glyceryl triacetate Nutrition 0.000 description 1

- 239000001087 glyceryl triacetate Substances 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000006163 transport media Substances 0.000 description 1

- 229960002622 triacetin Drugs 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/02—Manufacture of tobacco smoke filters

- A24D3/0204—Preliminary operations before the filter rod forming process, e.g. crimping, blooming

Definitions

- the invention relates to an apparatus and a method for processing at least one strip Filter material for the tobacco processing industry, especially filter tow strips, along a conveyor line and with at least one compressed air element, in particular for the strip.

- Such a device is known from EP 654 224 B1.

- a streak Filter material in particular filter tow, from one another connected fibers, e.g. made of cellulose acetate, continuous from a supply, e.g. pulled from a bale, spread, stretched and with a solvent, e.g. Triazetin sprayed, gathered at the sides, one with blowing air charged nozzle and then a funnel fed, from which the processed and compressed Filter strips fed to a filter rod machine becomes.

- the filter rod machine it becomes one Strips of filter formed with further compression continuously covered with a strip of wrapping material, then filter rods from the coated filter strand be cut off.

- Proven processing devices of the type described above are called AF 1, AF 2 and AF 3 by the Applicant built and distributed.

- Proven filter rod machines of the type described are under the Designation KDF 2 and KDF 3 built by the applicant and distributed.

- DE 198 11 014 A1 also describes a device for Manufacture of filter rods for rod-shaped articles of the tobacco processing industry in which the Filter tow strips along a stretching line, application line, Raff stretch, through one with in the conveying direction of the tow strip guided air flow Wind tunnel is passed through.

- the the Laminar air flow accompanying filter tow strips prevents air turbulence, so that a trouble-free or homogeneous specific tow treatment in the stretching zone, the Relaxation zone and gathering zone is guaranteed.

- the Air flow also serves as a transport medium for Removal of detached or loosely adhering tow fibers, so that even at high conveyor speeds Filter tow stripes a homogeneous treatment and Distribution of the filter material in the filter line reached becomes.

- the task is at the beginning of a device mentioned type in that at least one Suction device is provided on the suction side of the Conveyor path of the strip is arranged and pressure side is connected to the compressed air element.

- a compressed air organ for a strip for example Spreader nozzle with a compressed air source Compressed air is supplied.

- Suction air as blown air to the compressed air organ can on the Compressed air source can be dispensed with.

- Impurities e.g. avoided in the area of the stretching zone, because the tow fibers are led away from this area.

- others can also Compressed air organs as a spreader nozzle from the suction device be supplied with air.

- the suction device especially on the suction side, at least one filter device and / or one Has cleaning device for the suction air.

- a filter device for example, can rough the air flow and fine dust particles are removed, so that clean Blown air are passed on to the compressed air organs can. This makes the machine and the environment clean held because e.g. fine tow fibers retained and not be blown into the ambient air.

- the suction device has in particular on the pressure side, at least one, preferably controllable, throttle device to Blown air to the compressed air consumer with an adjustable To deliver pressure.

- control device and / or control device for the suction device is provided because this ensures an optimal setting and function for the suction and the individual spreader nozzles is guaranteed.

- the suction device regulated and / or controlled accordingly become.

- operation of the device can thus considering an economical mode of operation be optimized.

- control device and / or the control device by means of a machine center, in particular programmable logic controller (SPS) is trained.

- SPS programmable logic controller

- In the machine center all processes on one machine unit or in the entire machine is controlled and / or summarized regulated.

- the programmable logic controller has become machines proven.

- the device according to the invention is advantageously further developed in that the suction side of the suction device in a stretching zone of a stretching section of the Conveyor line is arranged.

- a Device as known from DE 198 11 014 A1 can be improved since there is already a suction device is available. This suction device can overall operated even more economically.

- the air is advantageously on the pressure side, preferably by means of a, in particular controllable, Throttle device, throttled.

- Optimal operation can be achieved if the Air flow depending on the air pressure on the Suction side and / or the pressure side regulated and / or is controlled.

- the air flow is advantageously controlled by means of a Machine center, in particular programmable logic Control (PLC), regulated and / or controlled.

- PLC programmable logic Control

- the air in a stretching zone is also preferred sucked a stretch of the conveyor line.

- the air will advantageously end up a section of the conveyor line, in particular Stretching section and / or application section and / or gathering section, suctioned off, so that existing suction devices can be used.

- the feed section 9 is used to feed a strip section to an inlet device schematically illustrated filter rod machine 11, e.g. from in the tobacco processing industry known type KDF 2 or KDF 3 of the applicant.

- the trigger line 3 in which the one here is not bales of filter material strips removed 2 is promoted, has a spreader nozzle 16, the Compressed air instead of a compressed air source from the suction device according to the invention described below receives.

- the compressed air serves to spread the conveyed Filter tow fabric in this section.

- a - controllable - spreader gland is e.g. in US-A-4,259 769.

- the filter tow strip 2 passes over a deflection roller 19 in the stretching section 4, on the one hand by a Roller pair 21 with the rollers 22, 23, on the other hand by a pair of rollers 24 with motor-driven rollers 26, 27 is limited.

- the rollers 22, 23 are from Towstrip towed, i.e. they run with more or less resistance empty. If necessary, they can be driven by a motor. You can also in one in a known manner with controllable force against each other be pressed.

- the filter tow 2 pre-stretched. It can be a controllable drying device trained conditioning device happen.

- a drying device is, for example, in EP 654 224 B1 described in detail.

- the stretching section 6 connects to the pair of rolls 24, in which the filter tow strip 2 is vertical or with a vertical component promoted from top to bottom becomes.

- a another pair of rollers 39 from motor-driven Rollers 41, 42 whose peripheral speeds are somewhat are greater than the peripheral speeds of the rollers 26, 27, so that the elastic filter tow is defined is stretched.

- the roller pairs 24 and 39 thus form the actual stretching device.

- the rollers 26 and 41 have a rigid, grooved surface, each one touch the resilient surface of the rollers 27 or 42.

- Such roller configurations are due to the aforementioned Filter tow conditioners AF 1, AF 2 and AF 3 known to the applicant and e.g. in US-A-3 317 965 and US-A-3,255,506.

- Another pair of rollers 43 is arranged downstream of the pair of rollers 39, whose peripheral speeds are lower than those of the rollers 41, 42, so that the filter tow 2 relaxes slightly when it is promoted.

- the pair of rollers 43 again has a roller 44 with a rigid, grooved Surface on that with the compliant surface the rollers 46 are in contact.

- the roller pairs 39 and 43 thus limit the, in the present case approximately horizontally arranged, order line 7, in an application device in the form of a spraying device is arranged.

- the sprayer can be formed as described in US-A-4,313,974 and sprayed the transported filter tow strip 2 from one or both sides with fine droplets one Solvent for the filter tow material e.g. Triacetin.

- a spreader nozzle is arranged upstream of the spraying device 18, so that the stretched filter tow 2 is spread out is and the solvent has a larger surface area of the Filter towstrip 2 wetted.

- This spreader nozzle 18th and that in front of the pair of rollers 21 of the stretching section 4 upstream spreader nozzle 17 are with compressed air applied in the manner described below.

- a gathering section 8 in which the filter tow strip 2 with predominantly vertical Component of a pair of rollers 51 with motor driven rollers 52, 53 conveyed from the bottom up becomes.

- the roller 52 has a rigid, grooved again Surface, the contact of the roller a compliant Surface.

- a feed path is arranged downstream of the pair of deflecting rollers 51 9, in which the filter tow strip 2 of adhering, for further processing disadvantageous electrostatic Loads are freed.

- the feed line 9 is also a so-called stuffing nozzle available with compressed air from a compressed air source or in the manner according to the invention set out below. After passing through the stuffing nozzle, the filter tow becomes one Filter rod machine 11 supplied.

- the filter tow strip is within the stretching section 6 by one between the pairs of rollers 24 and 39 extending on both sides of the filter tow strip 2 Passed wind tunnel 32, in which a parallel to the conveying direction of the filter tow strip Air flow is generated.

- Air flow is the wind tunnel 32 at the end of the stretching section 6 with a suction air connection connected to the suction side of a blower 38 54 provided.

- the wind tunnel 32 is open and thus forms one Air intake off.

- the wind tunnel 32 is through channel walls 33, 34 limited to the broadside of the Filter tow stripes are adjustable.

- the air in the wind tunnel 32 can be executed in the area of the pair of rollers 39, and in particular in the area of a Inlet gap of the pair of rollers 39 are suctioned off.

- the wind tunnel 32 is under the suction air connection 54 Interposition of a filter mat 36 via the connecting line 37 connected to the blower 38.

- the Filter mat 38 removed from the suction air stream entrained Particles and fiber particles as well as dust.

- the blower 38 is also connected to a control unit 31, which regulates the performance of the compressor fan 38.

- a throttle unit 49 is connected to the blower 38.

- the throttle unit 49 is connected in terms of Consumer groups by means of an associated with it Control unit 47 adjustable.

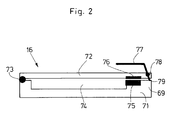

- the spreader nozzle 16 has a U-shaped Housing 71, which is a hinge joint 73 on one Has leg of the "U" on which a lid 72 is hinged is.

- a channel 74 inside the Spreader nozzle 16 is formed. Through the channel 74 in a plane perpendicular to the plane shown Filter tow strips transported.

- the spreader nozzle 16 is a flat, hinged nozzle in which the Tow running.

- the hinge joint 73 opposite leg 69 of the housing 71 magnets 75 trained.

- the magnet 75 of the housing 71 is compared with a magnet 76.

- the cover 72 in the area of the Magnets 75 be magnetic.

- the Nozzle 16 can be opened to insert the filter tow. Then the nozzle 16 is closed again.

- the strength of the magnets 75 and 76 is chosen so that a Open while the machine is operating or Device is not possible.

- Handle 77 provided which is rotatable about a pivot point 78 is mounted and has a lever arm 79 which at Opening the cover 72, the leg 69 of the housing 71 touched.

- handle 77 and lever arm 79 Due to suitable lever ratios of handle 77 and lever arm 79 can with a small force Distance between magnets 75 and 76 increased are reduced, which also reduces the magnetic forces become.

- the handle 77 is designed as a lever, so that the separation of the magnets 75, 76 additionally mechanically is supported. This will make much less Force needed to open the lid 72 without the To impair the locking function of the nozzle 16.

- the distance of the fulcrum 78 of the hinge joint 73 is greater than the distance between the magnets 76 and the hinge joint 73. This creates better leverage, so that this means less force to open the nozzle 16 is required.

- lever handle 77 By lever handle 77, pivot point 78 and Lever arm 79 mechanical means are available that the Open the spreader nozzle 16 and insert one Lighten the filter tow strip.

Landscapes

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

Abstract

Description

- Fig. 1

- schematisch eine Aufbereitungsvorrichtung gemäß der Erfindung und

- Fig. 2

- einen Querschnitt durch eine Ausbreiterdüse.

- 2

- Streifen

- 3

- Abzugsstrecke

- 4

- Vorreckstrecke

- 6

- Reckstrecke

- 7

- Auftragsstrecke

- 8

- Raffstrecke

- 9

- Zufuhrstrecke

- 11

- Filterstrangmaschine

- 12

- Versorgungsleitung

- 13

- Versorgungsleitung

- 14

- Versorgungsleitung

- 16

- Ausbreiterdüse

- 17

- Ausbreiterdüse

- 18

- Ausbreiterdüse

- 19

- Umlenkrolle

- 21

- Walzenpaar

- 22

- Walzen

- 23

- Walze

- 24

- Walzenpaar

- 26

- Walze

- 27

- Walze

- 31

- Regeleinheit

- 32

- Windkanal

- 33

- Wand

- 34

- Wand

- 36

- Filtermatte

- 37

- Leitung

- 38

- Verdichter

- 39

- Walzenpaar

- 41

- Walze

- 42

- Walze

- 43

- Walzenpaar

- 44

- Walze

- 46

- Walze

- 47

- Steuereinheit

- 48

- Leitung

- 49

- Drosseleinheit

- 51

- Walzenpaar

- 52

- Walze

- 53

- Walze

- 54

- Saugluftanschluß

- 59

- Auslaß

- 69

- Schenkel

- 71

- Gehäuse

- 72

- Deckel

- 73

- Scharniergelenk

- 74

- Kanal

- 75

- Magnet

- 76

- Magnet

- 77

- Griff

- 78

- Drehpunkt

- 79

- Hebelarm

Claims (17)

- Vorrichtung zum Aufbereiten wenigstens eines Streifens (2) aus Filtermaterial für die tabakverarbeitende Industrie, insbesondere Filtertowstreifen, entlang einer Förderstrecke (3, 4, 6, 7, 8, 9) und mit wenigstens einem Druckluftorgan (16, 17, 18), insbesondere für den Streifen (2), dadurch gekennzeichnet, daß wenigstens eine Absaugeinrichtung (38) vorgesehen ist, die saugseitig an der Förderstrecke (3, 4, 6, 7, 8, 9) des Streifens (2) angeordnet ist und druckseitig mit dem Druckluftorgan (16, 17, 18) verbunden ist.

- Vorrichtung nach Anspruch 1, dadurch gekennzeichnet, daß die Absaugeinrichtung (38), insbesondere saugseitig, wenigstens eine Filtereinrichtung (36) und/oder Reinigungseinrichtung aufweist.

- Vorrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß die Absaugeinrichtung (38), insbesondere druckseitig, wenigstens eine, vorzugsweise steuerbare, Drosseleinrichtung (49) aufweist.

- Vorrichtung nach einem oder mehreren der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß eine Regeleinrichtung (31) und/oder Steuereinrichtung für die Absaugeinrichtung (38) vorgesehen ist.

- Vorrichtung nach Anspruch 4, dadurch gekennzeichnet, daß wenigstens eine Druckmeßeinrichtung saugseitig und/oder druckseitig mit der Regeleinrichtung (31) und/oder Steuereinrichtung verbunden ist.

- Vorrichtung nach Anspruch 4 oder 5, dadurch gekennzeichnet, daß die Regeleinrichtung (31) und/oder Steuereinrichtung mittels einer Maschinenzentrale, insbesondere speicherprogrammierbare Steuerung (SPS), ausgebildet ist.

- Vorrichtung nach einem oder mehreren der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß die Saugseite der Absaugeinrichtung (38) in einer Reckzone einer Reckstrecke (6) der Förderstrecke (3, 4, 6, 7, 8, 9) angeordnet ist.

- Vorrichtung nach einem oder mehreren der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß die Saugseite der Absaugeinrichtung (31) am Ende eines Streckenabschnitts der Förderstrecke (3, 4, 6, 7, 8, 9), insbesondere Reckstrecke (6) und/oder Auftragstrecke (7) und/oder Raffstrecke (8), angeordnet ist.

- Verfahren zum Aufbereiten wenigstens eines Streifens (2) aus Filtermaterial für die tabakverarbeitende Industrie, insbesondere Filtertowstreifen, entlang einer Förderstrecke (3, 4, 6, 7, 8, 9) und mittels wenigstens eines Druckluftorgans (16, 17, 18), insbesondere für den Streifen (2), dadurch gekennzeichnet, daß Luft an der Förderstrecke (3, 4, 6, 7, 8, 9) abgesaugt wird und an das Druckluftorgan (16, 17, 18) geliefert wird.

- Verfahren nach Anspruch 9, dadurch gekennzeichnet, daß die abgesaugte Luft gefiltert und/oder gereinigt wird.

- Verfahren nach Anspruch 9 oder 10, dadurch gekennzeichnet, daß die Luft druckseitig, vorzugsweise mittels einer, insbesondere steuerbaren, Drosseleinrichtung (49), gedrosselt wird.

- Verfahren nach einem oder mehreren der Ansprüche 9 bis 11, dadurch gekennzeichnet, daß die Strömung der Luft geregelt und/oder gesteuert wird.

- Verfahren nach Anspruch 12, dadurch gekennzeichnet, daß die Luftströmung in Abhängigkeit des Luftdrucks auf der Saugseite und/oder der Druckseite geregelt und/oder gesteuert wird.

- Verfahren nach Anspruch 12 oder 13, dadurch gekennzeichnet, daß die Luftströmung mittels einer Maschinenzentrale, insbesondere speicherprogrammierbare Steuerung (SPS), geregelt und/oder gesteuert wird.

- Verfahren nach einem oder mehreren der Ansprüche 9 bis 14, dadurch gekennzeichnet, daß, insbesondere überschüssige, Luft auf der Druckseite in die Atmosphäre abgegeben wird.

- Verfahren nach einem oder mehreren der Ansprüche 9 bis 15, dadurch gekennzeichnet, daß die Luft am Ende einer Reckzone einer Reckstrecke (6) der Förderstrecke (3, 4, 6, 7, 8, 9) abgesaugt wird.

- Verfahren nach einem oder mehreren der Ansprüche 9 bis 15, dadurch gekennzeichnet, daß die Luft am Ende eines Streckenabschnitts der Förderstrecke (3, 4, 6, 7, 8, 9), insbesondere Reckstrecke (6) und/oder Auftragstrecke (7) und/oder Raffstrecke (8), abgesaugt wird.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10200326 | 2002-01-07 | ||

| DE10200326A DE10200326A1 (de) | 2002-01-07 | 2002-01-07 | Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial für die tabakverarbeitende Industrie |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1325685A2 true EP1325685A2 (de) | 2003-07-09 |

| EP1325685A3 EP1325685A3 (de) | 2004-05-12 |

| EP1325685B1 EP1325685B1 (de) | 2005-06-08 |

Family

ID=7711609

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02027381A Expired - Lifetime EP1325685B1 (de) | 2002-01-07 | 2002-12-09 | Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial für die tabakverarbeitende Industrie |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1325685B1 (de) |

| AT (1) | ATE297139T1 (de) |

| DE (2) | DE10200326A1 (de) |

| PL (1) | PL204896B1 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005211071A (ja) * | 2004-01-29 | 2005-08-11 | Hauni Maschinenbau Ag | フィルタートウ条片の別個の弛緩および噴霧 |

| DE102006011599A1 (de) * | 2006-03-10 | 2007-09-13 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| DE102006011587B4 (de) * | 2006-03-10 | 2008-04-03 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| DE102006011588B4 (de) * | 2006-03-10 | 2008-04-10 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| EP2255683A1 (de) | 2009-05-26 | 2010-12-01 | HAUNI Maschinenbau AG | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| CN103771140A (zh) * | 2014-02-24 | 2014-05-07 | 龙岩烟草工业有限责任公司 | 滤棒成型机丝束飞花在线收集与称重装置及滤棒成型机 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3255506A (en) | 1963-02-20 | 1966-06-14 | Eastman Kodak Co | Tow treatment |

| US3317965A (en) | 1964-09-11 | 1967-05-09 | Osaka Kiko Kabushiki Kaisha | Tow filament separating apparatus |

| US4259769A (en) | 1978-04-05 | 1981-04-07 | Hauni-Werke Korber & Co. Kg | Method and apparatus for banding tows of filamentary material |

| US4313974A (en) | 1978-04-05 | 1982-02-02 | Hauni-Werke Korber & Co. Kg. | Method of applying atomized liquid plasticizer to a running tow of filamentary filter material |

| US5590449A (en) | 1993-11-24 | 1997-01-07 | Hauni Maschinenbau Ag | Apparatus for stretching plasticizing and gathering a tow of filter material for tobacco smoke |

| DE19811014A1 (de) | 1998-03-13 | 1999-09-16 | Hauni Maschinenbau Ag | Verfahren und Vorrichtung zum Herstellen von Filterstäben für stabförmige Artikel der tabakverarbeitenden Industrie |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB793114A (en) * | 1955-08-09 | 1958-04-09 | Peter Henry Julian Byk | Improvements in or relating to filter plugs or wads |

| US4747814A (en) * | 1986-07-23 | 1988-05-31 | American Filtrona Corporation | Fiber separator |

| GB9200904D0 (en) * | 1992-01-16 | 1992-03-11 | Molins Plc | Cigarette filter manufacture |

| IT1272020B (it) * | 1992-03-26 | 1997-06-10 | Koerber Ag | Procedimento e macchina per trattare materiale per un cordone di filtro. |

-

2002

- 2002-01-07 DE DE10200326A patent/DE10200326A1/de not_active Withdrawn

- 2002-12-09 DE DE50203329T patent/DE50203329D1/de not_active Expired - Lifetime

- 2002-12-09 AT AT02027381T patent/ATE297139T1/de not_active IP Right Cessation

- 2002-12-09 EP EP02027381A patent/EP1325685B1/de not_active Expired - Lifetime

-

2003

- 2003-01-03 PL PL358113A patent/PL204896B1/pl unknown

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3255506A (en) | 1963-02-20 | 1966-06-14 | Eastman Kodak Co | Tow treatment |

| US3317965A (en) | 1964-09-11 | 1967-05-09 | Osaka Kiko Kabushiki Kaisha | Tow filament separating apparatus |

| US4259769A (en) | 1978-04-05 | 1981-04-07 | Hauni-Werke Korber & Co. Kg | Method and apparatus for banding tows of filamentary material |

| US4313974A (en) | 1978-04-05 | 1982-02-02 | Hauni-Werke Korber & Co. Kg. | Method of applying atomized liquid plasticizer to a running tow of filamentary filter material |

| US5590449A (en) | 1993-11-24 | 1997-01-07 | Hauni Maschinenbau Ag | Apparatus for stretching plasticizing and gathering a tow of filter material for tobacco smoke |

| EP0654224B1 (de) | 1993-11-24 | 2001-05-02 | Hauni Maschinenbau Aktiengesellschaft | Anordnung zum Aufbereiten eines Streifens aus Filtermaterial |

| DE19811014A1 (de) | 1998-03-13 | 1999-09-16 | Hauni Maschinenbau Ag | Verfahren und Vorrichtung zum Herstellen von Filterstäben für stabförmige Artikel der tabakverarbeitenden Industrie |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005211071A (ja) * | 2004-01-29 | 2005-08-11 | Hauni Maschinenbau Ag | フィルタートウ条片の別個の弛緩および噴霧 |

| EP1559333A3 (de) * | 2004-01-29 | 2007-03-21 | Hauni Maschinenbau AG | Separate Entspannung und Besprühung eines Filtertowstreifens |

| DE102006011599A1 (de) * | 2006-03-10 | 2007-09-13 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| DE102006011599B4 (de) * | 2006-03-10 | 2007-12-20 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| DE102006011587B4 (de) * | 2006-03-10 | 2008-04-03 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| DE102006011588B4 (de) * | 2006-03-10 | 2008-04-10 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| EP2255683A1 (de) | 2009-05-26 | 2010-12-01 | HAUNI Maschinenbau AG | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| CN101897477A (zh) * | 2009-05-26 | 2010-12-01 | 豪尼机械制造股份公司 | 烟草加工业的过滤嘴原料条带的处理 |

| DE102009022759A1 (de) | 2009-05-26 | 2010-12-02 | Hauni Maschinenbau Ag | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie |

| CN101897477B (zh) * | 2009-05-26 | 2015-09-09 | 豪尼机械制造股份公司 | 烟草加工业的过滤嘴原料条带的处理 |

| CN103771140A (zh) * | 2014-02-24 | 2014-05-07 | 龙岩烟草工业有限责任公司 | 滤棒成型机丝束飞花在线收集与称重装置及滤棒成型机 |

| CN103771140B (zh) * | 2014-02-24 | 2016-05-25 | 龙岩烟草工业有限责任公司 | 滤棒成型机丝束飞花在线收集与称重装置及滤棒成型机 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE50203329D1 (de) | 2005-07-14 |

| PL204896B1 (pl) | 2010-02-26 |

| EP1325685B1 (de) | 2005-06-08 |

| DE10200326A1 (de) | 2003-07-17 |

| EP1325685A3 (de) | 2004-05-12 |

| ATE297139T1 (de) | 2005-06-15 |

| PL358113A1 (en) | 2003-07-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19751598B4 (de) | Verfahren und Vorrichtung zum Behandeln eines Filtertowstreifens | |

| EP0654224B1 (de) | Anordnung zum Aufbereiten eines Streifens aus Filtermaterial | |

| EP0941673B1 (de) | Verfahren und Vorrichtung zum Herstellen von Filterstäben für stabförmige Artikel der tabakverarbeitenden Industrie | |

| DE2430517A1 (de) | Elektrostatische pulver-beschichtungsanlage | |

| DE2623547A1 (de) | Vorrichtung zum bilden eines tabakstranges | |

| CH661707A5 (de) | Verfahren und vorrichtung zur foerderung von faserfoermigen stoffen, insbesondere von in luft schwebend gefoerderten textilen faserflocken bei spinnereivorbereitungsmaschinen. | |

| DE1815021C3 (de) | Maschine zur Herstellung eines Wirrfaservlieses | |

| DE2634250B2 (de) | Verfahren und Vorrichtung zum Beschicken einer Karde mit Fasermaterial | |

| EP1325685B1 (de) | Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial für die tabakverarbeitende Industrie | |

| EP1169927B1 (de) | Verfahren und Vorrichtung zum Herstellen von Filterstäben der tabakverarbeitenden Industrie | |

| EP2255683B1 (de) | Aufbereitung eines Filtermaterialstreifens der Tabak verarbeitenden Industrie | |

| DE102004004688A1 (de) | Separate Entspannung und Besprühung eines Filtertowstreifens | |

| EP0535501A2 (de) | Entstaubungsanlage für Maschinen | |

| CH691380A5 (de) | Vorrichtung zum Abscheiden von aufgelösten Faserflocken aus einem Luftstrom. | |

| DE2339880A1 (de) | Pneumatische reinigungsanlage der streckwerke in vorspinn- und spinnmaschinen | |

| DE102004030171A1 (de) | Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial der Tabak verarbeitenden Industrie | |

| DE19522995B4 (de) | Vorrichtung zum Abscheiden von aufgelösten Faserflocken aus einem Luftstrom, z.B. Flockenbeschickung für eine Karde, Reiniger o. dgl. | |

| DE2907747A1 (de) | Pneumatische reinigungseinrichtung am einlauftisch einer spinnereimaschine | |

| EP0374541A2 (de) | Verfahren zur Reinigung eines Kardenbandes | |

| DE3532471A1 (de) | Fahrbare pneumatische vorrichtung zum absaugen und abblasen von faserflug bei textilmaschinen | |

| DE102005051523A1 (de) | Vorrichtung und Verfahren zum Aufbereiten wenigstens eines Streifens aus Filtermaterial der Tabak verarbeitenden Industrie | |

| EP1692957A1 (de) | Aufbereitung eines Streifens aus Filtermaterial der Tabak verarbeitenden Industrie | |

| CH246960A (de) | Einrichtung an Spinnmaschinen zum Abführen von Staub, Flaum und losen Fäden. | |

| EP2080440B1 (de) | Vorrichtung zum Transport von Tow | |

| DE102009022790A1 (de) | Vorrichtung zur Bearbeitung mindestens eines Filtertowstranges |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| 17P | Request for examination filed |

Effective date: 20041014 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SI SK TR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: PEHMOELLER, JUERGEN Inventor name: MOJE, JENS Inventor name: DITOMBEE, HARALD Inventor name: PETERS, STEPHAN Inventor name: FRICKE, VOLKER Inventor name: MEINS, THOMAS Inventor name: GLOGASA, JOACHIM Inventor name: WOLFF, STEPHAN Inventor name: ARNOLD, PETER-FRANZ Inventor name: HORN, SOENKE |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20050608 |

|

| REF | Corresponds to: |

Ref document number: 50203329 Country of ref document: DE Date of ref document: 20050714 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050908 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050908 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050908 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051209 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051231 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051231 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051231 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20060309 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061231 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061231 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: HAUNI MASCHINENBAU A.G. Effective date: 20051231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050608 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081217 Year of fee payment: 7 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091209 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20141218 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20141218 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20141222 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50203329 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20160101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160701 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151209 |